Professional Documents

Culture Documents

Air Test Gun For Tube Bundles

Air Test Gun For Tube Bundles

Uploaded by

thomasoburCopyright:

Available Formats

You might also like

- CMAS Training Manual P3Eng PDFDocument104 pagesCMAS Training Manual P3Eng PDFdigibillNo ratings yet

- PRC Memorandum Circular No. 03 (Hazard Pay Clarifiation On Risk Factor)Document1 pagePRC Memorandum Circular No. 03 (Hazard Pay Clarifiation On Risk Factor)ABI Alco QANo ratings yet

- Balcrank 1130-001 Tiger PumpDocument8 pagesBalcrank 1130-001 Tiger PumpJoseph GeraciNo ratings yet

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Valves & Controls: Crosby Safety Valves Style HSLDocument12 pagesValves & Controls: Crosby Safety Valves Style HSLeborresonNo ratings yet

- Catálogo Anderson Greenwood 400sDocument32 pagesCatálogo Anderson Greenwood 400sDaniela BeltranNo ratings yet

- Convertidor Mechanical S108KDocument8 pagesConvertidor Mechanical S108KALBERTONo ratings yet

- A 084 BDocument12 pagesA 084 BDenis JimenezNo ratings yet

- Katalog p310 - 07Document7 pagesKatalog p310 - 07agustinusidNo ratings yet

- Especificaciones Bomba Ventilador CATD10T - TestDocument36 pagesEspecificaciones Bomba Ventilador CATD10T - TestRafael RodriguezNo ratings yet

- Manual Valvula PCVDocument16 pagesManual Valvula PCVzamirgothNo ratings yet

- Pump Suction Diffuser ManualDocument2 pagesPump Suction Diffuser ManualAnonymous 7xHNgoKE6eNo ratings yet

- Low Torc ValveDocument4 pagesLow Torc Valvejinyuan74100% (2)

- Pressure Reducing Regulator FISHER Manual Serie 64Document8 pagesPressure Reducing Regulator FISHER Manual Serie 64Billy Isea DenaroNo ratings yet

- BaileyDocument14 pagesBaileyhecdomNo ratings yet

- DC2686 PDFDocument6 pagesDC2686 PDFPT DJAS SUCCES SUPPORTNo ratings yet

- Fischer Type 99Document8 pagesFischer Type 99piattaformaNo ratings yet

- Installation Instructions For PSI and Pikotek® Gaskets: Sleeves Through The Bolt HolesDocument4 pagesInstallation Instructions For PSI and Pikotek® Gaskets: Sleeves Through The Bolt Holesquiron2010No ratings yet

- 05-9040-269 ANGMC-6019-US Anderson Greenwood PDFDocument33 pages05-9040-269 ANGMC-6019-US Anderson Greenwood PDFDIONNY VELASQUEZNo ratings yet

- Iom WKM 310FDocument4 pagesIom WKM 310FNasir NaqviNo ratings yet

- SV 3 Safety ValveDocument7 pagesSV 3 Safety ValveWanderley FonsecaNo ratings yet

- Dwyer - Valvula de Bola Inox Serie BV2M, IOMDocument1 pageDwyer - Valvula de Bola Inox Serie BV2M, IOMGabriel Ortiz MontesNo ratings yet

- Fluid Components Full CatalogDocument464 pagesFluid Components Full Catalognegg 348No ratings yet

- 63 Injection Sampling AssembliesDocument4 pages63 Injection Sampling AssembliesAbdul Hannan NazeerNo ratings yet

- HansenDocument4 pagesHansenBruna MacedoNo ratings yet

- Iron Balancing Valves IOM For Hattersley ColourDocument8 pagesIron Balancing Valves IOM For Hattersley ColourMuhammad ElbarbaryNo ratings yet

- EZR Installation ManualDocument40 pagesEZR Installation ManualRoberto Aldayuz HerediaNo ratings yet

- 727 PosrvDocument7 pages727 Posrvtxlucky80No ratings yet

- API6D Ball Valves Inspection and Test ProceduresDocument5 pagesAPI6D Ball Valves Inspection and Test ProceduresChi Cha100% (3)

- Válve Relay Air Starters CAT E WaukeshaDocument8 pagesVálve Relay Air Starters CAT E WaukeshaJonatas Barbaglio Gomes PereiraNo ratings yet

- QuillsDocument4 pagesQuillsajostosNo ratings yet

- Conver 6358Document8 pagesConver 6358ALBERTONo ratings yet

- 4fJ - L, - C: HalliburtonDocument4 pages4fJ - L, - C: HalliburtonKhalfan Al HabsiNo ratings yet

- Sae J343-2010Document9 pagesSae J343-2010Job-AngelNo ratings yet

- Type OSB Safety Shut-Off ValveDocument8 pagesType OSB Safety Shut-Off ValvecartarNo ratings yet

- Fisherr 8510 and 8510B Eccentric Disc Control Valves (EMA) : FeaturesDocument20 pagesFisherr 8510 and 8510B Eccentric Disc Control Valves (EMA) : FeaturesFabián HerreraNo ratings yet

- GPT Installation Instructions - LoresDocument7 pagesGPT Installation Instructions - LoresEWheelerFKNo ratings yet

- Installation Instructions: Durametallic ML-200 SeriesDocument8 pagesInstallation Instructions: Durametallic ML-200 SerieslubangjarumNo ratings yet

- Pressure Test ProcedureDocument11 pagesPressure Test ProcedureRolando Nicanor0% (1)

- Valvulas de Control FisherDocument16 pagesValvulas de Control FisherAnonymous GKTRypNo ratings yet

- Aop b3 b6 IomDocument2 pagesAop b3 b6 IomrjNo ratings yet

- Valvulas de Bola - JAMESBURYDocument4 pagesValvulas de Bola - JAMESBURYcasv9No ratings yet

- 3-5400 SERIES Safety Relief Valves: Instruction ManualDocument16 pages3-5400 SERIES Safety Relief Valves: Instruction ManualPrashant ChauhanNo ratings yet

- Tyco Alarm ValveDocument22 pagesTyco Alarm ValveMohammed BaquarNo ratings yet

- Fisher 630 Series PDFDocument10 pagesFisher 630 Series PDFClemente Rafael Marval EscalonaNo ratings yet

- SIT630 Installation InstructionsDocument2 pagesSIT630 Installation Instructionsmelisa63No ratings yet

- Series V100 Ball ValveDocument20 pagesSeries V100 Ball ValvejenniferNo ratings yet

- Piping Inspector Questions 1Document6 pagesPiping Inspector Questions 1Badiuzzama786100% (1)

- Using The 9U5383 Vacuum Tester (1105) : Special InstructionDocument4 pagesUsing The 9U5383 Vacuum Tester (1105) : Special InstructionЕвгений АбрамовNo ratings yet

- Crosby Style HL Low Pressure Steel Full Nozzle Safety Valves Installation, Maintenance and Adjustment InstructionsDocument17 pagesCrosby Style HL Low Pressure Steel Full Nozzle Safety Valves Installation, Maintenance and Adjustment InstructionsTarek MohamedNo ratings yet

- Standard Pressure Testing ProcedureDocument10 pagesStandard Pressure Testing ProcedureAbdulbasit JunaidNo ratings yet

- RD Circulating ValveDocument6 pagesRD Circulating ValvearslanadeelNo ratings yet

- CAT CS533E Engine Part 4Document6 pagesCAT CS533E Engine Part 4Oecox Cah DjadoelNo ratings yet

- E 911 - 98 R04 - RTKXMQDocument4 pagesE 911 - 98 R04 - RTKXMQabualamalNo ratings yet

- Gilmont RotameterDocument8 pagesGilmont RotameterDavid Enrique Velásquez RiosNo ratings yet

- Rev00-Gasket Installation & Bolt Torquing ProcedureDocument24 pagesRev00-Gasket Installation & Bolt Torquing ProcedureHansel FrancisNo ratings yet

- TBV Series 21 20 Cryogenic Flanged Ball ValveDocument5 pagesTBV Series 21 20 Cryogenic Flanged Ball ValveJosip PobranNo ratings yet

- EZR RegulatorDocument40 pagesEZR RegulatorBranko BabicNo ratings yet

- Balanced Pressure Thermostatic Steam Trap: BPT21YDocument2 pagesBalanced Pressure Thermostatic Steam Trap: BPT21YJozsef MagyariNo ratings yet

- Unique Single Seat Valve-Simply UniqueDocument8 pagesUnique Single Seat Valve-Simply UniquelggomezupbNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Military Standard: WL-S 2155 (A@Document18 pagesMilitary Standard: WL-S 2155 (A@thomasoburNo ratings yet

- FX 3900 PVDocument194 pagesFX 3900 PVthomasoburNo ratings yet

- Design Calc Saud It SampleDocument25 pagesDesign Calc Saud It SampleglazetmNo ratings yet

- Steel Onesteel HandbookDocument34 pagesSteel Onesteel HandbookjlolhnpNo ratings yet

- Bolting Torques - Spiral Wound GasketsDocument1 pageBolting Torques - Spiral Wound GasketsthomasoburNo ratings yet

- Auto Drain 70APADH4000Document3 pagesAuto Drain 70APADH4000thomasoburNo ratings yet

- Mack Ball ValvesDocument10 pagesMack Ball ValvesthomasoburNo ratings yet

- Engineering Competency StandardsDocument11 pagesEngineering Competency StandardsRobbie van LeeuwenNo ratings yet

- 3% Rule Sizing For PSV-Compressible FlowDocument1 page3% Rule Sizing For PSV-Compressible FlowthomasoburNo ratings yet

- Varec 3650B 33-11518Document15 pagesVarec 3650B 33-11518thomasoburNo ratings yet

- Type A Pressure Relief Valve: Standard Features Parts List (Sizes 1/2" - 2")Document2 pagesType A Pressure Relief Valve: Standard Features Parts List (Sizes 1/2" - 2")thomasoburNo ratings yet

- Metaland KYS CatalogueDocument96 pagesMetaland KYS CataloguethomasoburNo ratings yet

- Eaton Hydraulic Power PackDocument6 pagesEaton Hydraulic Power PackthomasoburNo ratings yet

- Heat Transfer - Transient Hyperbolic Conduction in Hollow CylinderDocument6 pagesHeat Transfer - Transient Hyperbolic Conduction in Hollow CylinderthomasoburNo ratings yet

- Bond Ek Design and Construction Manual June 2012Document56 pagesBond Ek Design and Construction Manual June 2012rocketNo ratings yet

- Atlas Metals - Carbon Steel Pipe Pressure Rating ChartDocument4 pagesAtlas Metals - Carbon Steel Pipe Pressure Rating ChartthomasoburNo ratings yet

- Project Fianace 1Document46 pagesProject Fianace 17karswapnilNo ratings yet

- Inevitable AbortionDocument21 pagesInevitable AbortionJaysonPangilinanAbanNo ratings yet

- Maternity Benefit PolicyDocument2 pagesMaternity Benefit Policyshrija nairNo ratings yet

- 01 - Important Announcement For The Accepted ParticipantsDocument2 pages01 - Important Announcement For The Accepted ParticipantsMohammad Asif KabirNo ratings yet

- Control Valve Sourcebook (Refining) PDFDocument198 pagesControl Valve Sourcebook (Refining) PDFnaraNJORNo ratings yet

- 06 - Chapter 3Document28 pages06 - Chapter 3Tech NestNo ratings yet

- (WWW - Asianovel.com) - Isekai Tensei Harem Chapter 1 - Chapter 50Document291 pages(WWW - Asianovel.com) - Isekai Tensei Harem Chapter 1 - Chapter 50Jairo Custodio JurupeNo ratings yet

- Prelim Types of SexualityDocument12 pagesPrelim Types of SexualityAngelica SinoyNo ratings yet

- Vikoflex-7170 - Epoxided Soyabean OilDocument3 pagesVikoflex-7170 - Epoxided Soyabean Oilsriatul2006No ratings yet

- Am I Crazy, or Is It My ShrinkDocument225 pagesAm I Crazy, or Is It My ShrinkTheFreeSpirit100% (5)

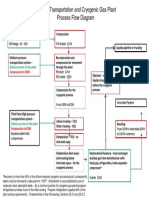

- Generic Transportation and Cryogenic Gas Plant Process Flow DiagramDocument1 pageGeneric Transportation and Cryogenic Gas Plant Process Flow DiagramSyahmi AbdullahNo ratings yet

- FMDS0300Document65 pagesFMDS0300Henry SuarezNo ratings yet

- Vistamore SDN BHD Project Quality Plan Section 1Document8 pagesVistamore SDN BHD Project Quality Plan Section 1Wan Mohamad Noor Hj IsmailNo ratings yet

- Class - 9 - Nstse - PQP - 10 Papers - 2019-20 - 2 in A4 PDFDocument106 pagesClass - 9 - Nstse - PQP - 10 Papers - 2019-20 - 2 in A4 PDFriddhi100% (4)

- Englis 8Document17 pagesEnglis 8Muhammad RafiNo ratings yet

- Biology CH 7 Practice TestDocument6 pagesBiology CH 7 Practice Testvaleria100% (2)

- The Periodic Table CDocument177 pagesThe Periodic Table Cmarius1966No ratings yet

- Soalan Saintis Muda 2017Document17 pagesSoalan Saintis Muda 2017Caryn YeapNo ratings yet

- Bullying - Moral Theology ProjectDocument10 pagesBullying - Moral Theology ProjectJaira GayodNo ratings yet

- List of Suppliers Who Have Submitted Their Consent For Including in The DPMC of Palnadu DTDocument11 pagesList of Suppliers Who Have Submitted Their Consent For Including in The DPMC of Palnadu DTSudheer KumarNo ratings yet

- Kinesio Tape in Paediatric Physiotherapy A Content Analysis of Practitioner ExperienceDocument9 pagesKinesio Tape in Paediatric Physiotherapy A Content Analysis of Practitioner ExperienceEemaNo ratings yet

- Family Business Daily: A Slice of AdviceDocument3 pagesFamily Business Daily: A Slice of Advicemaheen khanNo ratings yet

- Shipping Out of Sleepers FAT-TK-011-CHKDocument4 pagesShipping Out of Sleepers FAT-TK-011-CHKThai Hai LyNo ratings yet

- Do Dont - Does DoesntDocument2 pagesDo Dont - Does Doesntdeathnote lNo ratings yet

- Cell Structure and Function Pretest: The Organelle Has A Phospholipid MembraneDocument28 pagesCell Structure and Function Pretest: The Organelle Has A Phospholipid MembranelayanhaliloNo ratings yet

- CLC 18-10Nb: A NB Stabilized 18Cr-10Ni Austenitic Stainless Steel (347 Grade)Document4 pagesCLC 18-10Nb: A NB Stabilized 18Cr-10Ni Austenitic Stainless Steel (347 Grade)PeterWayNo ratings yet

- Chemistry Investegatory Project On AsprinDocument21 pagesChemistry Investegatory Project On Asprinmaruthu100% (1)

- PDFDocument69 pagesPDFRuel Gonzales79% (14)

Air Test Gun For Tube Bundles

Air Test Gun For Tube Bundles

Uploaded by

thomasoburOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Air Test Gun For Tube Bundles

Air Test Gun For Tube Bundles

Uploaded by

thomasoburCopyright:

Available Formats

EXPANSION SEAL TECHNOLOGIES

DC2050 04/93 REV. 7 07/03 PAGE 1 OF 7

OPERATING PROCEDURES FOR G-150 TUBE TESTING GUNS

NOTE: See pages 4-6 for parts and drawings of the G-150 as indicated in instructions below. PRIOR TO TESTING: 1. The tubes to be tested should be cleaned and any loose deposits or scale should be removed. If the tubes have not been cleaned, any foreign materials present may be ejected during the testing operation and may damage the test guns or injure the operators. The operators should always wear safety glasses or a face shield when testing with the G-150 or any type of pressure test guns. If the tubes have been acid cleaned please check with EST Customer Service regarding the compatibility of the test gun seals with the cleaning agent. Different types of elastomer seals are available as replacements. Make sure the test guns have the correct size Replacement Seal and Washer Set (2) for the tubes being tested. The seals and washers are correctly sized if the OD of the seal is between 0.02" to 0.06" (0.5mm to 1.5mm) smaller than the actual tube ID. Using seals that are too small may cause any of the following: premature seal wear, jamming of the test gun in the tube, or expulsion of the test gun from the tube end. Replacement seals for the G-150 testing guns can be manufactured for any tube I.D. from 0.28" to 1.23" (7.1mm to 31.3mm). For tube ID's larger than 1.23", contact EST for information on the G-150A Test Gun Package. The procedure for replacing the seal and washer sets is outlined below.

2. 3.

4.

TESTING PROCEDURE: Never actuate the injection gun unless the seal assembly is installed within the proper ID tube as the washers could be forced into the seal ID. The G-150 Tube Testing Guns come as a set. This set is comprised of: an air injection gun and a plugging gun. The air injection gun can be differentiated from the plugging gun because it incorporates the air control valve (10) and bleed valve (12). The plugging gun is a slave to the injection gun and will not operate without it. 1. Attach air supply to the air injection gun. The G-150 test guns will be operational on plant air supplies ranging from 40 to 125 psi (2.7 to 8.6 Bar) at a minimum of 5 cfm. If testing tube IDs from 0.28 to 0.48 (7.1 to 12.3 mm) the regulator assembly (part number GSA-REG) is required. Install regulator assembly (14) with arrow pointing towards gun onto nipple leak tight and attach air supply to regulator input. For tube IDs from 0.28 - 0.48 adjust regulator to 40 60 psi (2.7 to 4.1 Bar) by rotating adjustment knobs while viewing gage. Insert the air injection gun into one end of the tube to be tested and the plugging gun into the other end. Apply enough pressure to seat the back-up washer (3) firmly against the end of the tube. Maintain this pressure throughout the test.

2.

EXPANSION SEAL TECHNOLOGIES

DC2050 04/93 REV. 7 07/03 PAGE 2 OF 7

3. 4. 5. 6. 7.

After making sure that the plugging gun operator is ready, squeeze the handle of the air control valve (10) on the injection gun and hold until the reading on the pressure gauge (7) stabilizes. Release the handle of the air control valve (10). It will automatically return to the closed position isolating the tube being tested. The Tube is now under pressure. Both injection gun and plugging gun operators should observe the pressure gage (7) on their respective guns. Any decrease in the pressure indicated on the gauge (7) will indicate a leaking tube. Press the bleed valve (12) on the injection gun to bleed off the air pressure in the tube and air cylinders and to relax the seals. Remove the test guns and move on to the next tube. Mark each leaking tube encountered for repair. The total operation should be completed in 5 to 10 seconds. Your actual testing time will depend on the amount of time you choose to hold the test pressure. Repeat steps 2 through 7.

8.

INSTALLING REPLACEMENT SEALS: Replacement seals for the G-150 guns are supplied with the corresponding size washers. Always replace the seals and washers on both guns at the same time. 1. 2. 3. Remove the locknut (1) from the end of the support tube (4) and set it aside. Remove the Seal and Washer Set (2) from the support tube (4). Discard if worn. Under optimum testing conditions you should be able to test between 100 to 500 tubes per Replacement Seal and Washer Set. For replacement Seal and Washer sets of the same size, install on existing support tube (4). If you are changing the Seal and Washer set to a different size, keep in mind that the support tube assembly (5) may be required to change as well. To replace the support tube assembly, refer to the procedure outlined below. When replacing the locknut (1) on the support tube (4) do not use a wrench, screw it on finger tight only. A small space between the locknut, seal and washer set, and back-up washers is normal. There will be enough stroke in the air cylinder to compensate for this space.

4.

REPLACING THE SUPPORT TUBE ASSEMBLY: The G-150 test guns are originally shipped with three sets of support tube assemblies (5). These support tube assemblies will allow you to test tubes with ID's from 0.28 - 0.48, 0.49" to 0.83" and 0.84" to 1.23" (7.1mm to 12.3mm, 12.4mm to 21.2mm, and 21.3mm to 31.3mm respectively). 1. 2. Remove the Seal and Washer Sets (2) as outlined above. Using an open end wrench on the wrench flats provided on the piston and a pipe wrench on the support tube (4) gently unscrew the support tube from the piston.

EXPANSION SEAL TECHNOLOGIES

DC2050 04/93 REV. 7 07/03 PAGE 3 OF 7

3.

Choose the correct size support tubes for the tube ID being tested. All three sizes of support tubes will fit into the piston of the test gun. Use Never-seize or similar product to lubricate and seal the threads. Do not over tighten the support tube. Repeat steps 1 thru 3 for the remaining gun. If testing tube IDs from 0.28 - 0.48 (7.1mm to 12.3mm) thread the regulator assembly with arrow pointing towards gun onto nipple leak tight. Prior to replacing the Seal and Washer Set (2) and the Back-up Washer Set (3) inspect the support tube for scars left from the replacement procedure. File smooth if present.

4. 5. 6.

OTHER REPLACEMENTS AND REPAIRS: Under no conditions should you attempt to service the air cylinders. Any attempt to perform service on the cylinders may void any and all remaining warranties, implied or otherwise.

QUESTIONS? Contact EST Customer Service at any of the following locations with questions. In USA and Canada: tel: 800-355-7044, fax: 215-721-1101, e-mail: info@expansionseal.com In Europe: tel: +31-172-418841, fax: +31-172-418849; e-mail: info@estgrp.nl In Asia: tel: +65-6745-8560, fax: +65-6742-8700, e-mail: estasia@singnet.com.sg On the Internet: www.expansionseal.com Expansion Seal Technologies is part of the EST Group of companies. EST Group provides a complete range of repair products, services and replacement parts covering the life cycle of tubular heat exchangers and condensers; additionally EST provides products and services to facilitate pressure testing pipe, piping systems, pressure vessels and their components. Visit EST Group on the internet at www.estgrp.com.

EXPANSION SEAL TECHNOLOGIES

DC2050 04/93 REV. 7 07/03 PAGE 4 OF 7

TABLE 1 Seal & Washer sets listed below are not included in the G-150 Tube Test Gun Package. Seal & Washer sets are required for all applications. See Table 3 for XXXX sizing.

Item 2 Quantity Minimum 1 set Description Seal & Washer Set Part Number for Tube IDs Listed 0.28 - 0.48 0.49 - 0.83 0.84 - 1.23 GSA-XXXX-N (Neoprene)

TABLE 2 Replacement Parts for G150 Tube Testing Gun Set (Injection & Plugging Gun) Part # GSA-1500

Item 1 3 4 5 6 7 8 9 10 11 12 13 14 15 Quantity 1 each gun 1 each gun 1 each gun 1 each gun 1 1 each gun 1 each gun 1 1 1 1 2 1 1 each gun (Optional) Description Lock Nut Back-up Washer Set (includes elastomer & steel washer) Support Tube Support Tube Assembly (includes items 1,3 &4) Handle, ported w/o bleed valve (Injection Gun only) Pressure Gauge, 0-160 psi Cylinder Body Complete Reducing Nipple, 1/4-1/8 NPT (Injection Gun Only) Air Control Valve (Injection Gun Only) 2 1/2" Nipple, 1/4 NPT (Injection Gun Only) Bleed Valve (Injection Gun Only) Handle, w/o port (Plugging Gun Only) Regulator Assembly Support rod Extension (Available in 1, 2, 3, & 4ft lengths) Part Number for Tube IDs Listed 0.28 - 0.48 0.49 - 0.83 0.84 1.23 GSA-1530 GSA-1531 GSA-1532 GSA-1520 GSA-1510 GSA-1521 Supplied as part of item 5 GSA-1511 GSA-1571 GSA-1540 GSA-1580 GSA-1551 GSA-1550 GSA-1548 GSA-1560 GSA-1572 GSA-REG GSA-1510-XX Not required GSA-1511-XX GSA-1512-XX GSA-1512 GSA-1522

TABLE 3 Seal & Washer Set Part Numbers, GSA-XXXX-N, where XXXX is the number listed in the chart for the appropriate tube OD and BWG. Seal and Washer Sets for the tube IDs 0.28-0.48 contain (4) seals and (4) washers. All other Seal and Washer Sets contain (2) seals and (4) washers.

BWG 8-9 10-11 12-13 14-15 16-17 18-19 20-24 1/2 N/A N/A 0028 0033 0037 0040 0043 G-150 Seal & Washer Sets, Part Numbers (GSA-XXXX-N) 5/8 3/4 7/8 1 1 1/8 1 1/4 1 3/8 0030 0043 0056 0068 0081 0093 0106 0037 0047 0062 0072 0087 0097 0112 0040 0053 0065 0078 0090 0103 0115 0047 0056 0072 0083 0097 0110 0122 0050 0062 0075 0087 0100 0112 See G-150A 0053 0065 0078 0090 0103 0115 0056 0068 0081 0093 0106 0118 1 1/2 0118 0122 See G-150A

EXPANSION SEAL TECHNOLOGIES

DC2050 04/93 REV. 7 07/03 PAGE 5 OF 7

EXPANSION SEAL TECHNOLOGIES

DC2050 04/93 REV. 7 07/03 PAGE 6 OF 7

EXPANSION SEAL TECHNOLOGIES

DC2050 04/93 REV. 7 07/03 PAGE 7 OF 7

You might also like

- CMAS Training Manual P3Eng PDFDocument104 pagesCMAS Training Manual P3Eng PDFdigibillNo ratings yet

- PRC Memorandum Circular No. 03 (Hazard Pay Clarifiation On Risk Factor)Document1 pagePRC Memorandum Circular No. 03 (Hazard Pay Clarifiation On Risk Factor)ABI Alco QANo ratings yet

- Balcrank 1130-001 Tiger PumpDocument8 pagesBalcrank 1130-001 Tiger PumpJoseph GeraciNo ratings yet

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Valves & Controls: Crosby Safety Valves Style HSLDocument12 pagesValves & Controls: Crosby Safety Valves Style HSLeborresonNo ratings yet

- Catálogo Anderson Greenwood 400sDocument32 pagesCatálogo Anderson Greenwood 400sDaniela BeltranNo ratings yet

- Convertidor Mechanical S108KDocument8 pagesConvertidor Mechanical S108KALBERTONo ratings yet

- A 084 BDocument12 pagesA 084 BDenis JimenezNo ratings yet

- Katalog p310 - 07Document7 pagesKatalog p310 - 07agustinusidNo ratings yet

- Especificaciones Bomba Ventilador CATD10T - TestDocument36 pagesEspecificaciones Bomba Ventilador CATD10T - TestRafael RodriguezNo ratings yet

- Manual Valvula PCVDocument16 pagesManual Valvula PCVzamirgothNo ratings yet

- Pump Suction Diffuser ManualDocument2 pagesPump Suction Diffuser ManualAnonymous 7xHNgoKE6eNo ratings yet

- Low Torc ValveDocument4 pagesLow Torc Valvejinyuan74100% (2)

- Pressure Reducing Regulator FISHER Manual Serie 64Document8 pagesPressure Reducing Regulator FISHER Manual Serie 64Billy Isea DenaroNo ratings yet

- BaileyDocument14 pagesBaileyhecdomNo ratings yet

- DC2686 PDFDocument6 pagesDC2686 PDFPT DJAS SUCCES SUPPORTNo ratings yet

- Fischer Type 99Document8 pagesFischer Type 99piattaformaNo ratings yet

- Installation Instructions For PSI and Pikotek® Gaskets: Sleeves Through The Bolt HolesDocument4 pagesInstallation Instructions For PSI and Pikotek® Gaskets: Sleeves Through The Bolt Holesquiron2010No ratings yet

- 05-9040-269 ANGMC-6019-US Anderson Greenwood PDFDocument33 pages05-9040-269 ANGMC-6019-US Anderson Greenwood PDFDIONNY VELASQUEZNo ratings yet

- Iom WKM 310FDocument4 pagesIom WKM 310FNasir NaqviNo ratings yet

- SV 3 Safety ValveDocument7 pagesSV 3 Safety ValveWanderley FonsecaNo ratings yet

- Dwyer - Valvula de Bola Inox Serie BV2M, IOMDocument1 pageDwyer - Valvula de Bola Inox Serie BV2M, IOMGabriel Ortiz MontesNo ratings yet

- Fluid Components Full CatalogDocument464 pagesFluid Components Full Catalognegg 348No ratings yet

- 63 Injection Sampling AssembliesDocument4 pages63 Injection Sampling AssembliesAbdul Hannan NazeerNo ratings yet

- HansenDocument4 pagesHansenBruna MacedoNo ratings yet

- Iron Balancing Valves IOM For Hattersley ColourDocument8 pagesIron Balancing Valves IOM For Hattersley ColourMuhammad ElbarbaryNo ratings yet

- EZR Installation ManualDocument40 pagesEZR Installation ManualRoberto Aldayuz HerediaNo ratings yet

- 727 PosrvDocument7 pages727 Posrvtxlucky80No ratings yet

- API6D Ball Valves Inspection and Test ProceduresDocument5 pagesAPI6D Ball Valves Inspection and Test ProceduresChi Cha100% (3)

- Válve Relay Air Starters CAT E WaukeshaDocument8 pagesVálve Relay Air Starters CAT E WaukeshaJonatas Barbaglio Gomes PereiraNo ratings yet

- QuillsDocument4 pagesQuillsajostosNo ratings yet

- Conver 6358Document8 pagesConver 6358ALBERTONo ratings yet

- 4fJ - L, - C: HalliburtonDocument4 pages4fJ - L, - C: HalliburtonKhalfan Al HabsiNo ratings yet

- Sae J343-2010Document9 pagesSae J343-2010Job-AngelNo ratings yet

- Type OSB Safety Shut-Off ValveDocument8 pagesType OSB Safety Shut-Off ValvecartarNo ratings yet

- Fisherr 8510 and 8510B Eccentric Disc Control Valves (EMA) : FeaturesDocument20 pagesFisherr 8510 and 8510B Eccentric Disc Control Valves (EMA) : FeaturesFabián HerreraNo ratings yet

- GPT Installation Instructions - LoresDocument7 pagesGPT Installation Instructions - LoresEWheelerFKNo ratings yet

- Installation Instructions: Durametallic ML-200 SeriesDocument8 pagesInstallation Instructions: Durametallic ML-200 SerieslubangjarumNo ratings yet

- Pressure Test ProcedureDocument11 pagesPressure Test ProcedureRolando Nicanor0% (1)

- Valvulas de Control FisherDocument16 pagesValvulas de Control FisherAnonymous GKTRypNo ratings yet

- Aop b3 b6 IomDocument2 pagesAop b3 b6 IomrjNo ratings yet

- Valvulas de Bola - JAMESBURYDocument4 pagesValvulas de Bola - JAMESBURYcasv9No ratings yet

- 3-5400 SERIES Safety Relief Valves: Instruction ManualDocument16 pages3-5400 SERIES Safety Relief Valves: Instruction ManualPrashant ChauhanNo ratings yet

- Tyco Alarm ValveDocument22 pagesTyco Alarm ValveMohammed BaquarNo ratings yet

- Fisher 630 Series PDFDocument10 pagesFisher 630 Series PDFClemente Rafael Marval EscalonaNo ratings yet

- SIT630 Installation InstructionsDocument2 pagesSIT630 Installation Instructionsmelisa63No ratings yet

- Series V100 Ball ValveDocument20 pagesSeries V100 Ball ValvejenniferNo ratings yet

- Piping Inspector Questions 1Document6 pagesPiping Inspector Questions 1Badiuzzama786100% (1)

- Using The 9U5383 Vacuum Tester (1105) : Special InstructionDocument4 pagesUsing The 9U5383 Vacuum Tester (1105) : Special InstructionЕвгений АбрамовNo ratings yet

- Crosby Style HL Low Pressure Steel Full Nozzle Safety Valves Installation, Maintenance and Adjustment InstructionsDocument17 pagesCrosby Style HL Low Pressure Steel Full Nozzle Safety Valves Installation, Maintenance and Adjustment InstructionsTarek MohamedNo ratings yet

- Standard Pressure Testing ProcedureDocument10 pagesStandard Pressure Testing ProcedureAbdulbasit JunaidNo ratings yet

- RD Circulating ValveDocument6 pagesRD Circulating ValvearslanadeelNo ratings yet

- CAT CS533E Engine Part 4Document6 pagesCAT CS533E Engine Part 4Oecox Cah DjadoelNo ratings yet

- E 911 - 98 R04 - RTKXMQDocument4 pagesE 911 - 98 R04 - RTKXMQabualamalNo ratings yet

- Gilmont RotameterDocument8 pagesGilmont RotameterDavid Enrique Velásquez RiosNo ratings yet

- Rev00-Gasket Installation & Bolt Torquing ProcedureDocument24 pagesRev00-Gasket Installation & Bolt Torquing ProcedureHansel FrancisNo ratings yet

- TBV Series 21 20 Cryogenic Flanged Ball ValveDocument5 pagesTBV Series 21 20 Cryogenic Flanged Ball ValveJosip PobranNo ratings yet

- EZR RegulatorDocument40 pagesEZR RegulatorBranko BabicNo ratings yet

- Balanced Pressure Thermostatic Steam Trap: BPT21YDocument2 pagesBalanced Pressure Thermostatic Steam Trap: BPT21YJozsef MagyariNo ratings yet

- Unique Single Seat Valve-Simply UniqueDocument8 pagesUnique Single Seat Valve-Simply UniquelggomezupbNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Military Standard: WL-S 2155 (A@Document18 pagesMilitary Standard: WL-S 2155 (A@thomasoburNo ratings yet

- FX 3900 PVDocument194 pagesFX 3900 PVthomasoburNo ratings yet

- Design Calc Saud It SampleDocument25 pagesDesign Calc Saud It SampleglazetmNo ratings yet

- Steel Onesteel HandbookDocument34 pagesSteel Onesteel HandbookjlolhnpNo ratings yet

- Bolting Torques - Spiral Wound GasketsDocument1 pageBolting Torques - Spiral Wound GasketsthomasoburNo ratings yet

- Auto Drain 70APADH4000Document3 pagesAuto Drain 70APADH4000thomasoburNo ratings yet

- Mack Ball ValvesDocument10 pagesMack Ball ValvesthomasoburNo ratings yet

- Engineering Competency StandardsDocument11 pagesEngineering Competency StandardsRobbie van LeeuwenNo ratings yet

- 3% Rule Sizing For PSV-Compressible FlowDocument1 page3% Rule Sizing For PSV-Compressible FlowthomasoburNo ratings yet

- Varec 3650B 33-11518Document15 pagesVarec 3650B 33-11518thomasoburNo ratings yet

- Type A Pressure Relief Valve: Standard Features Parts List (Sizes 1/2" - 2")Document2 pagesType A Pressure Relief Valve: Standard Features Parts List (Sizes 1/2" - 2")thomasoburNo ratings yet

- Metaland KYS CatalogueDocument96 pagesMetaland KYS CataloguethomasoburNo ratings yet

- Eaton Hydraulic Power PackDocument6 pagesEaton Hydraulic Power PackthomasoburNo ratings yet

- Heat Transfer - Transient Hyperbolic Conduction in Hollow CylinderDocument6 pagesHeat Transfer - Transient Hyperbolic Conduction in Hollow CylinderthomasoburNo ratings yet

- Bond Ek Design and Construction Manual June 2012Document56 pagesBond Ek Design and Construction Manual June 2012rocketNo ratings yet

- Atlas Metals - Carbon Steel Pipe Pressure Rating ChartDocument4 pagesAtlas Metals - Carbon Steel Pipe Pressure Rating ChartthomasoburNo ratings yet

- Project Fianace 1Document46 pagesProject Fianace 17karswapnilNo ratings yet

- Inevitable AbortionDocument21 pagesInevitable AbortionJaysonPangilinanAbanNo ratings yet

- Maternity Benefit PolicyDocument2 pagesMaternity Benefit Policyshrija nairNo ratings yet

- 01 - Important Announcement For The Accepted ParticipantsDocument2 pages01 - Important Announcement For The Accepted ParticipantsMohammad Asif KabirNo ratings yet

- Control Valve Sourcebook (Refining) PDFDocument198 pagesControl Valve Sourcebook (Refining) PDFnaraNJORNo ratings yet

- 06 - Chapter 3Document28 pages06 - Chapter 3Tech NestNo ratings yet

- (WWW - Asianovel.com) - Isekai Tensei Harem Chapter 1 - Chapter 50Document291 pages(WWW - Asianovel.com) - Isekai Tensei Harem Chapter 1 - Chapter 50Jairo Custodio JurupeNo ratings yet

- Prelim Types of SexualityDocument12 pagesPrelim Types of SexualityAngelica SinoyNo ratings yet

- Vikoflex-7170 - Epoxided Soyabean OilDocument3 pagesVikoflex-7170 - Epoxided Soyabean Oilsriatul2006No ratings yet

- Am I Crazy, or Is It My ShrinkDocument225 pagesAm I Crazy, or Is It My ShrinkTheFreeSpirit100% (5)

- Generic Transportation and Cryogenic Gas Plant Process Flow DiagramDocument1 pageGeneric Transportation and Cryogenic Gas Plant Process Flow DiagramSyahmi AbdullahNo ratings yet

- FMDS0300Document65 pagesFMDS0300Henry SuarezNo ratings yet

- Vistamore SDN BHD Project Quality Plan Section 1Document8 pagesVistamore SDN BHD Project Quality Plan Section 1Wan Mohamad Noor Hj IsmailNo ratings yet

- Class - 9 - Nstse - PQP - 10 Papers - 2019-20 - 2 in A4 PDFDocument106 pagesClass - 9 - Nstse - PQP - 10 Papers - 2019-20 - 2 in A4 PDFriddhi100% (4)

- Englis 8Document17 pagesEnglis 8Muhammad RafiNo ratings yet

- Biology CH 7 Practice TestDocument6 pagesBiology CH 7 Practice Testvaleria100% (2)

- The Periodic Table CDocument177 pagesThe Periodic Table Cmarius1966No ratings yet

- Soalan Saintis Muda 2017Document17 pagesSoalan Saintis Muda 2017Caryn YeapNo ratings yet

- Bullying - Moral Theology ProjectDocument10 pagesBullying - Moral Theology ProjectJaira GayodNo ratings yet

- List of Suppliers Who Have Submitted Their Consent For Including in The DPMC of Palnadu DTDocument11 pagesList of Suppliers Who Have Submitted Their Consent For Including in The DPMC of Palnadu DTSudheer KumarNo ratings yet

- Kinesio Tape in Paediatric Physiotherapy A Content Analysis of Practitioner ExperienceDocument9 pagesKinesio Tape in Paediatric Physiotherapy A Content Analysis of Practitioner ExperienceEemaNo ratings yet

- Family Business Daily: A Slice of AdviceDocument3 pagesFamily Business Daily: A Slice of Advicemaheen khanNo ratings yet

- Shipping Out of Sleepers FAT-TK-011-CHKDocument4 pagesShipping Out of Sleepers FAT-TK-011-CHKThai Hai LyNo ratings yet

- Do Dont - Does DoesntDocument2 pagesDo Dont - Does Doesntdeathnote lNo ratings yet

- Cell Structure and Function Pretest: The Organelle Has A Phospholipid MembraneDocument28 pagesCell Structure and Function Pretest: The Organelle Has A Phospholipid MembranelayanhaliloNo ratings yet

- CLC 18-10Nb: A NB Stabilized 18Cr-10Ni Austenitic Stainless Steel (347 Grade)Document4 pagesCLC 18-10Nb: A NB Stabilized 18Cr-10Ni Austenitic Stainless Steel (347 Grade)PeterWayNo ratings yet

- Chemistry Investegatory Project On AsprinDocument21 pagesChemistry Investegatory Project On Asprinmaruthu100% (1)

- PDFDocument69 pagesPDFRuel Gonzales79% (14)