Professional Documents

Culture Documents

A-UAE-7717-956 - Global Remort

A-UAE-7717-956 - Global Remort

Uploaded by

AlbinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A-UAE-7717-956 - Global Remort

A-UAE-7717-956 - Global Remort

Uploaded by

AlbinCopyright:

Available Formats

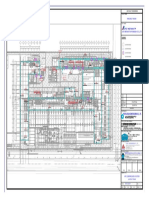

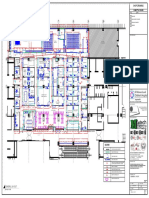

DRAWING NOTES

1. BASIS OF DESIGN

This drawing has been prepared from information supplied to us by, or on behalf of the Customer, who should check

that we have correctly interpreted his requirements and that all loadings, dimensions, details, erection, and dismantling

2 sequences etc. are as required and practicable.

7717-956

The following documents have been used to prepare this scheme:-

Customer Drawings: _________________________________________ =

Level 2 Customer Method Statement: _________________________________________ NONE SUPPLIED

Other Information: _________________________________________

3500 =

2. DESIGN CRITERIA

1250

System to be used: ....................................................

Cuplok & Fitting

System Grid: .................................................... AS SHOWN

Scaffold Height: .................................................... AS SHOWN

Number of boarded platforms: .................................................... AS SHOWN

Number of working platforms: .................................................... AS SHOWN

Sheeted or Clad Scaffold: .................................................... No

Tied to the permanent structure: ....................................................

No

Connected to buttress scaffold: .................................................... No

2000

3. CODE & REFERENCES

This drawing has been prepared in accordance with the following Code of Practices & References, where applicable.

3.1 General design for system scaffold.

4

BS EN 12811-1 Temporary works equipment Part 1:Scaffolds - Performance requirements and general design.

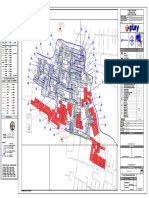

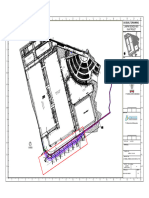

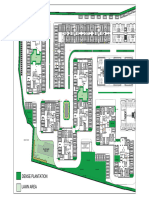

7717-956 Plan View 3.2 Wind loading: Methods for determining wind forces in the structure.

BS EN 1991-1-4 Euro code 1:Actions on structures - Part1-4:General actions - Wind actions.

0

3.3 Safe working loads

SGB Technical Data Sheets

4. APPLIED LOADS

Applied loads (unless otherwise indicated) where applicable:

Section 2 4.1 Dead loads

Scaffold self weight conforming to SGB Technical Data Sheets

2000

1 : 50 4.2 Live loads in accordance to Table 3 of BS EN 12811-1:2003 / Table 4.1 of TG2013

Load Class Load Duty Typical Usage UDL

Load Class 1 Inspection & Very Light Duty Inspection, painting, light cleaning 0.75 kN/m²

Scaffold

Load Class 2 Light Duty Scaffold Plastering, rendering, pointing, glazing 1.50 kN/m²

Denotes Tie location Load Class 3 General Purpose Scaffold General building work including normal 2.00 kN/m²

brick, block and stonework.

2000

Load Class 4 Heavy Duty Scaffold Heavy duty building work with large units 3.00 kN/m²

4.3 Wind loads/Wind speed

Basic wind velocity defined as 10 minute mean velocity in m/s at 10m above ground in open country with low vegetation

Level 2 with probability corresponding to a mean recurrence of 50 years normalized to sea level. Refer to the designated

3500 wind speed above.

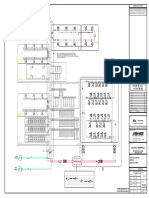

5. MAIN SCAFFOLDING EQUIPMENT

2000

5.1 Cuplok Verticals & Horizontal

Cuplok verticals and horizontals shall be 48.30mm diameter x 3.2mm wall thickness Grade 43c to BS4360 or S27J0H to

BS EN 10210 with a minimum yield strength of 275 N/mm²

5.2 Scaffold Tubes

Scaffold tubes shall be Grade S235GT with a minimum yield strength of 235 N/mm² conforming to EN 39. Type 3 tubes

shall be 48.30mm x 3.20mm thk., whilst type 4 tubes shall be 48.30mm x 4.0mm. All tubes shall be galvanized in

accordance to EN 10240 with coating thickness of 40µm to coating quality of B2.

5.3 Couplers & Fittings

2000

Couplers shall conform to EN 74 / BS EN 1139. Couplers shall be made as forged or pressed with a coating thickness of

15µm on its metallic parts.

5.4 Scaffold Boards

Plan View

Normal scaffold boards 225mm wide x 38mm thick shall be Class 24 with moisture content of 27% in accordance to TG20 /

0 BS 2482. Laminated boards are manufactured by gluing thin layer softwood veneer to form a billet that is hot-pressed

and cut into planks. SGB laminated boards have a maximum moisture content of 16% it's size are 38.1mm thick x

235mm wide. LVL scaffold boards are tested as per OSH(Standards & Regulations 29-CRF) 1926 Subpart L,

Appendix A.

Section 3

2000

5.5 Base Jack

Base jack shall be Grade S235 conforming to BS EN 12811-1 with minimum yield strength of 235 N/mm². For round thread

yield strength is 280 N/mm² while in trapezoidal thread yield strength is 320 N/mm². Its base plate shall be at least

1 : 50 6mm with plate area of 150cm². Overlapping length between jack and tubes shall be minimum 150mm. SGB

universal jack shall be extended to a maximum length of 340mm measured from ground to bottom of standard.

5.6 Other Components

Refer to SGB technical data sheets.

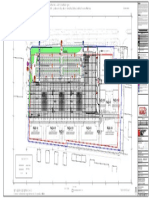

6. FOUNDATIONS/SUPPORT

Unless otherwise noted, no sole plates or other means of spreading the imposed loads are supplied by SGB. Where SGB

2000

equipment is supported, suspended, anchored or tied to an existing structure or the ground, the Customer must

ensure that the structure or ground is adequate to safely support the additional imposed loads

Level 2

3500 7. MODIFICATION

This drawing has been prepared using the Safe Working Loads of the SGB components specified. No alteration to

components, assembly, loading or any other aspect must be made without the expressed written authority from SGB.

Denotes Tie location 8. TYING AND BRACING

Limit slenderness with base to height ratio of 1:3.5 otherwise, tie back into the permanent structure using appropriate

ties.The Customer is responsible for ensuring all structures remain adequately tied and/or braced to carry the load

2000

and ensure stability. No ties or braces are to be removed or altered in any way without the expressed written

Denotes Green Mesh authority from SGB. Where SGB is supplying equipment only, the supply & fixing of all necessary ties is the

responsibility of the Customer.

9. TEMPORARY WORKING PLATFORMS

Unless specifically stated it is considered that any other working platforms (for erection or dismantling purposes), will be

designed, supplied and fitted by the Customer.

10. Obligation, Responsibilities & CDM

2000 2000 2000 2000 2000 2000 2000 This drawing constitutes SGB Risk Assessment in accordance with Regulation 11 of the current CDM Regulations 2007.

Plan View The elimination of general risk in the use of temporary works is by use of good practice. Guidance can be found

0 within relevant Codes, HSE publications and Guides. Wherever possible, risk is designed out of this proposal during

3

the design process.

7717-956 2

7717-956

Section 1 ************DO NOT TAKE RISK ! - IF IN DOUBT, ASK************

1 : 50

Plan View

1 : 50 Shop Drawing for Construction

This drawing is valid only with the associated assembly instructions. Measurements have to be verified on site.

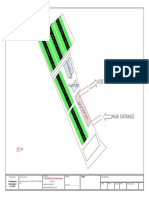

Scale: As Shown Client:

Date Name Dubai Petroleum

drawn: 10/11/23 MF UAE

worked: Project:

Cuplok Cuplok Cuplok Cuplok Cuplok

Ledger Cuplok

Int. Transom

Standard Ledger Standard Ledger

Cuplok ledger

Building face Plan brace every

8th bays minimum

TABLE SHOWING LENGTH OF BRACING TUBES (mm) checked: 10/11/23 Global Remort

SE

D RO LF Bay Length (mm)

P CL O

remark:

e

ub

ub

0m BAR SS

Global Remort

ING

T

0.6 P

ce

00

00

-

AM Vertical tube Tie Tube

Bra

25

25

Tube C L A N D R)

End Board Brace Cuplok

DD

ER D LE A DDE Lift Height 2500 1800 1600 1300 1200 1000 900 k

Ledger LA ,M ID OF L

Jac

4.0M

Scaffold Bearer Transom P

Universal AIL (T O TO M

Planks PR T

Jack TO B O

TO

2000 3500 3000 3000 2500 2500 2500 2500

Tube Universal

PR

AIL

M

Tube Swivel Brace

Tubes & Fittings

ai

1500 3500 2500 2500 2500 2500 2000 2000

Lift Height

Ledger Jack

e

Tube

ub

ub

n

Lace Coupler

T

IL

4.0M

Brace RA

00

00

Br

Cuplok

25

25

MID M ID Handrail

ac

0.4 RA Timber packing Face brace Cuplok standard

5 m Ledger Swivel

IL

1000 3000 2500 2000 2000 2000 2000 1500

e

protection Scaffold cladding

Coupler

Access Ladder Notes:

2.0M

Cuplok

Standard Can only be used to Connect Used to Connect Swivel Swivel For clad scaffolds, plan bracing is required in every lift, at a frequency of 1 bay in 8.This may be Jack Bracing

(Full extension) 3000 2500 2000 2000 2000 1500 1500

Cuplok Cuplok Base Base

Dubai

1000

Standard Standard Perpendicular Tubes Angular Tubes Plate

Coupler

Plate

Coupler Standard

positioned in the same bay as the face bracing. Bracing end bays should be avoided.

Al Quebeisi SGB LLC

e

ub

ub

T

T

M

SO

00

00

AN

25

25

TR

Tube Bracing Tube Fittings Tube Fittings Tube Bracing 2No. Tube Bracing Base & Head Plate Cuplok Standard TO

Bay Length

1000

E

TE

Typical Ladder Access Opening Standard Lacing Detail Int. Transom Detail

BOA

RD

RM

E DI A

Typical Illustration of a Through Tie 4mtr Tie Pattern Plan bracing details for clad scaffolds Lacing to Internal Beam Brackets 1500 1500 1500

to Cuplok Standard Double Coupler Swivel Coupler to Base & Head Plate to Base & Head Plate with Jack to Plain Baseplate HYP

IN TE

Techno Park

LA

NK

INT 3/

ER FO 4"

M ED

SS

R PL

Steel Structure CE

IA TE CO YW

VE OOD

10mm timber packing Double Coupler

Scaffold ST A C D ER TR R Adjustable Base Normal Ties Face

Swivel Scaffold Tie Tube A AN GA protection by client Double Coupler V-Ties Anchor Bolt V-Ties Building face Cuplok

SEE TYPICAL SECTION

Techno Park, Dubai , PO box 37656

ND S OM

D P

Tube Planks Standard AR LA T tubes are connected from brace

e

Coupler Planks D OR or equivalent at 5th bay ledger

ub

ub

Cuplok Swivel Tie Tube PO PP 50mm inner standard to outer

T

ST S U A N D R)

00

00

Face Brace Toe board clips ER LE DDE

25

25

Steel Gavlock DD D A Double Coupler standard

Gavlock or wrapover putlog LA ,M ID F L

24.7kN

Structure Coupler Coupler

Cuplok

coupler

Loose 0m

m

ma

x

B O

P

(T O TO M

T

O

Timber packing

protection

Concrete Column

Tel : +971 (0) 4 813 2000 Tel : +971 (0)48132000

15 AC T

SEE TYPICAL SECTION

Ledger Toe board C

Spigot LA ESS P OS Concrete Column

Fax : +971 (0) 4 813 2001 Fax : +971 (0)48132001

LA

DD DD RD

(TO ER ER BEA DA

Loose spigot BO SU AN

TTO P, MID PP RE ST

inside w/ M D

OF LE

OR

T

R

(TRA Timber packing 45.0 45.0

e

0° 0°

ub

ub

NSO

LA AND

2No. M10x80 bolt M) protection

T

DD Tie should be attached to the Tie below ledger

Board ER

00

00

) reveal tube within 150mm of

c/w nylok nut

25

25

retaining clamp the end opposite to the reveal

pin, whether latter is in the

Cuplok 2No. M10x80 bolt vertical or horizontal position

Anchor Tie below ledger

Ledger c/w nylok nut

End Board

Bearer Transom

Supatie

Structure

Butt

Tube

Ring

Bolt

using right angle couplers.

Cuplok standard Cuplok

www.sgb.ae www.sgb.ae

24.7kN Face brace Cuplok ledger standard Base jack

3Brd Hop-up Surface Notes:

Tie Tube Cuplok

Tensile SWL 24.7kN Bracket Int. Transom Cuplok

It is essential that the manner of wedging the reveal tube into the opening be Notes:

Bolt (12.5kN) + Scaffold Tubes Standard Structure Face firm, reliable and, if possible, positive rather than by friction, i.e. if the reveal Face bracing must be used in 1 bay in 8 as maximum. Atleast 2 bays must be braced if the

Cuplok

Coupler (6.1kN) +

Coupler (6.1kN) Cuplok Tie Tube

Cuplok

Standard

Ledger tube can be fixed behind indentations or masonry features. Ties should be

frequently checked for tightness during the life of the scaffold.

This type of tie is widely used on new construction work where concrete

columns can be used as the tie position. This particular method will also assist Standard

If ties are only connected to inside standard or ledger, V-Ties must be used

at a frequency of 1 in 5 bays structure is greater than 4bays. Bracing in the end bays should be avoided. CAD-File: Drawing-No.:

7717-956

Standard Standard Cuplok Ledger in preventing lateral movement.

Tension Standard Gravlock Connection Gravlock Connection Cuplok Standard Cuplok Node Point Cuplok End Board Tie Anchor Tie Anchor

Hop-Up Bracket Detail Swivel Face Brace Detail Toe Board Details Typical Skewed Ladder Access Detail-1 Typical Ladder Access Detail-2 Typical Illustration of a REVEAL Tie Typical Illustration of a BOX Tie Typical Illustration of a Lip Tie V-Ties Detail Face Bracing Details

Connection Detail to Steel Flange(view2) to Steel Flange(view1) Loose Spigot Connection Ledger Connection Bearer Detail (Supatie) (Ring Bolt or Similar)

A1 (594x841 mm) - HCAD

You might also like

- How To Bulk Upload WAV Files To Avaya Aura Media Server (AAMS) For Use As Communication Manager 7 AnnouncementsDocument8 pagesHow To Bulk Upload WAV Files To Avaya Aura Media Server (AAMS) For Use As Communication Manager 7 AnnouncementspawarsanjuNo ratings yet

- Cnc-Build 2x4 CNC Plasma Free PlansDocument6 pagesCnc-Build 2x4 CNC Plasma Free PlansAxels_Man_Cave73% (11)

- Panasonic+TC 32A400B+Fonte+TNP4G572+Document3 pagesPanasonic+TC 32A400B+Fonte+TNP4G572+campos santos100% (3)

- Baramati MIDC CompaniesDocument2 pagesBaramati MIDC CompaniesDeepak Nair75% (4)

- En Barranquilla Me Quedo La Linea - Trumpet in BB 1Document2 pagesEn Barranquilla Me Quedo La Linea - Trumpet in BB 1CesarAugustoRodriguezNo ratings yet

- Mya Kyun Thar - Shopping Centre DATE: 8-April-2023: Elv System Layout at Basement FloorDocument7 pagesMya Kyun Thar - Shopping Centre DATE: 8-April-2023: Elv System Layout at Basement Flooraungphyoe tharNo ratings yet

- Abd Distribusi - 15656 - Kel - Perwira - RW 17 - HP 554Document9 pagesAbd Distribusi - 15656 - Kel - Perwira - RW 17 - HP 554Tedi HermawanNo ratings yet

- Jed-Ksa-Sjm-Dod-Gen-Arc-Ge-124 - Door Schedule-01 - R0Document1 pageJed-Ksa-Sjm-Dod-Gen-Arc-Ge-124 - Door Schedule-01 - R0m.deghadyNo ratings yet

- Project Ruby: As Built DrawingDocument1 pageProject Ruby: As Built DrawingTôn Huỳnh ĐoànNo ratings yet

- B974832001P00-480V 462-MCC-004 Substation #24Document1 pageB974832001P00-480V 462-MCC-004 Substation #24te2.esNo ratings yet

- Notes: Notes: SR - No. Drawing No. Description: D47 A 1A-PI0009 001 CDocument1 pageNotes: Notes: SR - No. Drawing No. Description: D47 A 1A-PI0009 001 Cmohamed esmailNo ratings yet

- Left Side Elevation: Ground Floor PlanDocument1 pageLeft Side Elevation: Ground Floor PlanSooraj VsNo ratings yet

- Layout Dan Tipikal 6C DMS 28-03-24Document3 pagesLayout Dan Tipikal 6C DMS 28-03-24WigunaNo ratings yet

- Lay OutDocument1 pageLay OutDanny DidanzNo ratings yet

- Site Plan: PT. BANGUN BALE Lombok UtamaDocument1 pageSite Plan: PT. BANGUN BALE Lombok UtamaridhoNo ratings yet

- BCT MRV QTR Gad VR Type II v3 ModelDocument1 pageBCT MRV QTR Gad VR Type II v3 ModelThrk TwrNo ratings yet

- Club House: Neighbors Land - Syno 282 P Neighbors Land - Syno 282 PDocument1 pageClub House: Neighbors Land - Syno 282 P Neighbors Land - Syno 282 PRaghuKiranNo ratings yet

- Second Reflected Ceiling Layout - Part 01 2: Jordan Ahli Bank HeadquartersDocument1 pageSecond Reflected Ceiling Layout - Part 01 2: Jordan Ahli Bank HeadquartersRabee BataynehNo ratings yet

- Contract Drawing: Phase 3 Phase 1 & 2Document1 pageContract Drawing: Phase 3 Phase 1 & 2jendrikoNo ratings yet

- Panasonic TH-L32C4V (Board Nguon) TNP4G508Document1 pagePanasonic TH-L32C4V (Board Nguon) TNP4G508Lamdtiph LamNo ratings yet

- 8.water Supply Final ContourDocument1 page8.water Supply Final Contourdanaokasho11No ratings yet

- 12.04.2023 - BT - Ground Floor RCP CoordinatedDocument1 page12.04.2023 - BT - Ground Floor RCP Coordinatedmdhedayat3No ratings yet

- Eds1593 TS 01 04Document4 pagesEds1593 TS 01 04Dalia EwisNo ratings yet

- Untitled Extract PagesDocument1 pageUntitled Extract PagesDalia EwisNo ratings yet

- Meera Shantivanam - Master Plan-ModelDocument1 pageMeera Shantivanam - Master Plan-Modelm.jayaramNo ratings yet

- Perkerasan HalamanDocument1 pagePerkerasan Halamanrangga1487No ratings yet

- Incendio Nuevo P01 132235 I23 16550 Z Caracas Ccsambil Pci 1.8Document1 pageIncendio Nuevo P01 132235 I23 16550 Z Caracas Ccsambil Pci 1.8Danis MachadoNo ratings yet

- 2019 08 06 - 105 - R8 - Rev - Div Rly-Submitted-R5 PDFDocument1 page2019 08 06 - 105 - R8 - Rev - Div Rly-Submitted-R5 PDFSaurabh PandeyNo ratings yet

- A101 - General Layout - A1 - 19.07Document1 pageA101 - General Layout - A1 - 19.07Rodhel Mark PalermoNo ratings yet

- Arc DwgsDocument3 pagesArc DwgsrayhansayeedNo ratings yet

- 2ND HLDocument1 page2ND HLmhafidz1992No ratings yet

- Dost I Mezzo BrochureDocument23 pagesDost I Mezzo BrochuresindhsagarbillingNo ratings yet

- IPR003747-01-09a-510 - REV 04-03Document1 pageIPR003747-01-09a-510 - REV 04-03deepaknandan54No ratings yet

- Subdivision Lay OutDocument1 pageSubdivision Lay Outjher leeNo ratings yet

- 5Th Floor Plan Access Point Layout: KSK Capital LLCDocument1 page5Th Floor Plan Access Point Layout: KSK Capital LLCMD SajjadNo ratings yet

- First Floor Plan Access Point Layout: KSK Capital LLCDocument1 pageFirst Floor Plan Access Point Layout: KSK Capital LLCMD SajjadNo ratings yet

- CGK CGK2 Wac N SM 222Document1 pageCGK CGK2 Wac N SM 222ignasius desky p sNo ratings yet

- Faza XVDocument1 pageFaza XVНевена ШушићNo ratings yet

- 002 Revised Layout Plan For Stage-4Document1 page002 Revised Layout Plan For Stage-4mayur puriNo ratings yet

- ANNEXURE B2 Sewer Long SectionsDocument39 pagesANNEXURE B2 Sewer Long Sectionsdavid selekaNo ratings yet

- Methode BEKISTINGDocument18 pagesMethode BEKISTINGAndi Hermawan SantosoNo ratings yet

- Docking PlanDocument1 pageDocking PlanRoland GrardNo ratings yet

- ERES MI SUEÑO - Trumpet in BB 1 PDFDocument2 pagesERES MI SUEÑO - Trumpet in BB 1 PDFJairo Gomes AndradeNo ratings yet

- MBTA Revised-Bus-Network-Map (Static) 2022-10-27Document1 pageMBTA Revised-Bus-Network-Map (Static) 2022-10-27khaders6682No ratings yet

- Joka Soho+Master Plan-Model - SaptarshiDocument1 pageJoka Soho+Master Plan-Model - SaptarshiDiswag vlogNo ratings yet

- A101-Cec-Mh22-Dwg-Gf0101Document1 pageA101-Cec-Mh22-Dwg-Gf0101Adina MumraizNo ratings yet

- General Notes: Project DetailsDocument1 pageGeneral Notes: Project Detailsakash banathiaNo ratings yet

- HAHC AL 0 FD AR 01 02 OverviewDocument1 pageHAHC AL 0 FD AR 01 02 OverviewNWA INT General Trading & ContractingNo ratings yet

- Input INVDocument1 pageInput INVVươngNo ratings yet

- Cuadro de Construccion Poligono Plaza Etapa 1 Vs Etapa 2Document1 pageCuadro de Construccion Poligono Plaza Etapa 1 Vs Etapa 2David FloresNo ratings yet

- Kansai Railway Pass 3 DaysDocument2 pagesKansai Railway Pass 3 DaysPutri MahacakriNo ratings yet

- Drainage Overall1525693075875Document1 pageDrainage Overall1525693075875kuttyNo ratings yet

- Equipamientos Administrativos PunoDocument1 pageEquipamientos Administrativos PunoAldahir Sucari BanegasNo ratings yet

- Mezzanine Level LightingDocument1 pageMezzanine Level Lightingdanish0229No ratings yet

- LNX PST Msys 29x39 WEB 190813Document1 pageLNX PST Msys 29x39 WEB 190813Francisco Antonio Adasme QuintanillaNo ratings yet

- Línea Transporte Orlando FloridaDocument1 pageLínea Transporte Orlando FloridaJohanes PierreNo ratings yet

- Simbología en Pisos: Material Base Material Intermedio Material FinalDocument1 pageSimbología en Pisos: Material Base Material Intermedio Material FinalHeidi Covarrubias SánchezNo ratings yet

- American Cinematographer - January 2014Document100 pagesAmerican Cinematographer - January 2014Gonzalo RochaNo ratings yet

- CJ-JZ-KAIS - FDT-005 Distribution Layout Diagram (DLD)Document1 pageCJ-JZ-KAIS - FDT-005 Distribution Layout Diagram (DLD)Agayel darNo ratings yet

- AAC Goals Grid 2pg 6-10Document2 pagesAAC Goals Grid 2pg 6-10Cesar Gutierrez NegredoNo ratings yet

- Shdgosp-1: See Detail-ADocument1 pageShdgosp-1: See Detail-AEngr Muhammad Azam ThaheemNo ratings yet

- International StandardDocument10 pagesInternational StandardAlbinNo ratings yet

- 7717-Global Remort CALDocument25 pages7717-Global Remort CALAlbinNo ratings yet

- UTL3 RepairDocument6 pagesUTL3 RepairAlbinNo ratings yet

- Sample Project List: Sl. No Project Description Rig NameDocument5 pagesSample Project List: Sl. No Project Description Rig NameAlbinNo ratings yet

- 002 - Our List of ServicesDocument2 pages002 - Our List of ServicesAlbinNo ratings yet

- 001 - GR - CIVIL ProfileDocument47 pages001 - GR - CIVIL ProfileAlbinNo ratings yet

- Legazpi Certificate of Non-Availability of Stocks: Product Code Product Description UOM PriceDocument9 pagesLegazpi Certificate of Non-Availability of Stocks: Product Code Product Description UOM PriceGamas Pura JoseNo ratings yet

- RTPA ConfigDocument3 pagesRTPA Configsoufiane amraniNo ratings yet

- Techdoc Print Page PDFDocument3 pagesTechdoc Print Page PDFSuharto ZuhriNo ratings yet

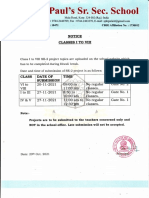

- St. Sr. School: Paul'sDocument4 pagesSt. Sr. School: Paul'sAmisha GuptaNo ratings yet

- Powerflex 700L Active Converter Power Module: User ManualDocument72 pagesPowerflex 700L Active Converter Power Module: User ManualThiện Lương MinhNo ratings yet

- Achieving The Singularity - TranscriptDocument4 pagesAchieving The Singularity - TranscriptMikelNo ratings yet

- Data Sheet DS Cast 50AR NM: General InformationsDocument1 pageData Sheet DS Cast 50AR NM: General InformationsJCSNo ratings yet

- Chapter One: Introduction To Human Computer Interaction: Software Engineering Department, Wolkite UniversityDocument39 pagesChapter One: Introduction To Human Computer Interaction: Software Engineering Department, Wolkite UniversityEstifanos0% (1)

- Practice Problem Based On Travelling Salesman Problem Using Branch and Bound ApproachDocument13 pagesPractice Problem Based On Travelling Salesman Problem Using Branch and Bound Approachvvvcxzzz3754No ratings yet

- Crisp & Fuzzy RelationsDocument29 pagesCrisp & Fuzzy RelationsSheetal AnandNo ratings yet

- CGT 163 F20 Syllabus v20Document10 pagesCGT 163 F20 Syllabus v20brinda mehtaNo ratings yet

- Multimaus en 200614 PDFDocument36 pagesMultimaus en 200614 PDFLaur MantescuNo ratings yet

- GE Fanuc Automation: Series 15Document434 pagesGE Fanuc Automation: Series 15Cha BatistaNo ratings yet

- The Weave of San FranciscoDocument3 pagesThe Weave of San FranciscoyrtalienNo ratings yet

- A Large-Scale Full-Wave Simulator For RF DesignsDocument55 pagesA Large-Scale Full-Wave Simulator For RF Designshuyadong1234No ratings yet

- Presentation On Project: Presented byDocument26 pagesPresentation On Project: Presented byAnujNo ratings yet

- FanC Whitepaper 1.1 Eng.34bfa504be19e3fc233bDocument35 pagesFanC Whitepaper 1.1 Eng.34bfa504be19e3fc233ballthatkmsNo ratings yet

- Belden MIPPDocument12 pagesBelden MIPPFrancois St-JacquesNo ratings yet

- SPE-160127-MS Kuparuk River Unit Field - The First 30 YearsDocument13 pagesSPE-160127-MS Kuparuk River Unit Field - The First 30 YearsGilbert OmittaNo ratings yet

- Rodillo Tandem BomagDocument4 pagesRodillo Tandem BomagyasserNo ratings yet

- Resume: Galipelli Gauthami UmapathiDocument2 pagesResume: Galipelli Gauthami UmapathiSagar KorNo ratings yet

- Ajit Kumar Singh: Mechanical EngineeringDocument2 pagesAjit Kumar Singh: Mechanical EngineeringpvenktashNo ratings yet

- 01 Ooad-Uml 01Document26 pages01 Ooad-Uml 01Hiren BhingaradiyaNo ratings yet

- Documents-Us-Global-Products-Pet-Radiopharmacy-Brochure-Tracercenter Vip Datasheet - PDFDocument4 pagesDocuments-Us-Global-Products-Pet-Radiopharmacy-Brochure-Tracercenter Vip Datasheet - PDFAsim AliNo ratings yet

- Flexo Uv Ink TroubleshootingDocument22 pagesFlexo Uv Ink TroubleshootingHiba Naser100% (1)

- BAMBALPITIYA PUMPING STATION - Outstanding WorkDocument3 pagesBAMBALPITIYA PUMPING STATION - Outstanding WorkShabeer Shaarim Abdul JabbarNo ratings yet

- 5 6133982140783657921Document5 pages5 6133982140783657921cos thetaNo ratings yet