Professional Documents

Culture Documents

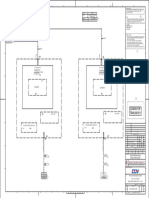

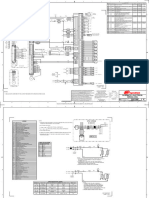

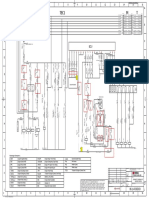

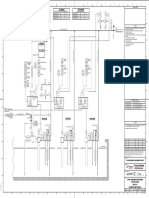

General Notes 8A22-V09 D01 MD-502-8A22-EG-PR-PID-1011 8A22-V01 8A22-R03

General Notes 8A22-V09 D01 MD-502-8A22-EG-PR-PID-1011 8A22-V01 8A22-R03

Uploaded by

BharathiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Notes 8A22-V09 D01 MD-502-8A22-EG-PR-PID-1011 8A22-V01 8A22-R03

General Notes 8A22-V09 D01 MD-502-8A22-EG-PR-PID-1011 8A22-V01 8A22-R03

Uploaded by

BharathiCopyright:

Available Formats

1 2 3 4 5 6 7 8 9 10 11 12

D01 MD-502-8A22-EG-PR-PID-1011 8A22-V01 8A22-R03 8A22-V09 UX GENERAL NOTES

REV DRAWING NUMBER

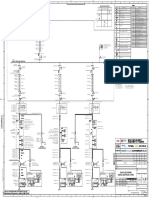

DCS START/STOP/REVERSE

GRANULATOR DRUM GRANULATOR HOSE AMMONIA SPARGER

AIR FLOW ACCUMULATOR A-A456 REVERSE 7011 DCS STATUS

1.- 1 DRAIN TO SUMP

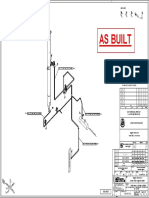

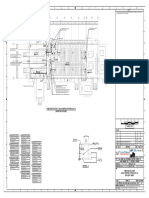

MA'ADEN PHOSPHATE PROJECT-A1 CONTRACTOR BORDER-REV A02

DESIGN CAPACITY : 650.0 ton/hr DESIGN CAPACITY : 9.3 ton/hr DESIGN TEMP : 70 °C MOTOR

LENGTH : 12.1 m

DIAMETER : 5.170 m

MAX DESIGN TEMP : 175.0 °C DESIGN PRESS : 1000.0 kPag I PERM. YS STATUS OFF NOTE 17

POWER DRIVE RATED : 200.0 kW X 2 DESIGN PRESS : 2000 kPa-g MATERIAL : Carbon Steel START

8000-CCTV-001 2.- THREAD NPT FEMALE CONNECTION FOR WATER AND STEAM HOSE FLUSH

A 7011 PREFERABLY TIED IN AT PIPE SIDE. A

BARRING DEVICE : 11 kW STATUS ON

DRIVER SPEED : 8.0 rpm A-A401 I-A401 I-A402

STOP SIGNAL TO C. ROOM 3.- MINIMUM DISTANCE TO 8A61-V06 INLET DUCT, WITH MAXIMUM SLOPE.

MATERIAL : CS+Rubber lining

SLOPE : 3.00 % I I I

STATUS ON 4.- STEAM AND PLANT AIR CONNECTIONS TO GRANULATOR AMMONIA

8A22-VC-001 SUPPLIER HEADER: MAX DISTANCE 1M. PREFERABLY TIED IN ON TOP OF PIPE.

I-A414 YS STATUS OFF

ESD 7012 PACKAGE UNIT 5.- PROVIDE ENOUGH SPACE AT GRANULATOR BACK FOR REMOVING

START/ NOTE 12 THE PR DISTRIBUTION TUBES (2 PR IN UNITS A&B. 1 PR IN UNITS C&D).

STOP UX DCS START/STOP/REVERSE 6.- CHECK VALVES TO BE INSTALLED AT A MAX. DISTANCE

HS 7012 DCS STATUS TO GRANULATOR OF 1 M TO THE RESPECTIVE DISTRIBUTION

FG VSD VSD

7012 PRE-SCRUBBER 8A61-V06 TUBES INLET OR TIE-IN.

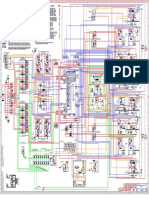

AAHH AT AE NOTE 3 1300-PWG-8A22-6401-ZQT1-NI

FROM GRANULATOR 20102 8A61-EG-PR-PID-1020

ELEVATOR 8A35-Y10 0401 0401 0401 I-A415 7.- COLLECTOR CLOSE TO GRANULATOR DRUM AND WITHOUT POCKETS.

908-FDS-8A35-4101-ZAB1-NI 64° MIN. FY LONG RADIUS ELBOWS (1.5 D) ARE PERMITTED ONLY IN MANIFOLD DESIGN.

20056 8A35-EG-PR-PID-1005 H ESD

AI AMMONIA 0405

B 0401 A-A407 8.- L1 AND L2 LENGTHS ARE 126MM AND 5294MM. B

NOTE 13 NOTE 20 NOTE 20 SULPHURIC ACID FLANGE TO BE INSTALLED INSIDE DRUM.

DCS START/STOP I S

FIC H FIT

FG

I-A414

DCS STATUS M M AAHH AT AE 0405 0405 9.- BALL VALVES OF ZERO LEAKS SHOULD BE INSTALLED,

YS UX TO AVOID AMMONIA LEAKAGE WHILE MAINTENANCE

I 0402 0402 0402 FE WORKS TAKE PLACE INSIDE GRANULATOR.

7014 7014 40-ASC-8A11-4502-AQT3-NI

HS H NOTE 24

AUTOMATIC START UP SEQUENCE AI AMMONIA FV 0405

0425 SULPHURIC ACID 10.- DELETED.

DCS 0402 RCKZXK RGAZXJ I 0405

NOTE 13 IAS RGAZXJ-1120 FROM HEADER

STATUS -1118 -1119 P

11.- CHUTE ANGLE <60°. A VIBRATOR OR PLANT AIR THRUST

NOTE 29

KS

YS UX NOTE 32 NOTE 32 SP F.C.

M 8A11-EG-PR-PID-1001 20020 CAN BE REQUIRED.

HS AUTOMATIC SHUT DOWN SEQUENCE 0418

NC

20

25

NC

15

20

7015 7015

0426 M M B294 RGAZXC-1121

PROCESS WATER 12.- TV SYSTEM TO SURVERY (FROM CONTROL ROOM)

8AWD-EG-PR-PID-1025 20734 GRANULATION DRUM AREA.

NOTE 26 HY NC

S NC

RGAZXJ-1117

0418 HS HS M 25-WPR-8A22-1013-AP01-NI 13.- AMMONIA DETECTOR CLOSE TO GRANULATOR AREA.

RCKZXK RGAZXJ

IAS 7015 7014 -1115 -1114 OD

C E.L. + 18.90 APPROX V01 ALLOY 20 AQT3 14.- A RUBBER BLADDER, ATTACHED AT THE GRANULATOR C

40x25 M

(D-X301) AQT3 AAB1 1 DISCHARGE CHUTE.

SP NITROGEN GAS FROM 15.- EQUIPMENT THAT CAN BE STARTED/OPERATED BOTH LOCALLY

GRANULATOR SUPPORT CLEANING MECHANISM HEADER AND FROM DCS, SHOULD HAVE REMOTE/LOCAL INDICATION

L1=126MM

A297

NOTE 8

8AFG-EG-PR-PID-1032 20654 OPERATION ON DCS. CHANGING FROM REMOTE/LOCAL SHOULD

R02 NOTE 5 NOT INITIATE THE INTERLOCK SEQUENCE.

BY VENDOR OF SULPH

L2=5294MM 25-GNN-8A22-0606-AAB1-NI

20069 8A21-EG-PR-PID-1007 ACID DISTRIBUTION TUBE

NOTE 8 16.- DELETED.

A-A408 SP

I 17.- GRANULATOR REVERSAL SHOULD NOT INITIATE TRIP SEQUENCE. TWO

BETE TYPE SPRAY NOZZLE X3 B383 M 125-ARS-8A21-1503-BQF2-SJ MOTORS INSTALLED, BOTH WITH COMMON START SWICH. SHUT DOWN

SP BSU1 BQF2 NOTE 22

PATTERN FLAT FAN OF ANY MOTOR WILL INITIATE TRIP SEQUENCE.

NC 50

FROM SLURRY PUMP

NC

TYPE NFS 50 DN20 PTFE ZLO ZSO

SP B382 8A21-P04A

BSU1

MALE CONNECTION NPT SJ 18.- A CAR SEAL MUST BE INSTALLED IN BLOCK VALVES AND BLEED/VENT

0420 0420

SJ

HIC SPRAY ANGLE 90° NOTES 2,31 8A21-EG-PR-PID-1010 20097 VALVE OF AMMONIA AND STEAM LINES TO PREVENT PERSONNEL INJURIES

R01 NOTE 5 B376

0409 INS M ZLC ZSC SP 100-ARS-8A22-1506-BQF2-SJ DURING GRANULATOR MAINTENANCE WORKS. PREVIOUSLY, THESE VALVES MUST

HV 20070 8A21-EG-PR-PID-1007 SP CHANGE THEIR NORMAL POSITION (CLOSE OR OPEN) TO ISOLATE THE

BAB3

D 0420 0420 NOTE 22 D

HC

NC

0409 B381 GRANULATOR IN ACCORDANCE WITH THE ISOLATION PROCEDURE.

B379 RETURN TO PN REACTOR

PROCESS WATER TO SJ SJ 8A21-R04

RGAZXC-1100 I 3%

GRANULATOR DRUM 8A22-V01 P IASRGAZXC-1101 NOTE 7 20096 8A21-EG-PR-PID-1010 19.- AUXILIARY MOTOR CONNECTED TO EMERGENCY POWER.

40-WPR-8A22-1806-AP01-NI 3%

20745 8AWD-EG-PR-PID-1025 125x100 SP SP

NOTES 22,25

BETE TYPE SPRAY NOZZLE X4

125-ARS-8A22-1505-BSU1-SJ

F.C. NC 50 SP SP 20.- BY GRANULATOR VENDOR.

NC

20

PATTERN HOLLOW CONE

NC

20

NC

25 B374

50

NC

NC 40 TYPE THF 9012 B442 B378 FROM SLURRY PUMP

B380

NC

VENTS TO 21.- ALL ITEMS HAVE 8A22 PREFIX EXCEPT WHERE INDICATED.

DN40 ALLOY 20

F.O.

80-VPG-8A22-9403-BFB1-NI SP IAS SJ 8A21-P04B

BSU1

RGLZXC-1102 25-VPG-8A22-9401-BFB1-NI FEMALE CONNECTION NPT

8A21-EG-PR-PID-1010 20098

SJ

8A11-EG-PR-PID-1001 20316 SPRAY ANGLE MEDIUM HY 22.- LINES OF PHOSPHORIC ACID (APC), SCRUBBING LIQUORS (LWA) AND SLURRY

B377 HV SP

NC 50

S (ARS) SHOULD NOT HAVE POCKETS AND BE FLANGED AT 6M

VENTS TO M 0420

NC

40x25 INS

0420 INTERVALS. THE USE OF ELBOWS SHALL BE REDUCED AS MUCH AS

80-VPG-8A11-9405-BFB1-NI B384 125-ARS-8A21-1504-BQF2-SJ

NOTE 18

BAB3

50

BSU1

POSSIBLE. SLURRY (ARS) LINES SHALL BE AS SHORT AND DIRECT AS POSSIBLE

HC

50-VPG-8A22-9403-BFB1-NI 20 KS NOTE 22

BFB1

SJ

8A11-EG-PR-PID-1001 20011 BETE TYPE SPRAY NOZZLE X1 SP WITH MINIMUM 8 TO 10 DIAMETERS BENDS (AVOID ELBOWS).

BGARXB-1116

NOTES 2,31

NI

A-A405 SET @ 2.0 MPa NC 0420

PATTERN FULL CONE SP INS M

I 25 x 50 H

PI INS M TYPE MP 375 DN25 316L B375 23.- PERSONNEL PROTECTION GUARDED BY MEANS OF SCREENS INSTEAD OF

BAB3

HC

I-A435 PSV MALE CONNECTION NPT B385 LP STEAM THERMAL INSULATION.

BQT2

0403

RGLZXK-1103

L BBARRC

NC IC

E SPRAY ANGLE 60° FROM PIPE RACK E

0403 BGARXC

I 20-AGL-8A22-5408-BQT2-IC -1134 POSSIBLE 24.- SULPHURIC ACID LINES SHOULD NOT HAVE POCKETS. PROVIDE LEAK

FIC FT -1125 CONNECTION TO 8ATD-EG-PR-PID-1029 20104

S FY COVERING ON ALL SULPHURIC ACID PIPING FLANGES, WITH SAFE DRAINAGE

0403

L

0403

0403 PT PI TI 50 NC R05 DUCKBILL SPARGER ACCESS DOORS

80-SLP-8A22-8406-BAB3-HC TO GRADE.

20 KS PSV

NC CSO 0403 SLOPING GRIZZLY

FE 0417 0403

M 20 0416 0416

DI PAH PI 25.- PROVIDE LEAK COVERING ON PN SLURRY PIPING FLANGES IN GRANULATOR

0403 CSO BFB1 BQT2

RGAZXB

ACCESIBLE AREAS TO OPERATORS.

RGARXC

TO SAFE

-1124

0403 BGLRXK- R03 0416

25 NC

-1104

LIQUID AMMONIA 20 0416 HY

20

40

20

I

BCKRSG 1109 PLACE

FROM HEADER P IAS -1106 (R-X203) S 0416 26.- SEE MD-502-8000-EG-PR-ILD-0004 CAUSE & EFFECT CHARTS LOGIC

80 20

20013 8A11-EG-PR-PID-1001 C F.C. PS 15

MATRIX PROCESS INTERLOCKS (DCS).

BBARRC NOTES 4,6,18 20 IAS 15

RCKZXK

50 FV 40 -1105 0416 25-PAS-8A22-3402-AZB1-NI 27.- EQUIPMENT PROPERTIES SHOWN IN THE TOP OF P&ID ARE REFERRED TO

-1110

50-AGL-8A11-5403-BFB1-IC

HV DESIGN DATA EXCEPT WHERE INDICATED.

RCKZXK

0403 NOTES 4,6,18 MIN PLANT AIR

-1108

RGASXA

0416 FROM PIPE RACK

-1113 28.- ESD BUTTONS HARDWIRED DIRECTLY TO MCC ARE PROVIDED ON ALL MOTORS.

NOTE 9 E.L. + 12.50 APPROX V09 8AAB-EG-PR-PID-1027 20101 THESE MOTORS' ESD INTERLOCKS ARE NOT SHOWN IN P&ID.

RBAZRH-1107

RGLZXK

F.C. 20

BQT2

-1111

40 NC

50 RGASXA-1123

BQT2

IC

NOTE 14 29.- 1 METER INTERNALLY TEFFLONED SPOOL LOCATED DOWNSTREAM

NC

F F

IC

OD

INS M ZSH ZAH CONTROL VALVE.

M GRANULATOR

NOTE 18

INS

GE

8 BY EPC

AAC4

0417 0417

SUPPLIER 30.- 8A22-A19B GRANULATOR HYDRAULIC JACK SYSTEM ITEM STORED AND

AZB1

I-A413

NI

A91B ZSHH ZAHH A91A COMMON FOR UNITS A AND B.

40 0417 0417

I

INS

TI NOTE 30 31.- APPLICABLE PIPING SPECIFICATION IN HOSE CONNECTIONS TO STAINLESS

HC GE 0424 STEEL PROCESS LINES WILL CHANGE INTO AP01 JUST UPSTREAM OF LAST

10-12 M IAS START/

LP STEAM NOTE 19 BLOCK VALVE.

NOTE 18 STOP

FROM PV-0501 NC TO DRYER DRUM

80-SLP-8A22-8405-AAC4-HC NOTE 23 32.- COOLING MOTOR.

20100 8ATD-EG-PR-PID-1029 NOTE 11 HS 8A31-V02

AGARXF-1112 80 M 7013

65° MIN

20106 8A31-EG-PR-PID-1012

NOTE 18

NOTE 20

25-SLP-8A22-8028-AAC4-HC XA XS

SP 0417 0417

A51

AUTOMATIC A-A431

15 T 25 LUBRICATION

I-A415 STOP UX DCS START/STOP

G

B073 SYSTEM I 7013 DCS STATUS PACKAGE UNITS G

STATUS OFF YS

I I-A421 8000-CCTV-001 TV SYSTEM

OD OD

3510 HS START/ STATUS ON YS

M I 7013 EQUIPMENT

1 1 UX 3510 STOP

DCS STATUS ITEM DESCRIPTION

PLANT AIR FROM PIPE RACK

40-PAS-8A22-3401-AZB1-NI 3510 SPILLAGES TO 8A22-A51

20655 8AAB-EG-PR-PID-1027 AUTOMATIC LUBRICATION SYSTEM

GRANULATOR ELEVATOR 8A22-A91A/B GRANULATOR HYDRAULIC JACK SYSTEM

NOTE 20 8A35-Y10 8A22-R03 GRANULATOR AMMONIA SPARGER

300-FDS-8A22-4402-ZAB1-NI 8A22-V01

20054 8A35-EG-PR-PID-1005 GRANULATOR DRUM

NOTE 11 8A22-VC-001 SURVEY GRANULATION IN GRANULATOR DRUM CAMERA

8A22-V09 AIR FLOW ACCUMULATOR

This drawing and all the information contained

herein it is the proprietary property of Ma'aden

DRAWN MTP 13/07/07

MA'ADEN PHOSPHATE

and is subject to confidentiality restrictions CHECKED

H

between Ma'aden and the recipent. The information

contained herein is provided for a limited purpose

GRA/CMP 13/07/07

DAP GRANULATION UNIT A H

ENGINEER AGM 13/07/07

and must be returned on request. Ma'aden makes

no respresentations or warranties that this APPROVED JGC/VBA 13/07/07

GRANULATION SECTION

information is complete or fit for any particular

purpose. Neither this drawing nor any information

concerning it may be copied, exhibited or furnished PROJECT No. 10409 MA'ADEN

PIPING & INSTRUMENTATION DIAGRAM

FER-P05111-P&ID-004 REACTION AND GRANULATION SECTION D01 28/02/12 AS BUILT JFSG AGM AGM ABA --- to others. Nor may photographs be taken of any DRAWING NUMBER REV

article fabricated or assembled from this drawing,

MD-502-8A22-EG-PR-PID-1011 D01

SCALE

DOCUMENT NUMBER REFERENCE DOCUMENTS REV DATE REVISION DESCRIPTION DRN CHK ENG APP MD without Ma'aden prior written consent. 160/12473 NTS A1

1 2 3 4 5 6 7 8 9 10 11 12

You might also like

- IEC TS 61836 - 2016 Solar Photovoltaic Energy Systems-Terms, Definitions and SymbolsDocument87 pagesIEC TS 61836 - 2016 Solar Photovoltaic Energy Systems-Terms, Definitions and SymbolsAAGNo ratings yet

- 8B22-V01 8B22-R03 8B22-V09: Granulator Drum Granulator Hose Ammonia Sparger Air Flow AccumulatorDocument1 page8B22-V01 8B22-R03 8B22-V09: Granulator Drum Granulator Hose Ammonia Sparger Air Flow AccumulatorBharathiNo ratings yet

- Air Flow Accumulator Granulator Drum Granulator Hose Ammonia SpargerDocument1 pageAir Flow Accumulator Granulator Drum Granulator Hose Ammonia SpargerBharathiNo ratings yet

- Pnid ExamplesDocument1 pagePnid Examplessecret soldierNo ratings yet

- Schematic, Electrical Wiring (Fs-Yd) 24276602 R: Detail ADocument3 pagesSchematic, Electrical Wiring (Fs-Yd) 24276602 R: Detail ArubenkolosovasNo ratings yet

- D-EP-P250-1225-1085 - 9 Asbuilt (E-2371) - Hydro Jetting P & IDDocument1 pageD-EP-P250-1225-1085 - 9 Asbuilt (E-2371) - Hydro Jetting P & IDvenkatesh tekkaliNo ratings yet

- DWC7894 11 06 - 00Document1 pageDWC7894 11 06 - 00nthekkumpuramNo ratings yet

- General Drawing Exchanger N°5Document1 pageGeneral Drawing Exchanger N°5calinvasco190670No ratings yet

- MoBo SchematicDocument3 pagesMoBo SchematicAbd Al-KhataibNo ratings yet

- R420-FR-2130 A/B: NotesDocument1 pageR420-FR-2130 A/B: NotesMubashir fareed100% (1)

- 65 93 PR Pid 01090 - 0001 - BDocument1 page65 93 PR Pid 01090 - 0001 - BgeocaustasNo ratings yet

- DECAL, WIRING SCHEMATIC (Xe), WFAN STR, VFD, SD, AIR COOLEDDocument4 pagesDECAL, WIRING SCHEMATIC (Xe), WFAN STR, VFD, SD, AIR COOLEDMarcos LunaNo ratings yet

- Eep 000097 0102148005 3 ST Det 0669 R02Document1 pageEep 000097 0102148005 3 ST Det 0669 R02Vikram DalalNo ratings yet

- Ut Mid 60 WPR2 231501 - 01 - Afc - 20230524Document1 pageUt Mid 60 WPR2 231501 - 01 - Afc - 20230524anujkumarNo ratings yet

- Werkstatt 01 SchematicsDocument9 pagesWerkstatt 01 Schematicsfelas37616No ratings yet

- Elec Schematic 2658488584 - 015Document24 pagesElec Schematic 2658488584 - 015aidaluz achahui condoriNo ratings yet

- wm-558 2d Drawing PDFDocument5 pageswm-558 2d Drawing PDFEgidijus DaukšysNo ratings yet

- UT1-E-300-OAA-DI-07001 - 0A Single Line Diagram Overall Electrical SystemDocument1 pageUT1-E-300-OAA-DI-07001 - 0A Single Line Diagram Overall Electrical SystemPrem SinghNo ratings yet

- Fender Rumble 15 2010 Schematic Rev-ADocument2 pagesFender Rumble 15 2010 Schematic Rev-Abeytullah50% (2)

- General Drawing Exchanger N°4Document1 pageGeneral Drawing Exchanger N°4calinvasco190670No ratings yet

- 4020-001A-VE-002 Rev 0 GENERAL ARRANGEMENT AMX9000 MIXER - Rev.0 Code2Document1 page4020-001A-VE-002 Rev 0 GENERAL ARRANGEMENT AMX9000 MIXER - Rev.0 Code2thoriq ikhwanNo ratings yet

- Detail Detail: Issued For Public CommentDocument1 pageDetail Detail: Issued For Public CommentChilakamarri SrikamalNo ratings yet

- General Drawing Exchanger N°2Document1 pageGeneral Drawing Exchanger N°2calinvasco190670No ratings yet

- Communications Board Schematic 754-301-10 Rev A: 4 3 2 1 Rev Eco Description By/Date Chk/Date RevisionsDocument1 pageCommunications Board Schematic 754-301-10 Rev A: 4 3 2 1 Rev Eco Description By/Date Chk/Date RevisionsElvisNo ratings yet

- DECAL, WIRING SCHEMATIC (Xe), VFD, SD, AIR COOLEDDocument4 pagesDECAL, WIRING SCHEMATIC (Xe), VFD, SD, AIR COOLEDMarcos LunaNo ratings yet

- BC 5300&5380 (1) FluidicDocument8 pagesBC 5300&5380 (1) FluidicCHARLIE BRICENo ratings yet

- e C7328 - 1F PDFDocument6 pagese C7328 - 1F PDFmina fawzyNo ratings yet

- 01 - 6040 BH MDG Sil - 01 - 01Document1 page01 - 6040 BH MDG Sil - 01 - 01JGFRVNo ratings yet

- 109018AE0026-27 - Rev - 0 Layout Panel de ControlDocument2 pages109018AE0026-27 - Rev - 0 Layout Panel de ControlAlonzo Rueda PeraltaNo ratings yet

- Atlantic Version: Applicator Data ODocument4 pagesAtlantic Version: Applicator Data OChung LeNo ratings yet

- Hyundai H-LCDVD2001 Schematics DiagramDocument40 pagesHyundai H-LCDVD2001 Schematics DiagramGeovanny SanJuanNo ratings yet

- iPhone5S 6.1 SchematicDocument56 pagesiPhone5S 6.1 SchematicRedNo ratings yet

- DX Split Unit - YorkDocument200 pagesDX Split Unit - YorkFaiyaz Bin Mazid AhmedNo ratings yet

- Схема пульта управленияDocument1 pageСхема пульта управленияДенис УмеренкоNo ratings yet

- Drawings r90 160 Fs Ss Electrical SchematicDocument2 pagesDrawings r90 160 Fs Ss Electrical Schematicingenieria4.0No ratings yet

- D-151-1225-0005G - 7 Revised Isolation PlanDocument1 pageD-151-1225-0005G - 7 Revised Isolation PlanTiến Dũng VũNo ratings yet

- Drawings r90 160 Vs Electrical SchematicDocument2 pagesDrawings r90 160 Vs Electrical Schematicingenieria4.0No ratings yet

- Reference Drawings:: 4mm " 20mm "Document1 pageReference Drawings:: 4mm " 20mm "ArielNo ratings yet

- Sharp Runtka611wjqz psd-0698 Psu SCHDocument2 pagesSharp Runtka611wjqz psd-0698 Psu SCHMarko VujinovićNo ratings yet

- 1 Engine TecDocument2 pages1 Engine TecRudy IndrawanNo ratings yet

- Plano Lepa-Lesj 1 UpdatedDocument1 pagePlano Lepa-Lesj 1 UpdatedAnonymous 4a9UwGNo ratings yet

- Esq Net Winner (t0534602)Document1 pageEsq Net Winner (t0534602)Paulo CostaNo ratings yet

- 210-87-Pr-Pid-00003 - 01 - Piping and Instrumentation Diagram Riser Platform Rt2 Closed Drain SystemDocument1 page210-87-Pr-Pid-00003 - 01 - Piping and Instrumentation Diagram Riser Platform Rt2 Closed Drain SystemIndra GunawanNo ratings yet

- 212A Patchbay Diagram Sept 2023Document1 page212A Patchbay Diagram Sept 2023Farid AhmadNo ratings yet

- Type 1 Drawing Rosemount 2140 Level Detector Vibrating Fork 2d PDF en 8218834Document3 pagesType 1 Drawing Rosemount 2140 Level Detector Vibrating Fork 2d PDF en 8218834Tien Nguyen TatNo ratings yet

- Layer Flag (Differentiate From Assy P/N) Layer Name (See Module Table) Base Number D92-1371-9 000000Document12 pagesLayer Flag (Differentiate From Assy P/N) Layer Name (See Module Table) Base Number D92-1371-9 000000carlosar1477No ratings yet

- Siemens: ASK DDocument1 pageSiemens: ASK DMurilo MonteiroNo ratings yet

- DWC7894 11 07 - 00Document1 pageDWC7894 11 07 - 00nthekkumpuramNo ratings yet

- DRP001 Ouf Gal 940110 K Ecr 001 002 S1Document1 pageDRP001 Ouf Gal 940110 K Ecr 001 002 S1pathanNo ratings yet

- D 1867 3E10 7603 - UpdateDocument1 pageD 1867 3E10 7603 - UpdateHadi SuagungNo ratings yet

- 12.1 CPU&Deflction Control CircuitDocument1 page12.1 CPU&Deflction Control CircuitAhmad SukijoNo ratings yet

- 13.8Kv Automatic Bus Transfer Scheme Panel +abts: A EA-381674 P HA556 3-1313003.05 4400004657Document1 page13.8Kv Automatic Bus Transfer Scheme Panel +abts: A EA-381674 P HA556 3-1313003.05 4400004657Anonymous BZQOJwWIh6No ratings yet

- MR150K GA Drawing 45980208 - FDocument2 pagesMR150K GA Drawing 45980208 - Flymn linNo ratings yet

- A300FU REV02A F BOM2 PlacementDocument9 pagesA300FU REV02A F BOM2 Placementkoimmark17No ratings yet

- Ed 0900 PRS Pid 000 09041CDocument1 pageEd 0900 PRS Pid 000 09041CMohamed ArafaNo ratings yet

- 915 11526 - Rev 5Document2 pages915 11526 - Rev 5Sonu KumarNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- S-03710 M54161-1-Rev. 1-As F 8506-Steam Drum AssemblyDocument1 pageS-03710 M54161-1-Rev. 1-As F 8506-Steam Drum Assemblywylie01No ratings yet

- Drawing Limit - N 19736.000: J94-C04-003-TP001Document1 pageDrawing Limit - N 19736.000: J94-C04-003-TP001illiasuddinNo ratings yet

- DRP001 Ouf Gal 940110 K Ecr 001 003 S1Document1 pageDRP001 Ouf Gal 940110 K Ecr 001 003 S1pathanNo ratings yet

- 31-ASME B31 CodesDocument1 page31-ASME B31 CodesBharathiNo ratings yet

- BS 1873 - 1975Document34 pagesBS 1873 - 1975BharathiNo ratings yet

- DOD-RGX-F051 Rev 2 - Material Receipt Cum Inspection ReportDocument1 pageDOD-RGX-F051 Rev 2 - Material Receipt Cum Inspection ReportBharathiNo ratings yet

- DOD-MST-INS-008 Installation and Testing of Fiber Optic Cable - Rev.0Document14 pagesDOD-MST-INS-008 Installation and Testing of Fiber Optic Cable - Rev.0BharathiNo ratings yet

- DOD-RGX-F049 Rev 0 - Over - Short - Damage ReportDocument1 pageDOD-RGX-F049 Rev 0 - Over - Short - Damage ReportBharathiNo ratings yet

- DOD-ITP-INS-008 - Cover Sheet - Rev.0Document2 pagesDOD-ITP-INS-008 - Cover Sheet - Rev.0BharathiNo ratings yet

- Dod-Rgx-F425 - Fibre Optic Cable Pre-Installation Test ReportDocument2 pagesDod-Rgx-F425 - Fibre Optic Cable Pre-Installation Test ReportBharathiNo ratings yet

- Electrical Symbols-Rotated PDFDocument3 pagesElectrical Symbols-Rotated PDFBharathiNo ratings yet

- DOD-RGX-F427 - FIBRE OPTIC CABLE Splice Termination Test ReportDocument2 pagesDOD-RGX-F427 - FIBRE OPTIC CABLE Splice Termination Test ReportBharathiNo ratings yet

- DOD-MST-INS-004, MST For Insta. of Tubes, Pipes & Pressure Testing.-Rev.0Document11 pagesDOD-MST-INS-004, MST For Insta. of Tubes, Pipes & Pressure Testing.-Rev.0BharathiNo ratings yet

- DOD-QCP-INS-002, Rev-0Document7 pagesDOD-QCP-INS-002, Rev-0BharathiNo ratings yet

- DOD-ITP - INS-008-ITP FOR Installation and Testing of Fiber Optic Cable - Rev.0Document2 pagesDOD-ITP - INS-008-ITP FOR Installation and Testing of Fiber Optic Cable - Rev.0Bharathi100% (1)

- Load CalculationDocument6 pagesLoad CalculationBharathi100% (1)

- DOD-ITP-INS-004 - Installation and Testing of Air and Impulse Piping, Tubing.-Rev-2Document1 pageDOD-ITP-INS-004 - Installation and Testing of Air and Impulse Piping, Tubing.-Rev-2BharathiNo ratings yet

- DOD MST INS 001 Rev.0Document8 pagesDOD MST INS 001 Rev.0BharathiNo ratings yet

- How To Convert Amps To Kilowatts & KW To AmpsDocument3 pagesHow To Convert Amps To Kilowatts & KW To AmpsBharathiNo ratings yet

- DOD-MST-INS-002, MST For Installation of Field Instruments.-Rev-1Document15 pagesDOD-MST-INS-002, MST For Installation of Field Instruments.-Rev-1BharathiNo ratings yet

- DOD-ITP-INS-002 - Installation of Field Instrument Rev.1Document3 pagesDOD-ITP-INS-002 - Installation of Field Instrument Rev.1BharathiNo ratings yet

- DOD QCP INS 001.rev.1Document7 pagesDOD QCP INS 001.rev.1BharathiNo ratings yet

- DOD-MST-INS-003 Insta. & Testing of Inst. Cables-Rev-0Document11 pagesDOD-MST-INS-003 Insta. & Testing of Inst. Cables-Rev-0BharathiNo ratings yet

- DOD-ITP-INS-003 - Rev-2Document4 pagesDOD-ITP-INS-003 - Rev-2BharathiNo ratings yet

- Water TherapyDocument3 pagesWater TherapyBharathiNo ratings yet

- DOD ITP INS 006 Rev 1Document1 pageDOD ITP INS 006 Rev 1BharathiNo ratings yet

- DOD-ITP - INS-008-ITP FOR Installation and Testing of Fiber Optic Cable - Rev.0Document1 pageDOD-ITP - INS-008-ITP FOR Installation and Testing of Fiber Optic Cable - Rev.0BharathiNo ratings yet

- Binder 1Document16 pagesBinder 1BharathiNo ratings yet

- DOD ITP INS 001 Rev 1Document1 pageDOD ITP INS 001 Rev 1BharathiNo ratings yet

- JACOBS Template (Repaired)Document5 pagesJACOBS Template (Repaired)BharathiNo ratings yet

- History MapsDocument2 pagesHistory MapsBharathiNo ratings yet

- Flu Vaccine Concent Form IisjDocument1 pageFlu Vaccine Concent Form IisjBharathiNo ratings yet

- Why Do We Use Vacuum Flask To Keep Hot Water or Tea For A Longer TimeDocument2 pagesWhy Do We Use Vacuum Flask To Keep Hot Water or Tea For A Longer TimeBharathiNo ratings yet

- Sorption Machines With HeatpipeDocument7 pagesSorption Machines With HeatpipeJeffrey L. FrushaNo ratings yet

- Rimslow Precoat-W 1850Document5 pagesRimslow Precoat-W 1850GgturyNo ratings yet

- 40.8245045sample - Question - BE - New CourseDocument40 pages40.8245045sample - Question - BE - New Courseabhi1361yadavNo ratings yet

- Civil Engineering Reference BookDocument463 pagesCivil Engineering Reference Bookenggakter58% (12)

- 1082 Rawlplug en R Hptii ZF Zinc Flake ThroughboltDocument8 pages1082 Rawlplug en R Hptii ZF Zinc Flake ThroughboltFreddie KooNo ratings yet

- Installation User Instruction (KMC Corporation)Document33 pagesInstallation User Instruction (KMC Corporation)Dan StroescuNo ratings yet

- Simulación Molecular de La Adsorción de Metano en Carbón Activado El Impacto de La Estructura de Los Poros y La Química de La SuperficieDocument8 pagesSimulación Molecular de La Adsorción de Metano en Carbón Activado El Impacto de La Estructura de Los Poros y La Química de La SuperficieAndres Felipe SaraviaNo ratings yet

- Fde MCQDocument14 pagesFde MCQahmedNo ratings yet

- Optical Encoder For Motion Control Through ArduinoDocument4 pagesOptical Encoder For Motion Control Through ArduinoMary LongNo ratings yet

- DMB-01-C-M24: TIMER M/FUNCTION 24VDC/24-240VAC SUPPLY 1 C/O 0.1S-100H Catalogue NoDocument4 pagesDMB-01-C-M24: TIMER M/FUNCTION 24VDC/24-240VAC SUPPLY 1 C/O 0.1S-100H Catalogue Noyassine yassineNo ratings yet

- AV179348Document1 pageAV179348khanh123ctmNo ratings yet

- 2/2 Solenoid Directional Valve Poppet Type, Pilot Operated Normally Open UNF Cartridge - 350 BarDocument2 pages2/2 Solenoid Directional Valve Poppet Type, Pilot Operated Normally Open UNF Cartridge - 350 BarOmkar TerkhedkarNo ratings yet

- Compendium: Solutions To Selected Exercises From John David Jackson: Classical Electrodynamics (3rd Edition)Document46 pagesCompendium: Solutions To Selected Exercises From John David Jackson: Classical Electrodynamics (3rd Edition)Bryan Jesus RANo ratings yet

- Cambridge Science - Chapter 4 - ElectricityDocument30 pagesCambridge Science - Chapter 4 - ElectricityDK01No ratings yet

- Chemexam2222 Made by Sherra 2Document34 pagesChemexam2222 Made by Sherra 2tantiadohannahmarielleNo ratings yet

- Collisional Orogens in Indonesia (Satyana Et Al., 2007, JCDocument64 pagesCollisional Orogens in Indonesia (Satyana Et Al., 2007, JCArie T Lapi-ITBNo ratings yet

- Buckling of Columns PDFDocument11 pagesBuckling of Columns PDFAhmedHatifNo ratings yet

- Manuscript For (CSTR - Batch Mode) - Group 1 - Ceeh2205iDocument8 pagesManuscript For (CSTR - Batch Mode) - Group 1 - Ceeh2205iNURSYAHIRAH MOHD NAZIRNo ratings yet

- Unit-2 Sensors Pressure SensorsDocument29 pagesUnit-2 Sensors Pressure Sensors17 CSE Lokesh VNo ratings yet

- GEHD Externally Heated Desiccant Dryer: Replacement Parts ListDocument3 pagesGEHD Externally Heated Desiccant Dryer: Replacement Parts ListLazaro GutierrezNo ratings yet

- Soil ReflectanceDocument26 pagesSoil ReflectanceJack LinnNo ratings yet

- 202211121648018939miclolab 300Document4 pages202211121648018939miclolab 300Ajish joNo ratings yet

- Free Standing Masonry Wall Design Based On TMS 402-16/13 & ACI 318-19Document6 pagesFree Standing Masonry Wall Design Based On TMS 402-16/13 & ACI 318-19biceli samet1No ratings yet

- Lighting For Residential BuildingsDocument74 pagesLighting For Residential BuildingscybershotNo ratings yet

- MME 2506 Refractory Materials 6Document47 pagesMME 2506 Refractory Materials 6dibyendu ChakrabartyNo ratings yet

- Quantum Dots - A Variety of New ApplicationsDocument290 pagesQuantum Dots - A Variety of New ApplicationsJosé RamírezNo ratings yet

- UNI T Catalogo 2022 1Document194 pagesUNI T Catalogo 2022 1Raúl Quintero MorenoNo ratings yet

- 300 CombinedDocument15 pages300 CombinedAnis AhmadNo ratings yet

- Satronic - Honeywell DKG972 DatasheetDocument17 pagesSatronic - Honeywell DKG972 DatasheetDario Mamani CastilloNo ratings yet