Professional Documents

Culture Documents

Comparing Pruv and Magnesium Stearate For External and Internal Lubrication During Rotary Tableting

Comparing Pruv and Magnesium Stearate For External and Internal Lubrication During Rotary Tableting

Uploaded by

Zeyad A AbdullahCopyright:

Available Formats

You might also like

- BS 4254Document19 pagesBS 4254gugaruban100% (4)

- OSTEORADIONECROSISDocument38 pagesOSTEORADIONECROSISAbel AbrahamNo ratings yet

- Botros, Kamal Kamel - Mohitpour, Mo - Van Hardeveld, Thomas - Pipeline Pumping and Compression Systems - A Practical Approach (2013, ASME Press) - Libgen - lc-1Document615 pagesBotros, Kamal Kamel - Mohitpour, Mo - Van Hardeveld, Thomas - Pipeline Pumping and Compression Systems - A Practical Approach (2013, ASME Press) - Libgen - lc-1PGR ING.No ratings yet

- Product Realization Process - MapDocument1 pageProduct Realization Process - Mapsenthildurai0% (1)

- MAG'Impact: The High-Performance Impactor: Cubicity and SimplicityDocument5 pagesMAG'Impact: The High-Performance Impactor: Cubicity and SimplicityPrekelNo ratings yet

- Mastercool Air Conditioner Service ManualDocument2 pagesMastercool Air Conditioner Service ManualJubril Akinwande100% (1)

- Fotocopias Ingles Tema Climate 1º EsoDocument6 pagesFotocopias Ingles Tema Climate 1º EsoMayOrdóñezNo ratings yet

- Frame Adhesives & HardenersDocument1 pageFrame Adhesives & HardenersSoleil JimenezNo ratings yet

- Vibration Damping Casters Casters For Clean Environment: CMPR Cmprs CMPG Cmpgs Chepa ChgpaDocument1 pageVibration Damping Casters Casters For Clean Environment: CMPR Cmprs CMPG Cmpgs Chepa ChgpacmpuckNo ratings yet

- Null 1Document1 pageNull 1Pardede AncisNo ratings yet

- Cajas Eaton FullerDocument51 pagesCajas Eaton FullerMECHAS151267% (3)

- Selec Chart Concrete enDocument1 pageSelec Chart Concrete enaliomairNo ratings yet

- 02 Stock Utilization Feb'24Document415 pages02 Stock Utilization Feb'24abhishek.baidyaNo ratings yet

- Cutting Tool Material PDFDocument43 pagesCutting Tool Material PDFsandeepNo ratings yet

- HD Rim Valve Guard PorosityDocument3 pagesHD Rim Valve Guard PorosityDurai NaiduNo ratings yet

- Selec Chart Concrete enDocument1 pageSelec Chart Concrete enRubal ShawNo ratings yet

- Catalogue Lubrification GBBDocument60 pagesCatalogue Lubrification GBBTIAGO FERNANDES DA SILVA VIEIRA LEITENo ratings yet

- 14meditran SX Ultra GleDocument1 page14meditran SX Ultra GleAkif SetiawanNo ratings yet

- RUBRIC ASSESSMENT 2008-2009 (SEM 1) Class: X-A Subject: TopicDocument63 pagesRUBRIC ASSESSMENT 2008-2009 (SEM 1) Class: X-A Subject: Topicapi-19618227No ratings yet

- Summary of Blasting Activity & Explosives Usage Prepared By, Approved ByDocument8 pagesSummary of Blasting Activity & Explosives Usage Prepared By, Approved Bydidi setiawanNo ratings yet

- Wall Chart NFMT eDocument1 pageWall Chart NFMT eArchana PathakNo ratings yet

- Guide To ODDocument2 pagesGuide To ODlb_BotsNo ratings yet

- Vol-I Part-II Section 5.B.3 1 Technical Investigation Report 487Document1 pageVol-I Part-II Section 5.B.3 1 Technical Investigation Report 487mayank dixitNo ratings yet

- Grading Sheet & Parameters For Proposed Design Plate ME158P-2Document7 pagesGrading Sheet & Parameters For Proposed Design Plate ME158P-2Yohan ManaligodNo ratings yet

- GreaseDocument5 pagesGreaseMhmood QadouraNo ratings yet

- Series: Super Mist SeparatorDocument5 pagesSeries: Super Mist Separatorherysyam1980No ratings yet

- MSS - Definitions - Coating MaterialsDocument4 pagesMSS - Definitions - Coating MaterialsIsmailEmreCanbolatNo ratings yet

- Personal Care Na Hair GuideDocument8 pagesPersonal Care Na Hair GuideIsabellaNo ratings yet

- 2021322-110 T-MGB-R2-GADDocument1 page2021322-110 T-MGB-R2-GADankit19200No ratings yet

- 20.COBIT5 For Assurance LaminateDocument2 pages20.COBIT5 For Assurance LaminateLuqman HakimNo ratings yet

- 0127 R8B 05 WP 311 01Document1 page0127 R8B 05 WP 311 01ABDERRAZZAKNo ratings yet

- Sturaco 7098Document1 pageSturaco 7098Tudor RatiuNo ratings yet

- Proton Persona 2016 PDFDocument2 pagesProton Persona 2016 PDFveltr0No ratings yet

- Former Pipa Awd Dia 4 Inch-KopDocument1 pageFormer Pipa Awd Dia 4 Inch-KopDhani Kurnia RamdhaniNo ratings yet

- Unit Cost AnalysisDocument1 pageUnit Cost Analysismanolito cresencioNo ratings yet

- GRP Scheme of Switchgear Generator, GT and UT 35620061800R00Document136 pagesGRP Scheme of Switchgear Generator, GT and UT 35620061800R00Rukma Goud Shakkari100% (1)

- Basf - 2015-Agro Brochure Asia Pacific enDocument9 pagesBasf - 2015-Agro Brochure Asia Pacific enAlfredo MéndezNo ratings yet

- Getting Paid Note Taking Guide 2.3.9.L1 PDFDocument3 pagesGetting Paid Note Taking Guide 2.3.9.L1 PDFJulianna ChmielNo ratings yet

- Shell Omala: Industrial Gear OilsDocument9 pagesShell Omala: Industrial Gear Oilshoussem houssemNo ratings yet

- Bunkers An Analysis of The Technical and Environme... - (PG 89 - 89)Document1 pageBunkers An Analysis of The Technical and Environme... - (PG 89 - 89)Clarcy CrawfordNo ratings yet

- 2021322-110 T-Mgb-R0-GadDocument1 page2021322-110 T-Mgb-R0-Gadankit19200No ratings yet

- F17110026-27 00 3 4Document1 pageF17110026-27 00 3 4iyytgfNo ratings yet

- Atzec MP DITDocument3 pagesAtzec MP DITClaudia SandovalNo ratings yet

- MAN-00051-XYLO-Special Tool Manual - Rev1Document28 pagesMAN-00051-XYLO-Special Tool Manual - Rev1Amanz MKNo ratings yet

- Plano Expo CMP2018Document1 pagePlano Expo CMP2018Roii RoyyNo ratings yet

- 0127 R8B 07 WP 311 01Document1 page0127 R8B 07 WP 311 01ABDERRAZZAKNo ratings yet

- Revised Foundation For 315 Mva Transformer 28 10 09 Model PDFDocument1 pageRevised Foundation For 315 Mva Transformer 28 10 09 Model PDFepe civilNo ratings yet

- UN Contractor Crew Competency Review Form G - 2011Document5 pagesUN Contractor Crew Competency Review Form G - 2011AKOGU J. AKPOCHI J.No ratings yet

- TRW Cross ReferenceDocument2 pagesTRW Cross Referenceeloyabner75% (4)

- 0000 DRG WD ST 007 PDFDocument1 page0000 DRG WD ST 007 PDFabidimisamNo ratings yet

- Angloamerican: Ifc - Issued For ConstructionDocument1 pageAngloamerican: Ifc - Issued For ConstructionLuis Fernando GONZALES HUMIRENo ratings yet

- HRB 4-1Document1 pageHRB 4-1gageanuconstantinNo ratings yet

- Fertilizer AdditivesDocument7 pagesFertilizer AdditivesmohsanmajeedNo ratings yet

- Design Markup - y DirDocument1 pageDesign Markup - y DirSUMAN CIVILNo ratings yet

- Product Data Sheets: Communications SystemDocument11 pagesProduct Data Sheets: Communications SystemjenkahNo ratings yet

- Nozzle Joints / Two-Fluid Nozzles Spray Nozzles: Male, Female Ends Female, Female EndsDocument1 pageNozzle Joints / Two-Fluid Nozzles Spray Nozzles: Male, Female Ends Female, Female EndsAmpera marzelaNo ratings yet

- TRN - Submersible Aerator PDFDocument3 pagesTRN - Submersible Aerator PDFGregorio Molina SosaNo ratings yet

- WEG CFW500 Installation Guide Parameter Reference 10007479673 en Es PT ZHDocument12 pagesWEG CFW500 Installation Guide Parameter Reference 10007479673 en Es PT ZHRicardo LeiteNo ratings yet

- Auto Refinishing: Technical Sheet Markk-LambDocument3 pagesAuto Refinishing: Technical Sheet Markk-Lambu nizamiNo ratings yet

- CNSK OiliteDocument36 pagesCNSK Oiliteaataylor83No ratings yet

- Company Profile & Catalogue PT Orindo Eratec 2021Document16 pagesCompany Profile & Catalogue PT Orindo Eratec 2021HSE Wana Dirga NusantaraNo ratings yet

- Report Akreditasi Batch MBT in Branch Batch 124 2024-04-04 08 48 26Document2 pagesReport Akreditasi Batch MBT in Branch Batch 124 2024-04-04 08 48 26Muhammad Agung PratamaNo ratings yet

- Ficha Tecnica Petzl ID L PDFDocument27 pagesFicha Tecnica Petzl ID L PDFMariano BoyaNo ratings yet

- Polamco Product Finder PDFDocument1 pagePolamco Product Finder PDFpaula09No ratings yet

- Unit 1 Topic ICHDocument10 pagesUnit 1 Topic ICHZeyad A AbdullahNo ratings yet

- Form 125 Example Batch Reconciliation Sheet For Tablet PackingDocument4 pagesForm 125 Example Batch Reconciliation Sheet For Tablet PackingZeyad A AbdullahNo ratings yet

- Pharmacognosy Unit 4 5th Short Important Questions Shahruddin KhanDocument16 pagesPharmacognosy Unit 4 5th Short Important Questions Shahruddin KhanZeyad A AbdullahNo ratings yet

- QA - Market Complaint Unit 4Document2 pagesQA - Market Complaint Unit 4Zeyad A AbdullahNo ratings yet

- Vol. 3, Issue 3, March 2015, PharmaTutor, Paper-4Document7 pagesVol. 3, Issue 3, March 2015, PharmaTutor, Paper-4Zeyad A AbdullahNo ratings yet

- Form 160 Example - Line - Clearance Opening and Cleaning Form For Tablet PackingDocument8 pagesForm 160 Example - Line - Clearance Opening and Cleaning Form For Tablet PackingZeyad A AbdullahNo ratings yet

- QMS 035 Deviation Report System SampleDocument6 pagesQMS 035 Deviation Report System SampleZeyad A AbdullahNo ratings yet

- U 1 PP 2 4th Sem B Pharm Pharmacy Wala Shahruddin Khan 18811494Document7 pagesU 1 PP 2 4th Sem B Pharm Pharmacy Wala Shahruddin Khan 18811494Zeyad A AbdullahNo ratings yet

- Form 400 Employee Signature RegisterDocument1 pageForm 400 Employee Signature RegisterZeyad A AbdullahNo ratings yet

- Melatonin Oral DropDocument3 pagesMelatonin Oral DropZeyad A AbdullahNo ratings yet

- Form 085 Released StickersDocument1 pageForm 085 Released StickersZeyad A AbdullahNo ratings yet

- RRT - DB - Mat WND enDocument2 pagesRRT - DB - Mat WND enZeyad A AbdullahNo ratings yet

- Form 140 Visitor Entry Into The FactoryDocument1 pageForm 140 Visitor Entry Into The FactoryZeyad A AbdullahNo ratings yet

- Project 1 7/5/2021Document1 pageProject 1 7/5/2021Zeyad A AbdullahNo ratings yet

- List of Glassware Used in Pharmaceuticals - PharmaguidelineDocument4 pagesList of Glassware Used in Pharmaceuticals - PharmaguidelineZeyad A AbdullahNo ratings yet

- Catalogue Tablet-Press 2019 V3Document16 pagesCatalogue Tablet-Press 2019 V3Zeyad A AbdullahNo ratings yet

- Us Cleanroom Standards CompliancewireDocument1 pageUs Cleanroom Standards CompliancewireZeyad A AbdullahNo ratings yet

- IndJPhaEdRes 54 3s s473Document12 pagesIndJPhaEdRes 54 3s s473Zeyad A AbdullahNo ratings yet

- Tube Filling and Sealing Machine Lab ModelDocument5 pagesTube Filling and Sealing Machine Lab ModelZeyad A AbdullahNo ratings yet

- PortaFab Mezzanine BrochureDocument2 pagesPortaFab Mezzanine BrochureZeyad A AbdullahNo ratings yet

- Ludipress Technical InformationDocument8 pagesLudipress Technical InformationZeyad A AbdullahNo ratings yet

- Product MonographDocument31 pagesProduct MonographZeyad A AbdullahNo ratings yet

- Good Practice Manufacturing Operation SampleDocument21 pagesGood Practice Manufacturing Operation SampleZeyad A AbdullahNo ratings yet

- Sodium Stearyl Fumarate Excipient Pubchem 1559559385Document2 pagesSodium Stearyl Fumarate Excipient Pubchem 1559559385Zeyad A AbdullahNo ratings yet

- GMP Clearance GuidanceDocument84 pagesGMP Clearance GuidanceZeyad A AbdullahNo ratings yet

- Tech Bulletin - Suglets - More Than MonographDocument2 pagesTech Bulletin - Suglets - More Than MonographZeyad A AbdullahNo ratings yet

- S 065 LBLDocument10 pagesS 065 LBLZeyad A AbdullahNo ratings yet

- Crosslinked Povidone Pubchem 1482747992Document4 pagesCrosslinked Povidone Pubchem 1482747992Zeyad A AbdullahNo ratings yet

- What Is Environmental Monitoring in Pharmaceutical IndustryDocument12 pagesWhat Is Environmental Monitoring in Pharmaceutical IndustryZeyad A AbdullahNo ratings yet

- 09 Nov 2016 180959770P8GWIJNEANNEXUREDocument2 pages09 Nov 2016 180959770P8GWIJNEANNEXUREZeyad A AbdullahNo ratings yet

- Lecture 4Document22 pagesLecture 4SUNDAS FATIMANo ratings yet

- Microsoft Word - ETERSET 2960-2 - MSDSDocument5 pagesMicrosoft Word - ETERSET 2960-2 - MSDSWinsonLimHuiWahNo ratings yet

- Material Sub Group Item CodeDocument2,818 pagesMaterial Sub Group Item Codegouri gouriNo ratings yet

- Phason FHC1D User ManualDocument16 pagesPhason FHC1D User Manuale-ComfortUSANo ratings yet

- Rice Sector PACRA - 1604759631Document29 pagesRice Sector PACRA - 1604759631Huzefa SarayiNo ratings yet

- PROJECT On Tea LeavesDocument15 pagesPROJECT On Tea LeavesBharat Singh83% (6)

- Cavitation Models in PIPENETDocument3 pagesCavitation Models in PIPENETSamarth PawarNo ratings yet

- Exploded View & Parts Listing Air Operated Double Diaphragm PumpDocument3 pagesExploded View & Parts Listing Air Operated Double Diaphragm PumpEdgar NercarNo ratings yet

- Module 7Document11 pagesModule 7Arlyn DatuinNo ratings yet

- Compact Evaporators: New Buffalo Trident GaccDocument16 pagesCompact Evaporators: New Buffalo Trident GaccPreeti gulatiNo ratings yet

- Neon NagaramDocument235 pagesNeon NagaramShammeer0% (1)

- Case Study Booklet 2 PDFDocument43 pagesCase Study Booklet 2 PDFguddu yadavNo ratings yet

- A Review On Ultra High Performance Concrete Part II. Hydration, Microstructure and Properties PDFDocument10 pagesA Review On Ultra High Performance Concrete Part II. Hydration, Microstructure and Properties PDFNocifLyesNo ratings yet

- Starkville Dispatch Eedition 7-29-20Document16 pagesStarkville Dispatch Eedition 7-29-20The DispatchNo ratings yet

- DPP 02 NTSE BY @class - 10 - MaterialsDocument1 pageDPP 02 NTSE BY @class - 10 - MaterialsShashwat MishraNo ratings yet

- Science G7 Q2 LP4Document13 pagesScience G7 Q2 LP4Lovely GuintoNo ratings yet

- Environmental Geotechniques: Theories of Ion ExchangeDocument21 pagesEnvironmental Geotechniques: Theories of Ion ExchangeTenkurala srujanaNo ratings yet

- Test Bank For The Practice of Statistics in The Life Sciences 4th Edition Brigitte BaldiDocument23 pagesTest Bank For The Practice of Statistics in The Life Sciences 4th Edition Brigitte BaldiDebra Franken100% (31)

- Re 51400Document14 pagesRe 51400Jamin Smtpng0% (1)

- MAC-LAB Assistant 5BDocument38 pagesMAC-LAB Assistant 5BAbdelhakszn SznNo ratings yet

- Drug Ana Surgery WardDocument11 pagesDrug Ana Surgery WardJames QuilingNo ratings yet

- IFU Acticor 439128-F EsDocument143 pagesIFU Acticor 439128-F EsMartin ArrietaNo ratings yet

- Criticism Herzberg TheoryDocument3 pagesCriticism Herzberg TheoryCaroline NerbasNo ratings yet

- Material HPLCDocument19 pagesMaterial HPLCIsmil ImamaNo ratings yet

- 00000102Document108 pages00000102Scary CreaturesNo ratings yet

Comparing Pruv and Magnesium Stearate For External and Internal Lubrication During Rotary Tableting

Comparing Pruv and Magnesium Stearate For External and Internal Lubrication During Rotary Tableting

Uploaded by

Zeyad A AbdullahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Comparing Pruv and Magnesium Stearate For External and Internal Lubrication During Rotary Tableting

Comparing Pruv and Magnesium Stearate For External and Internal Lubrication During Rotary Tableting

Uploaded by

Zeyad A AbdullahCopyright:

Available Formats

Comparing Pruv® and Magnesium Stearate for External

and Internal Lubrication During Rotary Tableting

K. Hofmann[1], K.– J. Steffens[1] and R. F. Lammens[2]

[1] Department of Pharmaceutical Technology, Rheinische Friedrich–Wilhelms–University, 53121 Bonn, Germany

[2] Technical Services Consult Lammens, 51373 Leverkusen, Germany

Introduction lubrication were compared with the internal Pearlitol® 200 SD

One of the most important ingredients of tablet lubrication ejection force data. lubricant concentration [%], internal lubrication

0 0,25 0,5 0,75 1 1,25 1,5 1,75

formulations is the lubricant. Lubricants reduce Tablettose® 70 was lubricated with 1.0 % and 1000 1000

Pruv

friction between the particles and die wall during Neosorb® P60W with 0.5 % lubricant. For Pearlitol® 900 Magnesium stearate Pharma veg

Mallinckrodt stearate

900

compression and between the tablet and the 200 SD and Emcompress Premium®, a 800

Internal lubrication

1,5 % Pruv 800

1,5 % Magnesium stearate Pharma veg

compressing tools during ejection. concentration of 1.5 % lubricant was used.

ejection force [N]

ejection force [N]

700 700

In most cases, the lubricant is added in a final step The tablets were compressed on a Fette 102i rotary 600 600

to the tablet mass (internal lubrication). The tablet press (24 stations, 9 mm R 15 EU B–type 500 500

400 400

concentration of the lubricant for most tablet blends punches, Fette, Schwarzenbek, Germany). For all

300 300

varies from 0.25 to 1.5 %. Using external lubrication, experiments, the rotor speed (60 rpm = 86400 200 200

the concentration of the lubricant can be reduced tablets per hour), the fill–o–matic speed (60 rpm), 100 100

down to 0.05 %. the pre–compression force (5 kN = 78.6 MPa) and 0 100 200 300 400 500 600 700 800 900 1000 1100

The aim of the present study was to optimize the main compression force (20 kN = 314 MPa) Fig. 4: Influence of spray rate on ejection force level

spray rate [g/h], external lubrication

lubrication spray rate using press chamber coating were kept constant.

(PKB II) with dry air and to investigate sodium As reported by Jahn [1] the filling depth has an Emcompress Premium®

stearyl fumarate as an alternative to the most influence on the amount of external lubricant per lubricant concentration [%], internal lubrication

commonly used magnesium stearate for external tablet. Therefore, the experiments were conducted 1000

0 0,25 0,5 0,75 1 1,25 1,5 1,75

1000

lubrication. at a filling depth of 7 mm. 900

Pruv

Magnesium stearate Pharma veg 900

Mallinckrodt stearate

800 Internal lubrication 800

1,5 % Pruv

1,5 % Magnesium stearate Pharma veg

Materials

ejection force [N]

ejection force [N]

Results and Discussion 700

600

1,5 % Mallinckrodt stearate 700

600

Two different types of magnesium stearate and The Mallinckrodt and have a stearate® Pruv® 500 500

sodium stearyl fumarate were used for external and crystalline structure, whereas magnesium stearate 400 400

internal lubrication: Pharma veg® is amorphous. 300 300

Magnesium stearate Pharma veg® (Baerlocher, 200 200

Germany) External lubrication 100

0 100 200 300 400 500 600 700 800

100

Mallinckrodt stearate® (Mallinckrodt, USA) For Emcompress Premium®, the ejection forces spray rate [g/h], external lubrication

Pruv® (JRS Pharma, Germany) were practically constant [Fig. 5], whereas for all Fig. 5: Influence of spray rate on ejection force level

The lubricants were characterized by x–ray powder other excipients the ejection force decreased when

diffraction and scanning electron microscopy. increasing the spray rate [Fig. 2, 3, 4]. Using external lubrication, all excipients could be

As obvious from Fig. 2 and 3, for Tablettose® 70 and compressed with the above listed lubricants, except

Pharmaceutical excipients with different compaction Neosorb® P60W, no significant differences between for Emcompress Premium® in combination with

behaviour were tested: the tested lubricants magnesium stearate Pharma magnesium stearate Pharma veg®.

α–Lactose monohydrate (Tablettose® 70, Meggle, veg® and Pruv® could be found. When using

Germany) Mallinckrodt stearate®, the ejection forces turned out Internal lubrication

Sorbitol (Neosorb® P60W, Roquette, France) to be slightly higher than for the other lubricants, As obvious from the encircled data points in Fig. 2,

Mannitol (Pearlitol® 200 SD, Roquette, France) although these differences have no practical aspect. for Tablettose® 70 the ejection forces obtained upon

Dibasic calcium phosphate dihydrate external and internal lubrication were identical for

(Emcompress Premium®, JRS Pharma, Germany) Tablettose® 70 the three tested lubricants.

lubricant concentration [%], internal lubrication When tableting Neosorb® P60W, the stearate

0 0,25 0,5 0,75 1 1,25 1,5 1,75

ejection forces were a bit smaller as the Pruv® ones,

Materials 1000

900

Pruv

Magnesium stearate Pharma veg

Mallinckrodt stearate

1000

900 but both types of lubricants seem to perform well

A mixture of powdered lubricant and air was 800 Internal lubrication

1 % Pruv

800 enough [Fig. 3].

sprayed directly onto the punch and die surfaces 1 % Magnesium stearate Pharma veg

Even at an internal lubricant concentration of 1.5 %,

ejection force [N]

ejection force [N]

700 1 % Mallinckrodt stearate 700

using the PKB II–system (K–Tron, Niederlenz, 600 600

Pearlitol® 200 SD could only be tableted with

Switzerland). To eliminate the effect of variation in 500 500

magnesium stearate Pharma veg® [Fig. 4]. Internal

air humidity, for all experiments dry air (Praxair, 400 400

lubrication with Pruv® and Mallinckrodt stearate®

300 300

Germany) was used. led to an adherence of the blend to the convex

200 200

The lubricant was deposited in a fill hopper. A twin 100 100

shaped surface of the upper punches.

screw feeder, located at the bottom of this hopper, 0 100 200 300 400 500 600 700 800 As obvious from Fig. 5, the ejection forces of the

conveyed the lubricant to the free fall tower. The spray rate [g/h], external lubrication

internal lubrication upon compressing Emcompress

Fig. 2: Influence of spray rate on ejection force level

lubricant was mixed with dry air and was Premium® were more or less the same. The ejection

transported to the spray nozzle. The position of the forces reached a level between Pruv® and

Neosorb® P60W

nozzle between the ejection and the filling area is Mallinckrodt stearate® using the PKB II–system.

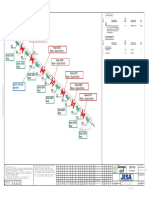

schematically shown in Fig. 1.

lubricant concentration [%], internal lubrication

0 0,25 0,5 0,75 1 1,25 1,5 1,75

tablet scraper spray nozzle 1000 1000

900

Pruv

Magnesium stearate Pharma veg

Mallinckrodt stearate

900

Conclusion

800

Internal lubrication

0,5 % Pruv 800 From the results it can be concluded that both

0,5 % Magnesium stearate Pharma veg

sodium stearyl fumarate and magnesium stearate

ejection force [N]

ejection force [N]

700 0,5 % Mallinckrodt stearate 700

upper punch filling area 600 600 can be used as effective external lubricants, the

500 500

former one being the lubricant of choice for

400 400

Pearlitol® 200 SD and Emcompress Premium® .

300 300

200 200

lower punch 100

0 100 200 300 400 500 600 700 800

100 References

spray rate [g/h], external lubrication [1] Jahn, Till, Press chamber coating as external

Fig. 3: Influence of spray rate on ejection force level lubrication for high speed rotary presses:

lubricant

Fig. 1: Position of the spray nozzle

lubricant spray rate optimization. Drug Dev Ind

Pearlitol® 200 SD and Emcompress Premium® are Pharm. 2005 Dec, 31 (10), 951-7

For optimizing the spray rate, the ejection force was powders, which in general require high lubricant

monitored. For Tablettose® 70 and Neosorb® P60W, concentrations. With Pruv® as an external lubricant,

the spray rate was varied from 100 to 700 g/h and the ejection forces were significantly lower as for the Acknowledgements

for Emcompress Premium® from 200 to 500 g/h. magnesium stearate types [Fig. 4 and 5]. Even at a The authors would like to thank for placing the

Upon compressing Pearlitol® 200 SD, the spray rate spray rate of 500 g/h, with magnesium stearate 102i at the University of Bonn as well as Meggle,

ranged from 300 to 1000 g/h. Pharma veg® sticking problems were observed Baerlocher, Roquette, Mallinckrodt and JRS

The ejection forces obtained with external upon tableting Emcompress Premium®. Pharma for the donation of excipients.

6th World Meeting on Pharmaceutics, Biopharmaceutics and Pharmazeutical Technology; Barcelona; Spain; 7th – 10th April 2008 corresponding author: katrin.hofmann@uni-bonn.de

You might also like

- BS 4254Document19 pagesBS 4254gugaruban100% (4)

- OSTEORADIONECROSISDocument38 pagesOSTEORADIONECROSISAbel AbrahamNo ratings yet

- Botros, Kamal Kamel - Mohitpour, Mo - Van Hardeveld, Thomas - Pipeline Pumping and Compression Systems - A Practical Approach (2013, ASME Press) - Libgen - lc-1Document615 pagesBotros, Kamal Kamel - Mohitpour, Mo - Van Hardeveld, Thomas - Pipeline Pumping and Compression Systems - A Practical Approach (2013, ASME Press) - Libgen - lc-1PGR ING.No ratings yet

- Product Realization Process - MapDocument1 pageProduct Realization Process - Mapsenthildurai0% (1)

- MAG'Impact: The High-Performance Impactor: Cubicity and SimplicityDocument5 pagesMAG'Impact: The High-Performance Impactor: Cubicity and SimplicityPrekelNo ratings yet

- Mastercool Air Conditioner Service ManualDocument2 pagesMastercool Air Conditioner Service ManualJubril Akinwande100% (1)

- Fotocopias Ingles Tema Climate 1º EsoDocument6 pagesFotocopias Ingles Tema Climate 1º EsoMayOrdóñezNo ratings yet

- Frame Adhesives & HardenersDocument1 pageFrame Adhesives & HardenersSoleil JimenezNo ratings yet

- Vibration Damping Casters Casters For Clean Environment: CMPR Cmprs CMPG Cmpgs Chepa ChgpaDocument1 pageVibration Damping Casters Casters For Clean Environment: CMPR Cmprs CMPG Cmpgs Chepa ChgpacmpuckNo ratings yet

- Null 1Document1 pageNull 1Pardede AncisNo ratings yet

- Cajas Eaton FullerDocument51 pagesCajas Eaton FullerMECHAS151267% (3)

- Selec Chart Concrete enDocument1 pageSelec Chart Concrete enaliomairNo ratings yet

- 02 Stock Utilization Feb'24Document415 pages02 Stock Utilization Feb'24abhishek.baidyaNo ratings yet

- Cutting Tool Material PDFDocument43 pagesCutting Tool Material PDFsandeepNo ratings yet

- HD Rim Valve Guard PorosityDocument3 pagesHD Rim Valve Guard PorosityDurai NaiduNo ratings yet

- Selec Chart Concrete enDocument1 pageSelec Chart Concrete enRubal ShawNo ratings yet

- Catalogue Lubrification GBBDocument60 pagesCatalogue Lubrification GBBTIAGO FERNANDES DA SILVA VIEIRA LEITENo ratings yet

- 14meditran SX Ultra GleDocument1 page14meditran SX Ultra GleAkif SetiawanNo ratings yet

- RUBRIC ASSESSMENT 2008-2009 (SEM 1) Class: X-A Subject: TopicDocument63 pagesRUBRIC ASSESSMENT 2008-2009 (SEM 1) Class: X-A Subject: Topicapi-19618227No ratings yet

- Summary of Blasting Activity & Explosives Usage Prepared By, Approved ByDocument8 pagesSummary of Blasting Activity & Explosives Usage Prepared By, Approved Bydidi setiawanNo ratings yet

- Wall Chart NFMT eDocument1 pageWall Chart NFMT eArchana PathakNo ratings yet

- Guide To ODDocument2 pagesGuide To ODlb_BotsNo ratings yet

- Vol-I Part-II Section 5.B.3 1 Technical Investigation Report 487Document1 pageVol-I Part-II Section 5.B.3 1 Technical Investigation Report 487mayank dixitNo ratings yet

- Grading Sheet & Parameters For Proposed Design Plate ME158P-2Document7 pagesGrading Sheet & Parameters For Proposed Design Plate ME158P-2Yohan ManaligodNo ratings yet

- GreaseDocument5 pagesGreaseMhmood QadouraNo ratings yet

- Series: Super Mist SeparatorDocument5 pagesSeries: Super Mist Separatorherysyam1980No ratings yet

- MSS - Definitions - Coating MaterialsDocument4 pagesMSS - Definitions - Coating MaterialsIsmailEmreCanbolatNo ratings yet

- Personal Care Na Hair GuideDocument8 pagesPersonal Care Na Hair GuideIsabellaNo ratings yet

- 2021322-110 T-MGB-R2-GADDocument1 page2021322-110 T-MGB-R2-GADankit19200No ratings yet

- 20.COBIT5 For Assurance LaminateDocument2 pages20.COBIT5 For Assurance LaminateLuqman HakimNo ratings yet

- 0127 R8B 05 WP 311 01Document1 page0127 R8B 05 WP 311 01ABDERRAZZAKNo ratings yet

- Sturaco 7098Document1 pageSturaco 7098Tudor RatiuNo ratings yet

- Proton Persona 2016 PDFDocument2 pagesProton Persona 2016 PDFveltr0No ratings yet

- Former Pipa Awd Dia 4 Inch-KopDocument1 pageFormer Pipa Awd Dia 4 Inch-KopDhani Kurnia RamdhaniNo ratings yet

- Unit Cost AnalysisDocument1 pageUnit Cost Analysismanolito cresencioNo ratings yet

- GRP Scheme of Switchgear Generator, GT and UT 35620061800R00Document136 pagesGRP Scheme of Switchgear Generator, GT and UT 35620061800R00Rukma Goud Shakkari100% (1)

- Basf - 2015-Agro Brochure Asia Pacific enDocument9 pagesBasf - 2015-Agro Brochure Asia Pacific enAlfredo MéndezNo ratings yet

- Getting Paid Note Taking Guide 2.3.9.L1 PDFDocument3 pagesGetting Paid Note Taking Guide 2.3.9.L1 PDFJulianna ChmielNo ratings yet

- Shell Omala: Industrial Gear OilsDocument9 pagesShell Omala: Industrial Gear Oilshoussem houssemNo ratings yet

- Bunkers An Analysis of The Technical and Environme... - (PG 89 - 89)Document1 pageBunkers An Analysis of The Technical and Environme... - (PG 89 - 89)Clarcy CrawfordNo ratings yet

- 2021322-110 T-Mgb-R0-GadDocument1 page2021322-110 T-Mgb-R0-Gadankit19200No ratings yet

- F17110026-27 00 3 4Document1 pageF17110026-27 00 3 4iyytgfNo ratings yet

- Atzec MP DITDocument3 pagesAtzec MP DITClaudia SandovalNo ratings yet

- MAN-00051-XYLO-Special Tool Manual - Rev1Document28 pagesMAN-00051-XYLO-Special Tool Manual - Rev1Amanz MKNo ratings yet

- Plano Expo CMP2018Document1 pagePlano Expo CMP2018Roii RoyyNo ratings yet

- 0127 R8B 07 WP 311 01Document1 page0127 R8B 07 WP 311 01ABDERRAZZAKNo ratings yet

- Revised Foundation For 315 Mva Transformer 28 10 09 Model PDFDocument1 pageRevised Foundation For 315 Mva Transformer 28 10 09 Model PDFepe civilNo ratings yet

- UN Contractor Crew Competency Review Form G - 2011Document5 pagesUN Contractor Crew Competency Review Form G - 2011AKOGU J. AKPOCHI J.No ratings yet

- TRW Cross ReferenceDocument2 pagesTRW Cross Referenceeloyabner75% (4)

- 0000 DRG WD ST 007 PDFDocument1 page0000 DRG WD ST 007 PDFabidimisamNo ratings yet

- Angloamerican: Ifc - Issued For ConstructionDocument1 pageAngloamerican: Ifc - Issued For ConstructionLuis Fernando GONZALES HUMIRENo ratings yet

- HRB 4-1Document1 pageHRB 4-1gageanuconstantinNo ratings yet

- Fertilizer AdditivesDocument7 pagesFertilizer AdditivesmohsanmajeedNo ratings yet

- Design Markup - y DirDocument1 pageDesign Markup - y DirSUMAN CIVILNo ratings yet

- Product Data Sheets: Communications SystemDocument11 pagesProduct Data Sheets: Communications SystemjenkahNo ratings yet

- Nozzle Joints / Two-Fluid Nozzles Spray Nozzles: Male, Female Ends Female, Female EndsDocument1 pageNozzle Joints / Two-Fluid Nozzles Spray Nozzles: Male, Female Ends Female, Female EndsAmpera marzelaNo ratings yet

- TRN - Submersible Aerator PDFDocument3 pagesTRN - Submersible Aerator PDFGregorio Molina SosaNo ratings yet

- WEG CFW500 Installation Guide Parameter Reference 10007479673 en Es PT ZHDocument12 pagesWEG CFW500 Installation Guide Parameter Reference 10007479673 en Es PT ZHRicardo LeiteNo ratings yet

- Auto Refinishing: Technical Sheet Markk-LambDocument3 pagesAuto Refinishing: Technical Sheet Markk-Lambu nizamiNo ratings yet

- CNSK OiliteDocument36 pagesCNSK Oiliteaataylor83No ratings yet

- Company Profile & Catalogue PT Orindo Eratec 2021Document16 pagesCompany Profile & Catalogue PT Orindo Eratec 2021HSE Wana Dirga NusantaraNo ratings yet

- Report Akreditasi Batch MBT in Branch Batch 124 2024-04-04 08 48 26Document2 pagesReport Akreditasi Batch MBT in Branch Batch 124 2024-04-04 08 48 26Muhammad Agung PratamaNo ratings yet

- Ficha Tecnica Petzl ID L PDFDocument27 pagesFicha Tecnica Petzl ID L PDFMariano BoyaNo ratings yet

- Polamco Product Finder PDFDocument1 pagePolamco Product Finder PDFpaula09No ratings yet

- Unit 1 Topic ICHDocument10 pagesUnit 1 Topic ICHZeyad A AbdullahNo ratings yet

- Form 125 Example Batch Reconciliation Sheet For Tablet PackingDocument4 pagesForm 125 Example Batch Reconciliation Sheet For Tablet PackingZeyad A AbdullahNo ratings yet

- Pharmacognosy Unit 4 5th Short Important Questions Shahruddin KhanDocument16 pagesPharmacognosy Unit 4 5th Short Important Questions Shahruddin KhanZeyad A AbdullahNo ratings yet

- QA - Market Complaint Unit 4Document2 pagesQA - Market Complaint Unit 4Zeyad A AbdullahNo ratings yet

- Vol. 3, Issue 3, March 2015, PharmaTutor, Paper-4Document7 pagesVol. 3, Issue 3, March 2015, PharmaTutor, Paper-4Zeyad A AbdullahNo ratings yet

- Form 160 Example - Line - Clearance Opening and Cleaning Form For Tablet PackingDocument8 pagesForm 160 Example - Line - Clearance Opening and Cleaning Form For Tablet PackingZeyad A AbdullahNo ratings yet

- QMS 035 Deviation Report System SampleDocument6 pagesQMS 035 Deviation Report System SampleZeyad A AbdullahNo ratings yet

- U 1 PP 2 4th Sem B Pharm Pharmacy Wala Shahruddin Khan 18811494Document7 pagesU 1 PP 2 4th Sem B Pharm Pharmacy Wala Shahruddin Khan 18811494Zeyad A AbdullahNo ratings yet

- Form 400 Employee Signature RegisterDocument1 pageForm 400 Employee Signature RegisterZeyad A AbdullahNo ratings yet

- Melatonin Oral DropDocument3 pagesMelatonin Oral DropZeyad A AbdullahNo ratings yet

- Form 085 Released StickersDocument1 pageForm 085 Released StickersZeyad A AbdullahNo ratings yet

- RRT - DB - Mat WND enDocument2 pagesRRT - DB - Mat WND enZeyad A AbdullahNo ratings yet

- Form 140 Visitor Entry Into The FactoryDocument1 pageForm 140 Visitor Entry Into The FactoryZeyad A AbdullahNo ratings yet

- Project 1 7/5/2021Document1 pageProject 1 7/5/2021Zeyad A AbdullahNo ratings yet

- List of Glassware Used in Pharmaceuticals - PharmaguidelineDocument4 pagesList of Glassware Used in Pharmaceuticals - PharmaguidelineZeyad A AbdullahNo ratings yet

- Catalogue Tablet-Press 2019 V3Document16 pagesCatalogue Tablet-Press 2019 V3Zeyad A AbdullahNo ratings yet

- Us Cleanroom Standards CompliancewireDocument1 pageUs Cleanroom Standards CompliancewireZeyad A AbdullahNo ratings yet

- IndJPhaEdRes 54 3s s473Document12 pagesIndJPhaEdRes 54 3s s473Zeyad A AbdullahNo ratings yet

- Tube Filling and Sealing Machine Lab ModelDocument5 pagesTube Filling and Sealing Machine Lab ModelZeyad A AbdullahNo ratings yet

- PortaFab Mezzanine BrochureDocument2 pagesPortaFab Mezzanine BrochureZeyad A AbdullahNo ratings yet

- Ludipress Technical InformationDocument8 pagesLudipress Technical InformationZeyad A AbdullahNo ratings yet

- Product MonographDocument31 pagesProduct MonographZeyad A AbdullahNo ratings yet

- Good Practice Manufacturing Operation SampleDocument21 pagesGood Practice Manufacturing Operation SampleZeyad A AbdullahNo ratings yet

- Sodium Stearyl Fumarate Excipient Pubchem 1559559385Document2 pagesSodium Stearyl Fumarate Excipient Pubchem 1559559385Zeyad A AbdullahNo ratings yet

- GMP Clearance GuidanceDocument84 pagesGMP Clearance GuidanceZeyad A AbdullahNo ratings yet

- Tech Bulletin - Suglets - More Than MonographDocument2 pagesTech Bulletin - Suglets - More Than MonographZeyad A AbdullahNo ratings yet

- S 065 LBLDocument10 pagesS 065 LBLZeyad A AbdullahNo ratings yet

- Crosslinked Povidone Pubchem 1482747992Document4 pagesCrosslinked Povidone Pubchem 1482747992Zeyad A AbdullahNo ratings yet

- What Is Environmental Monitoring in Pharmaceutical IndustryDocument12 pagesWhat Is Environmental Monitoring in Pharmaceutical IndustryZeyad A AbdullahNo ratings yet

- 09 Nov 2016 180959770P8GWIJNEANNEXUREDocument2 pages09 Nov 2016 180959770P8GWIJNEANNEXUREZeyad A AbdullahNo ratings yet

- Lecture 4Document22 pagesLecture 4SUNDAS FATIMANo ratings yet

- Microsoft Word - ETERSET 2960-2 - MSDSDocument5 pagesMicrosoft Word - ETERSET 2960-2 - MSDSWinsonLimHuiWahNo ratings yet

- Material Sub Group Item CodeDocument2,818 pagesMaterial Sub Group Item Codegouri gouriNo ratings yet

- Phason FHC1D User ManualDocument16 pagesPhason FHC1D User Manuale-ComfortUSANo ratings yet

- Rice Sector PACRA - 1604759631Document29 pagesRice Sector PACRA - 1604759631Huzefa SarayiNo ratings yet

- PROJECT On Tea LeavesDocument15 pagesPROJECT On Tea LeavesBharat Singh83% (6)

- Cavitation Models in PIPENETDocument3 pagesCavitation Models in PIPENETSamarth PawarNo ratings yet

- Exploded View & Parts Listing Air Operated Double Diaphragm PumpDocument3 pagesExploded View & Parts Listing Air Operated Double Diaphragm PumpEdgar NercarNo ratings yet

- Module 7Document11 pagesModule 7Arlyn DatuinNo ratings yet

- Compact Evaporators: New Buffalo Trident GaccDocument16 pagesCompact Evaporators: New Buffalo Trident GaccPreeti gulatiNo ratings yet

- Neon NagaramDocument235 pagesNeon NagaramShammeer0% (1)

- Case Study Booklet 2 PDFDocument43 pagesCase Study Booklet 2 PDFguddu yadavNo ratings yet

- A Review On Ultra High Performance Concrete Part II. Hydration, Microstructure and Properties PDFDocument10 pagesA Review On Ultra High Performance Concrete Part II. Hydration, Microstructure and Properties PDFNocifLyesNo ratings yet

- Starkville Dispatch Eedition 7-29-20Document16 pagesStarkville Dispatch Eedition 7-29-20The DispatchNo ratings yet

- DPP 02 NTSE BY @class - 10 - MaterialsDocument1 pageDPP 02 NTSE BY @class - 10 - MaterialsShashwat MishraNo ratings yet

- Science G7 Q2 LP4Document13 pagesScience G7 Q2 LP4Lovely GuintoNo ratings yet

- Environmental Geotechniques: Theories of Ion ExchangeDocument21 pagesEnvironmental Geotechniques: Theories of Ion ExchangeTenkurala srujanaNo ratings yet

- Test Bank For The Practice of Statistics in The Life Sciences 4th Edition Brigitte BaldiDocument23 pagesTest Bank For The Practice of Statistics in The Life Sciences 4th Edition Brigitte BaldiDebra Franken100% (31)

- Re 51400Document14 pagesRe 51400Jamin Smtpng0% (1)

- MAC-LAB Assistant 5BDocument38 pagesMAC-LAB Assistant 5BAbdelhakszn SznNo ratings yet

- Drug Ana Surgery WardDocument11 pagesDrug Ana Surgery WardJames QuilingNo ratings yet

- IFU Acticor 439128-F EsDocument143 pagesIFU Acticor 439128-F EsMartin ArrietaNo ratings yet

- Criticism Herzberg TheoryDocument3 pagesCriticism Herzberg TheoryCaroline NerbasNo ratings yet

- Material HPLCDocument19 pagesMaterial HPLCIsmil ImamaNo ratings yet

- 00000102Document108 pages00000102Scary CreaturesNo ratings yet