Professional Documents

Culture Documents

SEFIC Master Page

SEFIC Master Page

Uploaded by

Macromedica MacromedicaCopyright:

Available Formats

You might also like

- Page 1 of 6: Test Certificate No. 0000052877Document6 pagesPage 1 of 6: Test Certificate No. 0000052877panduranganraghurama78% (9)

- PQR 014 (Qualified Sa 106 GR BDocument5 pagesPQR 014 (Qualified Sa 106 GR Bersenthil100% (1)

- Valvulas de Compuerta 3-4 X 800Document3 pagesValvulas de Compuerta 3-4 X 800danielsalcedomringenierosNo ratings yet

- 026 To 033test ReportsDocument40 pages026 To 033test ReportsRahul MoottolikandyNo ratings yet

- nITP For Suspenion Hanger Pin Alt 2Document4 pagesnITP For Suspenion Hanger Pin Alt 2ABHISHEK KUMARNo ratings yet

- NEMA Gasket Aging - 105-AdvanceDocument8 pagesNEMA Gasket Aging - 105-AdvancerkcNo ratings yet

- Test Certificate: CM/L-NO:5530357Document2 pagesTest Certificate: CM/L-NO:5530357pranav kariaNo ratings yet

- Procedure Qualification Record (PQR) Khewari Development ProjectDocument2 pagesProcedure Qualification Record (PQR) Khewari Development Projectsar sarNo ratings yet

- MECH-REC 324 - Welder-Approval-Test-Report 2inches Uddin MD SalaDocument1 pageMECH-REC 324 - Welder-Approval-Test-Report 2inches Uddin MD SalatinzarmoeNo ratings yet

- Cal. Cert.-Sieves, Flakiness & Elongation Gauge (Alif Engg.Document4 pagesCal. Cert.-Sieves, Flakiness & Elongation Gauge (Alif Engg.OMAR MUKTHAR JAMAL MOHAMEDNo ratings yet

- Ydf Globo 1 PDFDocument3 pagesYdf Globo 1 PDFArnoldo Huertas garzonNo ratings yet

- Page 2 of 6: Test Certificate No. 0000052877Document1 pagePage 2 of 6: Test Certificate No. 0000052877pranesh kadam100% (2)

- Valvula de Bola-3-4 - CBG027595Document2 pagesValvula de Bola-3-4 - CBG027595danielsalcedomringenierosNo ratings yet

- Sir - Tds.taishanc - csm.EB 450GDocument1 pageSir - Tds.taishanc - csm.EB 450GAbdullah SahlyNo ratings yet

- M.E.Forge Tech: Customer:M/s L & T Valves LimitedDocument1 pageM.E.Forge Tech: Customer:M/s L & T Valves LimitedK.s. Raghavendra KumarNo ratings yet

- MS Sheets MTCDocument6 pagesMS Sheets MTCAmit Kumar OjhaNo ratings yet

- Purchase Spec. For Fittings (Sa815 Uns S31803)Document5 pagesPurchase Spec. For Fittings (Sa815 Uns S31803)Daison PaulNo ratings yet

- Transformer Test ReportDocument46 pagesTransformer Test ReportAkshay GatkalNo ratings yet

- CHECKLIST - FORK LIFT UpdatedDocument4 pagesCHECKLIST - FORK LIFT UpdatedAkhilNo ratings yet

- Weld ElectrodesDocument42 pagesWeld ElectrodesNarendraNo ratings yet

- RR3-3269 Eo1352Document2 pagesRR3-3269 Eo1352Deepak HoleNo ratings yet

- Fl10124 r33 Ae 2022-12-16 Final Er Gaf Asphalt Shingles Fl10124-r33 Installation-MethodDocument7 pagesFl10124 r33 Ae 2022-12-16 Final Er Gaf Asphalt Shingles Fl10124-r33 Installation-MethodIrene BorgesNo ratings yet

- Fme Mesaieed MTC 1103Document1 pageFme Mesaieed MTC 1103KyNo ratings yet

- Star Tube A5532-A5534 Igc.Document3 pagesStar Tube A5532-A5534 Igc.पवन द्विवेदीNo ratings yet

- 40SPAA-01 (8 Files Merged)Document143 pages40SPAA-01 (8 Files Merged)Navaneeth NagarajanNo ratings yet

- (WWW - Dillinger.de/certificate) : DNV GL Cert. No. 33-11582 IDHHDocument4 pages(WWW - Dillinger.de/certificate) : DNV GL Cert. No. 33-11582 IDHHDhanush NairNo ratings yet

- MIR - TankDocument10 pagesMIR - TankanandNo ratings yet

- Hojas de Cálcuo - PO-040 - ReviewedDocument86 pagesHojas de Cálcuo - PO-040 - Reviewedjuniuni18No ratings yet

- Globe 0.5in Up To 1.5in-Valve Spec - YTAN5 - R1Document4 pagesGlobe 0.5in Up To 1.5in-Valve Spec - YTAN5 - R1Ammanda ErnawanNo ratings yet

- 375 - 50WT Cat 3Document2 pages375 - 50WT Cat 3ATF PrécisionNo ratings yet

- BSEN 10204 Test Certificate 3.2 For CT-293Document15 pagesBSEN 10204 Test Certificate 3.2 For CT-293Anonymous FHkX0ANo ratings yet

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- XQT190001050101 HTHDocument10 pagesXQT190001050101 HTHvalveNo ratings yet

- Test Certificate: Zhejiang Huaxia Flow Technology Co.,LtdDocument1 pageTest Certificate: Zhejiang Huaxia Flow Technology Co.,LtdjohnjaricocNo ratings yet

- Test ReportDocument9 pagesTest ReportAlberto Aleman AquinoNo ratings yet

- Inspection Certificate Tl-23123Document28 pagesInspection Certificate Tl-23123rahuldhawale46No ratings yet

- Inspection Certificate Tl-23123Document28 pagesInspection Certificate Tl-23123rahuldhawale46No ratings yet

- Inspection Certificate Tl-23123Document28 pagesInspection Certificate Tl-23123rahuldhawale46No ratings yet

- Inspection Certificate Tl-23123Document28 pagesInspection Certificate Tl-23123rahuldhawale46No ratings yet

- Specification Main PartsDocument8 pagesSpecification Main PartsvalveNo ratings yet

- KLJ Hdpe BK 9606 Arat AratDocument1 pageKLJ Hdpe BK 9606 Arat AratDinesh SinghNo ratings yet

- 0707711343Document2 pages0707711343venkata krishna reddy MorthlaNo ratings yet

- 2037-PL-PL-0058-IR-T-014 Dated 10.12.19Document16 pages2037-PL-PL-0058-IR-T-014 Dated 10.12.19Dadaso Baburao Jamdar100% (1)

- Jindal Industries Pvt. Limited: Offer List/Sampling Plan (As Per ASTM A53/Approved QAP)Document7 pagesJindal Industries Pvt. Limited: Offer List/Sampling Plan (As Per ASTM A53/Approved QAP)Vikas Mani TripathiNo ratings yet

- Mill Test Certificate: Run Date 12/07/2018 OR0019M - JAZ User ID E1037Document1 pageMill Test Certificate: Run Date 12/07/2018 OR0019M - JAZ User ID E1037yugandhar100% (3)

- 516 GR70Document1 page516 GR70Artish PadaiyaNo ratings yet

- Aes Lab Qra Tories (P) Lti2: Analyzing Today FBR An Assured TomorrowDocument1 pageAes Lab Qra Tories (P) Lti2: Analyzing Today FBR An Assured TomorrowShreyansh SinghNo ratings yet

- Green Pipes Factory: Plastic Fittings-HDPE FABRICATED BUTT WELDDocument1 pageGreen Pipes Factory: Plastic Fittings-HDPE FABRICATED BUTT WELDmohd hyderNo ratings yet

- IndexDocument19 pagesIndexVishal Kanase(KCPL)No ratings yet

- 074 - ANPAM EnggDocument1 page074 - ANPAM EnggvinuNo ratings yet

- Hardox 450 T12Document1 pageHardox 450 T12RestuNo ratings yet

- MPS Sa-789 S31803 Rev0Document2 pagesMPS Sa-789 S31803 Rev0rabiprasad.iispl.comletedNo ratings yet

- Purchase Spec. For Pipes (Sa790)Document5 pagesPurchase Spec. For Pipes (Sa790)Daison PaulNo ratings yet

- Stress Calculation Stress Engineering Cover SheetDocument7 pagesStress Calculation Stress Engineering Cover SheetPappu Kishore KumarNo ratings yet

- Gpti Qicl J931 Mut 019Document3 pagesGpti Qicl J931 Mut 019uselessinstaid52No ratings yet

- PURCHASE SPEC. FOR PLATES-CLADDED (SA266 Gr.2 + S31803)Document6 pagesPURCHASE SPEC. FOR PLATES-CLADDED (SA266 Gr.2 + S31803)Daison PaulNo ratings yet

- Eb - 1977 - 2Document7 pagesEb - 1977 - 2sami maNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOarhamenterprises5401No ratings yet

- For Construction: Reliance Bangladesh LNG & Power LimitedDocument21 pagesFor Construction: Reliance Bangladesh LNG & Power LimitedCaspian DattaNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Algal BiorefineryDocument16 pagesAlgal BiorefineryONKAR ARORANo ratings yet

- Altig 316L PDFDocument1 pageAltig 316L PDFgst ajahNo ratings yet

- Instruction Manual: Bulletin No. MIE-B4301A Bulletin No. MIE-B4301ADocument33 pagesInstruction Manual: Bulletin No. MIE-B4301A Bulletin No. MIE-B4301AAdi PinemNo ratings yet

- Exercise On Rate of ReactioDocument4 pagesExercise On Rate of ReactiohahaNo ratings yet

- Basic Lost Wax Kilncasting: What This Tipsheet CoversDocument8 pagesBasic Lost Wax Kilncasting: What This Tipsheet CoversAli AhmadNo ratings yet

- Ficha Tecnica Filtro Hp101 Hy-ProDocument3 pagesFicha Tecnica Filtro Hp101 Hy-Projucergue16No ratings yet

- Aqua Ammonia PropertiesDocument0 pagesAqua Ammonia Propertieszeeshanahmad111No ratings yet

- MsdsDocument5 pagesMsdsJaka DwiraNo ratings yet

- Separation of Ethanol-Water Using Benzene As Entrainer: BackgroundDocument2 pagesSeparation of Ethanol-Water Using Benzene As Entrainer: BackgroundRushikesh uNo ratings yet

- Spectramax Quickdrop Uv Vis SpectrophotometerDocument5 pagesSpectramax Quickdrop Uv Vis SpectrophotometerDeepakrao Bornare PatilNo ratings yet

- Thixon Technical GuideDocument8 pagesThixon Technical GuideMohamed BendoudouchNo ratings yet

- Experiment 4Document3 pagesExperiment 4Siti Rahmah YahyaNo ratings yet

- SOP - Standard Operating Procedure For Manual Dispensing SystemsDocument82 pagesSOP - Standard Operating Procedure For Manual Dispensing Systemsrsmbgss575No ratings yet

- Dehydration Pervaporation of Ethyl Acetate-Water Mixture Via Sago/Pva Composite Membranes Using Response Surface MethodologyDocument6 pagesDehydration Pervaporation of Ethyl Acetate-Water Mixture Via Sago/Pva Composite Membranes Using Response Surface MethodologyJeff Gomez PerezNo ratings yet

- Chapter 8Document4 pagesChapter 8Clare ChenNo ratings yet

- HPLC - Back To BasicsDocument38 pagesHPLC - Back To Basicsmonday125No ratings yet

- Sfa-5.01 Filler Metal Procurement GuidelinesDocument10 pagesSfa-5.01 Filler Metal Procurement GuidelinesCesar Agustin LimousinNo ratings yet

- CSAT 2019 - Begg - Henry PDFDocument28 pagesCSAT 2019 - Begg - Henry PDFdocturboNo ratings yet

- Sumit CV 2019Document2 pagesSumit CV 2019Sumit SainiNo ratings yet

- Elephant ToothpasteDocument3 pagesElephant ToothpasteRobinGintingNo ratings yet

- CHAPTER 2 (Partial) : - Notation and TerminologyDocument16 pagesCHAPTER 2 (Partial) : - Notation and TerminologyxavierlthNo ratings yet

- Nitrogen N-5050 FillingDocument2 pagesNitrogen N-5050 FillingApriyan Tri KusumaNo ratings yet

- Multigas Air Quality Monitor: Environment TechnologiesDocument2 pagesMultigas Air Quality Monitor: Environment TechnologiesMichael MangadaNo ratings yet

- BCH 312 Carbohydrate Metabolsim (DR OSSAI)Document8 pagesBCH 312 Carbohydrate Metabolsim (DR OSSAI)maryjanenzubechukwu901No ratings yet

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument16 pagesSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingEdson Henderson De SilvaNo ratings yet

- Reference BooksDocument3 pagesReference BooksCalinescu Ionut-catalinNo ratings yet

- 18-10-2020 - SR - Super60 - Jee-Adv (2016-P1) - PTA-01 - Question Paper PDFDocument22 pages18-10-2020 - SR - Super60 - Jee-Adv (2016-P1) - PTA-01 - Question Paper PDFParthuNo ratings yet

- The Impact of Different Lactic Acid Bacteria Sourdoughs On The Quality Characteristics of Toast BreadDocument12 pagesThe Impact of Different Lactic Acid Bacteria Sourdoughs On The Quality Characteristics of Toast BreadmaurodiloretoNo ratings yet

- Analisis ProteinDocument52 pagesAnalisis ProteinTabetaP.Rosemayanti100% (1)

- Welding Machine - Project ReportDocument62 pagesWelding Machine - Project ReportTanvi KhuranaNo ratings yet

SEFIC Master Page

SEFIC Master Page

Uploaded by

Macromedica MacromedicaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SEFIC Master Page

SEFIC Master Page

Uploaded by

Macromedica MacromedicaCopyright:

Available Formats

Report No.

:US/SEFIC 3AL-22311

AUTHORIZED TESTING INC.

RIVERSIDE, CALIFORNIA USA

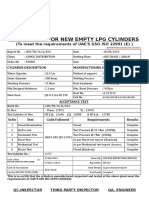

CERTIFICATE OF COMPLIANCE & TEST REPORT - SEAMLESS CYLINDERS

Manufactured under U.S. Department of Transportation

CYLINDER DESCRIPTION AND DESIGN CRITERIA:

Specification: DOT-3AL Service Pressure: 2015psig / 139bar

Cylinder Size: 4.375 in./ 111mm O.D. x 25.63in./ 651mm Long Test Pressure: 3365psig / 232bar

Minimum Volumetric Capacity: 277.7in.3 (4.55 L) Minimum Wall: 0.2in. / 5.08mm

Drawing No.:232G-2 Calculated Stress @ TP: 31574psig / 218N/mm2

MANUFACTURING PROCESS:

Construction: Hot forming shoulder and neck on the open end of an aluminum seamless impacted shell.

MATERIAL AND HEAT TREATMENT: AA6061 Heat treatment, quenching, and artificial

precipitation aging treatment to a “T6” temper.

Quantity: 300

REPORT DETAILS AND MARKINGS ON CYLINDERS:

Test Date: 5-2023

Serial Number Range: UG203401 thru UG203700 Inclusive

Heat No. or Code: 220928B2

Identifying Symbol: M 0814 Lot Numbers: LK/117~LK/118

Markings: Inspector’s

DOT-3AL2015 XXXXXXXXX M0814 12 22 SEFIC Mark:

CONSIGNED TO:

I hereby certify that I have determined that cylinders described on this report comply with the

requirements of U.S. Department of Transportation 3AL.

Remarks:

Signed:

Li De Qing

Authorized Testing Inc.

Date: May. 14, 2023

Report No.:US/SEFIC 3AL-22311

AUTHORIZED TESTING INC.

RIVERSIDE, CALIFORNIA USA

Serial Number Range: UG203401 thru UG203700 Inclusive

Cylinder Size: 4.375 in./ 111mm O.D. x 25.63in./ 651mm Long

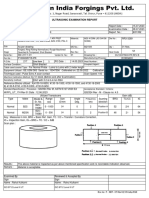

RECORD OF CHEMICAL ANALYSIS OF MATERIAL FOR CYLINDERS

Chemical Analysis for 6061 Aluminum

Other

Heat and/ Type of

each total

Code No. Analysis Cu Si Fe Mn Mg Zn Ti Cr Pb Bi Al

220928B2 Ladle 0.308 0.659 0.327 0.123 1.021 0.0073 0.0269 0.0885 0.0005 0.001 <0.05 <0.15 97.37

U116 Check 0.3011 0.6455 0.325 0.1055 1.0164 <0.0336 0.0252 0.0859 0.0006 0.0008 ≤0.05 ≤0.15 97.3864

Material Manufacturer: Suzhou MingHeng Metal Technology CO.,LTD

The above analyses have been verified to comply with material authorized by the specification.

Signed:

Li De Qing

Authorized Testing Inc.

Date: May. 14, 2023

Report No.:US/SEFIC 3AL-22311

AUTHORIZED TESTING INC.

RIVERSIDE, CALIFORNIA USA

RECORD OF PHYSICAL TESTS OF MATERIAL FOR CYLINDERS

Type of Heat Treatment: Heat treatment, quenching, and artificial precipitation aging treatment to a “T6” temper.

Cylinders Yield Tensile Elongation Flattening

Lot Sub-lot

Represented Strength Strength % Test

No. No. 2 2

Serial Numbers psig N/mm psig N/mm in 2 inch 9t

49155 339 54085 373 14.0

LK/117 LK/117 UG 203401 thru UG 203600 Pass

48430 334 53505 369 14.0

45095 311 50170 346 14.0

LK/118 LK/118 UG 203601 thru UG 203700 Pass

44515 307 49880 344 17.5

Signed:

Li De Qing

Authorized Testing Inc.

Date: May. 14, 2023

You might also like

- Page 1 of 6: Test Certificate No. 0000052877Document6 pagesPage 1 of 6: Test Certificate No. 0000052877panduranganraghurama78% (9)

- PQR 014 (Qualified Sa 106 GR BDocument5 pagesPQR 014 (Qualified Sa 106 GR Bersenthil100% (1)

- Valvulas de Compuerta 3-4 X 800Document3 pagesValvulas de Compuerta 3-4 X 800danielsalcedomringenierosNo ratings yet

- 026 To 033test ReportsDocument40 pages026 To 033test ReportsRahul MoottolikandyNo ratings yet

- nITP For Suspenion Hanger Pin Alt 2Document4 pagesnITP For Suspenion Hanger Pin Alt 2ABHISHEK KUMARNo ratings yet

- NEMA Gasket Aging - 105-AdvanceDocument8 pagesNEMA Gasket Aging - 105-AdvancerkcNo ratings yet

- Test Certificate: CM/L-NO:5530357Document2 pagesTest Certificate: CM/L-NO:5530357pranav kariaNo ratings yet

- Procedure Qualification Record (PQR) Khewari Development ProjectDocument2 pagesProcedure Qualification Record (PQR) Khewari Development Projectsar sarNo ratings yet

- MECH-REC 324 - Welder-Approval-Test-Report 2inches Uddin MD SalaDocument1 pageMECH-REC 324 - Welder-Approval-Test-Report 2inches Uddin MD SalatinzarmoeNo ratings yet

- Cal. Cert.-Sieves, Flakiness & Elongation Gauge (Alif Engg.Document4 pagesCal. Cert.-Sieves, Flakiness & Elongation Gauge (Alif Engg.OMAR MUKTHAR JAMAL MOHAMEDNo ratings yet

- Ydf Globo 1 PDFDocument3 pagesYdf Globo 1 PDFArnoldo Huertas garzonNo ratings yet

- Page 2 of 6: Test Certificate No. 0000052877Document1 pagePage 2 of 6: Test Certificate No. 0000052877pranesh kadam100% (2)

- Valvula de Bola-3-4 - CBG027595Document2 pagesValvula de Bola-3-4 - CBG027595danielsalcedomringenierosNo ratings yet

- Sir - Tds.taishanc - csm.EB 450GDocument1 pageSir - Tds.taishanc - csm.EB 450GAbdullah SahlyNo ratings yet

- M.E.Forge Tech: Customer:M/s L & T Valves LimitedDocument1 pageM.E.Forge Tech: Customer:M/s L & T Valves LimitedK.s. Raghavendra KumarNo ratings yet

- MS Sheets MTCDocument6 pagesMS Sheets MTCAmit Kumar OjhaNo ratings yet

- Purchase Spec. For Fittings (Sa815 Uns S31803)Document5 pagesPurchase Spec. For Fittings (Sa815 Uns S31803)Daison PaulNo ratings yet

- Transformer Test ReportDocument46 pagesTransformer Test ReportAkshay GatkalNo ratings yet

- CHECKLIST - FORK LIFT UpdatedDocument4 pagesCHECKLIST - FORK LIFT UpdatedAkhilNo ratings yet

- Weld ElectrodesDocument42 pagesWeld ElectrodesNarendraNo ratings yet

- RR3-3269 Eo1352Document2 pagesRR3-3269 Eo1352Deepak HoleNo ratings yet

- Fl10124 r33 Ae 2022-12-16 Final Er Gaf Asphalt Shingles Fl10124-r33 Installation-MethodDocument7 pagesFl10124 r33 Ae 2022-12-16 Final Er Gaf Asphalt Shingles Fl10124-r33 Installation-MethodIrene BorgesNo ratings yet

- Fme Mesaieed MTC 1103Document1 pageFme Mesaieed MTC 1103KyNo ratings yet

- Star Tube A5532-A5534 Igc.Document3 pagesStar Tube A5532-A5534 Igc.पवन द्विवेदीNo ratings yet

- 40SPAA-01 (8 Files Merged)Document143 pages40SPAA-01 (8 Files Merged)Navaneeth NagarajanNo ratings yet

- (WWW - Dillinger.de/certificate) : DNV GL Cert. No. 33-11582 IDHHDocument4 pages(WWW - Dillinger.de/certificate) : DNV GL Cert. No. 33-11582 IDHHDhanush NairNo ratings yet

- MIR - TankDocument10 pagesMIR - TankanandNo ratings yet

- Hojas de Cálcuo - PO-040 - ReviewedDocument86 pagesHojas de Cálcuo - PO-040 - Reviewedjuniuni18No ratings yet

- Globe 0.5in Up To 1.5in-Valve Spec - YTAN5 - R1Document4 pagesGlobe 0.5in Up To 1.5in-Valve Spec - YTAN5 - R1Ammanda ErnawanNo ratings yet

- 375 - 50WT Cat 3Document2 pages375 - 50WT Cat 3ATF PrécisionNo ratings yet

- BSEN 10204 Test Certificate 3.2 For CT-293Document15 pagesBSEN 10204 Test Certificate 3.2 For CT-293Anonymous FHkX0ANo ratings yet

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- XQT190001050101 HTHDocument10 pagesXQT190001050101 HTHvalveNo ratings yet

- Test Certificate: Zhejiang Huaxia Flow Technology Co.,LtdDocument1 pageTest Certificate: Zhejiang Huaxia Flow Technology Co.,LtdjohnjaricocNo ratings yet

- Test ReportDocument9 pagesTest ReportAlberto Aleman AquinoNo ratings yet

- Inspection Certificate Tl-23123Document28 pagesInspection Certificate Tl-23123rahuldhawale46No ratings yet

- Inspection Certificate Tl-23123Document28 pagesInspection Certificate Tl-23123rahuldhawale46No ratings yet

- Inspection Certificate Tl-23123Document28 pagesInspection Certificate Tl-23123rahuldhawale46No ratings yet

- Inspection Certificate Tl-23123Document28 pagesInspection Certificate Tl-23123rahuldhawale46No ratings yet

- Specification Main PartsDocument8 pagesSpecification Main PartsvalveNo ratings yet

- KLJ Hdpe BK 9606 Arat AratDocument1 pageKLJ Hdpe BK 9606 Arat AratDinesh SinghNo ratings yet

- 0707711343Document2 pages0707711343venkata krishna reddy MorthlaNo ratings yet

- 2037-PL-PL-0058-IR-T-014 Dated 10.12.19Document16 pages2037-PL-PL-0058-IR-T-014 Dated 10.12.19Dadaso Baburao Jamdar100% (1)

- Jindal Industries Pvt. Limited: Offer List/Sampling Plan (As Per ASTM A53/Approved QAP)Document7 pagesJindal Industries Pvt. Limited: Offer List/Sampling Plan (As Per ASTM A53/Approved QAP)Vikas Mani TripathiNo ratings yet

- Mill Test Certificate: Run Date 12/07/2018 OR0019M - JAZ User ID E1037Document1 pageMill Test Certificate: Run Date 12/07/2018 OR0019M - JAZ User ID E1037yugandhar100% (3)

- 516 GR70Document1 page516 GR70Artish PadaiyaNo ratings yet

- Aes Lab Qra Tories (P) Lti2: Analyzing Today FBR An Assured TomorrowDocument1 pageAes Lab Qra Tories (P) Lti2: Analyzing Today FBR An Assured TomorrowShreyansh SinghNo ratings yet

- Green Pipes Factory: Plastic Fittings-HDPE FABRICATED BUTT WELDDocument1 pageGreen Pipes Factory: Plastic Fittings-HDPE FABRICATED BUTT WELDmohd hyderNo ratings yet

- IndexDocument19 pagesIndexVishal Kanase(KCPL)No ratings yet

- 074 - ANPAM EnggDocument1 page074 - ANPAM EnggvinuNo ratings yet

- Hardox 450 T12Document1 pageHardox 450 T12RestuNo ratings yet

- MPS Sa-789 S31803 Rev0Document2 pagesMPS Sa-789 S31803 Rev0rabiprasad.iispl.comletedNo ratings yet

- Purchase Spec. For Pipes (Sa790)Document5 pagesPurchase Spec. For Pipes (Sa790)Daison PaulNo ratings yet

- Stress Calculation Stress Engineering Cover SheetDocument7 pagesStress Calculation Stress Engineering Cover SheetPappu Kishore KumarNo ratings yet

- Gpti Qicl J931 Mut 019Document3 pagesGpti Qicl J931 Mut 019uselessinstaid52No ratings yet

- PURCHASE SPEC. FOR PLATES-CLADDED (SA266 Gr.2 + S31803)Document6 pagesPURCHASE SPEC. FOR PLATES-CLADDED (SA266 Gr.2 + S31803)Daison PaulNo ratings yet

- Eb - 1977 - 2Document7 pagesEb - 1977 - 2sami maNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOarhamenterprises5401No ratings yet

- For Construction: Reliance Bangladesh LNG & Power LimitedDocument21 pagesFor Construction: Reliance Bangladesh LNG & Power LimitedCaspian DattaNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Algal BiorefineryDocument16 pagesAlgal BiorefineryONKAR ARORANo ratings yet

- Altig 316L PDFDocument1 pageAltig 316L PDFgst ajahNo ratings yet

- Instruction Manual: Bulletin No. MIE-B4301A Bulletin No. MIE-B4301ADocument33 pagesInstruction Manual: Bulletin No. MIE-B4301A Bulletin No. MIE-B4301AAdi PinemNo ratings yet

- Exercise On Rate of ReactioDocument4 pagesExercise On Rate of ReactiohahaNo ratings yet

- Basic Lost Wax Kilncasting: What This Tipsheet CoversDocument8 pagesBasic Lost Wax Kilncasting: What This Tipsheet CoversAli AhmadNo ratings yet

- Ficha Tecnica Filtro Hp101 Hy-ProDocument3 pagesFicha Tecnica Filtro Hp101 Hy-Projucergue16No ratings yet

- Aqua Ammonia PropertiesDocument0 pagesAqua Ammonia Propertieszeeshanahmad111No ratings yet

- MsdsDocument5 pagesMsdsJaka DwiraNo ratings yet

- Separation of Ethanol-Water Using Benzene As Entrainer: BackgroundDocument2 pagesSeparation of Ethanol-Water Using Benzene As Entrainer: BackgroundRushikesh uNo ratings yet

- Spectramax Quickdrop Uv Vis SpectrophotometerDocument5 pagesSpectramax Quickdrop Uv Vis SpectrophotometerDeepakrao Bornare PatilNo ratings yet

- Thixon Technical GuideDocument8 pagesThixon Technical GuideMohamed BendoudouchNo ratings yet

- Experiment 4Document3 pagesExperiment 4Siti Rahmah YahyaNo ratings yet

- SOP - Standard Operating Procedure For Manual Dispensing SystemsDocument82 pagesSOP - Standard Operating Procedure For Manual Dispensing Systemsrsmbgss575No ratings yet

- Dehydration Pervaporation of Ethyl Acetate-Water Mixture Via Sago/Pva Composite Membranes Using Response Surface MethodologyDocument6 pagesDehydration Pervaporation of Ethyl Acetate-Water Mixture Via Sago/Pva Composite Membranes Using Response Surface MethodologyJeff Gomez PerezNo ratings yet

- Chapter 8Document4 pagesChapter 8Clare ChenNo ratings yet

- HPLC - Back To BasicsDocument38 pagesHPLC - Back To Basicsmonday125No ratings yet

- Sfa-5.01 Filler Metal Procurement GuidelinesDocument10 pagesSfa-5.01 Filler Metal Procurement GuidelinesCesar Agustin LimousinNo ratings yet

- CSAT 2019 - Begg - Henry PDFDocument28 pagesCSAT 2019 - Begg - Henry PDFdocturboNo ratings yet

- Sumit CV 2019Document2 pagesSumit CV 2019Sumit SainiNo ratings yet

- Elephant ToothpasteDocument3 pagesElephant ToothpasteRobinGintingNo ratings yet

- CHAPTER 2 (Partial) : - Notation and TerminologyDocument16 pagesCHAPTER 2 (Partial) : - Notation and TerminologyxavierlthNo ratings yet

- Nitrogen N-5050 FillingDocument2 pagesNitrogen N-5050 FillingApriyan Tri KusumaNo ratings yet

- Multigas Air Quality Monitor: Environment TechnologiesDocument2 pagesMultigas Air Quality Monitor: Environment TechnologiesMichael MangadaNo ratings yet

- BCH 312 Carbohydrate Metabolsim (DR OSSAI)Document8 pagesBCH 312 Carbohydrate Metabolsim (DR OSSAI)maryjanenzubechukwu901No ratings yet

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument16 pagesSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingEdson Henderson De SilvaNo ratings yet

- Reference BooksDocument3 pagesReference BooksCalinescu Ionut-catalinNo ratings yet

- 18-10-2020 - SR - Super60 - Jee-Adv (2016-P1) - PTA-01 - Question Paper PDFDocument22 pages18-10-2020 - SR - Super60 - Jee-Adv (2016-P1) - PTA-01 - Question Paper PDFParthuNo ratings yet

- The Impact of Different Lactic Acid Bacteria Sourdoughs On The Quality Characteristics of Toast BreadDocument12 pagesThe Impact of Different Lactic Acid Bacteria Sourdoughs On The Quality Characteristics of Toast BreadmaurodiloretoNo ratings yet

- Analisis ProteinDocument52 pagesAnalisis ProteinTabetaP.Rosemayanti100% (1)

- Welding Machine - Project ReportDocument62 pagesWelding Machine - Project ReportTanvi KhuranaNo ratings yet