Professional Documents

Culture Documents

W15 001S ASME Ahmad Termizi

W15 001S ASME Ahmad Termizi

Uploaded by

HoJienHauOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

W15 001S ASME Ahmad Termizi

W15 001S ASME Ahmad Termizi

Uploaded by

HoJienHauCopyright:

Available Formats

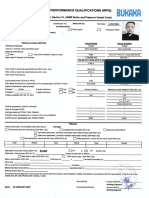

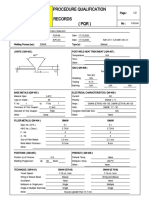

KBVensineerins:ar

FORM OW-'A4A WELDER PERFORMANCE OUAL|F|0AT|ONS {WPO}

(See OW-301, Sestion lX, ASME Boiler and Pressure Vessel Codel

Welder's name Ahmad Termizi bin Mohd Datar ldentification no. 8308230&5669 KBV.W15

Test Oesoiption

ldentificalion of WPS followed '

KBV-WP$0o1S Ehest coupon Eprodr"tion wetd

"

Specification and type/grade or UNS Number of base metal(s) P1G2: SA515 Grade 70 15.90 mm

Thickness

Testing VrriaHcs and Qualifcation Limits

Weldng Variables (QW-3501 Actual Values Range Oualified

Welding process{es} SMAW SMAW

Type (i.e.; manual, semi-automaticl used Manual

Backing (with/without)

SIIAW(VWhorrt) SMAW(WIh or\ tthout)

El Plate I Pipe (enter diameler if pipe or tube] Plate and Pipe

Base metal P-Number to P-Number Pl to P1 P1 to P15F, P34, & P41 to P49 &

unassignad m€aals of similar chernical

compcition to theso motab.

Flller metal F-Number(si SMAW- F4 SMAylI. F4, F3, F2, FI

Filler Metal Form (solidlmetal or flux cored/powder) (GTAW or PAWI

_-lwb"T,t!!r9_ (With or Wthont Backinq)

Deposit thickness for each process

Process I SMAW 3layers minimum fiv"= tr No SttrtAW: 15.9 mm Sl\lAW: Unlimited Thickness

Process 2

Position gualified (2G.6G, 3F, etc.)

n No

Plate & Pipe > 610 mm OD: F,V

Hate & 73mm< PiPe OD <6l0nm: F

Plate & Pipe - Fillet: F,H,V

Vertical progression (uphill or downhill) Uphill Uphill

lnert gas backing {GTAW, PaW, CUaWt

GTAW current typdpolarity (AC, DCEP, DCEN) SMAW- DCEP SMAW- DCEP

RESUTTS

Visual examination of completed weld {OW-302.4} Satis{actav

fiTransverse face and root bends toW-a62.3(all f!

Longitudinal bends [OW-462.3(b]l I SiOe bends (OW-462.2]

eioe bend specimen. corrosion-resistant weld metal overlay IQW-462,5tc)l

!

fr eip" "p""ilJT:::;':1,'i.";liJ;i":,lilil.li;',,"""H"11":T:fffl,l,1:ill;lllirusion row 462 s(el,

Type Resuh Type Resull Type Resuh

Alternalive Volumelric Examination Resulls {OW t9Jl: Satisfac'tory RTfilor UTE (check one]

Fillet weld fracture test (OW-181,2) Length and percent of delects

-

l] ritt"r welds in plare tQW462.4(b)l flritut wetds in pipe toW462.4{c}l

Macro examination {OW- 18zl) Fillel size (in.| ' x ' Concavitylmnvexity (in.)

Other lests

--: evaluated by

Film or specimens Wlson (Report No. :0$02-RT)

Company ETJ lnspec,tion Sdn Bhd

Mechanical tests qtnducted by ' Laboratory test no.

Welding supervised by Ho Jien Hau

We certify that the statemenls in this record are correct and thal the test coupons were prepared, welded. and tested in accordance with the

requirements of Section lX of the ASME BOILER AND PRESSURE VESSEL CODE.

Organizalion KBV Engineering Sdn Bhd

Date 12-02-2016

Cenified by

-

107113',

You might also like

- 37507022-WPS-PQR-SS-316 LDocument5 pages37507022-WPS-PQR-SS-316 LVarun Malhotra100% (6)

- Welding Procedure Specification FormatDocument3 pagesWelding Procedure Specification FormatAnonymous 4e7GNjzGW100% (1)

- WPS 6G CS Pipe CorrectDocument4 pagesWPS 6G CS Pipe CorrectAla ReguiiNo ratings yet

- Welder Test Certificate - CSDocument1 pageWelder Test Certificate - CSPrathamesh Omtech100% (4)

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- Ca6nm WPS/PQRDocument22 pagesCa6nm WPS/PQRDeepak0% (1)

- Welder Performance Qualifications (WPQ) : (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document18 pagesWelder Performance Qualifications (WPQ) : (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)mahendraNo ratings yet

- WPS1Document10 pagesWPS1bhavin178No ratings yet

- Vessel Spec SheetDocument1 pageVessel Spec SheetValiNo ratings yet

- Wpe1.Pp.163 Dandy Mulyana 4gDocument1 pageWpe1.Pp.163 Dandy Mulyana 4gBondet CutaxNo ratings yet

- WPQ Asme IxDocument1 pageWPQ Asme IxEDEN GONZALEZNo ratings yet

- WPQ Sunil Yadav W-13 PQR 003 Smaw - PipeDocument1 pageWPQ Sunil Yadav W-13 PQR 003 Smaw - Pipeharshileng3992100% (1)

- PWPS WPS PQR WPQDocument21 pagesPWPS WPS PQR WPQcsolanki658688% (8)

- Slamet WPQRDocument1 pageSlamet WPQRChandra Bintang W.PNo ratings yet

- SampleDocument5 pagesSample이훈No ratings yet

- Abdul Muhid WPQRDocument1 pageAbdul Muhid WPQRChandra Bintang W.PNo ratings yet

- WPQ Formats NEWDocument4 pagesWPQ Formats NEWMANABENDRA MAITRANo ratings yet

- Welder Performance Qualification (WPQ) According To ASME IX Hassan HussienDocument1 pageWelder Performance Qualification (WPQ) According To ASME IX Hassan HussienMahmoud shawkyNo ratings yet

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- WPQ 006Document1 pageWPQ 006vinuNo ratings yet

- Ocrte-9f2ol WelderDocument1 pageOcrte-9f2ol WelderSAHAJ DIGITAL ZONENo ratings yet

- WPS CuNiDocument4 pagesWPS CuNiSripathyNo ratings yet

- 3.ofis-W-39 - Ofis-Wps-02aDocument3 pages3.ofis-W-39 - Ofis-Wps-02aanandNo ratings yet

- WPQ Format - SMAWDocument3 pagesWPQ Format - SMAWBalkishan DyavanapellyNo ratings yet

- Qw-482 Welding Procedure Specification (WPS)Document3 pagesQw-482 Welding Procedure Specification (WPS)Sagar GourNo ratings yet

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- WPQ WeldCanada PDFDocument1 pageWPQ WeldCanada PDFAhmad DanielNo ratings yet

- Welding Procedure Specification (W.P.S) : Alstom India LimitedDocument2 pagesWelding Procedure Specification (W.P.S) : Alstom India LimitedAhmed saberNo ratings yet

- Screenshot 2023-01-31 at 5.18.21 PMDocument9 pagesScreenshot 2023-01-31 at 5.18.21 PMisanNo ratings yet

- Welder Certificate Akilesh YadavDocument1 pageWelder Certificate Akilesh Yadavtripatipankaj023No ratings yet

- WPS Dissimilar 11.08 MM Max.Document4 pagesWPS Dissimilar 11.08 MM Max.Sripathy50% (2)

- Format WPQDocument2 pagesFormat WPQAkash Singh TomarNo ratings yet

- Acfrogdgjpoczzmyytfkwbkh0koiyebkjw2cygu7mcl7x89emnhqrr79 8h9g0sneqlza Asreuqopw V3yccnxf6wf4ssafjrpko6znwt9uci Enrtbyu8y I2ju68Document6 pagesAcfrogdgjpoczzmyytfkwbkh0koiyebkjw2cygu7mcl7x89emnhqrr79 8h9g0sneqlza Asreuqopw V3yccnxf6wf4ssafjrpko6znwt9uci Enrtbyu8y I2ju68Daniel CamposNo ratings yet

- Amrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Document3 pagesAmrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Balkishan DyavanapellyNo ratings yet

- Toaz - Info Welding Procedure Specification Format PRDocument3 pagesToaz - Info Welding Procedure Specification Format PRKarim ZahranNo ratings yet

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Document2 pages(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- PT - SAE WPS PQR - MIGAS (PGDP) - Unlocked-2Document16 pagesPT - SAE WPS PQR - MIGAS (PGDP) - Unlocked-2Batara SinagaNo ratings yet

- Final - WPS PQR 86Document4 pagesFinal - WPS PQR 86Parag WadekarNo ratings yet

- Welder Performance Qualifications (WPQ) (ASME Boiler and Pressure Vessel Code)Document1 pageWelder Performance Qualifications (WPQ) (ASME Boiler and Pressure Vessel Code)Edinson Herrera VasquezNo ratings yet

- Diamond Engineering (Chennai) PVT LTD.,: Welder Qualification Test RecordDocument1 pageDiamond Engineering (Chennai) PVT LTD.,: Welder Qualification Test Recordmangalraj900No ratings yet

- WPQ Certificates Klis14Document8 pagesWPQ Certificates Klis14AdhicharanNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad MunadiNo ratings yet

- Wps No. 0 Rev. No. 19: Asme Section Ix Welding Procedure SpecificationDocument5 pagesWps No. 0 Rev. No. 19: Asme Section Ix Welding Procedure SpecificationAmit ChapagainNo ratings yet

- Graycor WPS 19 SampleDocument5 pagesGraycor WPS 19 SampleRaul SebastiamNo ratings yet

- Wps PQR FormDocument8 pagesWps PQR Formmayank0738No ratings yet

- Base Metals (Qw-403) Postweld Heat Treatment (Qw-407)Document2 pagesBase Metals (Qw-403) Postweld Heat Treatment (Qw-407)beyNo ratings yet

- RK PWPS PC 001Document2 pagesRK PWPS PC 001SudeepDPoojaryNo ratings yet

- JOINTS (QW-402) : Groove Design of Test CouponDocument2 pagesJOINTS (QW-402) : Groove Design of Test CouponbeyNo ratings yet

- Procedure Qualification Records (PQR) : KAL.f.009 REV:01 01.07.2002Document2 pagesProcedure Qualification Records (PQR) : KAL.f.009 REV:01 01.07.2002Walid BdeirNo ratings yet

- WPS 360-1 Rev0 PDFDocument14 pagesWPS 360-1 Rev0 PDFAhmed GomaaNo ratings yet

- JOINTS (QW-402) : Groove Design of Test CouponDocument2 pagesJOINTS (QW-402) : Groove Design of Test CouponbeyNo ratings yet

- 385 2 Internal Gtaw+SmawDocument2 pages385 2 Internal Gtaw+Smawsubash1688No ratings yet

- Negemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Document3 pagesNegemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Khaled GamalNo ratings yet

- Negemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Document3 pagesNegemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Khaled GamalNo ratings yet

- WQT Form (ASME) 04-23Document1 pageWQT Form (ASME) 04-23hanz bermejoNo ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationAhmed saber100% (2)

- All DocumentsDocument6 pagesAll DocumentsfaezNo ratings yet

- Rajagukguk - 2018 - J. - Phys. - Conf. - Ser. - 970 - 012025Document8 pagesRajagukguk - 2018 - J. - Phys. - Conf. - Ser. - 970 - 012025Dhiya Alfiyyah AnsarNo ratings yet

- Government of Andhra Pradesh Office of The Commissioner of Technical Education Andhrapradesh:Vijayawada Dated:11.07.2022Document3 pagesGovernment of Andhra Pradesh Office of The Commissioner of Technical Education Andhrapradesh:Vijayawada Dated:11.07.2022061 David RajuNo ratings yet

- Language Focus 1. Write The Sentences in The Passive Voice.: Uğur Middle SchoolDocument6 pagesLanguage Focus 1. Write The Sentences in The Passive Voice.: Uğur Middle SchoolÖZGÜR BERK GÜMÜŞNo ratings yet

- How Can I Turn On or Turn Off The Firewall in Windows XP Service Pack 2 or Later VersionsDocument3 pagesHow Can I Turn On or Turn Off The Firewall in Windows XP Service Pack 2 or Later VersionsgurungeNo ratings yet

- FJ Product Data Hydraulic Wiper Seal Beca 485 037253700 1631 08122015Document5 pagesFJ Product Data Hydraulic Wiper Seal Beca 485 037253700 1631 08122015Phan Đức NgọcNo ratings yet

- Role of Government of IndiaDocument5 pagesRole of Government of IndiaJesal PorechaNo ratings yet

- Cooling Only (50Hz) : RR SeriesDocument290 pagesCooling Only (50Hz) : RR SeriesstevenloNo ratings yet

- DSA Prelim PaperDocument1 pageDSA Prelim Papervinayakteli100No ratings yet

- MX RM CameraSoftwareManual en 200131Document557 pagesMX RM CameraSoftwareManual en 200131atalincNo ratings yet

- Acumatica PresentationDocument14 pagesAcumatica PresentationowenNo ratings yet

- FFd20 Skills and FeatsDocument18 pagesFFd20 Skills and FeatsSteampunkObrimosNo ratings yet

- Tekla CSC Fastrak 2018 v18.1.0 - Download Free SoftwareDocument1 pageTekla CSC Fastrak 2018 v18.1.0 - Download Free SoftwareMarvin MessiNo ratings yet

- Combustion of Gaseous and Liquid FuelsDocument2 pagesCombustion of Gaseous and Liquid FuelsLouie G Navalta0% (1)

- SP PresentationDocument15 pagesSP PresentationARGHYA MANDALNo ratings yet

- MIL 2nd Quarterly Exam - 2023Document5 pagesMIL 2nd Quarterly Exam - 2023LUCIENNE S. SOMORAY100% (1)

- Lidle Case StudyDocument7 pagesLidle Case StudyPradeep AnuradhaNo ratings yet

- Judgment and Permanent Injunction - Ubisoft DDoS CaseDocument3 pagesJudgment and Permanent Injunction - Ubisoft DDoS CaseHunter CookeNo ratings yet

- Ruxton & ColegraveDocument26 pagesRuxton & ColegraveLinneaNo ratings yet

- Bancollan PolybanropeDocument3 pagesBancollan PolybanropevietkhamNo ratings yet

- Document 17Document35 pagesDocument 17Weiyi LimNo ratings yet

- EXIT Chart Based Design of LDPC Codes For Higher OrderDocument5 pagesEXIT Chart Based Design of LDPC Codes For Higher Orderchaudhryadnanaslam3799No ratings yet

- DycodeX - SMARTernak - CommDocument42 pagesDycodeX - SMARTernak - CommwijaNo ratings yet

- SINE and COSINEDocument25 pagesSINE and COSINEGehg malaqueNo ratings yet

- Build A Full-Stack App - Ultimate Guide To AWS Amplify With ReactDocument19 pagesBuild A Full-Stack App - Ultimate Guide To AWS Amplify With ReactSayyid ShalahuddinNo ratings yet

- TSR NeuralDocument16 pagesTSR Neuralbt5112 KareenaNo ratings yet

- Persona: Owners ManualDocument32 pagesPersona: Owners ManualCesar PerezNo ratings yet

- ECG DigitizationDocument23 pagesECG Digitizationbt19104028 AshleshaNo ratings yet

- NRF - Air Conditioning Catalog 2015-2016 PDFDocument1,094 pagesNRF - Air Conditioning Catalog 2015-2016 PDFDesmond OeiNo ratings yet