Professional Documents

Culture Documents

3 Young's Modulus Uniform Bending

3 Young's Modulus Uniform Bending

Uploaded by

Gopala krishnanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3 Young's Modulus Uniform Bending

3 Young's Modulus Uniform Bending

Uploaded by

Gopala krishnanCopyright:

Available Formats

Figure 2.

1 Young’s modulus- Uniform bending

Figure 2.2 Model Graph

Department of Physical Sciences, Bannari Amman Institute of Technology, Sathyamangalam 11

Young’s Modulus - Uniform Bending

Expt. No. : Date:

AIM

To find the Young’s modulus of the given material of the beam by uniform bending.

GENERAL OBJECTIVE

To evaluate the elastic behavior of the given wooden beam by pin and microscope

experimental method and to find its Young’s modulus

SPECIFIC OBJECTIVES

1. To measure the thickness and breadth of the given wooden beam using screw gauge

and vernier caliper, respectively

2. To determine the elevation of the given wooden beam loaded on both ends by

uniform bending method

3. To find the slope from the graph drawn between the load versus elevation

4. To calculate the Young’s modulus of the wooden beam from the mean elevation and

slope obtained from table and graph, respectively

5. To analyze the elastic behavior of the given wooden beam from the results obtained

APPARATUS REQUIRED

Wooden beam

Weight hanger with slotted weights

Knife edges

Travelling microscope

Vernier caliper

Screw gauge

Metre scale

Department of Physical Sciences, Bannari Amman Institute of Technology, Sathyamangalam 12

LEAST COUNT FOR SCREW GAUGE

Pitch

Least Count (LC) =

Number of head scale divisions

Distance moved 5 mm

Pitch = = = 1mm

Number of rotations given 5

1 mm

LC = = 0.01mm

100

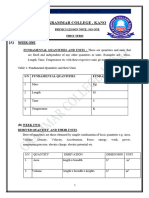

TABLE – I

To determine the thickness (d) of the beam using screw gauge

Zero Error (ZE) : ………. divisions Zero Correction (ZC) : ……….mm

Pitch Scale Head Scale

Observed Reading Correct Reading

S. No. Reading Coincidence

OR = PSR + ( HSC LC ) CR = OR ±ZC

PSR HSC

(10-3 m) ( 10-3 m)

10-3 m divisions

1

Mean (d) = ………. x10-3 m

Department of Physical Sciences, Bannari Amman Institute of Technology, Sathyamangalam 13

FORMULA

Young’s modulus of the material of the beam

3MgaL2

Y (N/m2)

2sbd 3

Symbol Explanation Unit

Y Young’s modulus of the material of the beam N/m2

M Load applied kg

L Distance between the knife edges m

a Distance between the load and the nearest knife edge m

g Acceleration due to gravity m /s2

b Breadth of the beam m

d Thickness of the beam m

s Elevation produced for ‘M’ kg load m

Unit Equivalent Units

N/m2 kg m s-2

-1

1 Pa

PREREQUISITE KNOWLEDGE

1. Elastic materials

Materials which can completely regain their original condition of shape and size on

removal of deforming forces are said to be elastic

2. Plastic materials

Materials which retain the deformed nature even after the removal of deforming

forces are said to be plastic

3. Hooke’s law

Within the elastic limit, the stress is directly proportional to the strain

Department of Physical Sciences, Bannari Amman Institute of Technology, Sathyamangalam 14

LEAST COUNT FOR VERNIER CALIPER

Least Count (LC) = Value of 1 Main Scale Division (MSD)/ Number of

divisions in the vernier

10 MSD = 1 cm

Value of 1 MSD = 1/10 cm = 0.1 cm

Number of divisions in the vernier = 10

LC = 0.1/ 10 = 0.01 cm

TABLE - II

To determine the breadth (b) of the beam using vernier caliper

LC = 0.01 cm Zero Error (ZE): ………. Zero Correction (ZC): ……….

Main Scale Vernier Scale Correct

Observed Reading

Reading Coincidence Reading

S. No. MSR VSC OR = MSR + (VSC × LC)

CR = OR ± ZC

(10-2 m) (divisions) (10-2 m)

(10-2 m)

1

Mean (b) = ………. x 10-2 m

Department of Physical Sciences, Bannari Amman Institute of Technology, Sathyamangalam 15

PROCEDURE

1. The given beam is supported on two knife edges separated by a distance ‘L’.

A pin is fixed vertically at the mid-point.

2. Two weight hangers are suspended, one each on either side of the knife edges so that

their distances from the nearer knife edge are equal. The beam is brought to the

elastic mood by loading and unloading it several times.

3. With the dead load ‘W’, the pin is focused through microscope. The microscope is

adjusted so that the horizontal crosswire coincides with the tip of the pin. The

microscope reading is taken.

4. The load is changed in steps of 0.05 kg and in each case the microscope reading is

taken during loading and unloading. The readings are tabulated. The elevation at the

mid-point for ‘M’ kg is calculated.

5. The distance between the knife edges (L) is measured using a metre scale. The

breadth (b) and thickness (d) of the beam are found using vernier caliper and screw

gauge, respectively.

Department of Physical Sciences, Bannari Amman Institute of Technology, Sathyamangalam 16

LEAST COUNT FOR TRAVELLING MICROSCOPE

Least Count (LC) = Value of 1 Main Scale Division (MSD)/ Number of

divisions in the vernier

20 MSD = 1 cm

Value of 1 MSD = 1/20cm = 0.05 cm

Number of divisions in the vernier = 50

LC = 0.05/50= 0.001 cm

TABLE -III

To find elevation‘s’

LC = 0.001 cm *TR= MSR + (VSC LC)

Microscope reading

Load Elevation

M Loading Unloading ‘s’ for M

(10-3 kg) Mean kg

MSR VSC TR MSR VSC TR ( 10-2 m )

( 10-2 m ) (div) ( 10-2 m ) ( 10-2m ) (div) ( 10-2 m ) ( 10-2 m )

W + 50

W + 100

W + 150

W+ 200

Mean (s) = ………. × 10-2 m

*Note: Total Reading (TR) = Main Scale Reading (MSR) + (VSC LC)

Department of Physical Sciences, Bannari Amman Institute of Technology, Sathyamangalam 17

RESULT

The Young’s modulus of the material of the given beam Y = ………. × 1010 N/m2

APPLICATIONS

AFM probe, wings of air craft, helicopter rotator, marine fittings, designing of bridges,

bicycle frames and wind mill turbine blades

VIVA VOCE QUESTIONS

1. What is the effect of temperature on elastic modulii?

2. Which dimension among breadth, thickness and length has significant role in

Young’s modulus? Why?

3. How do you ensure in your experiment that the elastic limit is not exceeded?

4. What kind of elasticity is observed in (a) suspension bridge (b) an automobile tyre?

STIMULATING QUESTIONS

1. Bridges are declared as unsafe after long use. Reason out.

2. Which one is more elastic, foam or steel? Justify your answer.

Department of Physical Sciences, Bannari Amman Institute of Technology, Sathyamangalam 18

OBSERVATION

Mass for the elevation M = ………. ×10-3 kg

Distance between two knife edges L = ………. ×10-2 m

Acceleration due to gravity g = ………. m / s2

Breadth of the beam b = ………. × 10-2 m

Thickness of the beam d = ………. × 10-3 m

Elevation produced for ‘M’ kg of load s = ………. × 10-2 m

Distance between one of the knife edges and the

adjacent weight hanger a = ………. × 10-2 m

CALCULATION

Young’s modulus of the material of the beam

3MgaL2

Y (N/m2)

2sbd 3

Department of Physical Sciences, Bannari Amman Institute of Technology, Sathyamangalam 19

Department of Physical Sciences, Bannari Amman Institute of Technology, Sathyamangalam 20

You might also like

- Art Commission ContractDocument2 pagesArt Commission Contractapi-274839425No ratings yet

- Sans10086 1 PDFDocument9 pagesSans10086 1 PDFMpho Michael RaphuluNo ratings yet

- Expropriated Properties Discussion in Uganda by Watwali The 111-1Document7 pagesExpropriated Properties Discussion in Uganda by Watwali The 111-1lubogoNo ratings yet

- Young'S Modulus by Non-Uniform Bending Expt - No: Date: AimDocument11 pagesYoung'S Modulus by Non-Uniform Bending Expt - No: Date: AimDhruvesh Mathur100% (1)

- Activity Statement InstructionsDocument159 pagesActivity Statement InstructionsTyron3054100% (1)

- Child Labour Non DoctrinalDocument3 pagesChild Labour Non DoctrinalanoojNo ratings yet

- Crawford Mud Racing Entry Form 1Document3 pagesCrawford Mud Racing Entry Form 1api-288080327No ratings yet

- Harris 1958 Labor and Education in MozambiqueDocument28 pagesHarris 1958 Labor and Education in MozambiquejmmcvNo ratings yet

- Youngs Modulus - Non Uniform BendingDocument5 pagesYoungs Modulus - Non Uniform Bendingdurairajgeetha318No ratings yet

- Young's ModulusDocument8 pagesYoung's ModulusNithish KumarNo ratings yet

- BS8161 Lab ManualDocument37 pagesBS8161 Lab ManualGopi Ganesan100% (1)

- BS8161 Lab Study MaterialDocument26 pagesBS8161 Lab Study MaterialGopi GanesanNo ratings yet

- Youngs ModulusDocument10 pagesYoungs Modulusconnectrix.gohetrixNo ratings yet

- Physics Lab Manual For Mechanical Branches FinalDocument26 pagesPhysics Lab Manual For Mechanical Branches FinalSuresh Kumar A PNo ratings yet

- Physics Lab Manual PDFDocument45 pagesPhysics Lab Manual PDFKRSHNAPRIYA KNo ratings yet

- Physics Expt 3 - Young's ModulusDocument8 pagesPhysics Expt 3 - Young's ModulusDebayan MaitiNo ratings yet

- Laboratory Experiments - PhysicsDocument36 pagesLaboratory Experiments - PhysicsMayank AgarwalNo ratings yet

- II Semester Physics Lab ManualDocument45 pagesII Semester Physics Lab ManualSivalingam Dinesh100% (3)

- VELTECH UNIVERSITY Young's Modulus Non Uniform BendingDocument18 pagesVELTECH UNIVERSITY Young's Modulus Non Uniform Bendingprathyusha100% (13)

- Young - S FLEXURE PDFDocument5 pagesYoung - S FLEXURE PDFprayashkr sahaNo ratings yet

- Bending of Beam - SKS - PDPDocument5 pagesBending of Beam - SKS - PDPVickeyNo ratings yet

- PHY Lab ManualDocument57 pagesPHY Lab ManualswathiNo ratings yet

- BMT Lab ManualDocument75 pagesBMT Lab Manualnenu localNo ratings yet

- Engg. Physics Lab Manual Youngs Modulus SL No 4Document2 pagesEngg. Physics Lab Manual Youngs Modulus SL No 4Jaqueem JamesNo ratings yet

- Physics Lab Manual For PH23132-2023-24 ODD SEMDocument45 pagesPhysics Lab Manual For PH23132-2023-24 ODD SEMradhaiseshNo ratings yet

- Determination of The Thickness of Glass To Test Surface Flatness by Using Michelson InterferometerDocument4 pagesDetermination of The Thickness of Glass To Test Surface Flatness by Using Michelson InterferometerEmmanuelDalesAlquizolaNo ratings yet

- 18MC102Document20 pages18MC102vikii100% (1)

- Expt 13 Plane Transmission GratingDocument3 pagesExpt 13 Plane Transmission GratingIkaNo ratings yet

- 11 TH ExptsDocument5 pages11 TH ExptsViomnath SadatcharamourthyNo ratings yet

- Bdu II Physics Lab BookDocument57 pagesBdu II Physics Lab BookMr V3NOMNo ratings yet

- Physics Laboratory ManualDocument39 pagesPhysics Laboratory ManualselvamNo ratings yet

- Experiment No.1Document4 pagesExperiment No.1SUPER CLASHNo ratings yet

- R WK YOs ADjbn 5 VSL FIv JFDocument15 pagesR WK YOs ADjbn 5 VSL FIv JF9bshrutiyadav16No ratings yet

- Laser Diffraction and InterferenceDocument7 pagesLaser Diffraction and Interferencesamantha rathNo ratings yet

- Resolving Power of Telescope by MR - CharisDocument3 pagesResolving Power of Telescope by MR - CharisCharis Israel Ancha50% (4)

- JEE Advanced Part Test 02B (10.05.2023) - 1 PDFDocument30 pagesJEE Advanced Part Test 02B (10.05.2023) - 1 PDFKunal QumarNo ratings yet

- Physics ManualvvDocument82 pagesPhysics ManualvvkitnamurtyNo ratings yet

- Bs8161 PLM Fy LM IsemDocument42 pagesBs8161 PLM Fy LM IsemIPR100% (1)

- Diffraction Grating (Additional)Document5 pagesDiffraction Grating (Additional)Dr. Deepak GuptaNo ratings yet

- .Trashed-1644798227-39 SESSIONDocument5 pages.Trashed-1644798227-39 SESSIONRakeshNo ratings yet

- Physics Instruction Manual 2015 16 SRM UniversityDocument65 pagesPhysics Instruction Manual 2015 16 SRM UniversityDEVVARUNNo ratings yet

- Determination of WavelegnthDocument3 pagesDetermination of Wavelegnthnaveensl0207No ratings yet

- Youngs Modulus - Non Uniform BendingDocument7 pagesYoungs Modulus - Non Uniform BendingECE 21 MOHANA GURU VNo ratings yet

- Physics Manual BSPH-191Document65 pagesPhysics Manual BSPH-191Doge DogeNo ratings yet

- Lab 1Document5 pagesLab 1Hoàng LongNo ratings yet

- Physics Laboratory ManualDocument38 pagesPhysics Laboratory ManualRavi RaneNo ratings yet

- Modulus of Rigidity DoneDocument5 pagesModulus of Rigidity DoneSujay Das SonuNo ratings yet

- Bs 8161 - Physicslaboratory: Course ObjectivesDocument67 pagesBs 8161 - Physicslaboratory: Course ObjectiveslevisNo ratings yet

- The Three-Dimensional (3-D) Transmission Cross-Coefficient For TCC ImagingDocument4 pagesThe Three-Dimensional (3-D) Transmission Cross-Coefficient For TCC Imagingocb81766No ratings yet

- Phy 1 FTDocument6 pagesPhy 1 FTMusa IsyakuNo ratings yet

- Statement:: To Determine The Uniaxial Compressive Strength of Rocks Using L-Type & N-Type Schmidt Rebound HammerDocument6 pagesStatement:: To Determine The Uniaxial Compressive Strength of Rocks Using L-Type & N-Type Schmidt Rebound Hammerusama elalaouiNo ratings yet

- B.Tech Lab Manual 2023Document57 pagesB.Tech Lab Manual 2023sonamthakur1419No ratings yet

- Experiment No. 15 Young's Modulus: Experiments For B. Tech. 1 Year Physics LaboratoryDocument5 pagesExperiment No. 15 Young's Modulus: Experiments For B. Tech. 1 Year Physics LaboratoryYusuf taiwoNo ratings yet

- Applied Physics LabDocument23 pagesApplied Physics LabPranav KothapalliNo ratings yet

- I PUC Revised Physics MannualDocument83 pagesI PUC Revised Physics MannualSankirth PNo ratings yet

- Grade - 11 - Study Material - Practical Exam - 23-24Document17 pagesGrade - 11 - Study Material - Practical Exam - 23-24monishchess2468No ratings yet

- Engineering Electromagnetics Practice Manual (PHY107P) B. Tech January - May 2019Document33 pagesEngineering Electromagnetics Practice Manual (PHY107P) B. Tech January - May 2019sid sNo ratings yet

- Experiment No. - 2: Fresnel's Bi-PrismDocument5 pagesExperiment No. - 2: Fresnel's Bi-PrismRajat PandaNo ratings yet

- 6 Air WedgeDocument8 pages6 Air Wedgesanthosh santhoshNo ratings yet

- Estimation of Apollo Lunar Dust Transport Using Optical Extinction MeasurementsDocument25 pagesEstimation of Apollo Lunar Dust Transport Using Optical Extinction Measurementsrattan5No ratings yet

- Single Slit Diffraction ExpDocument5 pagesSingle Slit Diffraction ExpNaresh KumarNo ratings yet

- Btech Cse 2021 06 16 4 6784Document8 pagesBtech Cse 2021 06 16 4 6784princeharit48No ratings yet

- First Sem Ge6163 Physics Lab ManualDocument133 pagesFirst Sem Ge6163 Physics Lab ManualPRIYA RAJINo ratings yet

- O level Physics Questions And Answer Practice Papers 2From EverandO level Physics Questions And Answer Practice Papers 2Rating: 5 out of 5 stars5/5 (1)

- Electron Beam-Specimen Interactions and Simulation Methods in MicroscopyFrom EverandElectron Beam-Specimen Interactions and Simulation Methods in MicroscopyNo ratings yet

- The Constitution of India Is Not An End But A Means To An EndDocument5 pagesThe Constitution of India Is Not An End But A Means To An EndNitin DhaterwalNo ratings yet

- Philippine Stock Exchange v. Court of Appeals, 281 SCRA 232 (1997)Document4 pagesPhilippine Stock Exchange v. Court of Appeals, 281 SCRA 232 (1997)Christian TalisayNo ratings yet

- Buy Bitcoin With Credit Card or Debit Card Immediatelyxberg PDFDocument2 pagesBuy Bitcoin With Credit Card or Debit Card Immediatelyxberg PDFVargas33Cross100% (1)

- Surpass Hit 7080 4.0: Commissioning Manual (Comn)Document23 pagesSurpass Hit 7080 4.0: Commissioning Manual (Comn)binhthuong2903No ratings yet

- Chin Hin - Quarter Announcement Q4 2021 (Final)Document31 pagesChin Hin - Quarter Announcement Q4 2021 (Final)KentNo ratings yet

- AFAR BOOKLET 2 AutoRecovered AutoRecoveredDocument222 pagesAFAR BOOKLET 2 AutoRecovered AutoRecoveredEmey CalbayNo ratings yet

- 07 - Chapter 2Document34 pages07 - Chapter 2midlaj keepayurNo ratings yet

- OscillationsDocument39 pagesOscillationsMurugan.SubramaniNo ratings yet

- 2020 Schlage PB8Document446 pages2020 Schlage PB8reyNo ratings yet

- The High Cost of Prescription Drugs CausesDocument5 pagesThe High Cost of Prescription Drugs Causesjuddy avottNo ratings yet

- Oit Furute of WorkDocument12 pagesOit Furute of WorkSANTHOSH KUMAR T MNo ratings yet

- Aift 2001Document89 pagesAift 2001Bhavesh MishraNo ratings yet

- Post Qualification Trade / Discipline No. of Posts Wage Group / Career Path / Pay ScaleDocument2 pagesPost Qualification Trade / Discipline No. of Posts Wage Group / Career Path / Pay ScaleJeshiNo ratings yet

- Excessive Delegated LegislationDocument14 pagesExcessive Delegated LegislationNagalikar LawNo ratings yet

- 1 - Pdfsam - CX600 V800R007C00 Hardware Description 02 - 1 - 5Document99 pages1 - Pdfsam - CX600 V800R007C00 Hardware Description 02 - 1 - 5josé martínezNo ratings yet

- Postal Employees Retreat Rights FAQS 5-24-2012Document3 pagesPostal Employees Retreat Rights FAQS 5-24-2012PostalReporter.com100% (1)

- Tree Removal Blacktown Council Regulations - SummaryDocument7 pagesTree Removal Blacktown Council Regulations - SummaryHazel Bangolan PatinoNo ratings yet

- 3-Admin Block Lighting LayoutDocument1 page3-Admin Block Lighting LayoutTafadzwa MurwiraNo ratings yet

- SAS - IntegrationGuide Apache HTTP Server SAMLDocument21 pagesSAS - IntegrationGuide Apache HTTP Server SAMLWalter BlokNo ratings yet

- Municipality of Tiwi v. Betito DigestDocument3 pagesMunicipality of Tiwi v. Betito DigestkathrynmaydevezaNo ratings yet

- Motion To Investigate Collusion and Chnage of AddressDocument3 pagesMotion To Investigate Collusion and Chnage of AddressConcepcion CejanoNo ratings yet

- EMW - Module - 2Document47 pagesEMW - Module - 2ROHITH MYSURUNo ratings yet

- Alu Inium Limited: A U Ium L DDocument2 pagesAlu Inium Limited: A U Ium L DDhruv TomarNo ratings yet