Professional Documents

Culture Documents

Preventive Template: PREV-0001407 #

Preventive Template: PREV-0001407 #

Uploaded by

sam.dumasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Preventive Template: PREV-0001407 #

Preventive Template: PREV-0001407 #

Uploaded by

sam.dumasCopyright:

Available Formats

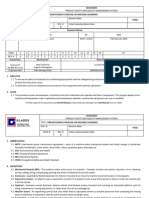

PREVENTIVE TEMPLATE

# PREV-0001407

Plant\Warehouse: DeLaFontaine (Hyattsville) Sender: Samuel Dumas

Equipment/Suite: Receiver: Samuel Dumas

Number: 565MID

Priority: Z07 - Dans la semaine

Description Punch Press Alceco (AME)

# of days 7

Location: Status: À faire

Division: Principale Classification: Préventif/Preventive

Group:

Work:

Component - Tag: GENERAL - 565MID

Code: 101400

08 Entretien mensuel/Monthly maintenance - mécanique

Assignment

W.O. # Department / Resource # / Parallel Time Planned Expense account

Comments (minutes)

PREV-0001407 Maintenance / Mechanic 1 / 45

Comments:

Monthly Maintenance (Security/Function Check)

Due date

Type : Frequency

2023-11-01 [44] 2023-12-01 [48] 2024-01-01 [1] 2024-02-01 [5]

2024-03-01 [9] 2024-04-01 [14] 2024-05-01 [18] 2024-06-03 [23]

2024-07-01 [27] 2024-08-01 [31] 2024-09-02 [36] 2024-10-01 [40]

2024-11-01 [44]

Check List (Equipment - Code - Description - Comments)

(Min. Limit - Nom. Limit - Max. Limit - Unit)

Test - Test multiple cycles of the mechanical press by pressing the pedal. This is just to make sure it's working before

mainteance

Blow - Blow all debries and dust away to make sure it's clean and ready for the maintenance.

Safety - Make sure you disconnect any power source before continuing the maintenance of this machine.

-Unplug the 120v power source

-Disconnect the air supply from the machine (Quick-Connect)

Inspection - Remove the guard, and inspect the pulley and belts. Replace parts if needed.

Inspection - Inspect pneumatic hoses and electric wire. Make sure there is no air leak. Replace/repair part(s) if dammaged.

Inspection - Check if any bolts are loose and tightens if needed. (Bolts for the guard, bolts on the bed etc)

Lubricate - If the machine has an FRL (Filter Regulator Lubricator), check the oil level in the small tank.

-Add pneumatic Oil if needed. (Shell Tellus S2-M-32 or equivalent)

-Remove water in the air filter if needed.

Inspection - Check if any cracks or loose bushings are present on the machine. If yes, advise your supervisor. (Visual

Inspection)

30 octobre 2023 INTERAL Page 1 of 2

PREVENTIVE TEMPLATE

# PREV-0001407

Lubricate - Fill the crankshaft bearing and big end oil reservoirs with Shell Tellus 46 oil or equivalent.

Inspection - Make sure the tooling is not broken and in good condition.

Lubricate - Lubricate the "Dog" with Shell Tellus S2-M-32 oil or equivalent.

Test - Test 5-6 cycles of the mechanical press by pressing the pedal. This is to make sure it's safe for operation and ready to

go.

Parts Component Tag Planned Qty Unit

Tools

30 octobre 2023 INTERAL Page 2 of 2

You might also like

- John Deere 540G-III, 548G-III, 640G-III, 648G-III, 748G-III Operation, Maintenance & Diagnostic Test Service Manual TM1870Document31 pagesJohn Deere 540G-III, 548G-III, 640G-III, 648G-III, 748G-III Operation, Maintenance & Diagnostic Test Service Manual TM1870Equipment ManualsNo ratings yet

- TM1403 John Deere 450G, 455G, 550G, 555G, 650G Crawler Diagnostic Operation Test Technical ManualDocument11 pagesTM1403 John Deere 450G, 455G, 550G, 555G, 650G Crawler Diagnostic Operation Test Technical Manualtteelsars0% (1)

- TB Boom Lift Service ManualDocument43 pagesTB Boom Lift Service ManualKhaled Kamel50% (2)

- TrioTC51 Instruction Manual 20120920 (SN. 316, 320 - 324, 344)Document99 pagesTrioTC51 Instruction Manual 20120920 (SN. 316, 320 - 324, 344)Justice Machiwana100% (3)

- TB Boom Lift Service ManualDocument43 pagesTB Boom Lift Service Manualtruck diesel solution0% (5)

- WI NG 6260 002 018 Oil Immersed Power Transformer Rev00Document11 pagesWI NG 6260 002 018 Oil Immersed Power Transformer Rev00MohamedElmahdyNo ratings yet

- 623C 4x4 Operator ManualDocument102 pages623C 4x4 Operator ManualPathitoVeraVeraNo ratings yet

- 616C Operator ManualDocument102 pages616C Operator ManualPathitoVeraVeraNo ratings yet

- 616 Operator ManualDocument102 pages616 Operator ManualPathitoVeraVeraNo ratings yet

- Manual Centrifuga UniversalDocument35 pagesManual Centrifuga Universallebiatan89No ratings yet

- Preventive Template: PREV-0001406 #Document2 pagesPreventive Template: PREV-0001406 #sam.dumasNo ratings yet

- Preventive Template: PREV-0001408 #Document1 pagePreventive Template: PREV-0001408 #sam.dumasNo ratings yet

- Machine Guarding EnforcementDocument11 pagesMachine Guarding EnforcementNoe AranelNo ratings yet

- 85D Excavator Diagnostic: Operation and Test Manual Compact Models 85DDocument719 pages85D Excavator Diagnostic: Operation and Test Manual Compact Models 85DFrancisco BauerNo ratings yet

- Volvo Tad650-750 Technical Workshop ManualDocument96 pagesVolvo Tad650-750 Technical Workshop ManualMouloud DerrahiNo ratings yet

- 40 F032 120E Crane (Crawler) Inspection Daily RevBDocument1 page40 F032 120E Crane (Crawler) Inspection Daily RevBrashid7930% (1)

- FILTRASIONDocument26 pagesFILTRASIONMario Núñez ObandoNo ratings yet

- Diesel Customer Information No. 289: Check of Valve RotationDocument12 pagesDiesel Customer Information No. 289: Check of Valve RotationmariodalNo ratings yet

- Heavy Equipment Daily Inspection ChecklistDocument1 pageHeavy Equipment Daily Inspection ChecklistDLPS HSENo ratings yet

- 04 - 03 - Annex C - Maintenance Plan - Ver03Document2 pages04 - 03 - Annex C - Maintenance Plan - Ver03ELILTANo ratings yet

- S-Ind-Me-08-Eng-Eng-13-001 Rev 000 Visual and Grease Maintenance Instruction of E-48 - E-53 & WW48 - WW53 - CS48 WECDocument9 pagesS-Ind-Me-08-Eng-Eng-13-001 Rev 000 Visual and Grease Maintenance Instruction of E-48 - E-53 & WW48 - WW53 - CS48 WECDeepakNo ratings yet

- 710G Technical ManualDocument679 pages710G Technical Manualjulio cesar cortez100% (1)

- Genie 51-30Document133 pagesGenie 51-30Jesus EscobarNo ratings yet

- DTSC-50 Manual PDFDocument106 pagesDTSC-50 Manual PDFAcosta JohnnyNo ratings yet

- Caterpillar Camshaft ReusabilityDocument59 pagesCaterpillar Camshaft ReusabilityDiaa MokhtarNo ratings yet

- General Testing and Adjusting Information: 390D Excavator Hydraulic SystemDocument2 pagesGeneral Testing and Adjusting Information: 390D Excavator Hydraulic SystemFauzan Almuhdor0% (1)

- M0097171 - Installation Procedure For C175-16 Centrifugal Oil Filter and Self-Cleaning Oil Filter Upgrade For Certain Off-Highway TrucksDocument53 pagesM0097171 - Installation Procedure For C175-16 Centrifugal Oil Filter and Self-Cleaning Oil Filter Upgrade For Certain Off-Highway TrucksAnderson Oliveira SilvaNo ratings yet

- Supplier Assesment SheetDocument24 pagesSupplier Assesment SheetManu Sharma100% (1)

- TM1541 John Deere 892ELC Excavator Diagnostic Operation Tests Technical ManualDocument10 pagesTM1541 John Deere 892ELC Excavator Diagnostic Operation Tests Technical ManualtteelsarsNo ratings yet

- Ndi06 32 12 00 001Document8 pagesNdi06 32 12 00 001Jorge FernandezNo ratings yet

- 520 WS3Document92 pages520 WS3Hassan HamdyNo ratings yet

- 55-1 MewpDocument3 pages55-1 MewpAkhilNo ratings yet

- Sis 2.0Document15 pagesSis 2.0sf.joe24No ratings yet

- Easygen-3000 Series (Package P1) Genset Control: ConfigurationDocument348 pagesEasygen-3000 Series (Package P1) Genset Control: ConfigurationAndresan507No ratings yet

- 4114 Keppel Fels V2 ManualDocument122 pages4114 Keppel Fels V2 ManualRAMON ARCENo ratings yet

- 13) SWP-13 Lock-Out-Tag-OutDocument5 pages13) SWP-13 Lock-Out-Tag-OutFIKdtec duplicateNo ratings yet

- OMF389371 UnlockedDocument174 pagesOMF389371 Unlockedeliminar348No ratings yet

- Om - DR 22 - Electrical Haenesses Got Short Circuit - 21 07 2023Document1 pageOm - DR 22 - Electrical Haenesses Got Short Circuit - 21 07 2023Rachid DadanniNo ratings yet

- TSB 2021 MAT 03036 XUV700 MT AT Diesel PDI CheckList 11aac0241 20243412959Document8 pagesTSB 2021 MAT 03036 XUV700 MT AT Diesel PDI CheckList 11aac0241 20243412959manukrishnan245No ratings yet

- Genie S-40 S045 Manual PDFDocument325 pagesGenie S-40 S045 Manual PDFstephen prosserNo ratings yet

- Shri Vishwakarama Skill University: Name Lalit Kumar ROLL NO. 20L5DMM14105 Topic Documents Use in IndustryDocument41 pagesShri Vishwakarama Skill University: Name Lalit Kumar ROLL NO. 20L5DMM14105 Topic Documents Use in IndustryVishal NarwalNo ratings yet

- John Deere 50C ZTS TM2056 Operation and Test Manual - Technical Manual #2 PRIME 314 PáginasDocument314 pagesJohn Deere 50C ZTS TM2056 Operation and Test Manual - Technical Manual #2 PRIME 314 Páginascr266332No ratings yet

- s125 - Manual de ServicioDocument298 pagess125 - Manual de ServicioChristian Andy H. Chavez100% (1)

- AVR Commissioning Rev01Document5 pagesAVR Commissioning Rev01pradeepmv159No ratings yet

- Ndi06 32 13 05 001Document8 pagesNdi06 32 13 05 001Jorge FernandezNo ratings yet

- P250000-9691-46-MAN-001 - Rev. 01Document254 pagesP250000-9691-46-MAN-001 - Rev. 01carlosorizabaNo ratings yet

- TAD 4, 5, 6 - 7 Series WM-Technical DataDocument92 pagesTAD 4, 5, 6 - 7 Series WM-Technical DataTrong Pham100% (2)

- Service Manual Grader: (Grader 96) S/N ACW900101 & Above (Grader 108) S/N AJ2E00101 & AboveDocument120 pagesService Manual Grader: (Grader 96) S/N ACW900101 & Above (Grader 108) S/N AJ2E00101 & AbovealexanderNo ratings yet

- Before/After: Service LetterDocument6 pagesBefore/After: Service Lettercjl08No ratings yet

- TM2075 - Tecnico Operacion y Prueba 644J-724JDocument1,146 pagesTM2075 - Tecnico Operacion y Prueba 644J-724Jdaniilo agudelo100% (1)

- PI261 OPT8-1931E AC-description Components ENG PDFDocument60 pagesPI261 OPT8-1931E AC-description Components ENG PDFEdmilson FonsecaNo ratings yet

- Vector 8500 Operators ManualDocument58 pagesVector 8500 Operators ManualПавел100% (1)

- TTV-IOM November 2006Document23 pagesTTV-IOM November 2006Ngô Khắc ToảnNo ratings yet

- Driller Controller User ManualDocument12 pagesDriller Controller User ManualYahya BA100% (1)

- OMKK54136Document60 pagesOMKK54136mogetzuNo ratings yet

- Request Form HuancayoDocument1 pageRequest Form HuancayoNilson Alminagorda MezaNo ratings yet

- 130G Excavator Diagnostic: Operation and Test Manual (T3/S3a) Models 130G (PIN: 1FF130GX - D040001 - )Document23 pages130G Excavator Diagnostic: Operation and Test Manual (T3/S3a) Models 130G (PIN: 1FF130GX - D040001 - )Tech revolutionNo ratings yet

- Petra Users Manual RWC RWCCDocument96 pagesPetra Users Manual RWC RWCCemdad.munshi01No ratings yet

- Detroit Diesel Series 60 Egr Tech Guide 2005Document10 pagesDetroit Diesel Series 60 Egr Tech Guide 2005thomas100% (51)

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistMa.socorro SaballaNo ratings yet

- Normal ForceDocument29 pagesNormal ForceRusella Mariz EsteronNo ratings yet

- Bio F 3 Cycle 2 Term 1 2023Document8 pagesBio F 3 Cycle 2 Term 1 2023profitableagripoultryNo ratings yet

- Draft - NH-70 - EIA HP - 4-8-23Document249 pagesDraft - NH-70 - EIA HP - 4-8-23shampa singhNo ratings yet

- Previous HSE Questions From The Chapter "ELECTROCHEMISTRY": E E - 2.303RT Log (M) NF (M)Document2 pagesPrevious HSE Questions From The Chapter "ELECTROCHEMISTRY": E E - 2.303RT Log (M) NF (M)Chemistry MESNo ratings yet

- 01 Health Safety & Environmental MGMTDocument134 pages01 Health Safety & Environmental MGMTLau Siong Kwong67% (3)

- Review: Recent Approaches in Herbal Drug StandardizationDocument9 pagesReview: Recent Approaches in Herbal Drug Standardizationkj0203No ratings yet

- LAB 3: Hydrostatics: IY472 - ThermofluidsDocument2 pagesLAB 3: Hydrostatics: IY472 - Thermofluidsafatima paintingNo ratings yet

- Construction and Logistics Plan For: 56a - 60 North RD, Three Bridges, Crawley. RH10 1RHDocument24 pagesConstruction and Logistics Plan For: 56a - 60 North RD, Three Bridges, Crawley. RH10 1RHCivil Engineer100% (1)

- Get To Know The Newly Redesigned Texas DL and ID Cards: Adult & Under 21 Identification CardDocument2 pagesGet To Know The Newly Redesigned Texas DL and ID Cards: Adult & Under 21 Identification Carddominique marshallNo ratings yet

- Program Kreativitas MahasiswaDocument28 pagesProgram Kreativitas Mahasiswawendi gunawanNo ratings yet

- PVC PDFDocument15 pagesPVC PDFsrabon1059No ratings yet

- Unique and Common Traits in Mycorrhizal SymbiosesDocument12 pagesUnique and Common Traits in Mycorrhizal SymbiosesThắng Trần BảoNo ratings yet

- NEW LTC - Price Update 2020Document13 pagesNEW LTC - Price Update 2020dwi prasetyo wibowoNo ratings yet

- University of Mines and Technology (Umat), TarkwaDocument22 pagesUniversity of Mines and Technology (Umat), TarkwaEugene AmpahNo ratings yet

- Drug Education and Vice ControlDocument16 pagesDrug Education and Vice ControlSinagTalaNo ratings yet

- Penerapan Sistem Haccp Jurusan Gizi Poltekkes Kemenkes MalangDocument3 pagesPenerapan Sistem Haccp Jurusan Gizi Poltekkes Kemenkes MalangGita Martha VIndiartiNo ratings yet

- CHEM 203 Introductory Chemical Techniques: Exp. 3: Determination of An Equilibrium ConstantDocument4 pagesCHEM 203 Introductory Chemical Techniques: Exp. 3: Determination of An Equilibrium ConstantCarl-Etienne ChaayaNo ratings yet

- Mexican FoodDocument4 pagesMexican FoodJavier SantanaNo ratings yet

- An Evaluation of Wheel Chair Cum Bed Mechanism With Side Panel Movement For BedDocument6 pagesAn Evaluation of Wheel Chair Cum Bed Mechanism With Side Panel Movement For BedMuhammad Hammad Sabir PansotaNo ratings yet

- Removable Guardrail SystemsDocument3 pagesRemovable Guardrail SystemsSaiful AnnasNo ratings yet

- Approach To Neonatal HyperbilirubinemiaDocument34 pagesApproach To Neonatal HyperbilirubinemiaNilesh HatzadeNo ratings yet

- Quick PharmaDocument4 pagesQuick Pharmahva.terrenceavillaNo ratings yet

- Price List: Heavy Duty Foodwaste Disposers and Electrical ControlsDocument39 pagesPrice List: Heavy Duty Foodwaste Disposers and Electrical Controlsedgar ricoNo ratings yet

- Pressure Vessel DesignDocument46 pagesPressure Vessel DesignAxenta0% (1)

- Three Winding or Tertiary Winding TransformerDocument7 pagesThree Winding or Tertiary Winding TransformergopalakrishnanNo ratings yet

- 4-Spare Parts Management 1Document76 pages4-Spare Parts Management 1Mohd Kamil100% (4)

- Self Help GroupsDocument18 pagesSelf Help Groupsykbharti101No ratings yet

- NCP Risk For InfectionDocument1 pageNCP Risk For InfectionBianca MaeNo ratings yet