Professional Documents

Culture Documents

Certificate of Functional Configuration Audit - Physical ... - NASA

Certificate of Functional Configuration Audit - Physical ... - NASA

Uploaded by

aizyadaizyadCopyright:

Available Formats

You might also like

- Annual Product Quality Review TemplateDocument9 pagesAnnual Product Quality Review Templateyasinpapers.datasNo ratings yet

- Factory Acceptance Test ProtocolDocument28 pagesFactory Acceptance Test ProtocolShabbir Hussain Palitanawala100% (7)

- HDT First Article Inspection Policy 01Document7 pagesHDT First Article Inspection Policy 01Srinivasan VenkatNo ratings yet

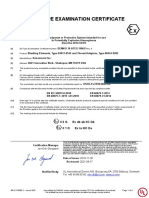

- DEMKO 18 ATEX 1986X Rev. 4Document3 pagesDEMKO 18 ATEX 1986X Rev. 4sefazNo ratings yet

- 2018 is-BAO Guidance CH 15Document30 pages2018 is-BAO Guidance CH 15EmNo ratings yet

- POST ACTIVITY REPORT TemplateDocument3 pagesPOST ACTIVITY REPORT TemplateRegion Personnel88% (8)

- Physical Configuration Audit ChecklistDocument4 pagesPhysical Configuration Audit ChecklistPetrrNo ratings yet

- Project Name System Verification Document: Company LogoDocument11 pagesProject Name System Verification Document: Company LogoFahad RustamNo ratings yet

- API Spec q1 9th EditionDocument3 pagesAPI Spec q1 9th Editionvtsusr fv80% (5)

- Sample Affidavit of Two Disinterested PersonsDocument1 pageSample Affidavit of Two Disinterested PersonsAileenJane Mallonga100% (3)

- Checklist DocumentDocument46 pagesChecklist DocumentGaurav Vishwakarma100% (2)

- 8 - Product Audit Checklist ASAP 7 11Document10 pages8 - Product Audit Checklist ASAP 7 11Sachin KumbharNo ratings yet

- List of PPAP DocsDocument4 pagesList of PPAP DocsSunilNo ratings yet

- How First Piece Inspection Procedure Enhances Production QualityDocument4 pagesHow First Piece Inspection Procedure Enhances Production QualityjackNo ratings yet

- Production Part Approval ProcessDocument3 pagesProduction Part Approval ProcessjitenderbawaliaNo ratings yet

- Template For Installation Qualification Protocol - Pharmaceutical GuidanceDocument6 pagesTemplate For Installation Qualification Protocol - Pharmaceutical GuidanceMSL IndiaNo ratings yet

- Appendix D13 Contents of Project Close-Out ReportDocument11 pagesAppendix D13 Contents of Project Close-Out ReportHamza ShujaNo ratings yet

- PPAP Elements DescriptionDocument3 pagesPPAP Elements DescriptionagungNo ratings yet

- Quality Test Specification QCS-83-4 FOR First Article Inspection (F.A.I.)Document10 pagesQuality Test Specification QCS-83-4 FOR First Article Inspection (F.A.I.)Amit GauravNo ratings yet

- Buffco Eng AS9100 Quality Manual 2-28-06Document26 pagesBuffco Eng AS9100 Quality Manual 2-28-06savlafNo ratings yet

- Ppap WorkbookDocument80 pagesPpap WorkbookalyankaNo ratings yet

- 1 Production Part Approval ProcessDocument42 pages1 Production Part Approval ProcessVinod Kaul100% (1)

- AS9102 FAI GuidelinesDocument27 pagesAS9102 FAI Guidelinesjamilvora100% (1)

- PF 8500Document10 pagesPF 8500ibrahime mohammedNo ratings yet

- Auto Part Manufacturing ProcessDocument4 pagesAuto Part Manufacturing ProcessKuldeep BohraNo ratings yet

- Quality Control Manual: Company Name Address City, State, ZipDocument10 pagesQuality Control Manual: Company Name Address City, State, ZipMarco CandoNo ratings yet

- First Article Inspection RequirementDocument2 pagesFirst Article Inspection RequirementRBThomas2011No ratings yet

- Visual Weld Inspection: Organizational IssuanceDocument7 pagesVisual Weld Inspection: Organizational IssuanceEdAlmNo ratings yet

- PowerPoint Presentation FAI AS9102Document29 pagesPowerPoint Presentation FAI AS9102Danny Fydm OliveiraNo ratings yet

- PpapDocument3 pagesPpapVlad NitaNo ratings yet

- Eurabo-347 - Qa Sign Off - 04092014Document4 pagesEurabo-347 - Qa Sign Off - 04092014BalasubrahmanyamNo ratings yet

- Design ProcessDocument7 pagesDesign Processrobert_kerr_29No ratings yet

- Control of Design Process ChangesDocument7 pagesControl of Design Process ChangesayushNo ratings yet

- When To Conduct A First Article InspectionDocument4 pagesWhen To Conduct A First Article InspectionCloud RedfieldNo ratings yet

- Guide For Successful Completion of First Article Inspection (Fai) ReportsDocument34 pagesGuide For Successful Completion of First Article Inspection (Fai) ReportsJohn OlayNo ratings yet

- AiscDocument3 pagesAiscvo thi kim xuyenNo ratings yet

- ISV Design Presentation - MRM-12!01!2024 - FinalDocument83 pagesISV Design Presentation - MRM-12!01!2024 - FinalMunish KanwarNo ratings yet

- Gorham-SD PMA2011X1.90151946Document62 pagesGorham-SD PMA2011X1.90151946ben foldsNo ratings yet

- Desktop Suveliance Nabl 218Document8 pagesDesktop Suveliance Nabl 218Vasu Raja0% (1)

- QM-F-7.1-15 Ver.2.0 - Annual Quality Audit of VendorsDocument5 pagesQM-F-7.1-15 Ver.2.0 - Annual Quality Audit of VendorssanjaydeNo ratings yet

- Product Qualification Requirements 2.0Document3 pagesProduct Qualification Requirements 2.0Amit SinghNo ratings yet

- Production Part Approval Process (PPAP)Document3 pagesProduction Part Approval Process (PPAP)psathishthevanNo ratings yet

- Qualification - Validation CPOB 2018 PDFDocument145 pagesQualification - Validation CPOB 2018 PDFmela milaniNo ratings yet

- PF Emissions eDocument17 pagesPF Emissions eibrahime mohammedNo ratings yet

- Competenz Assessment GuideDocument6 pagesCompetenz Assessment GuideChineselegolasNo ratings yet

- 1.5 Guidelines For Preparing Inspections & Test Plans (Itp) Agrarian Reform Communities ProjectDocument5 pages1.5 Guidelines For Preparing Inspections & Test Plans (Itp) Agrarian Reform Communities ProjectJason Angel BuñagNo ratings yet

- Fai 1Document5 pagesFai 1pawoe3064No ratings yet

- GMP ChecklistDocument11 pagesGMP ChecklistWerner Schrammel100% (1)

- 9 AuditsDocument3 pages9 Auditsnaveen yadavNo ratings yet

- SOP For Corrective Action and Preventive Action (CAPA) - Pharmaceutical GuidelinesDocument5 pagesSOP For Corrective Action and Preventive Action (CAPA) - Pharmaceutical GuidelinesAmit KumarNo ratings yet

- Aqpaxi Phase 2.rev13Document7 pagesAqpaxi Phase 2.rev13Isabel SierraNo ratings yet

- APQP FormatosDocument15 pagesAPQP FormatoseddiefloresNo ratings yet

- Sample SAT Procedure (Only For Reference)Document3 pagesSample SAT Procedure (Only For Reference)Mohammed SinanNo ratings yet

- What Is A First Article InspectionDocument2 pagesWhat Is A First Article InspectionCloud RedfieldNo ratings yet

- Be-Pdp-Fr-07-E Papso Form Roanoke To Sa - j7Document2 pagesBe-Pdp-Fr-07-E Papso Form Roanoke To Sa - j7Ricardo Frank CordeiroNo ratings yet

- Op4.0015 R3Document5 pagesOp4.0015 R3mulldoctor1No ratings yet

- PPAP ElementsDocument2 pagesPPAP ElementsSenthil Kumar Gunasekaran50% (2)

- Guideline 2 FAIDocument16 pagesGuideline 2 FAIMohamed HassanNo ratings yet

- B2 Documented Information For Externally Provided Products and ServicesDocument9 pagesB2 Documented Information For Externally Provided Products and ServicesaceNo ratings yet

- MAI 04 - In-Process, Inspection and Testing - DJ - v1Document11 pagesMAI 04 - In-Process, Inspection and Testing - DJ - v1IT Support - FernanNo ratings yet

- Production Part Approval ProcessDocument6 pagesProduction Part Approval ProcessleonardoNo ratings yet

- Codification of Statements on Auditing Standards: Numbers 122 to 133, January 2018From EverandCodification of Statements on Auditing Standards: Numbers 122 to 133, January 2018No ratings yet

- Improving Product Reliability and Software Quality: Strategies, Tools, Process and ImplementationFrom EverandImproving Product Reliability and Software Quality: Strategies, Tools, Process and ImplementationNo ratings yet

- Codification of Statements on Standards for Attestation Engagements, January 2018From EverandCodification of Statements on Standards for Attestation Engagements, January 2018No ratings yet

- Design and Implementation of Computerised Students' Identity CardDocument45 pagesDesign and Implementation of Computerised Students' Identity CardTUMUHIMBISE LUCKYNo ratings yet

- TLF-AGC 8.2 V5 May2020 Application For Exemption With SAQA CreditsDocument2 pagesTLF-AGC 8.2 V5 May2020 Application For Exemption With SAQA Creditsnokukhanyashoba02No ratings yet

- Birth NewDocument1 pageBirth NewDianne LlgnNo ratings yet

- Urn Uvci 01 Ro R48m1gyolqeny4wm5gwz3wxd67kp02#xDocument2 pagesUrn Uvci 01 Ro R48m1gyolqeny4wm5gwz3wxd67kp02#xDavidNo ratings yet

- Economic and Social Council: Economic Commission For EuropeDocument15 pagesEconomic and Social Council: Economic Commission For EuropeLaroyNo ratings yet

- SAP Conversion Syllabus Latest 2023Document2 pagesSAP Conversion Syllabus Latest 2023halol72006No ratings yet

- 51274.23.07.65.MP - Wire RopeDocument1 page51274.23.07.65.MP - Wire RopeRamprasadNo ratings yet

- Panchayat Secretary (GR VI) Digital AssistantDocument29 pagesPanchayat Secretary (GR VI) Digital AssistantKola PattabhiNo ratings yet

- Abhijit Samantray Docs PDFDocument13 pagesAbhijit Samantray Docs PDFAbhijit samantrayNo ratings yet

- Rabindra Bharati University: 56A, B.T. Road, Kolkata - 700050Document13 pagesRabindra Bharati University: 56A, B.T. Road, Kolkata - 700050Salman NoorNo ratings yet

- Aadhar AddressDocument1 pageAadhar AddressSureshBabu100% (2)

- Recruitment For The Post of Scientist C' in Icert, MeityDocument10 pagesRecruitment For The Post of Scientist C' in Icert, MeitySujeet VermaNo ratings yet

- CSC Job Portal: Mgo San Jose, Antique - Region ViDocument1 pageCSC Job Portal: Mgo San Jose, Antique - Region ViGilbert GonzalesNo ratings yet

- CCM-Application Handbook-2020Document41 pagesCCM-Application Handbook-2020Jacob LeeNo ratings yet

- B - Certification Report SampleDocument17 pagesB - Certification Report Samplemankrsha83No ratings yet

- Towards Decentralized Identity For Internet of ThingsDocument6 pagesTowards Decentralized Identity For Internet of ThingsRaullen ChaiNo ratings yet

- Prequalification of Concord SurveyDocument23 pagesPrequalification of Concord SurveyJason RazatlabNo ratings yet

- SADCAS F 60 (B) - Technical Requirements of ISO IEC 17025-2017 (Issue 2)Document30 pagesSADCAS F 60 (B) - Technical Requirements of ISO IEC 17025-2017 (Issue 2)Chi Jui HanNo ratings yet

- Affidavit of Loss: Jeffry Jude T. YapDocument1 pageAffidavit of Loss: Jeffry Jude T. YapChan DersNo ratings yet

- Second Special Drive Admission Rollover On Spot Admission Svs Bvoc ProgrammesDocument6 pagesSecond Special Drive Admission Rollover On Spot Admission Svs Bvoc ProgrammesNeelabh ParasharNo ratings yet

- Omnibus Certification of Authenticity and Veracity of DocumentsDocument2 pagesOmnibus Certification of Authenticity and Veracity of DocumentsFidel ZapataNo ratings yet

- StandardsforNonFoodSuppliers tcm137-70082Document12 pagesStandardsforNonFoodSuppliers tcm137-70082joyrjaelNo ratings yet

- 2023 Checklist For Newly Hired Teaching Non Teaching PositionsDocument3 pages2023 Checklist For Newly Hired Teaching Non Teaching PositionsMelba PeteroNo ratings yet

- Integrated Mepss - Section V - Snepco - SPDC - Combined Scope of WorkDocument365 pagesIntegrated Mepss - Section V - Snepco - SPDC - Combined Scope of WorkJoe EkanemNo ratings yet

- DGCA-AC 21-29 Amdt. 1 - Detecting and Reporting Suspected Unapproved PartsDocument10 pagesDGCA-AC 21-29 Amdt. 1 - Detecting and Reporting Suspected Unapproved Partsraihan zakyNo ratings yet

- MQA Certification UK Ltd.Document15 pagesMQA Certification UK Ltd.Yosy WonoasriNo ratings yet

Certificate of Functional Configuration Audit - Physical ... - NASA

Certificate of Functional Configuration Audit - Physical ... - NASA

Uploaded by

aizyadaizyadOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Certificate of Functional Configuration Audit - Physical ... - NASA

Certificate of Functional Configuration Audit - Physical ... - NASA

Uploaded by

aizyadaizyadCopyright:

Available Formats

Certificate of Functional Configuration

Audit/Physical Configuration Audit

(OR EQUIVALENT)

CERTIFICATION SIGNATURE PAGE

CONFIGURATION ITEM NAME PART NUMBER/SERIAL NUMBER DATE

An FCA/PCA has been conducted with results noted below and on the attached sheets.

FCA #1 - Certification of Qualification Test (Plus Attachment FCA #1)

FCA #2 - Certification of Deviations/Waivers (Plus Attachment FCA #2)

PCA #1 - Certification of Product Baseline (Plus Attachment PCA #1)

PCA #2 - Fabrication/Inspection Records

PCA #3 - Technical Documentation Control System Review

PCA #4 - Drawing Review (Plus Attachment PCA #4)

PCA #5 - Review of Shortages and Unincorporated Design Changes (Plus Attachment PCA #5)

We certify that the Configuration Item listed above has

Conditionally completed an FCA/PCA or its equivalent and this audit will be closed when all Action

Items written against this audit are declared closed.

Successfully completed the FCA/PCA or equivalent and is hereby declared closed.

CUSTOMER PRODUCT DEVELOPER

ENGINEERING PANEL ENGINEERING PANEL

QUALITY ASSURANCE REPRESENTATIVE QUALITY ASSURANCE REPRESENTATIVE

CONFIGURATION MANAGEMENT REPRESENTATIVE CONFIGURATION MANAGEMENT REPRESENTATIVE

FCA/PCA CO-CHAIR FCA/PCA CO-CHAIR

GRC 2069 (MAY 11)

Certificate of Functional Configuration

Audit/Physical Configuration Audit

(OR EQUIVALENT)

CI/CSCI NUMBER PART NUMBER/SERIAL NUMBER

NOMENCLATURE MANUFACTURER

DEVELOPMENT SPECIFICATION NUMBER PIA/PMP

FCA #1 Qualification Test Procedures and Results

The qualification test/analysis results have been reviewed to ensure that testing is adequate, properly done,

and certified. Test procedures and interface documents have been reviewed to assure that the documents

have been approved. We certify that the test data sheets have been reviewed to assure that the test was

witnessed as required, and that the

Procedures and results reviewed satisfy the requirements and are accepted.

Procedures and results reviewed do not satisfy the requirements.

Attachment FCA #1 is the list of documents reviewed and deficiencies found.

FCA #2 Review of Deviations/Waivers

A review of all deviations/waivers to engineering documentation that have been approved was conducted.

The purpose was to determine the extent to which the hardware/software undergoing FCA vary from

applicable engineering documentation and to form a basis for satisfactory compliance with this

documentation. We certify that all applicable deviations/waivers have been reviewed with the following

results:

There are no deviations/waivers against the CI/CSCI.

All deviations/waivers were reviewed. A list of approved and unapproved deviations/waivers is

attached.

Attachment FCA #2 is the list of approved and unapproved deviations/waivers and the related discrepancies

and/or comments.

GRC 2069 (MAY 11)

Certificate of Functional Configuration

Audit/Physical Configuration Audit

(OR EQUIVALENT)

CI/CSCI NUMBER

PCA #1 Certificate of Product Baseline

A purpose of this PCA was to ensure accuracy of the technical documentation (i.e., item specification and

product drawings) and to identify the Product Baseline.

We certify that the configuration item listed herein has been formally audited against its technical

documentation and that the configuration item's Product Baseline is

Acceptable

Conditional - See Action Items

Attachment PCA #1 lists the Product Baseline for the above CI/CSCI.

PCA #2 Fabrication and Inspection Records

Fabrication and inspection records have been reviewed to verify that they properly and accurately describe the

work accomplished and that the configuration of the item is accurately documented. Fabrication/Inspection

records used for "in-process" inspections contain (a) nomenclature and part numbers that agreed with the

drawings and (b) reflect the requirements of the released design configuration noted above. We certify that

these are

Acceptable

Not Acceptable - See Action Items

Configuration Verification

Configuration inspections conducted during the in-process operations verified that the configuration of the

hardware conforms to the technical documentation. The inspections verified that no differences exist between

"as-built" and "as-designed" configurations except as documented in the fabrication/inspections records and

this certificate. We certify that these are

Acceptable

Not Acceptable - See Action Items

Certification and Acceptance Test Procedures (CATP) and Results

The Certification and Acceptance Test Procedures and results have been reviewed to ensure that testing has

been completed and verified in accordance with PIA/PMP requirements. Acceptance testing was conducted

with approved Acceptance Test Procedures and results were accurately documented. We certify that these

are

Acceptable

Not Acceptable - See Action Items

GRC 2069 (MAY 11)

Certificate of Functional Configuration

Audit/Physical Configuration Audit

(OR EQUIVALENT)

CI/CSCI NUMBER

PCA #3 Technical Documentation Control System Review

A review of the technical documentation and control system was performed to ensure that the drawing system

and associated release system and QA system - used to control the drawings that were used during the

"in-process" physical inspections - provide drawings that have been reviewed to verify accuracy and that they

adequately define the configuration of the item so that it can be manufactured, tested, and inspected.

The hardware/software provider's system requires that technical documentation used for the 'in-process"

inspections: a) were released through an official controlled release system; b) met the quality and age

restrictions for engineering change incorporation described in the approved Configuration Management Plan

and applicable drawing requirements manual; c) provided continuity from top-level assemblies to piece-parts;

d) accurately describes the item being inspected.

We certify that

The technical documentation control system is acceptable.

The technical documentation control system is not acceptable. See Action Items.

PCA #4 Drawing Review

A review was performed comparing the drawings to the physical equipment to ensure that the latest drawing

changes had been incorporated into the equipment, that part numbers appearing on the equipment agree with

part numbers listed on the drawings, and that the drawings were complete and accurately describe the item. A

list of drawings reviewed is attached hereto as Attachment PCA #4.

We certify that

The drawings are complete and accurately describe the item being audited.

Discrepancies were found between the drawings and the item being audited. See Action Items.

PCA #5 Review of Shortages and Unincorporated Design Changes

Shortages and unincorporated design changes on the attached list have been reviewed and recommended

corrective action has been provided.

We certify that

There are no shortages or unincorporated design changes.

Attached is a list of shortages and/or unincorporated design changes with recommended corrective action.

Attachment PCA #5 is the list of shortages and/or unincorporated design changes, and the recommended

corrective action required.

GRC 2069 (MAY 11)

Qualification Test Procedures

and Test Results

CI/CSCI NUMBER NOMENCLATURE

SPECIFICATION NUMBER TEST PROCEDURES

SPECIFICATION

REFERENCE

DESCRIPTION TEST RESULT

TP REFERENCE

GRC 2069 (MAY 11)

Review Deviations/Waivers

CI/CSCI NUMBER NOMENCLATURE

DEVIATION/WAIVER DESCRIPTION

NUMBER

GRC 2069 (MAY 11)

Product Baseline Listing

CI/CSCI NUMBER NOMENCLATURE

DOCUMENT/DRAWING UNINCORPORATED

NUMBER TITLE REVISION CHANGES

GRC 2069 (MAY 11)

Documentation/Drawings

Reviewed

CI/CSCI NUMBER NOMENCLATURE

DRAWING TITLE

NUMBER

GRC 2069 (MAY 11)

Shortages and Unincorporated

Design Changes

CI/CSCI NUMBER NOMENCLATURE

DESCRIPTION CORRECTIVE ACTION

GRC 2069 (MAY 11)

FCA/PCA

Action Item

CI/CSCI NUMBER DATE

NOMENCLATURE

PAGE 1 OF

PROJECT/PROVIDER AUDIT LOCATION AL NUMBER

FINDING/OBSERVATION

RECOMMENDED SOLUTION/ACTION

CATEGORY

I Hardware/Software may not be delivered until this Action is closed.

II Documentation clean up will not holdup hardware/software delivery.

INITIATOR (Name, telephone number) ASSIGNED TO

PROVIDER CO-CHAIR CUSTOMER CO-CHAIR

CLOSURE (Attach documentation, if required)

PROVIDER CO-CHAIR APPROVAL CUSTOMER CO-CHAIR APPROVAL

GRC 2069 (MAY 11)

FCA/PCA

Action Item Instructions

1. Review - Enter the appropriate CI/CSCI and nomenclature in the blank spaces provided.

2. Project/Provider - Enter what defines the subject of the action to be taken or

correction to be made.

3. AL Number - Enter a number to be used for tracking purposes.

4. Finding/Observation - Define the problem. An Action Item may only be written against

a contractually binding requirement. The problem must be written to fully define the

requirement and the violation of that requirement.

5. Recommended Solution/Action - Provide a suggested solution that would satisfy the

closure of this Action Item.

6. Category - To be assigned by FCA/PCA Co-Chairpersons.

7. Closure - Evidence of closure action taken.

GRC 2069 (MAY 11)

You might also like

- Annual Product Quality Review TemplateDocument9 pagesAnnual Product Quality Review Templateyasinpapers.datasNo ratings yet

- Factory Acceptance Test ProtocolDocument28 pagesFactory Acceptance Test ProtocolShabbir Hussain Palitanawala100% (7)

- HDT First Article Inspection Policy 01Document7 pagesHDT First Article Inspection Policy 01Srinivasan VenkatNo ratings yet

- DEMKO 18 ATEX 1986X Rev. 4Document3 pagesDEMKO 18 ATEX 1986X Rev. 4sefazNo ratings yet

- 2018 is-BAO Guidance CH 15Document30 pages2018 is-BAO Guidance CH 15EmNo ratings yet

- POST ACTIVITY REPORT TemplateDocument3 pagesPOST ACTIVITY REPORT TemplateRegion Personnel88% (8)

- Physical Configuration Audit ChecklistDocument4 pagesPhysical Configuration Audit ChecklistPetrrNo ratings yet

- Project Name System Verification Document: Company LogoDocument11 pagesProject Name System Verification Document: Company LogoFahad RustamNo ratings yet

- API Spec q1 9th EditionDocument3 pagesAPI Spec q1 9th Editionvtsusr fv80% (5)

- Sample Affidavit of Two Disinterested PersonsDocument1 pageSample Affidavit of Two Disinterested PersonsAileenJane Mallonga100% (3)

- Checklist DocumentDocument46 pagesChecklist DocumentGaurav Vishwakarma100% (2)

- 8 - Product Audit Checklist ASAP 7 11Document10 pages8 - Product Audit Checklist ASAP 7 11Sachin KumbharNo ratings yet

- List of PPAP DocsDocument4 pagesList of PPAP DocsSunilNo ratings yet

- How First Piece Inspection Procedure Enhances Production QualityDocument4 pagesHow First Piece Inspection Procedure Enhances Production QualityjackNo ratings yet

- Production Part Approval ProcessDocument3 pagesProduction Part Approval ProcessjitenderbawaliaNo ratings yet

- Template For Installation Qualification Protocol - Pharmaceutical GuidanceDocument6 pagesTemplate For Installation Qualification Protocol - Pharmaceutical GuidanceMSL IndiaNo ratings yet

- Appendix D13 Contents of Project Close-Out ReportDocument11 pagesAppendix D13 Contents of Project Close-Out ReportHamza ShujaNo ratings yet

- PPAP Elements DescriptionDocument3 pagesPPAP Elements DescriptionagungNo ratings yet

- Quality Test Specification QCS-83-4 FOR First Article Inspection (F.A.I.)Document10 pagesQuality Test Specification QCS-83-4 FOR First Article Inspection (F.A.I.)Amit GauravNo ratings yet

- Buffco Eng AS9100 Quality Manual 2-28-06Document26 pagesBuffco Eng AS9100 Quality Manual 2-28-06savlafNo ratings yet

- Ppap WorkbookDocument80 pagesPpap WorkbookalyankaNo ratings yet

- 1 Production Part Approval ProcessDocument42 pages1 Production Part Approval ProcessVinod Kaul100% (1)

- AS9102 FAI GuidelinesDocument27 pagesAS9102 FAI Guidelinesjamilvora100% (1)

- PF 8500Document10 pagesPF 8500ibrahime mohammedNo ratings yet

- Auto Part Manufacturing ProcessDocument4 pagesAuto Part Manufacturing ProcessKuldeep BohraNo ratings yet

- Quality Control Manual: Company Name Address City, State, ZipDocument10 pagesQuality Control Manual: Company Name Address City, State, ZipMarco CandoNo ratings yet

- First Article Inspection RequirementDocument2 pagesFirst Article Inspection RequirementRBThomas2011No ratings yet

- Visual Weld Inspection: Organizational IssuanceDocument7 pagesVisual Weld Inspection: Organizational IssuanceEdAlmNo ratings yet

- PowerPoint Presentation FAI AS9102Document29 pagesPowerPoint Presentation FAI AS9102Danny Fydm OliveiraNo ratings yet

- PpapDocument3 pagesPpapVlad NitaNo ratings yet

- Eurabo-347 - Qa Sign Off - 04092014Document4 pagesEurabo-347 - Qa Sign Off - 04092014BalasubrahmanyamNo ratings yet

- Design ProcessDocument7 pagesDesign Processrobert_kerr_29No ratings yet

- Control of Design Process ChangesDocument7 pagesControl of Design Process ChangesayushNo ratings yet

- When To Conduct A First Article InspectionDocument4 pagesWhen To Conduct A First Article InspectionCloud RedfieldNo ratings yet

- Guide For Successful Completion of First Article Inspection (Fai) ReportsDocument34 pagesGuide For Successful Completion of First Article Inspection (Fai) ReportsJohn OlayNo ratings yet

- AiscDocument3 pagesAiscvo thi kim xuyenNo ratings yet

- ISV Design Presentation - MRM-12!01!2024 - FinalDocument83 pagesISV Design Presentation - MRM-12!01!2024 - FinalMunish KanwarNo ratings yet

- Gorham-SD PMA2011X1.90151946Document62 pagesGorham-SD PMA2011X1.90151946ben foldsNo ratings yet

- Desktop Suveliance Nabl 218Document8 pagesDesktop Suveliance Nabl 218Vasu Raja0% (1)

- QM-F-7.1-15 Ver.2.0 - Annual Quality Audit of VendorsDocument5 pagesQM-F-7.1-15 Ver.2.0 - Annual Quality Audit of VendorssanjaydeNo ratings yet

- Product Qualification Requirements 2.0Document3 pagesProduct Qualification Requirements 2.0Amit SinghNo ratings yet

- Production Part Approval Process (PPAP)Document3 pagesProduction Part Approval Process (PPAP)psathishthevanNo ratings yet

- Qualification - Validation CPOB 2018 PDFDocument145 pagesQualification - Validation CPOB 2018 PDFmela milaniNo ratings yet

- PF Emissions eDocument17 pagesPF Emissions eibrahime mohammedNo ratings yet

- Competenz Assessment GuideDocument6 pagesCompetenz Assessment GuideChineselegolasNo ratings yet

- 1.5 Guidelines For Preparing Inspections & Test Plans (Itp) Agrarian Reform Communities ProjectDocument5 pages1.5 Guidelines For Preparing Inspections & Test Plans (Itp) Agrarian Reform Communities ProjectJason Angel BuñagNo ratings yet

- Fai 1Document5 pagesFai 1pawoe3064No ratings yet

- GMP ChecklistDocument11 pagesGMP ChecklistWerner Schrammel100% (1)

- 9 AuditsDocument3 pages9 Auditsnaveen yadavNo ratings yet

- SOP For Corrective Action and Preventive Action (CAPA) - Pharmaceutical GuidelinesDocument5 pagesSOP For Corrective Action and Preventive Action (CAPA) - Pharmaceutical GuidelinesAmit KumarNo ratings yet

- Aqpaxi Phase 2.rev13Document7 pagesAqpaxi Phase 2.rev13Isabel SierraNo ratings yet

- APQP FormatosDocument15 pagesAPQP FormatoseddiefloresNo ratings yet

- Sample SAT Procedure (Only For Reference)Document3 pagesSample SAT Procedure (Only For Reference)Mohammed SinanNo ratings yet

- What Is A First Article InspectionDocument2 pagesWhat Is A First Article InspectionCloud RedfieldNo ratings yet

- Be-Pdp-Fr-07-E Papso Form Roanoke To Sa - j7Document2 pagesBe-Pdp-Fr-07-E Papso Form Roanoke To Sa - j7Ricardo Frank CordeiroNo ratings yet

- Op4.0015 R3Document5 pagesOp4.0015 R3mulldoctor1No ratings yet

- PPAP ElementsDocument2 pagesPPAP ElementsSenthil Kumar Gunasekaran50% (2)

- Guideline 2 FAIDocument16 pagesGuideline 2 FAIMohamed HassanNo ratings yet

- B2 Documented Information For Externally Provided Products and ServicesDocument9 pagesB2 Documented Information For Externally Provided Products and ServicesaceNo ratings yet

- MAI 04 - In-Process, Inspection and Testing - DJ - v1Document11 pagesMAI 04 - In-Process, Inspection and Testing - DJ - v1IT Support - FernanNo ratings yet

- Production Part Approval ProcessDocument6 pagesProduction Part Approval ProcessleonardoNo ratings yet

- Codification of Statements on Auditing Standards: Numbers 122 to 133, January 2018From EverandCodification of Statements on Auditing Standards: Numbers 122 to 133, January 2018No ratings yet

- Improving Product Reliability and Software Quality: Strategies, Tools, Process and ImplementationFrom EverandImproving Product Reliability and Software Quality: Strategies, Tools, Process and ImplementationNo ratings yet

- Codification of Statements on Standards for Attestation Engagements, January 2018From EverandCodification of Statements on Standards for Attestation Engagements, January 2018No ratings yet

- Design and Implementation of Computerised Students' Identity CardDocument45 pagesDesign and Implementation of Computerised Students' Identity CardTUMUHIMBISE LUCKYNo ratings yet

- TLF-AGC 8.2 V5 May2020 Application For Exemption With SAQA CreditsDocument2 pagesTLF-AGC 8.2 V5 May2020 Application For Exemption With SAQA Creditsnokukhanyashoba02No ratings yet

- Birth NewDocument1 pageBirth NewDianne LlgnNo ratings yet

- Urn Uvci 01 Ro R48m1gyolqeny4wm5gwz3wxd67kp02#xDocument2 pagesUrn Uvci 01 Ro R48m1gyolqeny4wm5gwz3wxd67kp02#xDavidNo ratings yet

- Economic and Social Council: Economic Commission For EuropeDocument15 pagesEconomic and Social Council: Economic Commission For EuropeLaroyNo ratings yet

- SAP Conversion Syllabus Latest 2023Document2 pagesSAP Conversion Syllabus Latest 2023halol72006No ratings yet

- 51274.23.07.65.MP - Wire RopeDocument1 page51274.23.07.65.MP - Wire RopeRamprasadNo ratings yet

- Panchayat Secretary (GR VI) Digital AssistantDocument29 pagesPanchayat Secretary (GR VI) Digital AssistantKola PattabhiNo ratings yet

- Abhijit Samantray Docs PDFDocument13 pagesAbhijit Samantray Docs PDFAbhijit samantrayNo ratings yet

- Rabindra Bharati University: 56A, B.T. Road, Kolkata - 700050Document13 pagesRabindra Bharati University: 56A, B.T. Road, Kolkata - 700050Salman NoorNo ratings yet

- Aadhar AddressDocument1 pageAadhar AddressSureshBabu100% (2)

- Recruitment For The Post of Scientist C' in Icert, MeityDocument10 pagesRecruitment For The Post of Scientist C' in Icert, MeitySujeet VermaNo ratings yet

- CSC Job Portal: Mgo San Jose, Antique - Region ViDocument1 pageCSC Job Portal: Mgo San Jose, Antique - Region ViGilbert GonzalesNo ratings yet

- CCM-Application Handbook-2020Document41 pagesCCM-Application Handbook-2020Jacob LeeNo ratings yet

- B - Certification Report SampleDocument17 pagesB - Certification Report Samplemankrsha83No ratings yet

- Towards Decentralized Identity For Internet of ThingsDocument6 pagesTowards Decentralized Identity For Internet of ThingsRaullen ChaiNo ratings yet

- Prequalification of Concord SurveyDocument23 pagesPrequalification of Concord SurveyJason RazatlabNo ratings yet

- SADCAS F 60 (B) - Technical Requirements of ISO IEC 17025-2017 (Issue 2)Document30 pagesSADCAS F 60 (B) - Technical Requirements of ISO IEC 17025-2017 (Issue 2)Chi Jui HanNo ratings yet

- Affidavit of Loss: Jeffry Jude T. YapDocument1 pageAffidavit of Loss: Jeffry Jude T. YapChan DersNo ratings yet

- Second Special Drive Admission Rollover On Spot Admission Svs Bvoc ProgrammesDocument6 pagesSecond Special Drive Admission Rollover On Spot Admission Svs Bvoc ProgrammesNeelabh ParasharNo ratings yet

- Omnibus Certification of Authenticity and Veracity of DocumentsDocument2 pagesOmnibus Certification of Authenticity and Veracity of DocumentsFidel ZapataNo ratings yet

- StandardsforNonFoodSuppliers tcm137-70082Document12 pagesStandardsforNonFoodSuppliers tcm137-70082joyrjaelNo ratings yet

- 2023 Checklist For Newly Hired Teaching Non Teaching PositionsDocument3 pages2023 Checklist For Newly Hired Teaching Non Teaching PositionsMelba PeteroNo ratings yet

- Integrated Mepss - Section V - Snepco - SPDC - Combined Scope of WorkDocument365 pagesIntegrated Mepss - Section V - Snepco - SPDC - Combined Scope of WorkJoe EkanemNo ratings yet

- DGCA-AC 21-29 Amdt. 1 - Detecting and Reporting Suspected Unapproved PartsDocument10 pagesDGCA-AC 21-29 Amdt. 1 - Detecting and Reporting Suspected Unapproved Partsraihan zakyNo ratings yet

- MQA Certification UK Ltd.Document15 pagesMQA Certification UK Ltd.Yosy WonoasriNo ratings yet