Professional Documents

Culture Documents

Screen Printing On Paper Using Jamun Ink

Screen Printing On Paper Using Jamun Ink

Uploaded by

Althea RivadeloOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Screen Printing On Paper Using Jamun Ink

Screen Printing On Paper Using Jamun Ink

Uploaded by

Althea RivadeloCopyright:

Available Formats

International Journal For Technological Research In Engineering

Volume 3, Issue 10, June-2016 ISSN (Online): 2347 - 4718

NATURAL JAMUN INK PREPARATION FOR SCREEN PRINTING

ON PAPER

Rubia1, Aman Bhardwaj2, Nishan Singh3

ABSTRACT: An attempt of natural jamun ink preparation STEPS FOLLOWED FOR NATURAL JAMUN INK

for screen printing on paper is made in this paper. Steps PREPARATION

followed for ink preparation are simple. Constituents used 250 gm of jamun pulp is grinded with 200ml of

for ink preparation are natural. Natural inks prepared from water for 2 minutes. Now this paste is boiled at

plants, fruits, vegetables, minerals, microbes are used 70°C for 30 minutes so that harmful bacteria and

mainly for printing on textile. Using natural inks have enzymes present in the sap becomes inactive.

various benefits like skin-friendly, less pollution generation, During this boiling process the colouring

eco-friendly, bio-degradable, non-toxic etc. Prepared jamun component anthocyanin present in jamun dissolved

ink is safe to eat and is non-toxic. Using natural inks for properly in water and gives purple colour.

paper is an alternate to synthetic inks which are harmful to Sap is filtered using muslin cloth and boiled again

human health. Prepared ink gives good colour strength to bring the final concentration to 100 ml.

when printed on paper. Now 1 tbsp of salt as preservative, 1½ tbsp of

Keywords: jamun, colourant, natural ink, paper arrow root powder for viscosity, 1 tbsp of gum

acacia paste as resin are added in the sap and sap is

I. INTRODUCTION boiled till the consistency of ink changes.

Nature has so many beautiful colours. We have used one Now the prepared ink is used for printing on paper

such colour from nature i.e. purple from jamun for natural using screen. Print obtained is shown in figure 1.

ink preparation for screen printing on paper. Colouring Prepared ink gives good colour strength of purple

component present in black current is anthocyanin. For ink colour.

preparation simple aqueous method is used. It is a traditional

method for extracting colour from natural resources. In this

method, colour containing compound if dry broken down into

small pieces or in powdered form by grinding and soaked

with water in vessel for some time to loosen the cell

structure. If colour containing compound is in wet form then

it is chopped down to fine pieces or grinded to fine paste.

Then these broken down pieces are boiled in water to get the

colouring component dissolved in water. This solution is Figure 1

filtered to separate colouring solution and non-colouring DATA ANALYSIS

remnant. Both can be used easily to impart colour to different Print was evaluated on various parameters which are shown

things. There are some disadvantages associated with this in table 1.

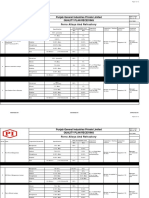

extraction method like slow process for extracting colour, Sr. Parameters Harad Powder Ink

high temperature requirement, large volume of water No.

requirement, heat sensitive colouring substances gets reduced

at high temperature, low dye yield, only water soluble 1. Sunlight exposure for 7 Stable

colouring components can be extracted. Components of days

prepared ink are shown in table 1.

2. Rub resistance test Stable (upto 1000

rounds)

Table 1. Components of prepared ink

Sr. No. Components of Ink Jamun Ink 3. Peel-off test Stable

1. Solvent Water

4. UV exposure for 6 hours Stable

2. Resin Gum acacia

5. Stability at low temperature Stable

3. Pigment Anthocyanin

6. Permanency of colour in Stable

4. Additive Salt, arrow root powder normal day-light conditions

www.ijtre.com Copyright 2016.All rights reserved. 3048

International Journal For Technological Research In Engineering

Volume 3, Issue 10, June-2016 ISSN (Online): 2347 - 4718

7. Drying time 3-5 sec.

8. Colour of printed ink Purple

II. RESULT AND DISCUSSION

Natural jamun Ink gives good colour strength of purple

colour when printed on paper. Ink used is easy to prepare,

economical and gives good print quality. After evaluation of

printed ink, it was found that ink is stable with respect to

various tests of rub-resistance, peel-off, sun exposure, UV

exposure, permanency of colour in normal day-light

conditions.

III. CONCLUSION

Following are the conclusion from this research work:

Jamun Ink is feasible for printing on paper using

screen printing.

Life of ink is from 50-60 days.

Simple manufacturing process.

Prepared ink is eco-friendly and easy to decompose.

This can be concluded that prepared purple jamun ink can be

a good alternate to synthetic inks. More research is required

in this field to standardize the method for ink preparation

from jamun.

REFERENCES

[1] Gupta, S. B. (2016). Screen Printing on Silk Fabric

using Natural Dye and Natural Thickening. Journal

of Textile Science & Engineering.

[2] Kumar, V. (2015). Natural Dyes: Application in

Eco-friendly Textile Dyeing and Printing.

International Research Journal of Biochemistry and

Biotechnology , 10-12.

[3] George Savvidis, E. K. (2014). Ink-jet printing of

cotton with natural dyes. Coloration Technology ,

200-204.

[4] Raja, S. S. (2014). Natural Dyes: Sources,

Chemistry, Application and Sustainability Issues.

Roadmap to Sustainable Textiles and Clothing , 37-

80.

[5] Mansour, K. R. (2013). Environmental production

of fashion colours from natural dyes. Chemical

Science Transactions , 670-683.

[6] M. Ram Kumar, P. P. (2012). Formulation and

Standardization of Herbal Based Edible Ink.

International Journal of Advances in Pharmacy and

Chemistry , 252-254.

www.ijtre.com Copyright 2016.All rights reserved. 3049

You might also like

- Piping Fabrication and Installation Procedure Rev.A1Document19 pagesPiping Fabrication and Installation Procedure Rev.A1Anh Võ71% (24)

- Alternative Ink PDFDocument33 pagesAlternative Ink PDFAira Ignacio100% (1)

- Lab Report Gas LawsDocument7 pagesLab Report Gas LawsSam SternfieldNo ratings yet

- SDS 97371 (Curing Agent 85671)Document11 pagesSDS 97371 (Curing Agent 85671)Eisya100% (1)

- Detail Study of Ink Fromulation From Natural ColourantsDocument3 pagesDetail Study of Ink Fromulation From Natural ColourantsEos ChavezNo ratings yet

- Using Natural Harad Powder Ink For Screen PrintingDocument3 pagesUsing Natural Harad Powder Ink For Screen PrintingPrabhu TexcomsNo ratings yet

- Proposal PenelitianDocument9 pagesProposal Penelitianfilda widaniatiNo ratings yet

- Ijramt2 5 4Document6 pagesIjramt2 5 4thiri phyo waiNo ratings yet

- Dyeing of Cotton Fabric Using Malabar Spinach (Basella Alba) Leaves Aqueous ExtractDocument4 pagesDyeing of Cotton Fabric Using Malabar Spinach (Basella Alba) Leaves Aqueous ExtractInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- IITDocument27 pagesIITcharli50% (2)

- Utilization of Onion Skin As Alternative Pimgent For Calligraphy InkDocument42 pagesUtilization of Onion Skin As Alternative Pimgent For Calligraphy InkJeska Gayanes100% (1)

- Formulation and Evaluation of Herbal Lipbalm From Amaranth Leaf Colour PigmentDocument12 pagesFormulation and Evaluation of Herbal Lipbalm From Amaranth Leaf Colour PigmentIJRASETPublicationsNo ratings yet

- Spinach Ink - Research Proposal - ReviseDocument26 pagesSpinach Ink - Research Proposal - ReviseSadie CangNo ratings yet

- 1 PrintingDocument4 pages1 PrintingRITIKNo ratings yet

- 83.oct Ijmte - CWDocument5 pages83.oct Ijmte - CWXile LeadNo ratings yet

- CapstoneDocument11 pagesCapstoneChristian PaulNo ratings yet

- Extraction of Natural Dye Collected From Outer Skin of Onion and It's Application On Silk FabricDocument7 pagesExtraction of Natural Dye Collected From Outer Skin of Onion and It's Application On Silk FabricUmar Farouq Mohammed GalibNo ratings yet

- Extraction of Natural Dye Collected From Outer Skin of Onion and It's Application On Silk FabricDocument7 pagesExtraction of Natural Dye Collected From Outer Skin of Onion and It's Application On Silk FabricUmar Farouq Mohammed GalibNo ratings yet

- Development of Latent Fingerprint by Turmeric PowderDocument8 pagesDevelopment of Latent Fingerprint by Turmeric Powdermrinaal vidaniNo ratings yet

- Ink PaperDocument8 pagesInk PaperPriyanka PatilNo ratings yet

- Mordant Printed Cotton Fabric Dyed in Natural Dye - KaleDocument4 pagesMordant Printed Cotton Fabric Dyed in Natural Dye - KaleAnne CalyxNo ratings yet

- Preliminary Investigation On Production of Brown Ink From Gmelina Arborea (ROXB) Fruit ExtractDocument7 pagesPreliminary Investigation On Production of Brown Ink From Gmelina Arborea (ROXB) Fruit ExtractEos ChavezNo ratings yet

- Alternative Ink PDFDocument33 pagesAlternative Ink PDFJohn Angolluan0% (1)

- Dermeto Review 1Document8 pagesDermeto Review 1mrinaal vidaniNo ratings yet

- Dyeing of Cotton With Natural Dye Extract From Coconut HuskDocument4 pagesDyeing of Cotton With Natural Dye Extract From Coconut HuskIJSTE100% (1)

- PATTERNSFROMNATUREDocument12 pagesPATTERNSFROMNATURElitaNo ratings yet

- EXPERIMENTALDocument13 pagesEXPERIMENTALsangeNo ratings yet

- Documents - Pub Narra Bark As InkpdfDocument22 pagesDocuments - Pub Narra Bark As InkpdfErving Lester MagtajasNo ratings yet

- JurnalllllDocument11 pagesJurnallllldickyferinando1605No ratings yet

- Jurnal SokletqsiDocument142 pagesJurnal Sokletqsidickyferinando1605No ratings yet

- 13 BiomordantDocument3 pages13 Biomordantnamratakushwah2016No ratings yet

- Natutaldyefrompseudostemofbanan PaperDocument10 pagesNatutaldyefrompseudostemofbanan Papermap solutionsNo ratings yet

- Banana Sap and Dye As An Alternative Ink Manuscript 1 3.docxxDocument18 pagesBanana Sap and Dye As An Alternative Ink Manuscript 1 3.docxxGelo Datu100% (2)

- 10reserch Chapter I V 2023 ORIGINALDocument17 pages10reserch Chapter I V 2023 ORIGINALLeica Escolano Riteral0% (1)

- Introduction CapstoneDocument4 pagesIntroduction Capstoneitsmeashley2811No ratings yet

- The Feasiblity of Using Indigenous DyestuffDocument2 pagesThe Feasiblity of Using Indigenous Dyestuffalvin90% (10)

- Natural Dyes 2Document9 pagesNatural Dyes 2lorena MedinaNo ratings yet

- CAPSTONE FINAL. Wilson Humprey and RandellDocument5 pagesCAPSTONE FINAL. Wilson Humprey and RandellWilson RomeroNo ratings yet

- Jurnal Spektrofotometri Serapan AtomDocument13 pagesJurnal Spektrofotometri Serapan Atom2OO11O39 Chenia NandiniNo ratings yet

- 101-Article Text-448-1-10-20211126Document6 pages101-Article Text-448-1-10-20211126Ida NurwahidahNo ratings yet

- Ejesm V15i4 3Document7 pagesEjesm V15i4 3Xile LeadNo ratings yet

- MACIJ16000117.pdf: Cite This PaperDocument7 pagesMACIJ16000117.pdf: Cite This PaperchalachewNo ratings yet

- Ijesrt: International Journal of Engineering Sciences & Research TechnologyDocument4 pagesIjesrt: International Journal of Engineering Sciences & Research Technologyمحمود عامرNo ratings yet

- fd8f PDFDocument9 pagesfd8f PDFMea Capistrano AlcalaNo ratings yet

- Cotton Dyeing With Natural Dye Extracted From Pomegranate PDFDocument5 pagesCotton Dyeing With Natural Dye Extracted From Pomegranate PDFAmalia RizkaNo ratings yet

- Ecofriendly Medical Textile Using Morinda Pubescens J. E. Smith As A Source of Natural DyeDocument4 pagesEcofriendly Medical Textile Using Morinda Pubescens J. E. Smith As A Source of Natural DyeGolam Rabbi SagorNo ratings yet

- Applications of Eco Friendly Natural Dyes On LeatherDocument5 pagesApplications of Eco Friendly Natural Dyes On LeatheraleauNo ratings yet

- Research Plan PDFDocument10 pagesResearch Plan PDFmohsin alamNo ratings yet

- Use of Senggani Leaves As An Alternative MaterialDocument8 pagesUse of Senggani Leaves As An Alternative Materialselwynjabines843No ratings yet

- Stabilitas Warna Bubuk Pewarna Dari Ekstrak Angkak - Irnia Nurika Jurnal Teknologi Pertanian Vol. 3 No. 1: 67 - 77Document11 pagesStabilitas Warna Bubuk Pewarna Dari Ekstrak Angkak - Irnia Nurika Jurnal Teknologi Pertanian Vol. 3 No. 1: 67 - 77GILANG BAGUS PAMUNGKASNo ratings yet

- Research IsolationDocument6 pagesResearch IsolationElena AbagaNo ratings yet

- 1 PBDocument11 pages1 PBTsania DzakiyaNo ratings yet

- Dyeing of Polyester With Natural DyesDocument9 pagesDyeing of Polyester With Natural DyesAnne CalyxNo ratings yet

- Utilization of The Mangrove BarkDocument11 pagesUtilization of The Mangrove BarkLeica Escolano RiteralNo ratings yet

- 163 161 PBDocument9 pages163 161 PBAbhimanyu SinghNo ratings yet

- Dyeing Cotton With Natural Dye Extracted From Syzygium Cordatum BarkDocument11 pagesDyeing Cotton With Natural Dye Extracted From Syzygium Cordatum BarkAnonymous izrFWiQNo ratings yet

- Extraction of Natural Dye From Ficus Cunia and Dyeing of Different FabricsDocument6 pagesExtraction of Natural Dye From Ficus Cunia and Dyeing of Different FabricsHaco Chinedu ObasiNo ratings yet

- Natural Dye PowderDocument4 pagesNatural Dye PowderpkksjpNo ratings yet

- 123 IloveyouDocument7 pages123 IloveyoumontecillomarlyNo ratings yet

- Mosquito Repellent by Orange PeelsDocument5 pagesMosquito Repellent by Orange PeelsBruhNo ratings yet

- Application of Purified Curcumin As Natural Dye On Cotton and PolyesterDocument7 pagesApplication of Purified Curcumin As Natural Dye On Cotton and PolyesterUmar Farouq Mohammed GalibNo ratings yet

- Analisys and application of dry cleaning materials on unvarnished pain surfacesFrom EverandAnalisys and application of dry cleaning materials on unvarnished pain surfacesNo ratings yet

- Japan Blue Indigo Dyeing Techniques: A Beginner's Guide to Shibori Tie-DyeingFrom EverandJapan Blue Indigo Dyeing Techniques: A Beginner's Guide to Shibori Tie-DyeingNo ratings yet

- 21ST AmericanlitDocument8 pages21ST AmericanlitAlthea RivadeloNo ratings yet

- Uploads - Old - Project - Caesar - 2-Revised ProposalDocument7 pagesUploads - Old - Project - Caesar - 2-Revised ProposalAlthea RivadeloNo ratings yet

- Sustainable PrintingDocument44 pagesSustainable PrintingAlthea RivadeloNo ratings yet

- Ucsp Module 4 Lecture Notes 1 18Document21 pagesUcsp Module 4 Lecture Notes 1 18Althea RivadeloNo ratings yet

- FORMULATION OF ORGANIC INK USING IpomoeaDocument38 pagesFORMULATION OF ORGANIC INK USING IpomoeaAlthea RivadeloNo ratings yet

- Do You Like Your Teachers? A Quantitative Research On Students' Perceptions of Teacher Gender CharacteristicsDocument8 pagesDo You Like Your Teachers? A Quantitative Research On Students' Perceptions of Teacher Gender CharacteristicsAlthea RivadeloNo ratings yet

- G11 Earth ScienceDocument14 pagesG11 Earth ScienceAlthea RivadeloNo ratings yet

- Physical Learning Environmentonthe Academic Achievementin Entrepreneurshipof Grade 10 Students JournalDocument12 pagesPhysical Learning Environmentonthe Academic Achievementin Entrepreneurshipof Grade 10 Students JournalAlthea RivadeloNo ratings yet

- Sketches by BozDocument831 pagesSketches by BozAlthea RivadeloNo ratings yet

- Approved Painting Scheme - ObraDocument21 pagesApproved Painting Scheme - ObraCaspian Datta100% (3)

- New Thick CylindersDocument44 pagesNew Thick CylindersVinay Korukonda100% (2)

- Oct 2020 Unit 5 wph15 New MsDocument19 pagesOct 2020 Unit 5 wph15 New MsMomen YasserNo ratings yet

- Agricultural Machinery and EquipmentDocument41 pagesAgricultural Machinery and EquipmentRolen VicenteNo ratings yet

- Kwinana Refinery 2007 2009Document249 pagesKwinana Refinery 2007 2009Khalid Mahmood100% (2)

- Dobre Et Al. - Inulin Extraction and EncapsulationDocument3 pagesDobre Et Al. - Inulin Extraction and EncapsulationEko Isro RiyantoNo ratings yet

- Pgil Master Ferro Alloy and Refrac ListDocument12 pagesPgil Master Ferro Alloy and Refrac ListrohitNo ratings yet

- Regarding Nitrogen Boosting.: ANWAR SADAT (Aqua Refinery)Document4 pagesRegarding Nitrogen Boosting.: ANWAR SADAT (Aqua Refinery)anwar sadatNo ratings yet

- A Bumpy Ride On The Diagnostic Bench of Massive Parallel Sequencing, The Case of The Mitochondrial GenomeDocument9 pagesA Bumpy Ride On The Diagnostic Bench of Massive Parallel Sequencing, The Case of The Mitochondrial GenomeMayra EduardoffNo ratings yet

- PV 1303Document10 pagesPV 1303tufantasma100% (2)

- AMIANTI RC-with GRP PDFDocument24 pagesAMIANTI RC-with GRP PDFahmedomar_953724702No ratings yet

- SKF3013 Physical Chemistry I: Prof. Dr. Ramli Ibrahim Dr. Norlaili Abu BakarDocument24 pagesSKF3013 Physical Chemistry I: Prof. Dr. Ramli Ibrahim Dr. Norlaili Abu BakarAisha NajihaNo ratings yet

- The First Experiment I Will Do Is Evaporative Cooling. The Supplies Needed AreDocument3 pagesThe First Experiment I Will Do Is Evaporative Cooling. The Supplies Needed AreMarinelle R. EumagueNo ratings yet

- Data Sheet U53Document2 pagesData Sheet U53edwinmenaNo ratings yet

- 2 RemovedDocument1 page2 RemovedNo NameNo ratings yet

- Permanent Mold CastingDocument15 pagesPermanent Mold CastingEka RosmitaliaNo ratings yet

- Exp 1 RubberDocument6 pagesExp 1 RubberArhmhklNo ratings yet

- BOA Group Axial Expansion JointsDocument24 pagesBOA Group Axial Expansion JointsA_ValsamisNo ratings yet

- Single Correct: Class: Adv - CC Time: 50 Min Class Test-4: Paragraph For Question Nos. 4 To 6Document5 pagesSingle Correct: Class: Adv - CC Time: 50 Min Class Test-4: Paragraph For Question Nos. 4 To 6bruh pogNo ratings yet

- Guidance On The Compilation of Safety Data SheetsDocument138 pagesGuidance On The Compilation of Safety Data SheetsAlexEcnomNo ratings yet

- Chem 113E Module 5 Nuclear ChemistryDocument20 pagesChem 113E Module 5 Nuclear ChemistryKenneth John FerrarizNo ratings yet

- Flowserve CV PDFDocument36 pagesFlowserve CV PDFAlvin SmithNo ratings yet

- Experiment 3: Adsorption: - Lecture On Adsorption TheoryDocument12 pagesExperiment 3: Adsorption: - Lecture On Adsorption TheoryFlorenceNo ratings yet

- CHEM 204 - Problem Set 2Document2 pagesCHEM 204 - Problem Set 2myriamNo ratings yet

- Unit 3 Natural Gas Liquids (NGL) Recovery UnitDocument22 pagesUnit 3 Natural Gas Liquids (NGL) Recovery Unitkhalimn100% (4)

- Chlorination CalculationsDocument23 pagesChlorination CalculationsOkwajja ClementNo ratings yet

- PBL 2020 Decarbonisation Options For The Dutch Offshore Natural Gas Industry 4161Document54 pagesPBL 2020 Decarbonisation Options For The Dutch Offshore Natural Gas Industry 4161FDNo ratings yet