Professional Documents

Culture Documents

Chen 2004

Chen 2004

Uploaded by

Eragon0101 TheDragonRiderCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chen 2004

Chen 2004

Uploaded by

Eragon0101 TheDragonRiderCopyright:

Available Formats

Proceedings of IMECE04

2004 ASME International Mechanical Engineering Congress and Exposition

November 13-20, 2004, Anaheim, California USA

IMECE2004-62303

Buoyancy Driven Microfluidics

Z. Chen, S. Qian, J. Wang, and H. H. Bau1

Dept. Mechanical Engineering and Applied Mechanics

University of Pennsylvania, Philadelphia, PA 19104-6315

It is not surprising that the use of buoyancy as a driving force in microfluidic systems has

attracted little or no attention. Buoyant forces are proportional to the volume and do not scale

favorably as the device size is reduced. Nevertheless, in certain biotechnological applications,

one can produce sufficiently large buoyancy forces to generate fluid motion at velocities on the

order of mm/s even in conduits with equivalent diameters of a few hundreds of microns. One

example is the thermal polymerase chain reaction (PCR) for DNA amplification. In this process,

the reagents’ temperature varies from about 55°C to 94°C. Such large temperature variations can

induce significant buoyant forces. Another class of systems that can be driven by buoyant forces

is rotating laboratories on a chip (lab on a CD). In such laboratories, large centrifugal

accelerations may induce significant buoyant forces even when the temperature variations are

relatively small. These temperature variations can be used to propel and control fluid flow.

In this presentation, we describe a successful demonstration of a self-actuated, continuous

flow (SAFC) PCR reactor for DNA amplification. The common PCR process requires one to

cycle the sample’s temperature from about 94C (denaturation) to 55°C (annealing) to 72°C

(extension). In most bench-top PCR reactors, the sample is maintained stationary while the

temperature is repetitively alternated, which makes it necessary to heat and cool both the

reagents and the heating block. This process results in considerable thermal inertia, and it is a

relatively slow and energy-intensive process. Some of these shortcomings can be overcome

through miniaturization and the use of continuous flow reactors. In continuous flow PCR

reactors, the temperatures of the three thermal zones are maintained fixed while the reagents are

circulated continuously through these thermal zones. Continuous flow reactors allow for

significantly shorter heating and cooling times with reduced energy consumption since it is not

necessary to combat the thermal inertia of the apparatus. The continuous flow reactors require,

however, a means for propelling the sample. In recent years, various means for propelling the

fluid, ranging from pressure to peristalsis to magneto-hydrodynamics, have been proposed. Here,

we put forward an intriguing alternative.

1

Corresponding author, bau@seas.upenn.edu

1 Copyright © 2004 by ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 11/11/2017 Terms of Use: http://www.asme.org/about-asme/terms-of-use

The relatively large temperature variations needed for PCR induce significant variations

in the fluid’s density, which we use to generate fluid motion. We constructed a closed loop

having a triangular shape and placed in the vertical plane (Fig. 1). The vertical leg was heated to

94°C (denaturation zone), part of the diagonal leg was maintained at 55°C (annealing zone), and

the horizontal leg was maintained at 72°C (extension zone). The upper part of the tube was

exposed to the ambient temperature to facilitate cooling from 94°C to 55°C. The closed loop

formed a thermosyphon, and the fluid’s density variations facilitated counter-clockwise

circulation. Flow velocities as high as 5mm/s were attained in a conduit with a 700µm diameter.

Interestingly, since for a given loop geometry both the buoyant and viscous forces are

proportional to the length of the loop, the flow velocity is only weakly dependent on the actual

length of the loop, and the loop can be readily scaled down in length with only moderate impact

on the fluid velocity. This assertion was demonstrated through experiments and theoretical

calculations.

The reagents circulated continuously among the various heated zones as required for

DNA amplification. Successful amplifications of 700-bp and 305-bp fragments of Bacillus

cereus genomic DNA have been demonstrated. Fig. 2 depicts gel images of the PCR products

compared with DNA amplification in bench top machines. The actual experimental data was

collected from a scaled up version of the apparatus depicted in Fig. 12.

We speculate that by judiciously heating various branches of a network (Fig. 3), we can

use buoyant forces to direct the flow to follow a desired path without the need for mechanical

valves. Work to prove the concept is ongoing, and the results will be described.

In summary, the paper describes our theoretical analysis and experimental verification of

a microfluidic system driven with buoyant forces. As an example of an application, a self-

driven, PCR machine was modeled, constructed, and successfully tested.

Acknowledgments: We enjoyed helpful discussions with Drs. D. Malamud, W. Abrams,

and Z. Wu (University of Pennsylvania, School of Dental Medicine) and P. Corstjens (Leiden

University). Ms. C. Davis and Mr. G. Tong (University of Pennsylvania, School of Dental

Medicine) assisted with the PCR experiments. The experimental and theoretical works were

supported, respectively, by NIH grant U01DE014964 and DARPA grant N66001-01-C-8056 to

the University of Pennsylvania.

2

Chen, Z., Qian, S., Abrams, W., R., Malamud, D., and Bau, H., H., 2004, Thermosyphon-based PCR Reactor:

Experiment and Modeling, Analytical Chemistry, 76, 3707-3715.

2 Copyright © 2004 by ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 11/11/2017 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Annealing

Fig. 1: A self-actuated PCR machine. The device zone (55°C)

was fabricated with polycarbonate using layered Denaturation

Conduit Heaters zone (94°C)

manufacturing. The heaters were fabricated by

vapor deposition of metal on the polycarbonate

and standard photolithographic processing.

Extension

zone (72°C)

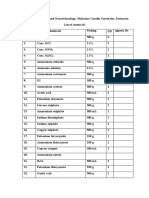

Fig. 2: Images of ethidium bromide stained

DNA products in a 1% agarose gel. A) Initial

denaturation of the self-actuated PCR was

performed outside the SAFC loop. Lanes A1-5:

700 bp fragment; lane A1- positive control I,

0.05 U/µL Taq and 27 ng/µL DNA template;

lane A2- positive control II, 0.1 U/µL Taq and

13.5 ng/µL DNA template; lanes A3 and 4-

SAFC PCR products using the same mixtures as

for controls I and II, respectively; Lane A5:

negative control using the same mixture as

control II without any DNA. Lanes A6-10: 305

bp DNA fragment; lane A6- positive control III,

0.05 U/µL Taq and 27 ng/µL DNA template; lane A7- positive control IV, 0.1 U/µL Taq and

13.5 ng/µL DNA template; lanes A8 and 9- SACF PCR products using the same mixtures as for

controls III and IV, respectively; Lane A10: negative control using the same mixture as control

IV without any DNA.

B) Initial denaturation of SAFC PCR was performed in the SAFC loop with all three heating

blocks maintained at 95 °C. Lane B1: positive control, 0.1 U/µL Taq and 13.5 ng/µL DNA

template. Lane B2: SAFC PCR products using the same mixture as the positive control.

Fig. 3: A device fabricated with polycarbonate to demonstrate the concept

of controlling fluid flow without the need for mechanical valves. Each of

the network branches is equipped with an individually controlled heater.

The flow path can be adjusted by judiciously adjusting the power input to

individual heaters.

3 Copyright © 2004 by ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 11/11/2017 Terms of Use: http://www.asme.org/about-asme/terms-of-use

You might also like

- Fixed-Bed Reactor Design and Diagnostics: Gas-Phase ReactionsFrom EverandFixed-Bed Reactor Design and Diagnostics: Gas-Phase ReactionsRating: 4 out of 5 stars4/5 (5)

- Continuous Stirred Tank Reactor: CHEN-410 Unit Operation LabDocument34 pagesContinuous Stirred Tank Reactor: CHEN-410 Unit Operation LabMohamad Abou DaherNo ratings yet

- Galvanizing AHSSDocument3 pagesGalvanizing AHSSTrial_TNo ratings yet

- Mini PCR MachineDocument4 pagesMini PCR MachineParijata JATA Mackey100% (16)

- Thermal Plasma Waste TreatmentDocument21 pagesThermal Plasma Waste Treatmentbiko56No ratings yet

- Engineering Science and Technology, An International JournalDocument6 pagesEngineering Science and Technology, An International Journalmuh amarNo ratings yet

- Enzyme Kinetics Above Denaturation Temperature: A Temperature-Jump/Stopped-Flow ApparatusDocument6 pagesEnzyme Kinetics Above Denaturation Temperature: A Temperature-Jump/Stopped-Flow ApparatusAshish TankNo ratings yet

- Journal of Process Control: Volume 8, Issues 5-6Document12 pagesJournal of Process Control: Volume 8, Issues 5-6Sarvesh GantalaNo ratings yet

- Sensors and Actuators B: ChemicalDocument7 pagesSensors and Actuators B: ChemicalAditya KashyapNo ratings yet

- Evaluation of Adiabatic Runaway Reaction and Vent Sizing For Emergency Relief From DSCDocument10 pagesEvaluation of Adiabatic Runaway Reaction and Vent Sizing For Emergency Relief From DSCsameer sahaanNo ratings yet

- Analytical Chemistry Volume 49 Issue 11 1977 [Doi 10.1021%2Fac50019a033] Brown, Alan P.; Anson, Fred C. -- Cyclic and Differential Pulse Voltammetric Behavior of Reactants Confined to the Electrode SurfaceDocument7 pagesAnalytical Chemistry Volume 49 Issue 11 1977 [Doi 10.1021%2Fac50019a033] Brown, Alan P.; Anson, Fred C. -- Cyclic and Differential Pulse Voltammetric Behavior of Reactants Confined to the Electrode SurfaceMagdalena ArdeleanNo ratings yet

- Prieto - BatchReactorScaleup, StatisticalExperimentalDesignDocument8 pagesPrieto - BatchReactorScaleup, StatisticalExperimentalDesignxxyyzz0003No ratings yet

- 6273 ArticleText 11076 1 10 20200422Document7 pages6273 ArticleText 11076 1 10 20200422Alcides Gabriel Armas PerezNo ratings yet

- Gas-Liquid Mass Transfer in Bubble Column and Oscillatory Baf Ed Column Using Electrical Resistance Tomography (ERT)Document5 pagesGas-Liquid Mass Transfer in Bubble Column and Oscillatory Baf Ed Column Using Electrical Resistance Tomography (ERT)rajuvadlakondaNo ratings yet

- 24 Jackowski F PDFDocument7 pages24 Jackowski F PDFZul FakriNo ratings yet

- Three Phase Reactor Model Pilot TrickleDocument11 pagesThree Phase Reactor Model Pilot TrickleThế vũ Đặng vănNo ratings yet

- Monolithic Integrated Microfluidic DNA Amplification and Capillary Electrophoresis Analysis SystemDocument9 pagesMonolithic Integrated Microfluidic DNA Amplification and Capillary Electrophoresis Analysis Systemandrianto_yuliNo ratings yet

- Heat Exchanger Report PDFDocument18 pagesHeat Exchanger Report PDFKeith QuinnNo ratings yet

- Dna-To-Go: A Portable Smartphone-Enabled PCR Assay PlatformDocument4 pagesDna-To-Go: A Portable Smartphone-Enabled PCR Assay PlatformAbhishek DubeyNo ratings yet

- Rugged Constant-Temperature Thermal Anemometer: Review of Scientific Instruments April 2016Document9 pagesRugged Constant-Temperature Thermal Anemometer: Review of Scientific Instruments April 2016AhmadNo ratings yet

- Review On Thermal Conductivity of Nanofluids: SciencedirectDocument10 pagesReview On Thermal Conductivity of Nanofluids: SciencedirectANBUKUMAR TNo ratings yet

- LTH Msc2007Document7 pagesLTH Msc2007Dianta RaNo ratings yet

- Simulation of Nucleate Boiling Under ANSYS-FLUENT Code by Using RPI Model Coupling With Artificial Neural NetworksDocument8 pagesSimulation of Nucleate Boiling Under ANSYS-FLUENT Code by Using RPI Model Coupling With Artificial Neural NetworksesnoufNo ratings yet

- Measurement of Condensed-Phase Reaction Kinetics in The Aerosol Phase Using Single Particle Mass SpectrometryDocument10 pagesMeasurement of Condensed-Phase Reaction Kinetics in The Aerosol Phase Using Single Particle Mass SpectrometryJanine MolinaNo ratings yet

- Determining Circulation Velocities in Vacuum Pans: January 2002Document10 pagesDetermining Circulation Velocities in Vacuum Pans: January 2002Artit BoonkoomNo ratings yet

- Atomic Absorption Spectroscopy For Mercury, Automated by Sequential Injection and Miniaturized in Lab-on-Valve SystemDocument5 pagesAtomic Absorption Spectroscopy For Mercury, Automated by Sequential Injection and Miniaturized in Lab-on-Valve SystemAsad KhanNo ratings yet

- Mass Ow Characteristics of R-407C Through Short-Tube OrificesDocument14 pagesMass Ow Characteristics of R-407C Through Short-Tube Orificesdiego calleNo ratings yet

- Adenariwo AdepojuDocument225 pagesAdenariwo AdepojustarykltNo ratings yet

- Transport Phenomenon Question Paper (M.tech)Document3 pagesTransport Phenomenon Question Paper (M.tech)Kiran SheelavantNo ratings yet

- Microvascular Composite Skin Panels For Hypersonic Aircraft: January 2014Document12 pagesMicrovascular Composite Skin Panels For Hypersonic Aircraft: January 2014Anthony SNo ratings yet

- Nextreme Whitepaper Use of Thin-Film Thermoelectrics in PCR Thermal CyclingDocument11 pagesNextreme Whitepaper Use of Thin-Film Thermoelectrics in PCR Thermal CyclingnisargNo ratings yet

- Awan 2018 IOP Conf. Ser. Mater. Sci. Eng. 414 012045Document11 pagesAwan 2018 IOP Conf. Ser. Mater. Sci. Eng. 414 012045ezekielNo ratings yet

- Adsorption of Water and EthanolDocument16 pagesAdsorption of Water and EthanolMario RossiNo ratings yet

- Sensors 12 08319 v2 PDFDocument20 pagesSensors 12 08319 v2 PDFRagaNo ratings yet

- Sensors 12 08319 v2 PDFDocument20 pagesSensors 12 08319 v2 PDFRagaNo ratings yet

- Catalytic Dehydration of Methanol To Dimethyl Ether. Kinetic Investigation and Reactor SimulationDocument8 pagesCatalytic Dehydration of Methanol To Dimethyl Ether. Kinetic Investigation and Reactor SimulationLuiz Rodrigo AssisNo ratings yet

- Experimental and Theoretical Study of Pool BoilingDocument11 pagesExperimental and Theoretical Study of Pool Boilingvaibhav pawarNo ratings yet

- Barnes2009 PDFDocument10 pagesBarnes2009 PDFTan Kong OoiNo ratings yet

- Installation and OverviewDocument9 pagesInstallation and OverviewSharon C. LunaNo ratings yet

- Matveev ThesisDocument174 pagesMatveev ThesisHarpreetSinghNo ratings yet

- Milligan SDAYieldingin PWA1480 Met Trans 1987Document12 pagesMilligan SDAYieldingin PWA1480 Met Trans 1987alehagernNo ratings yet

- Arendt1986 1Document6 pagesArendt1986 1HARSH DHOLAKIYANo ratings yet

- Hydrocarbon Sythesis From Syngas by Very High Pressure PlasmaDocument8 pagesHydrocarbon Sythesis From Syngas by Very High Pressure PlasmaIsmail RahimNo ratings yet

- Catalytic Dehydration of Methanol To DimDocument8 pagesCatalytic Dehydration of Methanol To DimNorma JenarezNo ratings yet

- Hysys Project of Chemical Reaction Engineering: Prepared By: Mahmoud Mohamed ID: 141761Document9 pagesHysys Project of Chemical Reaction Engineering: Prepared By: Mahmoud Mohamed ID: 141761Mahmoud HendawyNo ratings yet

- An Expert System Concept For Diagnosis and Monitoring of Gas Turbine Combustion ChambersDocument6 pagesAn Expert System Concept For Diagnosis and Monitoring of Gas Turbine Combustion ChamberssenthilNo ratings yet

- Microfluidic Genotyping by Rapid Serial PCR and HiDocument9 pagesMicrofluidic Genotyping by Rapid Serial PCR and Hiمحمد سامىNo ratings yet

- CFD Analysis For Natural Convection of A Vertical Tube With Various Fin ConfigurationsDocument50 pagesCFD Analysis For Natural Convection of A Vertical Tube With Various Fin ConfigurationsAyaz AhmedNo ratings yet

- 1 ω, 2 ω, and 3 ω methods for measurements of thermal propertiesDocument15 pages1 ω, 2 ω, and 3 ω methods for measurements of thermal propertiesTriều Huỳnh NhậtNo ratings yet

- 01 - Jibbs Et AlDocument11 pages01 - Jibbs Et AlAtul SanghaviNo ratings yet

- ELECTROCHEMICALDocument8 pagesELECTROCHEMICALHà Thị TrúcNo ratings yet

- Design and Scale-Up of Polycondensation Reactors: Hydrodynamics in Horizontal Stirred Tanks and Pervaporation Membrane ModulesDocument158 pagesDesign and Scale-Up of Polycondensation Reactors: Hydrodynamics in Horizontal Stirred Tanks and Pervaporation Membrane ModulesArmiee InfiniteNo ratings yet

- Automation Highlights From The LiteratureDocument5 pagesAutomation Highlights From The LiteratureOng Wei QuanNo ratings yet

- Calculation Methods For Thick Walled Components Under Creep Fatigue - Review and Advanced ConceptsDocument9 pagesCalculation Methods For Thick Walled Components Under Creep Fatigue - Review and Advanced ConceptsMarcus BaltesNo ratings yet

- CFD Studies in The Prediction of Thermal Striping in An LMFBRDocument12 pagesCFD Studies in The Prediction of Thermal Striping in An LMFBRjofredjosephNo ratings yet

- Heat Driven Thermal Acoustic Cooler For Liquid Nitrogen TemperatureDocument4 pagesHeat Driven Thermal Acoustic Cooler For Liquid Nitrogen Temperaturekirubha.jaishriramNo ratings yet

- CorrosionProductSampling - GoodDocument10 pagesCorrosionProductSampling - Good_Greg_No ratings yet

- Heat Transfer Master ThesisDocument7 pagesHeat Transfer Master Thesiskristenwilsonpeoria100% (2)

- Thermal CyclerDocument20 pagesThermal CyclersalguerotiNo ratings yet

- A System Simulation Study of The EnhanceDocument6 pagesA System Simulation Study of The Enhancekeltoma.boutaNo ratings yet

- Maleic AcidDocument6 pagesMaleic AcidLeidy Viviana Diaz GuarinNo ratings yet

- Testing in Sheet Metals PDFDocument23 pagesTesting in Sheet Metals PDFshanthakumargcNo ratings yet

- Biology The Dynamic Science 4th Edition Russell Solutions ManualDocument25 pagesBiology The Dynamic Science 4th Edition Russell Solutions ManualDebraLarsoncbag100% (61)

- Warren1962 PDFDocument6 pagesWarren1962 PDFaznan fatkurezaNo ratings yet

- Answer Paper 2 PAP 1 2015Document7 pagesAnswer Paper 2 PAP 1 2015Nick LeeNo ratings yet

- Edexcel AS Chemistry Note 2 - Writing Balance Chemical EquationsDocument5 pagesEdexcel AS Chemistry Note 2 - Writing Balance Chemical EquationsSajaniNo ratings yet

- HT AssignmentDocument2 pagesHT AssignmentShiva KumarNo ratings yet

- Properties of Materials With Temperature VariationDocument50 pagesProperties of Materials With Temperature VariationcliffrajjoelNo ratings yet

- PRT 140 Physical Chemistry Programme Industrial Chemical Process SEM 1 2013/2014Document72 pagesPRT 140 Physical Chemistry Programme Industrial Chemical Process SEM 1 2013/2014Anusia ThevendaranNo ratings yet

- 7 Electric Fields in Material SpaceDocument19 pages7 Electric Fields in Material SpaceMarc RiveraNo ratings yet

- Item 716,719,, 726,727, 729, 733, 734, 735 (REVISED) M Final 6Document42 pagesItem 716,719,, 726,727, 729, 733, 734, 735 (REVISED) M Final 6Julius fernan VegaNo ratings yet

- SCH 3u-HomeworkDocument5 pagesSCH 3u-HomeworkLutfiana Miftahul JannahNo ratings yet

- Electrophilic Aromatic Substitution Rxns Practice ExamDocument25 pagesElectrophilic Aromatic Substitution Rxns Practice ExamgizatowerNo ratings yet

- List of Chemistry MnemonicsDocument53 pagesList of Chemistry Mnemonicsप्रो. आनंदNo ratings yet

- Lis of Chemicals NewDocument6 pagesLis of Chemicals NewDhanya K RNo ratings yet

- EN MIKRON Pyrometer M67 - ManualDocument52 pagesEN MIKRON Pyrometer M67 - ManualBruno SantosNo ratings yet

- Geokimia Panas Bumi Gunungapi Slamet Jawa TengahDocument24 pagesGeokimia Panas Bumi Gunungapi Slamet Jawa TengahZakariyaNo ratings yet

- Biocompatibility in Eu MDRDocument11 pagesBiocompatibility in Eu MDRsachin100% (1)

- Misganaw - Thesis Work - After Defense CorrectionDocument92 pagesMisganaw - Thesis Work - After Defense Correctioncitizen tadesseNo ratings yet

- Effect of Iron Ore Pellet Size On Its Properties and MicrostructureDocument8 pagesEffect of Iron Ore Pellet Size On Its Properties and Microstructurevitaliy khmelNo ratings yet

- Repurposing of Kinase Inhibitors To Target C-Abl As PotentialDocument10 pagesRepurposing of Kinase Inhibitors To Target C-Abl As PotentialShreeya BhatNo ratings yet

- Evolving Khuff FormationsDocument11 pagesEvolving Khuff FormationsrajkumarfNo ratings yet

- Analytical SeparationDocument20 pagesAnalytical SeparationalrizmemisNo ratings yet

- IP ProjectDocument4 pagesIP ProjecthoikliangNo ratings yet

- Redox TitrationDocument4 pagesRedox TitrationIan Lemuel VirtucioNo ratings yet

- Combustion CalculationsDocument6 pagesCombustion CalculationsMauro FerrareseNo ratings yet

- Blast Valve PV-KK-WDocument2 pagesBlast Valve PV-KK-Wyousufbasha100% (1)

- MTRL 280 Midterm 1Document5 pagesMTRL 280 Midterm 1JaymiNo ratings yet

- Etd4264 PDFDocument163 pagesEtd4264 PDFrahma rahmaNo ratings yet

- COA of Magnesium Ascorbyl PhosphateDocument1 pageCOA of Magnesium Ascorbyl PhosphatePan EmmaNo ratings yet

![Analytical Chemistry Volume 49 Issue 11 1977 [Doi 10.1021%2Fac50019a033] Brown, Alan P.; Anson, Fred C. -- Cyclic and Differential Pulse Voltammetric Behavior of Reactants Confined to the Electrode Surface](https://imgv2-1-f.scribdassets.com/img/document/187125064/149x198/1d5b47c140/1385436295?v=1)