Professional Documents

Culture Documents

701 Test Kit User Guide-1101217

701 Test Kit User Guide-1101217

Uploaded by

Hafiani HichamCopyright:

Available Formats

You might also like

- Techsheet w10740624 RevbDocument44 pagesTechsheet w10740624 RevbPaulStaplesNo ratings yet

- RC3563 Manual EnglishDocument6 pagesRC3563 Manual EnglishTomasz KarczewskiNo ratings yet

- Model#MVWX655DW0 Washer W10677676 - Tech SheetDocument22 pagesModel#MVWX655DW0 Washer W10677676 - Tech SheetbiggbioNo ratings yet

- W10240504 Maytag Bravos MVWX600XW0 MCT Washer Tech SheetDocument44 pagesW10240504 Maytag Bravos MVWX600XW0 MCT Washer Tech SheetJason ArnoldNo ratings yet

- Part B - Member of The Energy Institute Competence GridDocument6 pagesPart B - Member of The Energy Institute Competence GridMohab AymanNo ratings yet

- Manual Megger MJ159Document16 pagesManual Megger MJ159Patricia NaranjoNo ratings yet

- CAE2743BQ0 Technical Info SheetDocument40 pagesCAE2743BQ0 Technical Info SheetNicholas KaminskiNo ratings yet

- Adopting Best Practices in Blown Film ExtrusionDocument16 pagesAdopting Best Practices in Blown Film ExtrusionHafiani HichamNo ratings yet

- Home Theater Working DrawingsDocument1 pageHome Theater Working DrawingsAcoustics GlobalNo ratings yet

- I499D User ManualDocument2 pagesI499D User ManualXion NgNo ratings yet

- Instructions No. TK-7: Backflow Preventer Test Kit Field Testing ProcedureDocument2 pagesInstructions No. TK-7: Backflow Preventer Test Kit Field Testing ProcedureAli mohammadNo ratings yet

- 160 LW Bending Tester v2.0Document4 pages160 LW Bending Tester v2.0Sá StrapassonNo ratings yet

- Testing ABB Circuit Breakers Utilizing Ekip ConnectDocument30 pagesTesting ABB Circuit Breakers Utilizing Ekip ConnectAri KristianNo ratings yet

- Multi TesterDocument1 pageMulti Testerkat_mupada100% (2)

- 5991 2053enDocument5 pages5991 2053enEnrico LiaNo ratings yet

- EC20 Pocket Conductivity Tester Instruction Manual: Apera Instruments, LLCDocument8 pagesEC20 Pocket Conductivity Tester Instruction Manual: Apera Instruments, LLCThomas GalindoNo ratings yet

- E405-04 (2012) Standard Test Methods For Wear Testing Rotary Operators For WindowsDocument4 pagesE405-04 (2012) Standard Test Methods For Wear Testing Rotary Operators For WindowsMuhammad SalmanNo ratings yet

- Free Digital Multimeter Calibration ProcedureDocument10 pagesFree Digital Multimeter Calibration ProcedureGordinhorsNo ratings yet

- WTW 4800 XQDocument48 pagesWTW 4800 XQoroxcooNo ratings yet

- Raw Cashew Moisture Tester: Operating ManualDocument24 pagesRaw Cashew Moisture Tester: Operating ManualSIVARAMANJAGANATHANNo ratings yet

- Switching and MultiplexingDocument24 pagesSwitching and MultiplexingHay packupNo ratings yet

- User'S Guide Mini Analog Multimeter Model 38073: OperationDocument1 pageUser'S Guide Mini Analog Multimeter Model 38073: OperationGasdiesel Mechanic0% (1)

- For Service Technician'S Use Only: Voltage Measurement Safety InformationDocument48 pagesFor Service Technician'S Use Only: Voltage Measurement Safety Informationjorge castilloNo ratings yet

- TJM Section5 CommissioningDocument6 pagesTJM Section5 CommissioningVishal PatelNo ratings yet

- D 3474 - 90 R97 Rdm0nzqtotbsotcDocument3 pagesD 3474 - 90 R97 Rdm0nzqtotbsotcHernan MartNo ratings yet

- Life Assessment of Transformer A Case Study) PDFDocument8 pagesLife Assessment of Transformer A Case Study) PDFZeeshaan BhattNo ratings yet

- Manual Multiteste Digital UNI-T136BDocument2 pagesManual Multiteste Digital UNI-T136Bramon elias hicher leonNo ratings yet

- WhitePaper ConductivityMeasurements-USP645 EN 30431332 LRDocument8 pagesWhitePaper ConductivityMeasurements-USP645 EN 30431332 LRAlexis CastroNo ratings yet

- DM397 Manual PDFDocument15 pagesDM397 Manual PDFAngel RomeroNo ratings yet

- Manual DMM PDFDocument13 pagesManual DMM PDFMujtabaAliNo ratings yet

- 066 LW Tensile Tester v2.0 PDFDocument4 pages066 LW Tensile Tester v2.0 PDFMarkusNo ratings yet

- Periodic PV Inverter Test ProcedureDocument2 pagesPeriodic PV Inverter Test ProcedureInfos PkcNo ratings yet

- TestingDocument9 pagesTestingEric LopezNo ratings yet

- For Service Technician'S Use Only: Voltage Measurement Safety InformationDocument48 pagesFor Service Technician'S Use Only: Voltage Measurement Safety Informationdan themanNo ratings yet

- WI-NG-6460-002-102 Post Energization In-Service Test Rev01Document12 pagesWI-NG-6460-002-102 Post Energization In-Service Test Rev01Mohamed NasrNo ratings yet

- Manual Tecnico Whirlpool RevCDocument56 pagesManual Tecnico Whirlpool RevCGustavo RangelNo ratings yet

- Washing Machine Model # 110.26002012 Tech Sheet - W10468342 - Rev CDocument44 pagesWashing Machine Model # 110.26002012 Tech Sheet - W10468342 - Rev CMelissa MorganNo ratings yet

- Service Manual: Job AidDocument30 pagesService Manual: Job AidJim HarmkeNo ratings yet

- Imada - Emx SeriesDocument7 pagesImada - Emx SeriesAzmatul RohayaNo ratings yet

- BK Precision 875B ManualDocument37 pagesBK Precision 875B ManualMiguel A JimenezNo ratings yet

- C224 E057bDocument20 pagesC224 E057bBoy LondonNo ratings yet

- The Calibration and Use of Torque Meters Used in Packaging ApplicationsDocument3 pagesThe Calibration and Use of Torque Meters Used in Packaging ApplicationsfelipeNo ratings yet

- Schneider Recloser, Load Break Switch, Sectionaliser 2902134 PDFDocument10 pagesSchneider Recloser, Load Break Switch, Sectionaliser 2902134 PDFSanjay BhattNo ratings yet

- E 251 - 92 (2014)Document20 pagesE 251 - 92 (2014)Saiful ShokriNo ratings yet

- manualESM1500 ESM750Document46 pagesmanualESM1500 ESM750vietnamdong.vndNo ratings yet

- Pundit Lab Operating Instructions English HighDocument32 pagesPundit Lab Operating Instructions English HighRhyza Jullianne RodrigoNo ratings yet

- UT136A/B/C/D Handheld Digital Multimeter Operating Manual: Button Function and Auto Power Off Safety InformationDocument2 pagesUT136A/B/C/D Handheld Digital Multimeter Operating Manual: Button Function and Auto Power Off Safety InformationAdolfo Estuardo Villagran LopezNo ratings yet

- Battery Internal Resistance TesterDocument3 pagesBattery Internal Resistance TesterSYEDNo ratings yet

- Analog High Voltage Megohmmeter: User's GuideDocument8 pagesAnalog High Voltage Megohmmeter: User's GuideAdam SonenshineNo ratings yet

- GFCI Receptacle Tester Instructions CraftsmanDocument1 pageGFCI Receptacle Tester Instructions Craftsmanvomofe1666No ratings yet

- PRODUCT TESTING FILE Mahidlawon Decreased QuestionsDocument3 pagesPRODUCT TESTING FILE Mahidlawon Decreased QuestionsJeffcaster ComelNo ratings yet

- AET 23 - User ManualDocument22 pagesAET 23 - User ManualSatyavan L RoundhalNo ratings yet

- Qdoc - Tips Volvo g930 Motor Grader Service Repair ManualpdfDocument16 pagesQdoc - Tips Volvo g930 Motor Grader Service Repair ManualpdfLarzon Rodriguez0% (1)

- UniversalDocument11 pagesUniversalAnonymous TYGiADNo ratings yet

- Multifunction Digital: Clamp MeterDocument9 pagesMultifunction Digital: Clamp MeterAgung DuemilanoveNo ratings yet

- Flooring Resistance Test Kit: Flooring That Keeps You GroundedDocument2 pagesFlooring Resistance Test Kit: Flooring That Keeps You GroundedSing Yew LamNo ratings yet

- ASTM E18 (2019) - Part17Document1 pageASTM E18 (2019) - Part17david4231993No ratings yet

- Pre Commissioning Check List For Addressable Fire Alarm Voice Evacuation System Testing CommissioningDocument2 pagesPre Commissioning Check List For Addressable Fire Alarm Voice Evacuation System Testing CommissioningNaing Win TunNo ratings yet

- E-Dwt-H Electronic Deadweight Tester-: A Modern Replacement For The Conventional Deadweight TesterDocument4 pagesE-Dwt-H Electronic Deadweight Tester-: A Modern Replacement For The Conventional Deadweight TesterutpalshubhamNo ratings yet

- Insulation Tester + DMM Model MG320: User ManualDocument15 pagesInsulation Tester + DMM Model MG320: User ManualMl ValkyrierNo ratings yet

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- Design and Implementation of Portable Impedance AnalyzersFrom EverandDesign and Implementation of Portable Impedance AnalyzersNo ratings yet

- Static LocatorDocument1 pageStatic LocatorHafiani HichamNo ratings yet

- 1902006Document4 pages1902006Hafiani HichamNo ratings yet

- Antistatic 1Document12 pagesAntistatic 1Hafiani HichamNo ratings yet

- 1002006Document4 pages1002006Hafiani HichamNo ratings yet

- Tinius MeltPlastometerDocument6 pagesTinius MeltPlastometerHafiani HichamNo ratings yet

- STIFFNESS TesterDocument4 pagesSTIFFNESS TesterHafiani HichamNo ratings yet

- Exceed™ 1018KB: Metallocene Polyethylene ResinDocument2 pagesExceed™ 1018KB: Metallocene Polyethylene ResinHafiani HichamNo ratings yet

- Factors Affecting The Seal IntegrityDocument17 pagesFactors Affecting The Seal IntegrityHafiani HichamNo ratings yet

- Ico ExDocument2 pagesIco ExHafiani HichamNo ratings yet

- Exceed™ 1018MK: Performance PolymerDocument2 pagesExceed™ 1018MK: Performance PolymerHafiani HichamNo ratings yet

- Ico FastDocument2 pagesIco FastHafiani HichamNo ratings yet

- Effect of Taper Tension Profile PDFDocument13 pagesEffect of Taper Tension Profile PDFHafiani HichamNo ratings yet

- Battery Size Template (18mm & Below) : Fat 4/3 A 4/3 A A 4/5 A 2/3 A 1/2 A 1/3 ADocument2 pagesBattery Size Template (18mm & Below) : Fat 4/3 A 4/3 A A 4/5 A 2/3 A 1/2 A 1/3 AHafiani HichamNo ratings yet

- Ico PlainDocument2 pagesIco PlainHafiani HichamNo ratings yet

- Vestel RF47T - Service - Manual - 50041508 PDFDocument43 pagesVestel RF47T - Service - Manual - 50041508 PDFHafiani Hicham50% (2)

- VeriVide CAC LED Datasheet 2019Document2 pagesVeriVide CAC LED Datasheet 2019Arthur ThiesenNo ratings yet

- Hush HouseDocument2 pagesHush Housephutd09No ratings yet

- 1246 SP 4 Emm 24003 B2Document132 pages1246 SP 4 Emm 24003 B2Arash Aghagol100% (1)

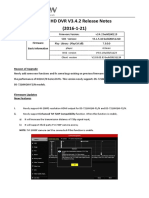

- Turbo HD DVR V3.4.2 Release Notes - ExternalDocument3 pagesTurbo HD DVR V3.4.2 Release Notes - Externalcrishtopher saenzNo ratings yet

- The Modernist Moment at The University of LeedsDocument26 pagesThe Modernist Moment at The University of LeedstobyNo ratings yet

- Flood Study Submittal Checklist: Local No-Impact Fema Lomr/ClomrDocument4 pagesFlood Study Submittal Checklist: Local No-Impact Fema Lomr/ClomrSarath VkNo ratings yet

- Us 1 NUM 10xx Series CNC Backup/ Restore Procedures Using NUMBackUp 14 10xx NUMBackupDocument3 pagesUs 1 NUM 10xx Series CNC Backup/ Restore Procedures Using NUMBackUp 14 10xx NUMBackupHa Pro50% (2)

- TOC M2 HandwrittenDocument46 pagesTOC M2 HandwrittenFullmetalNo ratings yet

- Mt4gui CheatsheetDocument2 pagesMt4gui Cheatsheetbinosp2No ratings yet

- Modeling Bounded RationalityDocument220 pagesModeling Bounded RationalityprithvijitmNo ratings yet

- Installation Manual: ModelDocument20 pagesInstallation Manual: ModelJohan VargasNo ratings yet

- Team6 Legend 5BVLCDocument8 pagesTeam6 Legend 5BVLCAna Sofia MuñizNo ratings yet

- Give Your Recommended Intervention in The Case Study Assigned To Your Division. Case Study 1: Oriental MindoroDocument4 pagesGive Your Recommended Intervention in The Case Study Assigned To Your Division. Case Study 1: Oriental MindoroMark-Christopher Roi Pelobello MontemayorNo ratings yet

- Purchasing Process Pt. 2: Laboratory ExerciseDocument6 pagesPurchasing Process Pt. 2: Laboratory ExercisebeverlybandojoNo ratings yet

- DCRM 6 Channel NewDocument9 pagesDCRM 6 Channel NewSayan ChatterjeeNo ratings yet

- El Mehdi Ben MaallaDocument12 pagesEl Mehdi Ben Maallasergio londoñoNo ratings yet

- Considerations in Contact Lens Use Under Adverse ConditionsDocument178 pagesConsiderations in Contact Lens Use Under Adverse ConditionsGusti Andhika AzwarNo ratings yet

- WPS No.: 1.203 Rev.: 4Document2 pagesWPS No.: 1.203 Rev.: 4beyNo ratings yet

- 6SL3210-1KE15-8AF2 Datasheet enDocument2 pages6SL3210-1KE15-8AF2 Datasheet enzenagyNo ratings yet

- CH 19 Cash and Liquidity Management Appendix Class WorkDocument4 pagesCH 19 Cash and Liquidity Management Appendix Class WorkMhmd KaramNo ratings yet

- RT Usersguide PDFDocument36 pagesRT Usersguide PDFRoy RamosNo ratings yet

- KELAS XI SUMATIF (ULANGAN HARIAN) - HORTATORY EXPOSITION TEXT - DieditDocument5 pagesKELAS XI SUMATIF (ULANGAN HARIAN) - HORTATORY EXPOSITION TEXT - Dieditbagussetiawan76634No ratings yet

- The American City - What Works, What Doesn't - Garvin, Alexander - New York, 1996 - New York - McGraw-Hill - 9780070229198 - Anna's ArchiveDocument504 pagesThe American City - What Works, What Doesn't - Garvin, Alexander - New York, 1996 - New York - McGraw-Hill - 9780070229198 - Anna's ArchiveElshaday MaregaNo ratings yet

- Science: Quarter 3 - Module 5: Climate ChangeDocument32 pagesScience: Quarter 3 - Module 5: Climate ChangeMelanie Tagudin TrinidadNo ratings yet

- HDMI Cable Modeling and Analysis With TDR DataDocument9 pagesHDMI Cable Modeling and Analysis With TDR DataAmmar AbdullahNo ratings yet

- Waves in Isotropic Media: Dielectrics and Conductors: in This Lecture You Will LearnDocument10 pagesWaves in Isotropic Media: Dielectrics and Conductors: in This Lecture You Will LearnHuseyin OztoprakNo ratings yet

- Activity 3 EntrepDocument2 pagesActivity 3 EntrepCHLOE ANNE CORDIALNo ratings yet

- Port Loko User RequirementsDocument8 pagesPort Loko User RequirementsDanNo ratings yet

701 Test Kit User Guide-1101217

701 Test Kit User Guide-1101217

Uploaded by

Hafiani HichamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

701 Test Kit User Guide-1101217

701 Test Kit User Guide-1101217

Uploaded by

Hafiani HichamCopyright:

Available Formats

USER GUIDE TB-9017

Analog Surface Resistance Megohmmeter Kit

Operation and Maintenance Made in the

United States of America

1. Main Selector Switch: The main function selector

switch allows the selection of desired test function.

2. TEST Button: This button engages the Tester and

activates the test function selected.

3. OHMS Scale: This scale is used in conjunction

with the SURFACE TEST functions to indicate the

amount of resistance measured.

4. CONTINUITY Scale: This scale indicates the total

resistance of the test setup (meter, leads, weights,

and calibration plate) in the CONTINUITY TEST

function.

5. BATTERY Scale: This scale indicates the charge

level of the main battery of the Tester in the

BATTERY TEST function by verifying the open

circuit output test voltage.

6. Test Jacks: These jacks are used to connect the

Figure 1. SCS 701 Analog Surface Resistance Tester to the test leads.

Megohmmeter Kit. 7. Mechanical Zero Adjust: This control is used to zero

the pointer.

Description

The 701 Analog Surface Resistance Megohmmeter Kit Operating Instructions

includes a hand-held megohmmeter and accessories. Warning:

The kit has been specifically designed for evaluating • Turn off the Tester before connecting or

the resistive characteristics of static control surface disconnecting test leads, or before moving test

materials and testing installed surfaces as specified in weights.

ESD Association Standards. • Do not use this Tester with any accessories not

specifically designed to be used with this product.

The Tester has four test functions which allow the user • Do not use this Tester to measure live circuits.

to measure the resistance of a static control surface

at either of two test voltages, verify proper Tester Caution: The test weights included in this kit are

performance, and check the electrical continuity of the heavy, exercise care in handling. Note: The following

test set-up. procedures should be followed each time the Tester is

used.

Battery Test: Place the Tester on a table top or other

stable surface. Set the main selector switch to BATTERY

TEST. Press TEST and hold for 15 seconds. The pointer

should come to rest in the green area of the BATTERY

scale. If the pointer is in the red area to the left of

100V, replace the battery and retest. If the pointer is in

the red area to the right of 100V, the tester may need

recalibration.

Figure 2. SCS 701 Analog Surface Resistance

Megohmmeter Kit, controls, connectors and indicators.

Controls, Connectors, & Indicators

Before attempting any operation of the Tester, become

familiar with each control. A thorough understanding of

how the Tester operates will help avoid mistakes and

prolong its useful life.

Figure 3. Analog Surface Resistance Megohmmeter Kit,

continuity test.

SCS - 926 JR Industrial Drive, Sanford, NC 27332 • (919) 718-0000 • Website: StaticControl.com

TB-9017 Page 1 of 6 July 2015 © 2015 DESCO INDUSTRIES, INC.

Employee Owned

Continuity Test: Place the Tester on a table top or This test involves measurement of the total resistance

other stable surface and attach the leads as shown in from the static control surface through the conductor or

Figure . Place the test weights on the calibration plate ground cord to the ESD GROUND (ESDG), verifying the

or other bare metal surface and plug in the test leads. static control system is functioning correctly.

Set the main selector switch to CONTINUITY TEST.

Press TEST. The pointer should come to rest in the Note: ESD-S4.1 suggests that a static control surface

green section of the CONTINUITY scale. If not, the that measures in the range of 1 x 106 ohms to 1 x 109

test leads may be defective or the weights may require ohms.

maintenance or cleaning.

Surface Test (Resistance Measurement): Refer

to the two following sections to determine which

measurement(s) should be used for your application.

Place the Tester on a table top or other stable surface

and attach the leads as shown in the appropriate sketch

figures 5-1 through 5-5. Set the Main Selector Switch

to the desired SURFACE TEST voltage. Place the test

weight(s) on the surface to be tested and connect the

test leads. Press TEST for 15 seconds and then read the

resistance from the OHMS scale. After all readings have

been completed, return the Main Selector Switch to the

OFF position. Figure 4. Periodic Preformace Tests of Installed

Surfaces.

Resistance Measurement of Static The following procedures should be followed when

Control Work Surfaces testing installed static control surfaces:

A. Complete BATTERY TEST and CONTINUITY TEST.

This section provides a summary of the types of surface

measurements specified and described by ESD-S4.1. B. Set the SCS 701 Analog Surface Resistance

Megohmmeter Kit on a table top or other stable

Measurements are performed for three reasons: surface and place a test weight at the desired test

1. Periodic performance testing of installed static point as shown in Figure 5. Connect the test leads

control work surfaces. to the meter using the right angle banana plugs at

2. Qualification of installed static control work surfaces. the meter. Then connect one of the test leads to the

3. Evaluation of static control work surface materials. test weight and the other to the ESD GROUND using

one of the supplied clips.

Note: The following paragraphs are offered as C. Test the static control surface using the 100 volts

a condensed summary of the test methods and SURFACE TEST. Press the TEST button for 15

procedures outlined in the EOS/ESD standard. For seconds, allowing the pointer to stabilize; record the

complete details, refer to the standard. readings for each test point. If the reading is below

1 x 106 ohms, check the static control surface for an

Test Description alternate path to ground; correct and retest. If some or

1. Periodic Performance Testing Of Installed Static all the readings are above 1x109 ohms, the static

Control Surfaces: (Measurement of resistance from control surface may be dirty. Clean the surface using

the top of an installed surface to ESD GROUND the manufacturer’s recommended cleaning procedure.

(RTS-ESDG) at ambient temperature and humidity). If the resistance reading is “infinite,” there is an

interruption (open) in the ground connection; repair

Note: ESD GROUND is the point at which the ground and retest.

cord or other grounding conductor from the static

control surface is connected. The ground point may be

an electrical ground, building ground, or other suitable

ground. If you have questions concerning the correct

ground, refer to ANSI/ESD STANDARD S6.1 and/or

contact a qualified electrician.

This Resistance-to-Ground test verifies the surface

is working correctly and will drain a static charge in a

reasonable time.

Figure 5. Qualification Tests of Installed Surfaces.

SCS - 926 JR Industrial Drive, Sanford, NC 27332 • (919) 718-0000 • Website: StaticControl.com

TB-9017 Page 2 of 6 © 2015 DESCO INDUSTRIES, INC.

Employee Owned

2. Qualification of Installed Static Control Surfaces

[Measurement of resistance of the top surface to

the groundable point of the static control surface

(RTS-GP)]. GROUNDABLE POINT is the point

at which the grounding conductor is connected

to the static control surface; the GROUNDABLE

POINT is most commonly a snap (mats), a bolt

(laminate), or a strip of conductive foil tape (flooring).

This QUALIFICATION measurement is similar

to those described in the test description section

and is used to verify the correct installation of the Figure 6. Material Evaluation Sample Configuration.

GROUNDABLE POINT by the manufacturer or by

the user. While the test procedure is the same, the

test setup is slightly different; see Figure 5.

3. Evaluation of Static Control Materials:

[Measurement of the resistance between two points

on top of a static control surface (RTS-TS), and the

resistance between a point on the surface and the

groundable point (RTS-GP)] Material measurements

are done to determine the intrinsic electrical

properties of static control work surface materials.

Note: Values obtained by these tests may not reflect Figure 7. Material Evaluation Surface to Groundable

how a material will perform when installed as a static Point Test.

control surface.

Procedure: Place the SCS 701 Analog Surface Resis-

Material evaluations are typically done at two tance Megohmmeter Kit on a table top or other stable

humidities (12% RH and 50% RH) to determine surface. Connect the test leads to the Tester by means

whether the electrical properties of the material of the right angle banana plugs. Connect the other end

are humidity-dependent. If the low humidity test of one of the leads to one of the test weights and place

results are borderline or not within the expected the weight on the surface to be tested. Use one of the

ranges, caution should be exercised when using supplied clips to connect the other lead to the ground-

such materials in winter months or in dry conditions. able point on the static control surface. Depress TEST

To assure test accuracy, a minimum of six samples button for 15 seconds and then record the reading.

should be tested.

E. Surface-to-surface Test: Test samples as shown in

The test procedure is as follows: Figure 8 use both test weights and repeat the same

A. Prepare a minimum of six samples of each material test procedure used to determine (RTS-GP).

to be tested as shown in Figure 6. F. Repeat A through E after conditioning samples at

B. Clean samples per manufacturers recommended 73°F (23°C) and 12% RH. Use the same test points

cleaning procedures. Condition samples at 73°F and record the values.

(23° C) and 50% RH for 48-72 hours.

STATIC CONTROL SURFACE GROUNDABLE POINTS

Note: Samples must be maintained at the appropriate

humidity level throughout the test procedures.

C. Complete BATTERY TEST and CONTINUITY TEST.

D. Surface-to-Groundable Point Test: Test samples

per Figure 7, using both the 100 volts and 10 volts

SURFACE TEST ranges at 50% RH and record the

values as (RTS-GP).

7 OHMS

8 10

10

6

9 10

10

10

10 5

11

10

10 0

100M 10M

1G 1M

1M

TO TEST W EIGHT AT TEST

100M 10M

10G 100K 100K

FAIL

100G 10K 0

PA

SS 0

CONTINUITY

100V BATTE RY

TAUT BAN D

SUSPENSION

POINT A & B

SURF AC E

BA TTE RY OF F TEST

TEST 10V

CONTINUITY 100V

TEST

TEST

READ MA NU AL BEFORE US E

Figure 8. Material Evaluation Surface to Surface Test.

SCS - 926 JR Industrial Drive, Sanford, NC 27332 • (919) 718-0000 • Website: StaticControl.com

TB-9017 Page 3 of 6 © 2015 DESCO INDUSTRIES, INC.

Employee Owned

Resistance Measurement of Static Control Flooring I. Perform a minimum of five tests per contiguous floor

This section provides a summary of installed or applied surface material or a minimum of five tests per 5,000

floor material measurements specified and described by square feet (464.5 m2) of floor material, whichever is

ESD-S7.1. greater. A minimum of three of the five tests should

be conducted in those areas that are subject to wear

Note: The following paragraphs are offered as a co or have chemical or water spillage or are visibly dirty.

densed summary of the test methods and procedures

outlined in the EOS/ESD standard. For complete details, Test Procedure for Resistance Point to Point

refer to the standard. A. Complete BATTERY TEST and CONTINUITY TEST.

If required clean electrodes as described in Test

PERIODIC PERFORMANCE TESTING OF INSTALLED Weight Cleaning section below.

OR APPLIED FLOORING MATERIALS B. Before testing new floor mats or newly installed

(Measurement of resistance from the surface of an floors, clean mats/floors per manufacturer’s recom-

installed floor to GROUNDABLE POINT at ambient mendations. For testing of floor finishes or monitor-

temperature and humidity). ing of existing floor materials, test in an as-is condi-

tion.

Note: GROUNDABLE POINT is a point on the floor C. Perform tests at ambient humidity.

material that is intended to accommodate an electrical D. Place the Tester and test weight at the desired test

connection from the floor material to an appropriate location.

electrical ground. The ground point may be an electrical E. Connect test leads of the meter to the test weights.

ground, building ground, or other suitable ground. If you F. Set meter to 100V. Place test weights three feet

have questions concerning the correct ground, refer to apart on the surface of the material being tested.

EOS/ESD Standard 6.0 and/or contact a qualified G. Push test button and record the resistance after the

electrician. measurement has stabilized or after 15 seconds.

Release test button.

The Resistance-to-Ground test verifies the surface is H. Repeat the procedure placing the test weights three

working correctly and will drain a static charge in a feet apart on the surface at different locations.

reasonable time. This test involves measurement of I. Perform a minimum of five tests per contiguous floor

the total resistance from the static control surface surface material or a minimum of five tests per 5,000

through the conductor or ground cord to the ESD square feet (464.5 m2) of floor material, whichever is

GROUND (ESDG), verifying the static control system is greater. A minimum of three of the five tests should

functioning correctly. Note: ESD 7.1 is designed to be conducted in those areas that are subject to wear

measure floor materials with resistances of 2.5 x 104 to or have chemical or water spillage or are visibly dirty.

1.0 x 1011 ohms.

Maintenance

The following procedures should be followed when Caution: Batteries are intended for use in applications

testing installed static control floor mats or flooring subject to replacement only by a trained service

surfaces. technician. Use only non-rechargeable batteries.

Test Procedure for Resistance to Ground Battery Replacement

A. Complete BATTERY TEST and CONTINUITY TEST.

B. Before testing new floor mats or newly installed

floors, clean mats/floors per manufacturer’s

recommendations. For testing of floor finishes or

monitoring of existing floor materials, test in an as-is

condition.

C. Perform tests at ambient humidity.

D. Place the SCS 701 Analog Surface Resistance

Megohmmeter Kit and test weight at the desired test

location.

E. Connect one lead of the meter to ground with

supplied clip and the other lead to the test weight.

F. Set meter to 100V. Place test weight on the surface

of the material being tested.

G. Push test button and record the resistance after the

measurement has stabilized or after 15 seconds. Figure 9. Battery Replacement.

Release test button.

H. Repeat the procedure placing the test weight on the

surface at different locations.

SCS - 926 JR Industrial Drive, Sanford, NC 27332 • (919) 718-0000 • Website: StaticControl.com

TB-9017 Page 4 of 6 © 2015 DESCO INDUSTRIES, INC.

Employee Owned

Before attempting to replace battery, place main selector Technical Data

switch in the OFF position.

The following electrical specifications are valid for

The circuitry enclosed in the SCS 701 Analog Surface operating temperatures of 65°F (18°C) to 82°F (28°C), at

Resistance Megohmmeter Kit produces high voltages. relative humidity up to 90% for altitudes up to 2000 m,

Make sure that the main selector switch is in the OFF unless otherwise noted. Pollution degree 2, class 3.

position before removing the back cover.

Test Measurement Open Internal

A. To open the back cover, remove the screw located in Function Range Circuit Resistance

the center of the back cover. (±5% ±2° of arc.) Voltage

B. The batteries are held in place by a metal bracket at

the top of the Tester. To release this bracket, turn the Continuity 0 to 10 10V ± .7V 500 ohms

screw located in the center of the bracket counter megohms

clockwise until the bracket swings free. The batteries

will now slide out.

C. Install new batteries as shown in Figure 9. 10V 105 ohms to 1011 10V ± .7V 2 ohms

ohms

Note: Improper battery installation will damage this

Tester. 100V 105 ohms to 1011 100V ± 7V 2 ohms

ohms

D. Replace bracket and tighten bracket screw. Replace

back cover and cover screw. Physical Data

Test Weight Cleaning Tester Size

Caution: The test probes included in this kit are heavy.

4.6"(H) x 3.3"(W) x 1.7"(D) Weight: 5 lbs. (2.27 Kg)

Exercise care in handling. After a period of use, the

conductive rubber pads on the test weights may become each

soiled, causing the weight to fail the CONTINUITY TEST.

To clean the surface of the conductive pad, use a 70% (11.7 x 8.4 x 4.3 cm) Diameter: 2.7” (6.8 cm)

Isopropyl alcohol/water mixture on a clean low-linting

cloth. Allow surface to “air dry” 15 minutes before use. Weight: 11 oz (5.9 kg) Height: 5.1" (13.0 cm)

(w/ handle and pad)

Zero Adjustment

On occasion, due to handling, vibration, or other causes, Safety Information

the pointer on the Tester may need adjustment. To zero Warning:

the pointer, turn the main selector switch to the OFF • Turn off the Tester before connecting or

position. Place the Tester on a level stable surface and disconnecting test leads, or before moving test

turn the mechanical zero adjust screw until the pointer is weights.

over the left most mark on the OHMS scale. • Do not use this Tester with any accessories not

specifically designed to be used with this product.

Replacement Parts • Do not use this Tester to measure live circuits.

The following parts are user-replaceable parts: • The circuitry enclosed in the SCS 701 Analog

Surface Resistance Megohmmeter Kit produces high

Description Part Number voltages. Make sure that the main selector switch is

Megohmmeter 701 701-M in the OFF position before removing the back cover.

Test Weight (each) 701-W

Caution:

Test Leads (pair) 701-L

• The test weights included in this kit are heavy.

Insulated “Bulldog” Clip 3037 Exercise care in handling.

Non-insulated Alligator Clip 3038 • Improper battery installation will damage this Tester.

User Guide • Tester to be used indoors only.

Batteries (2) 1.5 volt AA Cell, To reduce the risks associated with environmental

3.6 volt AA Ceel Lithium contamination from the device along with the Lithium

and Akaline battery:

*Recommended Batteries: Model TL-5903 TADIRAN, • At the end of service life, dispose of the charge

ER6 Maxell, Saft LS 14500, Zeus ER14505 analyzer and batteries in accordance with federal,

state and local requirements.

SCS - 926 JR Industrial Drive, Sanford, NC 27332 • (919) 718-0000 • Website: StaticControl.com

TB-9017 Page 5 of 6 © 2015 DESCO INDUSTRIES, INC.

Employee Owned

Regulatory Information Limited Warranty, Warranty Exclusions, Limit of

WEEE Statement Liability and RMA Request Instructions

The following information is only for EU-members States:

The mark shown to the right is in compliance with Waste See the SCS Warranty -

Electrical and Electronic Equipment Directive 2002/96/ http://staticcontrol.descoindustries.com/warranty.aspx

EC (WEEE). The mark indicates the requirement NOT to

dispose the equipment as unsorted municipal waste, but

use the return and collection systems according to local

law.

Intertek Statement

Intertek Listed to US and Canada Safety Standards

Mark of Conformity to European Directives (Conformité

Européene).

Certified by Intertek Testing Services and meets US and

Canada safety requirements.

CE Statement

Meets CE (European Conformity) requirements.

FCC

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions: (1)

this device may not cause harmful interference, and

(2) this device must accept any interference received,

including interference that may cause undesired

operation.

Note:

• This equipment has been tested and found to

comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits

are designed to provide a reasonable protection

against harmful interference when the equipment

is operated in a commercial environment. This

equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in

accordance with the instruction manual, may cause

harmful interference to radio communications.

Operation of this equipment in a residential area is

likely to cause harmful interference in which case the

user will be required to correct the interference at

their own expense.

• Modifications to this device shall not be made

without the written consent of SCS. Unauthorized

modifications may void the authority granted under

Federal Communication Rules and Industry Canada

Rules permitting the operation of this device.

• Per the European Battery Directive, Alkaline

Batteries are not provided with the equipment and

must be locally sourced.

ICES Statement

This Class A digital apparatus complies with Canadian

ICES-003.

Cet appareil numérique de la classe A est conforme à la

NMB-003 du Canada.

SCS - 926 JR Industrial Drive, Sanford, NC 27332 • (919) 718-0000 • Website: StaticControl.com

TB-9017 Page 6 of 6 © 2015 DESCO INDUSTRIES, INC.

Employee Owned

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

SCS:

701

You might also like

- Techsheet w10740624 RevbDocument44 pagesTechsheet w10740624 RevbPaulStaplesNo ratings yet

- RC3563 Manual EnglishDocument6 pagesRC3563 Manual EnglishTomasz KarczewskiNo ratings yet

- Model#MVWX655DW0 Washer W10677676 - Tech SheetDocument22 pagesModel#MVWX655DW0 Washer W10677676 - Tech SheetbiggbioNo ratings yet

- W10240504 Maytag Bravos MVWX600XW0 MCT Washer Tech SheetDocument44 pagesW10240504 Maytag Bravos MVWX600XW0 MCT Washer Tech SheetJason ArnoldNo ratings yet

- Part B - Member of The Energy Institute Competence GridDocument6 pagesPart B - Member of The Energy Institute Competence GridMohab AymanNo ratings yet

- Manual Megger MJ159Document16 pagesManual Megger MJ159Patricia NaranjoNo ratings yet

- CAE2743BQ0 Technical Info SheetDocument40 pagesCAE2743BQ0 Technical Info SheetNicholas KaminskiNo ratings yet

- Adopting Best Practices in Blown Film ExtrusionDocument16 pagesAdopting Best Practices in Blown Film ExtrusionHafiani HichamNo ratings yet

- Home Theater Working DrawingsDocument1 pageHome Theater Working DrawingsAcoustics GlobalNo ratings yet

- I499D User ManualDocument2 pagesI499D User ManualXion NgNo ratings yet

- Instructions No. TK-7: Backflow Preventer Test Kit Field Testing ProcedureDocument2 pagesInstructions No. TK-7: Backflow Preventer Test Kit Field Testing ProcedureAli mohammadNo ratings yet

- 160 LW Bending Tester v2.0Document4 pages160 LW Bending Tester v2.0Sá StrapassonNo ratings yet

- Testing ABB Circuit Breakers Utilizing Ekip ConnectDocument30 pagesTesting ABB Circuit Breakers Utilizing Ekip ConnectAri KristianNo ratings yet

- Multi TesterDocument1 pageMulti Testerkat_mupada100% (2)

- 5991 2053enDocument5 pages5991 2053enEnrico LiaNo ratings yet

- EC20 Pocket Conductivity Tester Instruction Manual: Apera Instruments, LLCDocument8 pagesEC20 Pocket Conductivity Tester Instruction Manual: Apera Instruments, LLCThomas GalindoNo ratings yet

- E405-04 (2012) Standard Test Methods For Wear Testing Rotary Operators For WindowsDocument4 pagesE405-04 (2012) Standard Test Methods For Wear Testing Rotary Operators For WindowsMuhammad SalmanNo ratings yet

- Free Digital Multimeter Calibration ProcedureDocument10 pagesFree Digital Multimeter Calibration ProcedureGordinhorsNo ratings yet

- WTW 4800 XQDocument48 pagesWTW 4800 XQoroxcooNo ratings yet

- Raw Cashew Moisture Tester: Operating ManualDocument24 pagesRaw Cashew Moisture Tester: Operating ManualSIVARAMANJAGANATHANNo ratings yet

- Switching and MultiplexingDocument24 pagesSwitching and MultiplexingHay packupNo ratings yet

- User'S Guide Mini Analog Multimeter Model 38073: OperationDocument1 pageUser'S Guide Mini Analog Multimeter Model 38073: OperationGasdiesel Mechanic0% (1)

- For Service Technician'S Use Only: Voltage Measurement Safety InformationDocument48 pagesFor Service Technician'S Use Only: Voltage Measurement Safety Informationjorge castilloNo ratings yet

- TJM Section5 CommissioningDocument6 pagesTJM Section5 CommissioningVishal PatelNo ratings yet

- D 3474 - 90 R97 Rdm0nzqtotbsotcDocument3 pagesD 3474 - 90 R97 Rdm0nzqtotbsotcHernan MartNo ratings yet

- Life Assessment of Transformer A Case Study) PDFDocument8 pagesLife Assessment of Transformer A Case Study) PDFZeeshaan BhattNo ratings yet

- Manual Multiteste Digital UNI-T136BDocument2 pagesManual Multiteste Digital UNI-T136Bramon elias hicher leonNo ratings yet

- WhitePaper ConductivityMeasurements-USP645 EN 30431332 LRDocument8 pagesWhitePaper ConductivityMeasurements-USP645 EN 30431332 LRAlexis CastroNo ratings yet

- DM397 Manual PDFDocument15 pagesDM397 Manual PDFAngel RomeroNo ratings yet

- Manual DMM PDFDocument13 pagesManual DMM PDFMujtabaAliNo ratings yet

- 066 LW Tensile Tester v2.0 PDFDocument4 pages066 LW Tensile Tester v2.0 PDFMarkusNo ratings yet

- Periodic PV Inverter Test ProcedureDocument2 pagesPeriodic PV Inverter Test ProcedureInfos PkcNo ratings yet

- TestingDocument9 pagesTestingEric LopezNo ratings yet

- For Service Technician'S Use Only: Voltage Measurement Safety InformationDocument48 pagesFor Service Technician'S Use Only: Voltage Measurement Safety Informationdan themanNo ratings yet

- WI-NG-6460-002-102 Post Energization In-Service Test Rev01Document12 pagesWI-NG-6460-002-102 Post Energization In-Service Test Rev01Mohamed NasrNo ratings yet

- Manual Tecnico Whirlpool RevCDocument56 pagesManual Tecnico Whirlpool RevCGustavo RangelNo ratings yet

- Washing Machine Model # 110.26002012 Tech Sheet - W10468342 - Rev CDocument44 pagesWashing Machine Model # 110.26002012 Tech Sheet - W10468342 - Rev CMelissa MorganNo ratings yet

- Service Manual: Job AidDocument30 pagesService Manual: Job AidJim HarmkeNo ratings yet

- Imada - Emx SeriesDocument7 pagesImada - Emx SeriesAzmatul RohayaNo ratings yet

- BK Precision 875B ManualDocument37 pagesBK Precision 875B ManualMiguel A JimenezNo ratings yet

- C224 E057bDocument20 pagesC224 E057bBoy LondonNo ratings yet

- The Calibration and Use of Torque Meters Used in Packaging ApplicationsDocument3 pagesThe Calibration and Use of Torque Meters Used in Packaging ApplicationsfelipeNo ratings yet

- Schneider Recloser, Load Break Switch, Sectionaliser 2902134 PDFDocument10 pagesSchneider Recloser, Load Break Switch, Sectionaliser 2902134 PDFSanjay BhattNo ratings yet

- E 251 - 92 (2014)Document20 pagesE 251 - 92 (2014)Saiful ShokriNo ratings yet

- manualESM1500 ESM750Document46 pagesmanualESM1500 ESM750vietnamdong.vndNo ratings yet

- Pundit Lab Operating Instructions English HighDocument32 pagesPundit Lab Operating Instructions English HighRhyza Jullianne RodrigoNo ratings yet

- UT136A/B/C/D Handheld Digital Multimeter Operating Manual: Button Function and Auto Power Off Safety InformationDocument2 pagesUT136A/B/C/D Handheld Digital Multimeter Operating Manual: Button Function and Auto Power Off Safety InformationAdolfo Estuardo Villagran LopezNo ratings yet

- Battery Internal Resistance TesterDocument3 pagesBattery Internal Resistance TesterSYEDNo ratings yet

- Analog High Voltage Megohmmeter: User's GuideDocument8 pagesAnalog High Voltage Megohmmeter: User's GuideAdam SonenshineNo ratings yet

- GFCI Receptacle Tester Instructions CraftsmanDocument1 pageGFCI Receptacle Tester Instructions Craftsmanvomofe1666No ratings yet

- PRODUCT TESTING FILE Mahidlawon Decreased QuestionsDocument3 pagesPRODUCT TESTING FILE Mahidlawon Decreased QuestionsJeffcaster ComelNo ratings yet

- AET 23 - User ManualDocument22 pagesAET 23 - User ManualSatyavan L RoundhalNo ratings yet

- Qdoc - Tips Volvo g930 Motor Grader Service Repair ManualpdfDocument16 pagesQdoc - Tips Volvo g930 Motor Grader Service Repair ManualpdfLarzon Rodriguez0% (1)

- UniversalDocument11 pagesUniversalAnonymous TYGiADNo ratings yet

- Multifunction Digital: Clamp MeterDocument9 pagesMultifunction Digital: Clamp MeterAgung DuemilanoveNo ratings yet

- Flooring Resistance Test Kit: Flooring That Keeps You GroundedDocument2 pagesFlooring Resistance Test Kit: Flooring That Keeps You GroundedSing Yew LamNo ratings yet

- ASTM E18 (2019) - Part17Document1 pageASTM E18 (2019) - Part17david4231993No ratings yet

- Pre Commissioning Check List For Addressable Fire Alarm Voice Evacuation System Testing CommissioningDocument2 pagesPre Commissioning Check List For Addressable Fire Alarm Voice Evacuation System Testing CommissioningNaing Win TunNo ratings yet

- E-Dwt-H Electronic Deadweight Tester-: A Modern Replacement For The Conventional Deadweight TesterDocument4 pagesE-Dwt-H Electronic Deadweight Tester-: A Modern Replacement For The Conventional Deadweight TesterutpalshubhamNo ratings yet

- Insulation Tester + DMM Model MG320: User ManualDocument15 pagesInsulation Tester + DMM Model MG320: User ManualMl ValkyrierNo ratings yet

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- Design and Implementation of Portable Impedance AnalyzersFrom EverandDesign and Implementation of Portable Impedance AnalyzersNo ratings yet

- Static LocatorDocument1 pageStatic LocatorHafiani HichamNo ratings yet

- 1902006Document4 pages1902006Hafiani HichamNo ratings yet

- Antistatic 1Document12 pagesAntistatic 1Hafiani HichamNo ratings yet

- 1002006Document4 pages1002006Hafiani HichamNo ratings yet

- Tinius MeltPlastometerDocument6 pagesTinius MeltPlastometerHafiani HichamNo ratings yet

- STIFFNESS TesterDocument4 pagesSTIFFNESS TesterHafiani HichamNo ratings yet

- Exceed™ 1018KB: Metallocene Polyethylene ResinDocument2 pagesExceed™ 1018KB: Metallocene Polyethylene ResinHafiani HichamNo ratings yet

- Factors Affecting The Seal IntegrityDocument17 pagesFactors Affecting The Seal IntegrityHafiani HichamNo ratings yet

- Ico ExDocument2 pagesIco ExHafiani HichamNo ratings yet

- Exceed™ 1018MK: Performance PolymerDocument2 pagesExceed™ 1018MK: Performance PolymerHafiani HichamNo ratings yet

- Ico FastDocument2 pagesIco FastHafiani HichamNo ratings yet

- Effect of Taper Tension Profile PDFDocument13 pagesEffect of Taper Tension Profile PDFHafiani HichamNo ratings yet

- Battery Size Template (18mm & Below) : Fat 4/3 A 4/3 A A 4/5 A 2/3 A 1/2 A 1/3 ADocument2 pagesBattery Size Template (18mm & Below) : Fat 4/3 A 4/3 A A 4/5 A 2/3 A 1/2 A 1/3 AHafiani HichamNo ratings yet

- Ico PlainDocument2 pagesIco PlainHafiani HichamNo ratings yet

- Vestel RF47T - Service - Manual - 50041508 PDFDocument43 pagesVestel RF47T - Service - Manual - 50041508 PDFHafiani Hicham50% (2)

- VeriVide CAC LED Datasheet 2019Document2 pagesVeriVide CAC LED Datasheet 2019Arthur ThiesenNo ratings yet

- Hush HouseDocument2 pagesHush Housephutd09No ratings yet

- 1246 SP 4 Emm 24003 B2Document132 pages1246 SP 4 Emm 24003 B2Arash Aghagol100% (1)

- Turbo HD DVR V3.4.2 Release Notes - ExternalDocument3 pagesTurbo HD DVR V3.4.2 Release Notes - Externalcrishtopher saenzNo ratings yet

- The Modernist Moment at The University of LeedsDocument26 pagesThe Modernist Moment at The University of LeedstobyNo ratings yet

- Flood Study Submittal Checklist: Local No-Impact Fema Lomr/ClomrDocument4 pagesFlood Study Submittal Checklist: Local No-Impact Fema Lomr/ClomrSarath VkNo ratings yet

- Us 1 NUM 10xx Series CNC Backup/ Restore Procedures Using NUMBackUp 14 10xx NUMBackupDocument3 pagesUs 1 NUM 10xx Series CNC Backup/ Restore Procedures Using NUMBackUp 14 10xx NUMBackupHa Pro50% (2)

- TOC M2 HandwrittenDocument46 pagesTOC M2 HandwrittenFullmetalNo ratings yet

- Mt4gui CheatsheetDocument2 pagesMt4gui Cheatsheetbinosp2No ratings yet

- Modeling Bounded RationalityDocument220 pagesModeling Bounded RationalityprithvijitmNo ratings yet

- Installation Manual: ModelDocument20 pagesInstallation Manual: ModelJohan VargasNo ratings yet

- Team6 Legend 5BVLCDocument8 pagesTeam6 Legend 5BVLCAna Sofia MuñizNo ratings yet

- Give Your Recommended Intervention in The Case Study Assigned To Your Division. Case Study 1: Oriental MindoroDocument4 pagesGive Your Recommended Intervention in The Case Study Assigned To Your Division. Case Study 1: Oriental MindoroMark-Christopher Roi Pelobello MontemayorNo ratings yet

- Purchasing Process Pt. 2: Laboratory ExerciseDocument6 pagesPurchasing Process Pt. 2: Laboratory ExercisebeverlybandojoNo ratings yet

- DCRM 6 Channel NewDocument9 pagesDCRM 6 Channel NewSayan ChatterjeeNo ratings yet

- El Mehdi Ben MaallaDocument12 pagesEl Mehdi Ben Maallasergio londoñoNo ratings yet

- Considerations in Contact Lens Use Under Adverse ConditionsDocument178 pagesConsiderations in Contact Lens Use Under Adverse ConditionsGusti Andhika AzwarNo ratings yet

- WPS No.: 1.203 Rev.: 4Document2 pagesWPS No.: 1.203 Rev.: 4beyNo ratings yet

- 6SL3210-1KE15-8AF2 Datasheet enDocument2 pages6SL3210-1KE15-8AF2 Datasheet enzenagyNo ratings yet

- CH 19 Cash and Liquidity Management Appendix Class WorkDocument4 pagesCH 19 Cash and Liquidity Management Appendix Class WorkMhmd KaramNo ratings yet

- RT Usersguide PDFDocument36 pagesRT Usersguide PDFRoy RamosNo ratings yet

- KELAS XI SUMATIF (ULANGAN HARIAN) - HORTATORY EXPOSITION TEXT - DieditDocument5 pagesKELAS XI SUMATIF (ULANGAN HARIAN) - HORTATORY EXPOSITION TEXT - Dieditbagussetiawan76634No ratings yet

- The American City - What Works, What Doesn't - Garvin, Alexander - New York, 1996 - New York - McGraw-Hill - 9780070229198 - Anna's ArchiveDocument504 pagesThe American City - What Works, What Doesn't - Garvin, Alexander - New York, 1996 - New York - McGraw-Hill - 9780070229198 - Anna's ArchiveElshaday MaregaNo ratings yet

- Science: Quarter 3 - Module 5: Climate ChangeDocument32 pagesScience: Quarter 3 - Module 5: Climate ChangeMelanie Tagudin TrinidadNo ratings yet

- HDMI Cable Modeling and Analysis With TDR DataDocument9 pagesHDMI Cable Modeling and Analysis With TDR DataAmmar AbdullahNo ratings yet

- Waves in Isotropic Media: Dielectrics and Conductors: in This Lecture You Will LearnDocument10 pagesWaves in Isotropic Media: Dielectrics and Conductors: in This Lecture You Will LearnHuseyin OztoprakNo ratings yet

- Activity 3 EntrepDocument2 pagesActivity 3 EntrepCHLOE ANNE CORDIALNo ratings yet

- Port Loko User RequirementsDocument8 pagesPort Loko User RequirementsDanNo ratings yet