Professional Documents

Culture Documents

SOP For Laser Cutting

SOP For Laser Cutting

Uploaded by

Saravana kumar NagarajanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SOP For Laser Cutting

SOP For Laser Cutting

Uploaded by

Saravana kumar NagarajanCopyright:

Available Formats

标准化作业指导书Standard Operating Procedure

激光切割

Laser Cutting

内部产品编号 版本号

00002 D

Item Number Revision Level

生产 质量

Louis Lu Burns Zhang

Production Quality

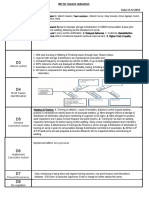

序号 步骤 操作要求 检验/测试 备注/图片

Item Sub-step Operation Requirements Inspection / Test Comments/ Pictures

1. Operators are required to check 1. PM Checklist;

the machine based on the items on 2. Raw material part

PM checklist and make sure the number;

Machine and

machine is under good condition;

1 material

2. Check and make sure correct

conformation

material is being used and put on

the bed;

1. Operators are required to check See more details in

the program to ensure it works. programs transfer and

set up procedure

Program

2

checks

1. Press the control button on the No bow allowed

control panel and make sure the

machine works well;

2.

3 Cutting

1. Slide down door and take the Check if the parts for

part from machine; flash

Taking part

4 out of

equipment

1. Check the parts for first piece, in 1. See more details in

process and last piece; the Inspection

2. Green tags should be put on the Instruction Card ;

parts for first and last piece; 2.

5 Checks

file:///conversion/tmp/activity_task_scratch/705574952.xls] File number:XXXXX Prepared by: Burns Zhang

标准化作业指导书Standard Operating Procedure

激光切割

Laser Cutting

内部产品编号 版本号

00002 D

Item Number Revision Level

1. First piece should be put on the 1. Operation station,

table, which is lose to the manufacturing date

equipment; and operator name

2. If first piece checks are should be put on the

acceptable, continue production green tag.

until the shift is over or the order is

6 Identification completed;

3. Last piece should be checked as

well by following Inspection

Instruction Card, but it should be

put on the top of the pallet.

1. The location of the parts on the Make sure the location

pallet should be considered, to is correct for bending

avoid opposite bending in the next

operation.

Parts

7

location

1. When the shift or the order is 1. Data regarding 内部产品编号

Item Number

版本号

Revision Level

done, operators are required to fill good, bad should be 订单号 生产批号

Work Order DMP Lot No.

out the flow ticket with detailed recorded, which will 钢材规格 钢材批号

information; be the input to Steel PN Steel Lot

Document 2. Part should be identified stored productivity and

工序名称 生产日期

8

序号 合格数量 报废数 返修数 机台号码 班别 作业员 备注

Operation Production

Item Qty Good Scrap Rework Machine No. Shift Operator Note

filling by following production internal quality 1

Name

激光切割

Date

Laser Cutting

identification and control of performance. 2

折弯

Brake forming

nonconforming material. 3

牙纹成型

Drill and tap

包装

4

Packing

补充说明

Additional Information

所需工具,量具

工具/量具图片 工序布局

Required Tools and Standard Layout

Gages and Tools

Gages

Height gages and

Operator

caliper, clamps

file:///conversion/tmp/activity_task_scratch/705574952.xls] File number:XXXXX Prepared by: Burns Zhang

You might also like

- Sbi Mains Admit CardDocument2 pagesSbi Mains Admit CardnavneetNo ratings yet

- Quality Planning SopDocument4 pagesQuality Planning SopSaravana kumar NagarajanNo ratings yet

- Laser Welding PFMEADocument1 pageLaser Welding PFMEASaravana kumar NagarajanNo ratings yet

- Technical Delivery Condition: Applicable To Parts: Ring WCFN0055Document4 pagesTechnical Delivery Condition: Applicable To Parts: Ring WCFN0055Balram JiNo ratings yet

- Jerry Vigil CVDocument2 pagesJerry Vigil CVMktNeutralNo ratings yet

- Cutting Procedure WorkingDocument3 pagesCutting Procedure Workingrial100% (1)

- Daily QAQC Check SheetsDocument1 pageDaily QAQC Check Sheetsfhairuz.wahidNo ratings yet

- In Process QC FormatDocument9 pagesIn Process QC FormatSunil ChaubeyNo ratings yet

- QAP ITP Bhogat - REV-01Document8 pagesQAP ITP Bhogat - REV-01Ramkunwar YadavNo ratings yet

- ADAPTER Class E Rev 1 - 5.2.2018Document16 pagesADAPTER Class E Rev 1 - 5.2.2018Rajbir SinghNo ratings yet

- Sample Report 3Document23 pagesSample Report 3raulNo ratings yet

- Iqc Chapter 01 PDFDocument8 pagesIqc Chapter 01 PDFNaveen Kumar GunisettyNo ratings yet

- Pre Production ProcedureDocument1 pagePre Production ProcedureNguyen Quoc TriNo ratings yet

- P.E.S.B. Engineering SDN - BHD.: Quality PolicyDocument1 pageP.E.S.B. Engineering SDN - BHD.: Quality PolicyZulhasri WahapNo ratings yet

- Packing InstructionsDocument1 pagePacking Instructionsmdhiron200345No ratings yet

- Windals Precision Pvt. Ltd. Rudrapur: Pre-Dispatch Inspection ReportDocument2 pagesWindals Precision Pvt. Ltd. Rudrapur: Pre-Dispatch Inspection ReportMurtza ArzaiNo ratings yet

- Sample Quality Assurance Plan For Welded Ss Fittings: 25% by 1 After 100% by 2Document2 pagesSample Quality Assurance Plan For Welded Ss Fittings: 25% by 1 After 100% by 2Dhvanit JoshiNo ratings yet

- FINAL Inspection Report PO#KL-3448 PDFDocument21 pagesFINAL Inspection Report PO#KL-3448 PDFArslan HaiderNo ratings yet

- Fabrication FlowchartDocument1 pageFabrication FlowchartDonny100% (1)

- (Signed) Quality Manual Revision K 7th EditionDocument32 pages(Signed) Quality Manual Revision K 7th EditionCricri Cri100% (1)

- It Is To Launch.: CompanyDocument10 pagesIt Is To Launch.: CompanyTeffi Boyer MontoyaNo ratings yet

- Ask Team To Add Company Logo Her "Shri Ganesh Engineering"Document4 pagesAsk Team To Add Company Logo Her "Shri Ganesh Engineering"manoj thakkar100% (1)

- Weld Consumables SelectionDocument3 pagesWeld Consumables SelectionArputharaj Maria LouisNo ratings yet

- Inspection CertificateDocument1 pageInspection CertificateAtanasio PerezNo ratings yet

- Painting Report Cd3Document15 pagesPainting Report Cd3sivaNo ratings yet

- RF Pad Test ReportDocument1 pageRF Pad Test ReportKarthikNo ratings yet

- Quality RequirementsDocument26 pagesQuality RequirementsDilip PatilNo ratings yet

- Attachment D (SAEP 316)Document1 pageAttachment D (SAEP 316)imtiazNo ratings yet

- Nspection Eport: EneralDocument3 pagesNspection Eport: Eneralberbin josNo ratings yet

- Preheating Procedure For Equipment Nozzle Modification (Cs and LTCS)Document6 pagesPreheating Procedure For Equipment Nozzle Modification (Cs and LTCS)Rakesh RanjanNo ratings yet

- Fabricators QC Qa Plan Checklist Form 675 070 17Document3 pagesFabricators QC Qa Plan Checklist Form 675 070 17novernandoNo ratings yet

- Non Conformance Log Sheet - 2019Document4 pagesNon Conformance Log Sheet - 2019vinothNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- FDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Document15 pagesFDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Gisela ViskaNo ratings yet

- Pull Off Test Report RefinaryDocument3 pagesPull Off Test Report RefinaryZaid Raslan AyoubNo ratings yet

- CNC HMC Acc CheckDocument2 pagesCNC HMC Acc CheckKalees WaranNo ratings yet

- Z TMT Bill DetailsDocument340 pagesZ TMT Bill DetailssantrssbNo ratings yet

- Report No Date Customer Name Heat No Material Grade Size No of Pieces Weight Color CodeDocument1 pageReport No Date Customer Name Heat No Material Grade Size No of Pieces Weight Color CodeRohit VishwakarmaNo ratings yet

- Fit Up Report: Project Name Project No. Tank No. Report No. DateDocument1 pageFit Up Report: Project Name Project No. Tank No. Report No. DatekarthikumarnpNo ratings yet

- Company DeckDocument26 pagesCompany DeckRajeshkumar AnandhanNo ratings yet

- WPS List PDFDocument2 pagesWPS List PDFNAVANEETH NAVANINo ratings yet

- Incoming Material Inspection Report: Date of ReceiptDocument1 pageIncoming Material Inspection Report: Date of ReceiptRaj MNo ratings yet

- Team Mentor/ Leader Mr. Manish Gautam, Team Members:-Rakesh Kumar, Uday Gururani, Ankur Agarwal, Arvind, Antony, Sathish, RohitDocument1 pageTeam Mentor/ Leader Mr. Manish Gautam, Team Members:-Rakesh Kumar, Uday Gururani, Ankur Agarwal, Arvind, Antony, Sathish, RohitRakesh KumarNo ratings yet

- Material Comparison ListDocument1 pageMaterial Comparison Listdarren84No ratings yet

- General Format For Girder Fabrication Check ListDocument4 pagesGeneral Format For Girder Fabrication Check ListBhanu Pratap ChoudhuryNo ratings yet

- Baking and Drying Temperature of ElectrodesDocument1 pageBaking and Drying Temperature of ElectrodesshisNo ratings yet

- Aql Inspection ReportDocument2 pagesAql Inspection ReportArjun Singh100% (1)

- Purpose:: Procedure Manual FifoDocument3 pagesPurpose:: Procedure Manual FifoartiNo ratings yet

- Testing Inspection of Engineering MaterialsDocument1 pageTesting Inspection of Engineering MaterialsSalem GarrabNo ratings yet

- Weld ShrinkageDocument16 pagesWeld ShrinkageWeff JingNo ratings yet

- Pickling Work InstructionDocument1 pagePickling Work InstructionmanesarkarNo ratings yet

- Works Instructions Micro Hardness TesterDocument2 pagesWorks Instructions Micro Hardness Testeryadu kumar singhNo ratings yet

- Gate & Globe PDFDocument0 pagesGate & Globe PDFZoebairNo ratings yet

- Label Control ProcedureDocument4 pagesLabel Control ProcedureSudeesha Wenura Bandara100% (1)

- Mau ReportDocument30 pagesMau ReportNguyễn Hoàng DũngNo ratings yet

- Cutting Plan FormatDocument1 pageCutting Plan FormatPrinceRaghavNo ratings yet

- Quality Control Plan: ClientDocument7 pagesQuality Control Plan: ClienteliiiiiiNo ratings yet

- STD-InSP-0007 (Fitting Inspection Report)Document3 pagesSTD-InSP-0007 (Fitting Inspection Report)airbroomNo ratings yet

- Bs Tech: Electrodes Issue and Return RegisterDocument1 pageBs Tech: Electrodes Issue and Return RegisterRhannie GarciaNo ratings yet

- Asme 1325-18 (2007)Document1 pageAsme 1325-18 (2007)Matthew TaylorNo ratings yet

- QAP K-HouseDocument4 pagesQAP K-HouseAbhinash TamangNo ratings yet

- Std-Insp-0001 (Proceudre For Storage, Drying (Baking), Issue and Control of Welding Consumables)Document5 pagesStd-Insp-0001 (Proceudre For Storage, Drying (Baking), Issue and Control of Welding Consumables)airbroomNo ratings yet

- Regent Garment - IED-SOP 020 Scan & PackDocument3 pagesRegent Garment - IED-SOP 020 Scan & Packie.madeups.ktml1No ratings yet

- Standard Operating Procedure / Work Instructions / Visual AidsDocument3 pagesStandard Operating Procedure / Work Instructions / Visual AidsSwapnil BachhavNo ratings yet

- EMS Manual Sample GoodDocument181 pagesEMS Manual Sample GoodSaravana kumar NagarajanNo ratings yet

- Index page Method SheetDocument1 pageIndex page Method SheetSaravana kumar NagarajanNo ratings yet

- Front page Work Instruction-GasDocument1 pageFront page Work Instruction-GasSaravana kumar NagarajanNo ratings yet

- Valex Inspection ReportDocument1 pageValex Inspection ReportSaravana kumar NagarajanNo ratings yet

- RiskregisterDocument27 pagesRiskregisterSaravana kumar NagarajanNo ratings yet

- Context Partial IMS GlobalDocument6 pagesContext Partial IMS GlobalSaravana kumar NagarajanNo ratings yet

- ANSI Safety LabelsDocument4 pagesANSI Safety LabelsSaravana kumar NagarajanNo ratings yet

- Id Number Title Year OrganizationDocument34 pagesId Number Title Year OrganizationSaravana kumar NagarajanNo ratings yet

- QMS Process Matrix & ApplicationDocument2 pagesQMS Process Matrix & ApplicationSaravana kumar NagarajanNo ratings yet

- Quality Plan BHEL GoodDocument80 pagesQuality Plan BHEL GoodSaravana kumar NagarajanNo ratings yet

- Process Flowchart Sales 06 08 04Document2 pagesProcess Flowchart Sales 06 08 04Saravana kumar NagarajanNo ratings yet

- GEMÜ R690: Pneumatically Operated Diaphragm ValveDocument27 pagesGEMÜ R690: Pneumatically Operated Diaphragm ValveSaravana kumar NagarajanNo ratings yet

- Excel SPCDocument3 pagesExcel SPCSaravana kumar NagarajanNo ratings yet

- ProE InstalDocument2 pagesProE InstalSaravana kumar NagarajanNo ratings yet

- LMMS5LCDocument1 pageLMMS5LCSaravana kumar NagarajanNo ratings yet

- AJVS Service RMA GuideDocument8 pagesAJVS Service RMA GuideSaravana kumar NagarajanNo ratings yet

- CautionDocument1 pageCautionSaravana kumar NagarajanNo ratings yet

- Process Control:: Introduction To Quality ControlDocument11 pagesProcess Control:: Introduction To Quality ControlSaravana kumar NagarajanNo ratings yet

- Metal Gasket Face Seal FittingsDocument12 pagesMetal Gasket Face Seal FittingsSaravana kumar NagarajanNo ratings yet

- 5s Pillars of The Visual WorkplaceDocument35 pages5s Pillars of The Visual WorkplaceSaravana kumar NagarajanNo ratings yet

- Assembly Processin Aircraft ConstructionDocument8 pagesAssembly Processin Aircraft ConstructionSaravana kumar NagarajanNo ratings yet

- Packaging Specification Data Sheet: (FORM 150NA)Document17 pagesPackaging Specification Data Sheet: (FORM 150NA)Saravana kumar NagarajanNo ratings yet

- Runout ControlsDocument24 pagesRunout ControlsSaravana kumar NagarajanNo ratings yet

- SOP Equipment Validation Issue-6Document15 pagesSOP Equipment Validation Issue-6Saravana kumar NagarajanNo ratings yet

- PPAP Dimensional Test ResultsDocument1 pagePPAP Dimensional Test ResultsSaravana kumar NagarajanNo ratings yet

- Orbit Asme STDDocument10 pagesOrbit Asme STDSaravana kumar NagarajanNo ratings yet

- Product Identification-SOPDocument2 pagesProduct Identification-SOPSaravana kumar NagarajanNo ratings yet

- Inspection Equipment InstructionDocument21 pagesInspection Equipment InstructionSaravana kumar NagarajanNo ratings yet

- 14 Central Bank vs. CA, 106 SCRA 143 PDFDocument2 pages14 Central Bank vs. CA, 106 SCRA 143 PDFSilver Anthony Juarez Patoc100% (1)

- Path o PhysiologyDocument2 pagesPath o PhysiologyPotato BroNo ratings yet

- Women Leaving Work Because of Family ResponsibilityDocument2 pagesWomen Leaving Work Because of Family ResponsibilityKshamaChopraNo ratings yet

- 637 - 2024 Lab-1 Polyphase PowerDocument14 pages637 - 2024 Lab-1 Polyphase Powereren.alliNo ratings yet

- ADC InterfacingDocument37 pagesADC InterfacingSaurav ChaudharyNo ratings yet

- Socio-Economics Survey Using A Structured QuestionnaireDocument67 pagesSocio-Economics Survey Using A Structured QuestionnaireCenon Marco MoperaNo ratings yet

- Bat CountDocument10 pagesBat CountManuel Martinez CortesNo ratings yet

- AE23 Capital BudgetingDocument4 pagesAE23 Capital BudgetingCheska AgrabioNo ratings yet

- Chapter 4 - Food and Beverage IndustryDocument73 pagesChapter 4 - Food and Beverage IndustryWen MinozaNo ratings yet

- Resume OF Md. Moshiur Rahman: Higher Secondary Certificate (HSC)Document2 pagesResume OF Md. Moshiur Rahman: Higher Secondary Certificate (HSC)Decor Interior LtdNo ratings yet

- PHD Thesis in Education in PakistanDocument7 pagesPHD Thesis in Education in Pakistanbk156rhq100% (2)

- Plant Design TemplateDocument13 pagesPlant Design TemplateRishabhGupta 2k20umba32No ratings yet

- F33 - Mall of Emirates Metro To Al Barsha 3 Dubai Bus Service TimetableDocument4 pagesF33 - Mall of Emirates Metro To Al Barsha 3 Dubai Bus Service TimetableDubai Q&ANo ratings yet

- Form REN-01 Application For REN RegistrationDocument2 pagesForm REN-01 Application For REN RegistrationNajib MohamedNo ratings yet

- Article Climate Change From Sharm El Sheikh COP 27 To Dubai COP 28 by Nabeel MunirDocument7 pagesArticle Climate Change From Sharm El Sheikh COP 27 To Dubai COP 28 by Nabeel MunirMaham SajjadNo ratings yet

- Analysis of Thermal Behavior of High Frequency Transformers Using Finite Element MethodDocument6 pagesAnalysis of Thermal Behavior of High Frequency Transformers Using Finite Element Methodkar mugilanNo ratings yet

- Test Unit Safety Valves - enDocument12 pagesTest Unit Safety Valves - enAndreas SetiadiNo ratings yet

- ATADU2002 DatasheetDocument3 pagesATADU2002 DatasheethindNo ratings yet

- Radiation Resistance of ElastomersDocument3 pagesRadiation Resistance of ElastomersBubai111No ratings yet

- Tumabini Vs PeopleDocument7 pagesTumabini Vs PeopleAthea Justine YuNo ratings yet

- Chapter No.1 - Introduction To Personal SellingDocument52 pagesChapter No.1 - Introduction To Personal SellingAyush100% (1)

- Multifix All Mechanical Anchor - Design GuideDocument28 pagesMultifix All Mechanical Anchor - Design GuideConstantino L. Ramirez III0% (1)

- RSB Application Form - New 04242013 1st PageDocument1 pageRSB Application Form - New 04242013 1st PageBoyTibsNo ratings yet

- Presentation 1Document15 pagesPresentation 1sruthi_k7776No ratings yet

- AMF-120 K4 FenceDocument1 pageAMF-120 K4 FenceAnupam AjayanNo ratings yet

- APM30H Amp Amp TMC11H Amp Amp IBBS200D Amp Amp IBBS200T Ver PDFDocument83 pagesAPM30H Amp Amp TMC11H Amp Amp IBBS200D Amp Amp IBBS200T Ver PDFЖаннаNo ratings yet

- MSC 84-18-2 - Technical Co-Operation On Domestic Ferry Safety (Secretariat)Document2 pagesMSC 84-18-2 - Technical Co-Operation On Domestic Ferry Safety (Secretariat)Batman KasarungNo ratings yet

- Common Rail Injector CroosreferenceDocument6 pagesCommon Rail Injector Croosreferenceคุณชายธวัชชัย เจริญสุขNo ratings yet