Professional Documents

Culture Documents

Thermal Analysis

Thermal Analysis

Uploaded by

I. NOORAMOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thermal Analysis

Thermal Analysis

Uploaded by

I. NOORAMCopyright:

Available Formats

Thermal Analysis

Thermal analysis is a type of analytical technique used to study the physical and chemical

properties of a material as a function of temperature, time, and/or environment. It involves

applying heat or cooling to a sample and monitoring its physical and/or chemical

changes.Thermal analysis can be categorized into two main types:

Isothermal analysis: In isothermal analysis, the temperature of the sample is held constant

while its physical and/or chemical properties are monitored over time. This technique is

useful for studying the kinetics of phase transformations, reactions, and degradation

processes.

Non-isothermal analysis: In non-isothermal analysis, the temperature of the sample is

varied over time in a controlled manner, while its physical and/or chemical properties are

monitored. This technique is useful for studying the thermal stability, thermal behavior,

and phase transitions of materials.

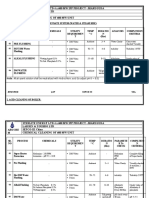

DSC: A Differential Scanning Calorimeter (DSC) measures temperatures of a reference

material and a sample while changing the sample temperature in accordance with a program, and

then measures the amount of heat from the temperature difference.

Measuring objects: Melting, Glass Transitions, Crystallization, Curing Reaction, Examination

of Thermal History, Specific Heat

Principle:

When a furnace is heated, a sample and a reference material are heated at a slightly

slower rate than the furnace temperature.

When the sample start to melt, the sample temperature stop rising (because of the heat

used for melting). However, the temperature of the reference material increases.

After melting, the sample temperature rises again following the furnace temperature.

(Sample temperature) - (Reference material temperature) corresponds to DSC signals.

Sample data of DSC:

The DSC curve shows a shift of the baseline around 77°C, indicating "glass transition". Also, an

exothermic peak is observed around 130°C, indicating an exothermic reaction caused by

crystallization. The endothermic peak observed at around 250°C refers to an endothermic

reaction by "melting". Crystallization after glass transition and subsequent melting were

observed, indicating that the sample was in an amorphous state with little crystallization by

quenching after heating.

For this reason, the thermal history of materials can be confirmed by measuring with a DSC

(differential scanning calorimeter).

dynamic Mechanical Analysis (DMA ):

Dynamic mechanical Analysis (DMA) is the study of the relationships between the sample’s

dimensions (length or volume) and its temperature under constant oscillating load, i. e. under

stress or strian. Stress is the force per unit area. Strain is the change of dimension to the original

one.

In DMA, the sample properties as elastic modulus and tensile strength are measured. Modulus is

the ratio of stress to strain.

You might also like

- 1.2 The Mole ConceptDocument6 pages1.2 The Mole ConceptCicy IrnaNo ratings yet

- DSC Lab ReportDocument3 pagesDSC Lab ReportkomalramNo ratings yet

- Differential Scanning Calorimetry (DSC)Document96 pagesDifferential Scanning Calorimetry (DSC)Rajesh DwivediNo ratings yet

- TOPIC 2 Lab ReportDocument9 pagesTOPIC 2 Lab ReportMasriza Eyzza100% (1)

- Axial Flow Fans PDFDocument66 pagesAxial Flow Fans PDFCodruţ ErașcuNo ratings yet

- Chapter 2Document7 pagesChapter 2林哲璋No ratings yet

- Unit - 5Document56 pagesUnit - 5Baskar Singh GNo ratings yet

- LEC 10 THERMAL ANALYSIS (1)Document32 pagesLEC 10 THERMAL ANALYSIS (1)ishafatimapakistaniNo ratings yet

- Differential Scanning CalorimetryDocument7 pagesDifferential Scanning CalorimetryAli HussnainNo ratings yet

- Differential Scanning Calorimeter (DSC)Document7 pagesDifferential Scanning Calorimeter (DSC)Fi FialaNo ratings yet

- Thermal Analysis 3Document61 pagesThermal Analysis 3Itz HamzaNo ratings yet

- Differential Scanning Calorimeter: Maulana Azad National Institute of Technology, BhopalDocument70 pagesDifferential Scanning Calorimeter: Maulana Azad National Institute of Technology, Bhopalricha_msmeNo ratings yet

- Differentialscanningcalorimetry 221101152123 464b39b3Document26 pagesDifferentialscanningcalorimetry 221101152123 464b39b3anujaNo ratings yet

- Aya Alla Mahmoud - 5632Document11 pagesAya Alla Mahmoud - 5632aya mahmoudNo ratings yet

- ThermalanalysisDocument88 pagesThermalanalysisbinteadamNo ratings yet

- Differential Scanning CalorimetryDocument12 pagesDifferential Scanning CalorimetryGEAIA ENERGY ENVIRONNo ratings yet

- Unit 2Document17 pagesUnit 2akashdhevaNo ratings yet

- Hermal Ethods of Nalysis: Mr. Ganesh B. Nigade, Assistant Professor, PDEA's S. G. R. S. College of Pharmacy, SaswadDocument35 pagesHermal Ethods of Nalysis: Mr. Ganesh B. Nigade, Assistant Professor, PDEA's S. G. R. S. College of Pharmacy, Saswadchemistchemist85No ratings yet

- Differential Scanning CalorimetryDocument7 pagesDifferential Scanning CalorimetryKenesei GyörgyNo ratings yet

- Thermal Analysis: Presented By: MD Meraj Anjum M.Pharm 1 Year Bbau, LucknowDocument25 pagesThermal Analysis: Presented By: MD Meraj Anjum M.Pharm 1 Year Bbau, LucknowA. MerajNo ratings yet

- Thermal AnalysisDocument8 pagesThermal AnalysisHafsa QasimNo ratings yet

- DSC ShortsDocument7 pagesDSC Shortsamh.fpdNo ratings yet

- Chemistry of Peptides: A Coupling Reaction in Peptide SynthesisDocument17 pagesChemistry of Peptides: A Coupling Reaction in Peptide SynthesisRakesh KoreNo ratings yet

- Thermal 1Document13 pagesThermal 1Michaela Lei Asusano BadeNo ratings yet

- Thermal Analysis: by Deepak PoddarDocument38 pagesThermal Analysis: by Deepak Poddaranuj phalswalNo ratings yet

- Pharmaceutical Chemistry-III B (Pharmaceutical Analysis) : PHARM-516-1Document32 pagesPharmaceutical Chemistry-III B (Pharmaceutical Analysis) : PHARM-516-1daud faisalNo ratings yet

- Differential Scanning CalorimetryDocument21 pagesDifferential Scanning Calorimetryhimadrisahu88No ratings yet

- DokumentDocument1 pageDokumentNikaNo ratings yet

- DSC NotesDocument19 pagesDSC NotesMohammed Munawar pNo ratings yet

- Fundamentals of The Differential Scanning Calorimetry Application in Materials Science A Wierzbicka-MiernikDocument7 pagesFundamentals of The Differential Scanning Calorimetry Application in Materials Science A Wierzbicka-Miernikmahiyatripty360No ratings yet

- Thermal Methods of AnalysisDocument37 pagesThermal Methods of AnalysisSai krishnaNo ratings yet

- Materiales de IngeniriaDocument20 pagesMateriales de Ingeniriasofia pulidoNo ratings yet

- Unit 8-Thermal Analysis-IIDocument3 pagesUnit 8-Thermal Analysis-IIAli SheikhNo ratings yet

- DSC Analysis of Solute Clustering Behavior in 6082 Aluminum AlloyDocument5 pagesDSC Analysis of Solute Clustering Behavior in 6082 Aluminum AlloyNeel NadparaNo ratings yet

- 7-Thermal AnalysisDocument27 pages7-Thermal AnalysisMaaz ZafarNo ratings yet

- THERMAL Analysis - Parth Gathiyawala (2019033800133937) Ind. Mat. (2019-2020)Document33 pagesTHERMAL Analysis - Parth Gathiyawala (2019033800133937) Ind. Mat. (2019-2020)Parth GathiyawalaNo ratings yet

- Fluorimetry AsignDocument7 pagesFluorimetry Asignshonu2009No ratings yet

- Research and Reviews Journal of Pharmaceutical AnalysisDocument12 pagesResearch and Reviews Journal of Pharmaceutical Analysismade hNo ratings yet

- DSC PresentationDocument11 pagesDSC Presentationhareesh13h100% (1)

- Differential Scanning Calorimetry (DSC) : Mr. Sagar Kishor SavaleDocument27 pagesDifferential Scanning Calorimetry (DSC) : Mr. Sagar Kishor SavaleDivya Tripathy100% (1)

- Unit - VDocument38 pagesUnit - VSrikanth PalaniswamyNo ratings yet

- Differential Thermal Analysis (Dta)Document17 pagesDifferential Thermal Analysis (Dta)himadrisahu88No ratings yet

- Differential Scanning CalorimetryDocument38 pagesDifferential Scanning CalorimetrySukhwant SinghNo ratings yet

- Thermal Characterization Techniques2019 - HandoutsDocument8 pagesThermal Characterization Techniques2019 - HandoutsMuhammad OsamaNo ratings yet

- Unit 1 NotesDocument16 pagesUnit 1 NotesSAJITH NFNo ratings yet

- Differential Scanning CalorimetryDocument60 pagesDifferential Scanning CalorimetryMariyam100% (2)

- Presented by - Smruti Ranjan Masanta M.PHARM (1 YR) PharmacologyDocument20 pagesPresented by - Smruti Ranjan Masanta M.PHARM (1 YR) Pharmacologyangel.lopez6383No ratings yet

- Differential Scanning Calorimetry (DSC)Document9 pagesDifferential Scanning Calorimetry (DSC)DanielNo ratings yet

- Thermal AnalysisDocument47 pagesThermal Analysishafsa BNo ratings yet

- Sophomore Research PaperDocument45 pagesSophomore Research Paperapi-282020141No ratings yet

- Differential Scanning CalorimetryDocument6 pagesDifferential Scanning CalorimetrySurender MalikNo ratings yet

- Form 4 - IGCSE Physics - ThermometersDocument13 pagesForm 4 - IGCSE Physics - ThermometersMr. Borges93% (57)

- Diagrams Bi SNDocument18 pagesDiagrams Bi SNgláucia_gabriellaNo ratings yet

- Grade 10 CH 6 To SendDocument36 pagesGrade 10 CH 6 To SendZynx DixonNo ratings yet

- Thermal Analysis 19 Feb 2023Document29 pagesThermal Analysis 19 Feb 2023eeman tariqNo ratings yet

- Experiment 106 Specific Heat: PhysicsDocument4 pagesExperiment 106 Specific Heat: PhysicsJag MasterNo ratings yet

- Lecture 5Document11 pagesLecture 5Rahmeh EL saaiedehNo ratings yet

- Lec 23Document11 pagesLec 23Neeraj PrasadNo ratings yet

- Operation and Application of Differential Scanning Calorimetry (DSC) in PharmaceuticalsDocument21 pagesOperation and Application of Differential Scanning Calorimetry (DSC) in PharmaceuticalsMd Tayfuzzaman100% (1)

- Differential Thermal Analysis (DTA)Document21 pagesDifferential Thermal Analysis (DTA)Dr. Saad B. H. Farid0% (1)

- Differential Thermal Analysis (Dta)Document21 pagesDifferential Thermal Analysis (Dta)Shaise Jacob100% (6)

- Prelim - Phy Scie11Document3 pagesPrelim - Phy Scie11JaenicaPaulineCristobalNo ratings yet

- Acid Base Lecture 2Document32 pagesAcid Base Lecture 2noor uddinNo ratings yet

- Afp MSDSDocument3 pagesAfp MSDSINGENIERÍA Y MANTENIMIENTO CLINICO LTDANo ratings yet

- Gillfab 4004B: Product Data SheetDocument2 pagesGillfab 4004B: Product Data SheetHerri S.No ratings yet

- Chemical Cleaning ChartDocument4 pagesChemical Cleaning ChartSudhanshu DashNo ratings yet

- Class 12 Chemistry Revision Notes Chemical KineticsDocument23 pagesClass 12 Chemistry Revision Notes Chemical Kineticsrohit rajputNo ratings yet

- 〈2021〉 MICROBIAL ENUMERATION TESTS-NUTRITIONAL AND DIETARY SUPPLEMENTSDocument5 pages〈2021〉 MICROBIAL ENUMERATION TESTS-NUTRITIONAL AND DIETARY SUPPLEMENTSehsan050628No ratings yet

- Study Guide No. 1 Carbohydrates (Part 1) A. General Test For Carbohydrates 1. Molisch TestDocument2 pagesStudy Guide No. 1 Carbohydrates (Part 1) A. General Test For Carbohydrates 1. Molisch TestMichael Ralf SionosaNo ratings yet

- Broccoli Sulforaphane An Insight Into The Analytical Aspect and Uv Spectroscopic Method Development and ValidationDocument16 pagesBroccoli Sulforaphane An Insight Into The Analytical Aspect and Uv Spectroscopic Method Development and ValidationDuniaNo ratings yet

- FGM Mud Log Book Jan 2022Document61 pagesFGM Mud Log Book Jan 2022ongcchemist gd chitraNo ratings yet

- PN671, PN672, PN673Document6 pagesPN671, PN672, PN673TÀi VÕNo ratings yet

- Calculating and Measuring WaterDocument3 pagesCalculating and Measuring WaterOvidiu LevNo ratings yet

- Acids and BasesDocument18 pagesAcids and Basesjansen manlapazNo ratings yet

- Conceptual Improvement Isomerism Answers PDFDocument13 pagesConceptual Improvement Isomerism Answers PDFd anjilappa50% (2)

- Electrode and Its TypesDocument10 pagesElectrode and Its TypesPratheep AddrinNo ratings yet

- Adoc - Tips - Kandungan Aflatoksin b1 b2 g1 Dan g2 Pada Kacang TDocument10 pagesAdoc - Tips - Kandungan Aflatoksin b1 b2 g1 Dan g2 Pada Kacang TDwi Rahmah AgustinaNo ratings yet

- Jacs 3c03786Document10 pagesJacs 3c03786Nongnuch ArtrithNo ratings yet

- AOAC Hydroxymethylfurfural in HoneyDocument6 pagesAOAC Hydroxymethylfurfural in HoneyJessica triana pinedaNo ratings yet

- ChemistryDocument12 pagesChemistryZdhdhdNo ratings yet

- Study Guide SAMDocument73 pagesStudy Guide SAMbramturf20032No ratings yet

- XII-AIATS - Pen & Paper - 1Document5 pagesXII-AIATS - Pen & Paper - 1pritishahdeo71725No ratings yet

- Pdf&rendition 1Document9 pagesPdf&rendition 1ArchanaNo ratings yet

- Tsca Toxic Substanteces Control ActDocument1 pageTsca Toxic Substanteces Control ActAlbert Casanova FernandezNo ratings yet

- Austenitic Ductile Iron Castings For Pressure-Containing Parts Suitable For Low-Temperature ServiceDocument5 pagesAustenitic Ductile Iron Castings For Pressure-Containing Parts Suitable For Low-Temperature ServiceHoem ITNo ratings yet

- Tb5661en Ultimus Film Tech Brief MsDocument4 pagesTb5661en Ultimus Film Tech Brief MsImran AsgharNo ratings yet

- WO2015194611A1 - Aqueous Emulsion, Coating Film, Cured Product, and Laminate - Google PatentsDocument33 pagesWO2015194611A1 - Aqueous Emulsion, Coating Film, Cured Product, and Laminate - Google PatentsAsit RayNo ratings yet

- Chemical Safety Answer KeyDocument5 pagesChemical Safety Answer KeyHermoine GrangerNo ratings yet