Professional Documents

Culture Documents

Industrial Alloy Chart Sept14

Industrial Alloy Chart Sept14

Uploaded by

Selvakumar Natarajan0 ratings0% found this document useful (0 votes)

5 views1 pageAlloy chart for solder paste

Original Title

industrial_alloy_chart_sept14

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAlloy chart for solder paste

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

5 views1 pageIndustrial Alloy Chart Sept14

Industrial Alloy Chart Sept14

Uploaded by

Selvakumar NatarajanAlloy chart for solder paste

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

Industrial Alloys

AIM offers a broad range of alloys for SMT, wave soldering, hand soldering, and various applications. See the chart

below for a listing of common alloys. Other alloys are available upon request.

SOLDER FORM AVAILABILITY

MELTING SOLDER BAR CORED SOLID SOLDER SOLDER

ALLOY COMMENT

POINT °C PASTE SOLDER WIRE WIRE PREFORMS SPHERES

Alloy for low temperature applications. Attention should be

Sn42/Bi58 138 paid to potential embrittlement issues and poor thermal

fatigue properties.

Similar characteristics to Sn42/Bi58, with improved fatigue

Sn42/Bi57/Ag1 138

characteristics.

Sn63/Pb37 183 Standard electronic assembly alloy prior to RoHS.

The lowest melting point and least expensive of the tin-silver-

CASTIN®

217 copper family of alloys. Proven reliability and compatibility

Sn/Ag2.5/Cu0.8/Sb0.5

with current parts and processes.

SAC305

217-218 Tin-silver-copper alloy in line with JEIDA recommendation.

Sn/Ag3/Cu0.5

SAC387 Alternative tin-silver-copper alloy. Similar characteristics as

217-218

Sn/Ag3.8/Cu0.7 SAC305 with slightly higher cost of metals.

SAC405 High-silver tin-silver-copper alloy. Similar characteristics as

217-218

Sn/Ag4/Cu0.5 SAC305 with higher cost of metals.

Low cost Sn-Ag-Cu alloy. Far superior fluidity as compared to

SAC+0307

217-227 other alloys and makes of bar, resulting in excellent flow when

Sn/Ag0.3/Cu0.7

used in wave soldering.

SAC+0107 Lowest available silver version of the SAC alloy family. This

217-228

Sn/Ag0.1/Cu0.7 alloy is a low cost alternative for flow soldering.

May not have adequate thermal reliability or wetting and

Sn96.5/Ag3.5 221 requires higher soldering temperatures than tin-silver-copper

alloys.

Alloy for high-temperature applications only. Costly due to

Sn97.5/Ag2.5 221-240

high silver content.

SN100C® Ni and Ge-doped Sn/Cu alloy. Bright solder joints, improved

227

Sn/Cu0.7/Ni0.05+Ge wetting.

Cost-effective alternative for wave soldering and hand

Sn99.3/Cu0.7 227 soldering applications. Attention should be paid to poor

wetting and fatigue properties.

Alternative low-cost lead-free alloy manufactured with a small

SCAN 227

amount of performance enhancing dopants.

Sn97/Cu3 227-300 Alloy for high-temperature applications only.

Alloy for high-temperature applications only. Poor wetting.

Sn95/Sb5 232-240

Less cost-prohibitive than Sn/Ag.

Alloy for high temperature applications. Attention should

Bi95/Ag5 262.5 be paid to potential embrittlement issues and poor thermal

fatigue properties.

Au80/Sn20 281 Eutectic die-attach alloy. Costly due to high gold content.

High-temperature alloy used mainly for semiconductor

Sn5/Pb93.5/Ag1.5 305-306 attachment to ceramic boards. Also used in fuse and thermal

couple attachment

Alloy for high-temperature applications. Attention should

Bi95/Sb5 308 be paid to potential embrittlement issues and poor thermal

fatigue properties.

Au88/Ge12 356 Gold die-attach alloy.

You might also like

- 2k Duolingo PlusDocument158 pages2k Duolingo PlusThomas De Doncker0% (1)

- A Complete Guide to Watch Repair - Barrels, Fuses, Mainsprings, Balance Springs, Pivots, Depths, Train Wheels and Common Stoppages of WatchesFrom EverandA Complete Guide to Watch Repair - Barrels, Fuses, Mainsprings, Balance Springs, Pivots, Depths, Train Wheels and Common Stoppages of WatchesRating: 4 out of 5 stars4/5 (1)

- Creation of Control PlanDocument4 pagesCreation of Control PlanAnthonyNo ratings yet

- Advantages and Disadvantages: Composition Fa Mily °C To Xic CommentsDocument34 pagesAdvantages and Disadvantages: Composition Fa Mily °C To Xic Commentsk27571No ratings yet

- Electrode Dan Welding Wires 1646204294Document7 pagesElectrode Dan Welding Wires 1646204294Gibran RamadhanNo ratings yet

- Mn-Mo Gas Shileded (E90T1-D3, E100T5-D2) PDFDocument1 pageMn-Mo Gas Shileded (E90T1-D3, E100T5-D2) PDFborovniskiNo ratings yet

- Ss Filler Wire SelectionDocument26 pagesSs Filler Wire Selectionlemuel bacsaNo ratings yet

- Alloy 22205 Stainless Steel Material Property Data SheetDocument4 pagesAlloy 22205 Stainless Steel Material Property Data Sheethriveroll2No ratings yet

- Gas Tungsten Arc Welding Practice:: Jobs 19-J1-J19 (Plate)Document8 pagesGas Tungsten Arc Welding Practice:: Jobs 19-J1-J19 (Plate)Willy UioNo ratings yet

- Weld Duplex Ss SteelDocument12 pagesWeld Duplex Ss SteelSan JaNo ratings yet

- SolderDocument11 pagesSolderahmedNo ratings yet

- Ati 2205 PDFDocument6 pagesAti 2205 PDFGetapo RaminNo ratings yet

- Flux-Core Solder : Flux Reducing Agent ReduceDocument86 pagesFlux-Core Solder : Flux Reducing Agent ReduceIonut Ciprian CojocaruNo ratings yet

- Lesson Plan: Brass PropertiesDocument7 pagesLesson Plan: Brass Propertiessurajit biswasNo ratings yet

- Kestra Flux Cored Wire Catalog MSCDocument16 pagesKestra Flux Cored Wire Catalog MSCCassiano MiralhaNo ratings yet

- BrassDocument10 pagesBrassArjun CpNo ratings yet

- Aluminium Alloy 7075 Data SheetDocument1 pageAluminium Alloy 7075 Data SheetFaris AlmarshadNo ratings yet

- 254SMO 性能Document8 pages254SMO 性能yw_oulalaNo ratings yet

- 254SMO 性能Document8 pages254SMO 性能yw_oulalaNo ratings yet

- SAC ALLOY 305 MaterialDocument2 pagesSAC ALLOY 305 Materialmuki10No ratings yet

- High Quality Products For Welding and CladdingDocument25 pagesHigh Quality Products For Welding and Claddingsanketpavi21100% (1)

- 90cual Mig WireDocument1 page90cual Mig WireAris WicaksonoNo ratings yet

- Stainless Steel ASTM A815 S31803: Specifications Alloy DesignationsDocument2 pagesStainless Steel ASTM A815 S31803: Specifications Alloy Designationsallouche_abdNo ratings yet

- Repair and MaintenanceDocument4 pagesRepair and MaintenanceElMacheteDelHuesoNo ratings yet

- Study of Mechanical Properties of Zn-27Al Alloy Cast in Metal Mould at Different Casting ConditionsDocument4 pagesStudy of Mechanical Properties of Zn-27Al Alloy Cast in Metal Mould at Different Casting ConditionserpublicationNo ratings yet

- Material Specifications For Furnace Tubes, Headers, and FittDocument5 pagesMaterial Specifications For Furnace Tubes, Headers, and FittAleem QureshiNo ratings yet

- Nickel-Iron For Cast Iron: Data SheetDocument3 pagesNickel-Iron For Cast Iron: Data SheetSandro ChiliquingaNo ratings yet

- 1a Arc Weld ProcessesDocument45 pages1a Arc Weld ProcessesskgcNo ratings yet

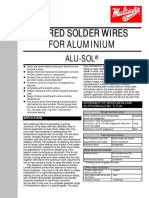

- Cored Solder Wires Cored Solder Wires For Aluminium: Alu-SolDocument4 pagesCored Solder Wires Cored Solder Wires For Aluminium: Alu-Solpaula09No ratings yet

- SolderDocument12 pagesSolderJustin Francis BriggsNo ratings yet

- Copper AlloysDocument4 pagesCopper AlloysMuhammed SulfeekNo ratings yet

- Electrical Properties of Lead Solder AlloyDocument9 pagesElectrical Properties of Lead Solder AlloyVedant PrustyNo ratings yet

- E 7016 Product-SheetDocument1 pageE 7016 Product-SheetAlireza TakrimiNo ratings yet

- 22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeDocument7 pages22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeOnM deptNo ratings yet

- Cu ZN 10Document1 pageCu ZN 10Sara RiddleNo ratings yet

- Met 05 Nonferrous WeldingDocument16 pagesMet 05 Nonferrous WeldingRaghu vamshiNo ratings yet

- COPPER-110: Nearest StandardDocument3 pagesCOPPER-110: Nearest StandardPS Pinturas pinturasNo ratings yet

- Fontargen Sales ProgramDocument20 pagesFontargen Sales ProgramCarlos Nombela PalaciosNo ratings yet

- Copper AlloysDocument39 pagesCopper Alloys1209540046No ratings yet

- LM4 Aluminium Casting Alloy (Al - Si5Cu3) : Chemical CompositionDocument3 pagesLM4 Aluminium Casting Alloy (Al - Si5Cu3) : Chemical Compositiona.suleimanNo ratings yet

- Sec 02 CF Steel BarsDocument17 pagesSec 02 CF Steel Barstravis8zimmermannNo ratings yet

- Zinc PlatingDocument3 pagesZinc Platingjavier.garcia6281No ratings yet

- Alloy Steels: Table 4.2 Typical Mechanical Properties of Some Commercial Steels at Room TemperatureDocument2 pagesAlloy Steels: Table 4.2 Typical Mechanical Properties of Some Commercial Steels at Room TemperatureBharathi SrinivasanNo ratings yet

- Al600 UNS N06600Document4 pagesAl600 UNS N06600kart_rlNo ratings yet

- Improving The Corrosion Resistance of Duplex Stainless Steel WeldsDocument29 pagesImproving The Corrosion Resistance of Duplex Stainless Steel WeldsRaghuram BathulaNo ratings yet

- Aalco Metals LTD Stainless Steel ASTM A815 S31803 261Document2 pagesAalco Metals LTD Stainless Steel ASTM A815 S31803 261Irvin PajueloNo ratings yet

- LM6 Alloy Detail PDFDocument4 pagesLM6 Alloy Detail PDFramashishNo ratings yet

- LM6 Alloy DetailDocument4 pagesLM6 Alloy DetaildsoNo ratings yet

- Aluminized t1 TubingDocument4 pagesAluminized t1 TubingshankosiNo ratings yet

- LM6 Aluminium Casting Alloy (Al - Sil2) : Chemical CompositionDocument4 pagesLM6 Aluminium Casting Alloy (Al - Sil2) : Chemical Compositionbaskaran.marieNo ratings yet

- Material Product Data Sheet Copper & Copper Alloy (Brass, Bronze) Thermal Spray WiresDocument4 pagesMaterial Product Data Sheet Copper & Copper Alloy (Brass, Bronze) Thermal Spray WiresSerkan ÖzcanNo ratings yet

- Specification Sheet: 2205: (UNS S32205/S31803)Document2 pagesSpecification Sheet: 2205: (UNS S32205/S31803)Haytham MohamedNo ratings yet

- How To Weld 254 SMODocument12 pagesHow To Weld 254 SMOsateesh chand100% (7)

- Aws Stainless Steel ClassificationDocument1 pageAws Stainless Steel ClassificationMcmiltondmordomNo ratings yet

- TMP 10401-Fusible Alloy-2147145127Document20 pagesTMP 10401-Fusible Alloy-2147145127Anonymous oyUAtpKNo ratings yet

- #97751 Flux and Solder Compatibility 97751 r5Document2 pages#97751 Flux and Solder Compatibility 97751 r5Enrico PiccininiNo ratings yet

- Copper and Its AlloysDocument6 pagesCopper and Its AlloysNaidra AbarquezNo ratings yet

- Piping Inspection 22.01.2020Document72 pagesPiping Inspection 22.01.2020KarthikNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonRating: 4 out of 5 stars4/5 (1)

- TrainingDocument11 pagesTrainingSelvakumar Natarajan100% (1)

- Space Grade CCGA Presentation-1Document8 pagesSpace Grade CCGA Presentation-1Selvakumar NatarajanNo ratings yet

- Role of PLM in The Electronics LifecycleDocument18 pagesRole of PLM in The Electronics LifecycleSelvakumar NatarajanNo ratings yet

- Brochure of TrueX RoHS Handheld XRF ROHS AnalyzerDocument5 pagesBrochure of TrueX RoHS Handheld XRF ROHS AnalyzerSelvakumar NatarajanNo ratings yet

- Flexible Circuits Manufacturing GuideDocument66 pagesFlexible Circuits Manufacturing GuideSelvakumar NatarajanNo ratings yet

- Media Preparation and Uses in Medical MicrobiologyDocument20 pagesMedia Preparation and Uses in Medical MicrobiologyPrincewill SeiyefaNo ratings yet

- Manual Serviço - Aiwa NSX-D77, NSX-T76, NSX-T77Document48 pagesManual Serviço - Aiwa NSX-D77, NSX-T76, NSX-T77fabioferraoNo ratings yet

- Prilepin's ChartDocument7 pagesPrilepin's ChartHenry Clayton0% (1)

- Essentials of Project Management Course OutlineDocument3 pagesEssentials of Project Management Course OutlinetesfaNo ratings yet

- 1 - Solved - The Food Services Division of Cedar River Amusement Par.Document2 pages1 - Solved - The Food Services Division of Cedar River Amusement Par.RATRINo ratings yet

- A Detailed Lesson Plan in Sine Rule 1Document13 pagesA Detailed Lesson Plan in Sine Rule 1Byron Apuli MajadasNo ratings yet

- Recent Advances in Enhanced Flooded Battery For Smart Mild Hybrid Power TrainsDocument29 pagesRecent Advances in Enhanced Flooded Battery For Smart Mild Hybrid Power Trains3 GamerNo ratings yet

- EXPERIMENTAL - PDF (Journal Article)Document10 pagesEXPERIMENTAL - PDF (Journal Article)Jeric C. ManaliliNo ratings yet

- Biochem Lab NotesDocument26 pagesBiochem Lab NotesRicky Justin NgoNo ratings yet

- Tenses 2Document13 pagesTenses 2Rocio Valverde PastorNo ratings yet

- Q Paper PracticalDocument2 pagesQ Paper PracticalSanjay L. RathodNo ratings yet

- Bestiary of The Rosewood Highlands Draft 1-4-08!07!19Document82 pagesBestiary of The Rosewood Highlands Draft 1-4-08!07!19Stefano Chiaramonti100% (2)

- Adjusting Entries, Worksheet and FSDocument26 pagesAdjusting Entries, Worksheet and FSBianca RoswellNo ratings yet

- All Pass Comb FiltersDocument13 pagesAll Pass Comb Filterspho144No ratings yet

- Avanti Service Lift Pegasus - A Safe Investment: DesignDocument2 pagesAvanti Service Lift Pegasus - A Safe Investment: DesignFrancisco GarciaNo ratings yet

- Neurobiologic Theories and PsychopharmacologyDocument3 pagesNeurobiologic Theories and Psychopharmacologygeorgeloto12100% (1)

- Surface To Air Missile SA-10 (S300)Document4 pagesSurface To Air Missile SA-10 (S300)Branislav LackovicNo ratings yet

- At The AirportDocument6 pagesAt The AirportAlen KuharićNo ratings yet

- Equity ApplicationDocument3 pagesEquity ApplicationanniesachdevNo ratings yet

- Composite Materials Based On Hemp and Flax For Low-Energy BuildingsDocument23 pagesComposite Materials Based On Hemp and Flax For Low-Energy Buildingsmn.gautamNo ratings yet

- Simbol A4Document3 pagesSimbol A4ibnu100% (1)

- 89C51 Instruction SetDocument49 pages89C51 Instruction SetYashaswini B Srinivas100% (1)

- Zumba DLPDocument8 pagesZumba DLPJohnne Erika LarosaNo ratings yet

- English Unit 9 - Ni Putu Angelika RistyaDocument3 pagesEnglish Unit 9 - Ni Putu Angelika RistyaAngel LikaNo ratings yet

- The Mavericks MNIT 1st Year 2022-23Document3 pagesThe Mavericks MNIT 1st Year 2022-23Shantul KhandelwalNo ratings yet

- International Expansion StrategyDocument15 pagesInternational Expansion StrategykananguptaNo ratings yet

- Laura Su ResumeDocument1 pageLaura Su Resumeapi-280311314No ratings yet

- TR Technology Radar Vol 27 enDocument43 pagesTR Technology Radar Vol 27 enstart-up.roNo ratings yet

- Nanofiltration - WikipediaDocument7 pagesNanofiltration - WikipediaSrinivas DsNo ratings yet