Professional Documents

Culture Documents

Mill Scale Separation

Mill Scale Separation

Uploaded by

Amir AbbaszadehOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mill Scale Separation

Mill Scale Separation

Uploaded by

Amir AbbaszadehCopyright:

Available Formats

MILL SCALE SEPARATION

FEWER FILTERS AND LOWER COSTS

Polymer Static mixer

Thickener

Clean

DynaSand

cooling

water

Oil Sludge Wash water

Cooling water

Scale pit

Mill scale forms during steel production. It is a Fewer filters and lower costs contents processed often amount to a full 400 Input values: Output values:

thin oxide coating that is created when steel is When it comes to separating a hard material like mg/l. This process is also relatively insensitive SS: < 400 mg/l < 10 mg/l

hot-rolled. When the steel is cooled down with mill scale, the continuous movement of sand in to oil emulsions and has proved to be very effec- Oil: < 50 mg/l < 5 mg/l

water during the rolling process, the mill scale the DynaSand system truly comes into its own, tive at separating them too. A lamella can be

breaks off. The cooling water is re-used over and partly because it clears away very high amounts used to take care of the wash water from the Dy- Example: Oxelösund steelworks, Sweden

over again, which means that mill scale and oil of accumulated mill scale and partly because it naSand system, or a Sala thickener with a rate of Production approx 10,000 tonnes of steel

residue particles need to be separated off. Mill enables you to achieve excellent separation re- 2 m/h. Polymers are added to the thickener. Our Cold water flow rate: 1,120 m3/h

scale often also contains valuable alloying ele- sults with very high flow rates. This means fewer tried-and-tested process solution for mill scale Filters: 20 pcs, total filter area of 100 m2.

ments such as tungsten, vanadium and molyb- filters are required and the investment and op- has been installed in more than 150 steelworks Temperature: 25-30°C.

denum, which provides a strong incentive to re- erating costs are low. In these types of applica- over the past 20 years. Input values: Output values

cover the separated material. tion, the flow rates for DynaSand filters are usu- SS: 30-100 mg/l < 10 mg/l

ally in the range of 20-30 m/h. The mill scale Oil: 5-15 mg/l < 2 mg/l

You might also like

- Araldite CY 225 Hardener HY 925 Filler Silica Flour: Araldite Casting Resin SystemDocument8 pagesAraldite CY 225 Hardener HY 925 Filler Silica Flour: Araldite Casting Resin SystemZackNo ratings yet

- CD225M Dri-Prime Pump: Features SpecificationsDocument2 pagesCD225M Dri-Prime Pump: Features SpecificationsDodyNo ratings yet

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisFrom EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisRating: 5 out of 5 stars5/5 (1)

- Side Stream FiltrationDocument1 pageSide Stream FiltrationAmit ChaudharyNo ratings yet

- Technical Data Sheet - KrafftDocument2 pagesTechnical Data Sheet - Krafftcrili69No ratings yet

- Spakester 9260 - and - Spakester 1192 1Document1 pageSpakester 9260 - and - Spakester 1192 1Menoddin shaikhNo ratings yet

- Applications & Our Customers: New Sawdeshi SugarDocument2 pagesApplications & Our Customers: New Sawdeshi Sugarshanu vermaNo ratings yet

- Gulf FidelityDocument1 pageGulf FidelityBudi SetiawanNo ratings yet

- New Developments in Non Cement RefractoriesDocument9 pagesNew Developments in Non Cement RefractoriesfelipecastilhodesouzaNo ratings yet

- Oil-X FabricatedDocument4 pagesOil-X FabricatedMohsen ParpinchiNo ratings yet

- TDS SV3 SV3 240325Document2 pagesTDS SV3 SV3 240325barritojaiNo ratings yet

- Tds 1111147 enDocument2 pagesTds 1111147 enCadar CatalinNo ratings yet

- MDP - SLT - SDV - SDF - E Vaccuum Pump 1Document12 pagesMDP - SLT - SDV - SDF - E Vaccuum Pump 1HARUMUKIZA Jean DomitienNo ratings yet

- Solidos Suspendidos AMIAD - Oil&Gas Brochure EN PDFDocument8 pagesSolidos Suspendidos AMIAD - Oil&Gas Brochure EN PDFLuis Alejandro Mariño - RamguzNo ratings yet

- Immersible Pumps ENDocument5 pagesImmersible Pumps ENKarinaNo ratings yet

- High Pressure Pump: ScrewpumpDocument8 pagesHigh Pressure Pump: ScrewpumpPratik LikharNo ratings yet

- Flow Measurement Solution-General CatalogDocument9 pagesFlow Measurement Solution-General CatalogXu EmilyNo ratings yet

- K40plus 01 T ADocument12 pagesK40plus 01 T AromanvauchetskiNo ratings yet

- Case Study - ZLD Plant at SABMiller, Aurangabad PDFDocument2 pagesCase Study - ZLD Plant at SABMiller, Aurangabad PDFmarysarkerNo ratings yet

- An in Plant Training at Presented By: Bombay Dyeing and Mfg. Co. LTDDocument29 pagesAn in Plant Training at Presented By: Bombay Dyeing and Mfg. Co. LTDnikhilshaiwale1865No ratings yet

- DynamosDocument15 pagesDynamosAlanNo ratings yet

- Separation: Oil Oil Oil Oil OilDocument109 pagesSeparation: Oil Oil Oil Oil OilKhaledAhmedNo ratings yet

- TECHNICAL VOGEL L Series - English Only ITT 1 PDFDocument94 pagesTECHNICAL VOGEL L Series - English Only ITT 1 PDFadamNo ratings yet

- Grease ConvertorsDocument12 pagesGrease ConvertorsRoyce AgabasNo ratings yet

- Pressure Gauge ExcelDocument4 pagesPressure Gauge Excelafzal_aabNo ratings yet

- Asonic HQ 72-102 - EnglishDocument2 pagesAsonic HQ 72-102 - EnglishCleiton Luiz CordeiroNo ratings yet

- 41-Drying of SC PDFDocument8 pages41-Drying of SC PDFWaleed KhanNo ratings yet

- Ammonia NH3Document9 pagesAmmonia NH3Nikhil TanwarNo ratings yet

- Condensate - Recovery - Solutions SB S71 02 ENDocument16 pagesCondensate - Recovery - Solutions SB S71 02 ENpxpingenieriaNo ratings yet

- Product Information Sheet - OIL-X Compressed Air Filter Grades AO and AA - (English)Document4 pagesProduct Information Sheet - OIL-X Compressed Air Filter Grades AO and AA - (English)ademgsNo ratings yet

- Penray 2798N Tech Data SheetDocument2 pagesPenray 2798N Tech Data SheetJuan MancipeNo ratings yet

- Stannolume Bright Acid Tin: Technical Data SheetDocument7 pagesStannolume Bright Acid Tin: Technical Data SheetLuuThiThuyDuong100% (2)

- CD250M Dri-Prime Pump: Features SpecificationsDocument2 pagesCD250M Dri-Prime Pump: Features SpecificationsMohamed Badian TraoreNo ratings yet

- 2300x3500mm Technical Data 1Document15 pages2300x3500mm Technical Data 1salesNo ratings yet

- Chevron - PDS - Compressor Oils - CapellaWF - v0519Document2 pagesChevron - PDS - Compressor Oils - CapellaWF - v0519Bekir ManavogluNo ratings yet

- Plastic Industry BrochureDocument4 pagesPlastic Industry BrochurePuguh SantosoNo ratings yet

- Utility Vehicles Compressors (Diesel) GommairDocument9 pagesUtility Vehicles Compressors (Diesel) GommairRotair spaNo ratings yet

- Selector ValvesDocument23 pagesSelector Valveswalk111No ratings yet

- Technical Data Sheet: Cadmium Brilliant ProcessDocument3 pagesTechnical Data Sheet: Cadmium Brilliant ProcessSharan Kumar GNo ratings yet

- Technical Data Sheet: Cadmium Brilliant ProcessDocument3 pagesTechnical Data Sheet: Cadmium Brilliant ProcessSharan Kumar GNo ratings yet

- Ipol Rubber Process Oil 501 PDFDocument5 pagesIpol Rubber Process Oil 501 PDFvinoth kumar SanthanamNo ratings yet

- Kral Screw Pumps Overview en UsDocument24 pagesKral Screw Pumps Overview en UsSergeyNo ratings yet

- Thermex Hydraulic Oil CoolersDocument9 pagesThermex Hydraulic Oil Coolersmajid fardniaNo ratings yet

- Condensate Recovery Solutions SB S71 02 enDocument16 pagesCondensate Recovery Solutions SB S71 02 ensenthil031277No ratings yet

- ZJD-R Lubrication Oil Regeneration PlantDocument11 pagesZJD-R Lubrication Oil Regeneration PlantEdgarNo ratings yet

- Diesel Engine SystemDocument46 pagesDiesel Engine SystemOladokun Sulaiman Olanrewaju90% (10)

- Marine Diesel (Xi Weeks) : Departemen Teknik Sistem Perkapalan ITS SurabayaDocument23 pagesMarine Diesel (Xi Weeks) : Departemen Teknik Sistem Perkapalan ITS SurabayaRazaq PayapoNo ratings yet

- JM Katalog Oljebronslager 8191 Folder - enGB - v4Document4 pagesJM Katalog Oljebronslager 8191 Folder - enGB - v4Nisam OdavdeNo ratings yet

- Case Analysis Kunst 1600Document4 pagesCase Analysis Kunst 1600karansangarNo ratings yet

- Aicd SLBDocument2 pagesAicd SLBCláudio VirgílioNo ratings yet

- GL XX Mobil SHC Elite SeriesDocument3 pagesGL XX Mobil SHC Elite SeriesFulkan HadiyanNo ratings yet

- ADU Desalting PDFDocument100 pagesADU Desalting PDFHARSHA DEEPTHI GUNANA (N150434)No ratings yet

- Asonic HQ 72-102: High-Temperature Lubricating Grease For Low-Noise Rolling BearingsDocument2 pagesAsonic HQ 72-102: High-Temperature Lubricating Grease For Low-Noise Rolling BearingsShaleh AhmadNo ratings yet

- Resinex KW 8 LDocument2 pagesResinex KW 8 LplennyNo ratings yet

- Technical Specification Twin EngDocument2 pagesTechnical Specification Twin EngJorge Coke SilvaNo ratings yet

- NSB Liquid Ring CompressorDocument8 pagesNSB Liquid Ring Compressorboom10100% (1)

- Mission 85 DTH Hammer: Operation and Maintenance GuidelinesDocument8 pagesMission 85 DTH Hammer: Operation and Maintenance GuidelinesVEERAMANINo ratings yet

- Lub CatalogDocument24 pagesLub CatalogPendeta MudaNo ratings yet

- Mechanisms of Sulfate Removal From Subsurface Calcium Chloride Brines: Heletz-Kokhav Oilfields, IsraelDocument9 pagesMechanisms of Sulfate Removal From Subsurface Calcium Chloride Brines: Heletz-Kokhav Oilfields, IsraelAmir AbbaszadehNo ratings yet

- Bit Meler Ps20ns+-EngDocument4 pagesBit Meler Ps20ns+-EngAmir AbbaszadehNo ratings yet

- ST730993-3 2dDocument1 pageST730993-3 2dAmir AbbaszadehNo ratings yet

- Executive Summary - FinalDocument22 pagesExecutive Summary - FinalAmir AbbaszadehNo ratings yet

- Review On Condenser Air Leak Test: International Journal of Pure and Applied Mathematics No. 16 2018, 3197-3205Document10 pagesReview On Condenser Air Leak Test: International Journal of Pure and Applied Mathematics No. 16 2018, 3197-3205Amir AbbaszadehNo ratings yet

- Review On Condenser Air Leak Test: International Journal of Pure and Applied Mathematics No. 16 2018, 3197-3205Document10 pagesReview On Condenser Air Leak Test: International Journal of Pure and Applied Mathematics No. 16 2018, 3197-3205Amir AbbaszadehNo ratings yet

- Thermocompressors: Engineered For EfficiencyDocument4 pagesThermocompressors: Engineered For EfficiencyAmir AbbaszadehNo ratings yet

- Accepted Manuscript: Chemical Engineering and ProcessingDocument38 pagesAccepted Manuscript: Chemical Engineering and ProcessingAmir AbbaszadehNo ratings yet

- Falling-Film Evaporation On Horizontal Tubes-A Critical ReviewDocument19 pagesFalling-Film Evaporation On Horizontal Tubes-A Critical ReviewAmir Abbaszadeh100% (1)

- Turbair Blower (Type RC)Document2 pagesTurbair Blower (Type RC)Amir AbbaszadehNo ratings yet

- Turbair Blower (Type RT)Document2 pagesTurbair Blower (Type RT)Amir AbbaszadehNo ratings yet

- A Presentation On Lithium Bromide Absorption Refrigeration SystemDocument15 pagesA Presentation On Lithium Bromide Absorption Refrigeration SystemAmir AbbaszadehNo ratings yet

- CTV Svx009a GB - 07012016Document56 pagesCTV Svx009a GB - 07012016Amir AbbaszadehNo ratings yet

- Product and Application Handbook EU-Vol IIDocument1 pageProduct and Application Handbook EU-Vol IIAmir AbbaszadehNo ratings yet

- Rasmussen Eric SPX PDFDocument18 pagesRasmussen Eric SPX PDFAmir AbbaszadehNo ratings yet

- A Numerical Approach To Off-Design Performance of Dry Cooling Systems in Power PlantsDocument16 pagesA Numerical Approach To Off-Design Performance of Dry Cooling Systems in Power PlantsAmir AbbaszadehNo ratings yet

- Kong 2017Document15 pagesKong 2017Amir AbbaszadehNo ratings yet

- Cooling Technology Institute "Why Every Air Cooled System Condensor Needs A Cooling Tower" (2003)Document16 pagesCooling Technology Institute "Why Every Air Cooled System Condensor Needs A Cooling Tower" (2003)Amir AbbaszadehNo ratings yet

- Rasmussen Eric SPXDocument18 pagesRasmussen Eric SPXAmir AbbaszadehNo ratings yet

- Wall Heat Transfer in Gas-Fired Furnaces: Effect of Radiation ModellingDocument12 pagesWall Heat Transfer in Gas-Fired Furnaces: Effect of Radiation ModellingAmir AbbaszadehNo ratings yet

- Appendix A: Conversion FactorsDocument2 pagesAppendix A: Conversion FactorsAmir AbbaszadehNo ratings yet

- Effect of Ambient Design Temperature On Air-Cooled Binary Plant OutputDocument16 pagesEffect of Ambient Design Temperature On Air-Cooled Binary Plant OutputAmir AbbaszadehNo ratings yet

- Dry Wet Cooling Systems and Flue Gas System ENEXIODocument55 pagesDry Wet Cooling Systems and Flue Gas System ENEXIOAmir AbbaszadehNo ratings yet

- Car Bottom Furnace: Standard FeaturesDocument2 pagesCar Bottom Furnace: Standard FeaturesAmir AbbaszadehNo ratings yet

- Bogie Hearth Furnaces enDocument2 pagesBogie Hearth Furnaces enAmir AbbaszadehNo ratings yet

- Civil-Natural Cooling TowerDocument52 pagesCivil-Natural Cooling TowerAmir Abbaszadeh100% (2)

- Condenser SimulationDocument8 pagesCondenser SimulationAmir AbbaszadehNo ratings yet

- Engineering Design Guidelines - Cooling Towers - Rev01Document33 pagesEngineering Design Guidelines - Cooling Towers - Rev01Ayman Imad El Mulki100% (1)

- Applied Energy: Chun-Cheng Chang, Shyan-Shu Shieh, Shi-Shang Jang, Chan-Wei Wu, Ying TsouDocument9 pagesApplied Energy: Chun-Cheng Chang, Shyan-Shu Shieh, Shi-Shang Jang, Chan-Wei Wu, Ying TsouAmir AbbaszadehNo ratings yet

- Building and Sustaining Performance Excellence in OrganizationsDocument9 pagesBuilding and Sustaining Performance Excellence in OrganizationsMok MokNo ratings yet

- Result-Based Performance Management System (RPMS) : PortfolioDocument19 pagesResult-Based Performance Management System (RPMS) : PortfolioNota Belz100% (4)

- 116 - 1329216276 - LARS DatasheetDocument4 pages116 - 1329216276 - LARS DatasheetDário GalvãoNo ratings yet

- # (PAPAYA Plus) Catalog Eng Ver.2021 - CompressedDocument5 pages# (PAPAYA Plus) Catalog Eng Ver.2021 - CompressedTONDERAINo ratings yet

- Control System Toolbox - Designing Cascade Control System With PI Controllers DemoDocument5 pagesControl System Toolbox - Designing Cascade Control System With PI Controllers Demojricardo01976No ratings yet

- Scope and Need of Modern Food Processing TechniquesDocument5 pagesScope and Need of Modern Food Processing TechniquesShivaniNo ratings yet

- What Is Quantum Dot Technology?Document8 pagesWhat Is Quantum Dot Technology?antonNo ratings yet

- Codemeter For Mac Os X: Runtime Kit Version 6.40BDocument3 pagesCodemeter For Mac Os X: Runtime Kit Version 6.40BdenipujinNo ratings yet

- Multi-Hole CageDocument7 pagesMulti-Hole Cagemet-calcNo ratings yet

- Combined Impact and Attrition MethodDocument7 pagesCombined Impact and Attrition MethodBernadette Beltran33% (3)

- Picolink RF601Document45 pagesPicolink RF601StemplarsNo ratings yet

- 2019-2020 Graduate Studies Fee Schedule - MastersDocument4 pages2019-2020 Graduate Studies Fee Schedule - MastersShez ZyNo ratings yet

- Deflection Prestressed ConcreteDocument48 pagesDeflection Prestressed Concreteajith chandranNo ratings yet

- Manual Norac UC3 2004 446BC-MAN2dDocument64 pagesManual Norac UC3 2004 446BC-MAN2daritmeticsNo ratings yet

- ECE 345 / ME 380 Introduction To Control Systems Lecture Notes 2Document6 pagesECE 345 / ME 380 Introduction To Control Systems Lecture Notes 2blzz2netNo ratings yet

- The Framework - Training Module 1Document63 pagesThe Framework - Training Module 1arigosakisanNo ratings yet

- Pengukuran Tingkat Kematangan Simaster M F5155afeDocument12 pagesPengukuran Tingkat Kematangan Simaster M F5155afeseptian maulanaNo ratings yet

- Nato Air Commander: Solitaire Strategic Air Command in World War IiiDocument12 pagesNato Air Commander: Solitaire Strategic Air Command in World War IiiTom MaxsonNo ratings yet

- Hypothesis Testing LectureDocument28 pagesHypothesis Testing LectureyogibhNo ratings yet

- Planning The New VentureDocument17 pagesPlanning The New VentureStoryKingNo ratings yet

- 89 Series Coupler - MoellerDocument3 pages89 Series Coupler - Moellermayadin yadin100% (1)

- Android Activity Lifecycle - JavatpointDocument8 pagesAndroid Activity Lifecycle - JavatpointAdityaNo ratings yet

- Operator'S Manual Px15P-Xxx-Xxx-Axxx: 1-1/2" Diaphragm PumpDocument12 pagesOperator'S Manual Px15P-Xxx-Xxx-Axxx: 1-1/2" Diaphragm PumpNashrullah AhmadNo ratings yet

- Durgampudi Padmaja Email: Objective:-: 3. Good Experience On Handling Database Backups (UsingDocument15 pagesDurgampudi Padmaja Email: Objective:-: 3. Good Experience On Handling Database Backups (UsingVissup12345100% (1)

- Bieniawski - Engineering Rock Mass Clasification PDFDocument249 pagesBieniawski - Engineering Rock Mass Clasification PDFJorge Luis Castro Orellana100% (1)

- Price R$ 216: Pousada Caravelas Di San RoccoDocument2 pagesPrice R$ 216: Pousada Caravelas Di San RoccoRildo ReisNo ratings yet

- Microsoft Word - Deployment Diagram - An - An IntroductionDocument6 pagesMicrosoft Word - Deployment Diagram - An - An IntroductionChandra MohanNo ratings yet

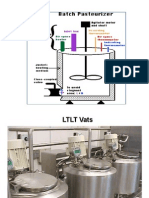

- Pasteurization IIDocument19 pagesPasteurization IIMohammad Ashraf Paul100% (1)

- EMS-BGF Windows IG V13.5 en PDFDocument40 pagesEMS-BGF Windows IG V13.5 en PDFCount_ZNo ratings yet