Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

28 viewsFastener Catalogue

Fastener Catalogue

Uploaded by

santomas000The document is a Boeing-maintained specification report that was last revised on November 26, 2022. It contains over 100 specification IDs and their respective revisions for processes related to manufacturing parts and assemblies. The specifications cover topics like materials and substitutions, fastener installation, fluid lines, electrical bonding, composite manufacturing, cleaning, inspection and more.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Astm D 1265Document5 pagesAstm D 1265Jorge Kovach Alvarado50% (2)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Syllabus 1styearDocument40 pagesSyllabus 1styearAjayaHSNo ratings yet

- Id Number Title Year OrganizationDocument46 pagesId Number Title Year Organizationcrm100% (1)

- Schneider Electric-Technical CodeDocument42 pagesSchneider Electric-Technical CodeElica ElectricNo ratings yet

- 220kV Busbar & Bus Coupler Control & Relay Panel - 07.09.18Document49 pages220kV Busbar & Bus Coupler Control & Relay Panel - 07.09.18Guru Mishra100% (1)

- Chardon Cross Reference Chart PDFDocument3 pagesChardon Cross Reference Chart PDFEng BruccyNo ratings yet

- Chardon Cross Reference ChartDocument3 pagesChardon Cross Reference ChartEng BruccyNo ratings yet

- BS EN 1011-3-2000 - Recommendations For Arc Welding of Stainless Steels PDFDocument25 pagesBS EN 1011-3-2000 - Recommendations For Arc Welding of Stainless Steels PDF0502ravi100% (1)

- Bass& BacDocument24 pagesBass& BacsreeramNo ratings yet

- REVISION: AN: Airbus - Maintained Specification ReportDocument9 pagesREVISION: AN: Airbus - Maintained Specification ReportSergeyNo ratings yet

- Transmital Log - ACTIVE1Document40 pagesTransmital Log - ACTIVE1Hafeez AhmedNo ratings yet

- REVISION: M: Boeing/Spirit - Maintained Specification ReportDocument21 pagesREVISION: M: Boeing/Spirit - Maintained Specification ReportMASOUDNo ratings yet

- No Document NumberDocument15 pagesNo Document NumberArmawan 99No ratings yet

- Bridge Plug-Cement RetainerDocument7 pagesBridge Plug-Cement RetainerhabibimarioNo ratings yet

- Pasta MC PKG - No DISCIPLINA Tag - No Tag - Description Form - Sheet ConcatenadoDocument11 pagesPasta MC PKG - No DISCIPLINA Tag - No Tag - Description Form - Sheet ConcatenadoDieizon KummerNo ratings yet

- Weekly Progress Report: Pertamina Phe Onwj LTD Pipeline Replacement & Topside ModificationDocument9 pagesWeekly Progress Report: Pertamina Phe Onwj LTD Pipeline Replacement & Topside ModificationElias EliasNo ratings yet

- Option-2-Piping Support Structural BOQDocument12 pagesOption-2-Piping Support Structural BOQMaqsood Ibn Shaikhul ArfeenNo ratings yet

- 1833-301-02 DeleteDocument3 pages1833-301-02 DeleteIveel PurevdorjNo ratings yet

- B013578 Electrical Schematics ED3005Document57 pagesB013578 Electrical Schematics ED3005SantiagoNo ratings yet

- Mip Bohler PipelineDocument32 pagesMip Bohler PipelineDaniel StuparekNo ratings yet

- M10676-Bom Rev-B - KyDocument18 pagesM10676-Bom Rev-B - KykanarendranNo ratings yet

- 6112-12-BW2 Wrapper Material ElectricoDocument8 pages6112-12-BW2 Wrapper Material ElectricoPlasmodiums clansNo ratings yet

- EI Erection Tender Additional Work Silo, ConvDocument18 pagesEI Erection Tender Additional Work Silo, ConvSaurabh Kumar SinghNo ratings yet

- Balance Works (U&O)Document3 pagesBalance Works (U&O)Amresh KumarNo ratings yet

- AK-0-EE-IP-01-001 - Arrangement Plan of Excitation AC&DC Bus-Duct - FCDDocument57 pagesAK-0-EE-IP-01-001 - Arrangement Plan of Excitation AC&DC Bus-Duct - FCDrajbharath.pNo ratings yet

- Perda No 4 Tahun 2011Document66 pagesPerda No 4 Tahun 2011Kelink Hari PrasetyoNo ratings yet

- CHARDON Part Number Reference Chart Elastimold Part Number Description Elastimold Cooper TEDocument3 pagesCHARDON Part Number Reference Chart Elastimold Part Number Description Elastimold Cooper TEErnesto Pieruccini RamirezNo ratings yet

- Weekly Progress Report: Pertamina Phe Onwj LTD Pipeline Replacement & Topside ModificationDocument6 pagesWeekly Progress Report: Pertamina Phe Onwj LTD Pipeline Replacement & Topside ModificationElias EliasNo ratings yet

- Tamil Nadu Generation and Distribution Corporation LTDDocument23 pagesTamil Nadu Generation and Distribution Corporation LTDMinh TríNo ratings yet

- Purchase Order Requisition R-1910-0318 Rev 0Document27 pagesPurchase Order Requisition R-1910-0318 Rev 0AnaNo ratings yet

- TgsgtubeDocument33 pagesTgsgtubechilukamariNo ratings yet

- E Pipe & Fittings With SampleDocument138 pagesE Pipe & Fittings With Samplep4p7 projectsNo ratings yet

- 200 A Loadbreak Connectors: 25 KV Posi-Break Elbow and CapDocument19 pages200 A Loadbreak Connectors: 25 KV Posi-Break Elbow and CapCARHUAMACA PASCUAL mhNo ratings yet

- P021.46 DB54 Mat Mech 001Document115 pagesP021.46 DB54 Mat Mech 001p4p7 projectsNo ratings yet

- Wig 1000 P DS 0002.0.appDocument8 pagesWig 1000 P DS 0002.0.appzodhhashoNo ratings yet

- Option-1-Piping Support Structural BOQ PDFDocument12 pagesOption-1-Piping Support Structural BOQ PDFMaqsood Ibn Shaikhul ArfeenNo ratings yet

- 2227 Valerus Drawing List r6Document6 pages2227 Valerus Drawing List r6Avi NashNo ratings yet

- MOS-0570-5685619-00 CombinedDocument11 pagesMOS-0570-5685619-00 Combinedarmsarabia01No ratings yet

- Apator Disconecting FUSEDocument26 pagesApator Disconecting FUSEAnonymous yugocxnNo ratings yet

- ListDocument3 pagesListprabhutheniNo ratings yet

- Wir Piping Update April 26 2018Document10 pagesWir Piping Update April 26 2018jaymarNo ratings yet

- MTOCO001008Document8 pagesMTOCO001008Mohamed Rizk100% (1)

- Standard Const Material SpecDocument320 pagesStandard Const Material SpecElin IrhamnaNo ratings yet

- PVC Conduits, Fittings & Accessories PDFDocument70 pagesPVC Conduits, Fittings & Accessories PDFHaytham BafoNo ratings yet

- Ga & Boq - LDB PanelDocument3 pagesGa & Boq - LDB PanelrinkukachhelaNo ratings yet

- BWB - PRIME Approval List: AIRBUS INDUSTRIES: WWW - Flugzeuggalvanik.deDocument8 pagesBWB - PRIME Approval List: AIRBUS INDUSTRIES: WWW - Flugzeuggalvanik.deVIJAY YADAVNo ratings yet

- Copie de Standards Check ListDocument7 pagesCopie de Standards Check ListAbakar MahamatNo ratings yet

- F 400 Sewer Materials and Structures: Section No. Subject DateDocument56 pagesF 400 Sewer Materials and Structures: Section No. Subject DateAbdulRahman SharifNo ratings yet

- 1833-307-02 DeleteDocument3 pages1833-307-02 DeleteIveel PurevdorjNo ratings yet

- Welding Consumables For Pipeline ConstructionDocument32 pagesWelding Consumables For Pipeline ConstructionElias KapaNo ratings yet

- Ductile Iron Fittings CatalogueDocument12 pagesDuctile Iron Fittings Catalogueramkesh rathaurNo ratings yet

- Index SPFN 2010Document14 pagesIndex SPFN 2010NeozaqeNo ratings yet

- A I B T B V: N Ntroduction TO U ECH ALL AlvesDocument51 pagesA I B T B V: N Ntroduction TO U ECH ALL AlvesvankarpNo ratings yet

- 18th July MTA#024 Rev.01 - Scope of SupplyDocument5 pages18th July MTA#024 Rev.01 - Scope of Supplyمحمد اصدNo ratings yet

- Base PortafusibleDocument6 pagesBase PortafusiblePablito AteNo ratings yet

- Saep 310Document38 pagesSaep 310paul cafeNo ratings yet

- Suprajit Price List Sep-2021Document36 pagesSuprajit Price List Sep-2021Manish ChandNo ratings yet

- Pressure Seal Check ValvesDocument18 pagesPressure Seal Check ValvesthomasnafNo ratings yet

- Apron Electrical Works: Subject Items Unit Qty. Brand Name Delivery Status MSRDocument5 pagesApron Electrical Works: Subject Items Unit Qty. Brand Name Delivery Status MSRayhanarmanNo ratings yet

- Natural Gas System Line & Valve List: I.P.D.CDocument10 pagesNatural Gas System Line & Valve List: I.P.D.CepbamdadNo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Advances in Ceramic Armor XFrom EverandAdvances in Ceramic Armor XJerry C. LaSalviaNo ratings yet

- 14 September 2009: Subsea Challenges in Deep PanukeDocument22 pages14 September 2009: Subsea Challenges in Deep Panukeharan2000No ratings yet

- Architectural - Sheet Metal - CollieDocument42 pagesArchitectural - Sheet Metal - CollieWissam AlameddineNo ratings yet

- Corrosion On Stainless SteelDocument3 pagesCorrosion On Stainless SteelMondayNo ratings yet

- Ice Melt Buyer'S Guide Ice Melt Buyer'S GuideDocument7 pagesIce Melt Buyer'S Guide Ice Melt Buyer'S GuidelyndondrNo ratings yet

- Magnesium AlloyDocument22 pagesMagnesium AlloyPrethev100% (1)

- 1995-Microbes Onboard ShipsDocument43 pages1995-Microbes Onboard ShipsAnakin SkywalkerNo ratings yet

- API-570-Exam-100-Q (계산문제 정리할수 있는 문제) PDFDocument23 pagesAPI-570-Exam-100-Q (계산문제 정리할수 있는 문제) PDFasNo ratings yet

- 2011 Syllabi New 22.08.2013Document295 pages2011 Syllabi New 22.08.2013invincible_shalin6954No ratings yet

- Bearing For Clean EnviromentDocument14 pagesBearing For Clean Enviromentصالح سميرNo ratings yet

- Superhydrophobic CoatingDocument28 pagesSuperhydrophobic CoatingAldrei Zamm Recamadas100% (1)

- Corrosion of Metals in Marine Environments An OverviewDocument23 pagesCorrosion of Metals in Marine Environments An OverviewGustavo VicierraNo ratings yet

- ACI PRC-201.1-08 Guide For Conducting A Visual Inspection of Concrete in ServiceDocument19 pagesACI PRC-201.1-08 Guide For Conducting A Visual Inspection of Concrete in ServiceGikoNo ratings yet

- 2 e Lech Tro ChemistryDocument39 pages2 e Lech Tro ChemistryrahmaNo ratings yet

- 16 PTIRecommendationsforStayCableDesignTestingandInstallationDocument23 pages16 PTIRecommendationsforStayCableDesignTestingandInstallationBeratErtekin100% (1)

- The Indian Institute of WeldingDocument10 pagesThe Indian Institute of WeldingSandeep MohantyNo ratings yet

- Engineering Failure Analysis: Jivan Kumar, Swati Biswas, M.D. Ganeshachar, S.N. Narendra Babu, S. RamachandraDocument12 pagesEngineering Failure Analysis: Jivan Kumar, Swati Biswas, M.D. Ganeshachar, S.N. Narendra Babu, S. RamachandraAgy RandhikoNo ratings yet

- Concrete ProjectionDocument28 pagesConcrete ProjectionMooneer El AssaadNo ratings yet

- Hempel Coating Reference Handbook GBDocument145 pagesHempel Coating Reference Handbook GBGerardo Castillo100% (2)

- Cap 9. Aplicaciones de MA en Recubrimiento PDFDocument67 pagesCap 9. Aplicaciones de MA en Recubrimiento PDFEduardo LozanoNo ratings yet

- Zink Phosphate ZP 10Document5 pagesZink Phosphate ZP 10Shamshir ChemicalsNo ratings yet

- Strut Technical DataDocument15 pagesStrut Technical DataJOFRANo ratings yet

- Penguard Primer: Technical Data SheetDocument5 pagesPenguard Primer: Technical Data SheetRekhis OussamaNo ratings yet

- 2007gates Hyd Cat10-10-07Document598 pages2007gates Hyd Cat10-10-07jaysx5No ratings yet

- Demo UdsDocument15 pagesDemo UdsvesselengineerNo ratings yet

- G2593R9Document21 pagesG2593R9TanaNo ratings yet

- Corrossion Control of Underwater PilesDocument23 pagesCorrossion Control of Underwater Pilesvaradha s nairNo ratings yet

- Designing Concrete For Exposure To SeawaterDocument3 pagesDesigning Concrete For Exposure To SeawaterSaeedNo ratings yet

Fastener Catalogue

Fastener Catalogue

Uploaded by

santomas0000 ratings0% found this document useful (0 votes)

28 views12 pagesThe document is a Boeing-maintained specification report that was last revised on November 26, 2022. It contains over 100 specification IDs and their respective revisions for processes related to manufacturing parts and assemblies. The specifications cover topics like materials and substitutions, fastener installation, fluid lines, electrical bonding, composite manufacturing, cleaning, inspection and more.

Original Description:

Original Title

fastener catalogue

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document is a Boeing-maintained specification report that was last revised on November 26, 2022. It contains over 100 specification IDs and their respective revisions for processes related to manufacturing parts and assemblies. The specifications cover topics like materials and substitutions, fastener installation, fluid lines, electrical bonding, composite manufacturing, cleaning, inspection and more.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

28 views12 pagesFastener Catalogue

Fastener Catalogue

Uploaded by

santomas000The document is a Boeing-maintained specification report that was last revised on November 26, 2022. It contains over 100 specification IDs and their respective revisions for processes related to manufacturing parts and assemblies. The specifications cover topics like materials and substitutions, fastener installation, fluid lines, electrical bonding, composite manufacturing, cleaning, inspection and more.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 12

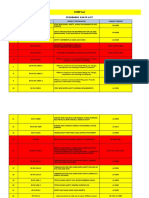

74000002 - REVISION: U BOEING - MAINTAINED SPECIFICATION REPORT

*Updates reflected through 11/26/2022

ID REVISION DESCRIPTION

005W0900 F INTERIM PARTS - SPARES

012W6100 SHT.1 P MATERIALS, PART & PROCESS SUBSTITUTION AND EQUIVALENTS -- SHT.1

012W6100 SHT.2 D MATERIALS, PARTS AND PROCESS SUBSTITUTION AND EQUIVALENTS -- SHT.2

65-88700 SHT 01 AC MATERIAL PARTS AND PROCESS SUBSTITUTIONS AND EQUIVALENTS

65-88700 SHT 05 AD MATERIAL PARTS AND PROCESS SUBSTITUTIONS AND EQUIVALENTS

BAC001PREF Y PREFACE

BAC1490 BM 90 DEGREE, ALUMINUM FORMED

BAC1492 AT MISCELLANEOUS, METAL, FORMED

BAC1493 CG CHANNEL, U-SHAPED, ALUMINUM, FORMED

BAC1494 BD CHANNEL, C-SHAPE, ALUMINUM, FORMED

BAC1518-1213 - I MISCELLANEOUS, ALUMINUM, EXTRUDED

BAC1518-1369 - I AND "H" ALUMINUM, EXTRUDED

BAC1534 V SHIM, LAMINATED, AL ALLOY, CRES AND TITANIUM SURFACE BONDED

BAC1670 V ANGLE, TITANIUM, EXTRUDED

BAC1670-147 - ANGLE, TITANIUM, EXTRUDED

BAC1670-148 - ANGLE, TITANIUM, EXTRUDED

BAC1670-150 - ANGLE, TITANIUM, EXTRUDED

BAC1670-152 - ANGLE, TITANIUM, EXTRUDED

BAC3113 D EXTRUSION, HINGE HALF

BAC5000 BA SEALING, GENERAL

BAC5000-1 B REPACKAGING AND FREEZING OF SEALANT BY END USERS

BAC5001 N FLUID LINES, FITTINGS AND PRESSURE TESTING

BAC5001-1 H CUT OFF, END FORMING, HANDLING AND MARKING OF TUBES AND DUCTS

BAC5001-10 J TUBE INSTALLATION, TUBE FITTING TIGHTENING AND TUBE CLAMPING

BAC5001-11 G INSTALLATION OF EXTERNALLY SWAGED HYDRAULIC FITTINGS

BAC5001-12 D FORMING AND STRAIGHTENING OF DUCTS

BAC5001-13 - FLARELESS TUBE END ROLLER SWAGE FABRICATION, 5080 PSI RATED

BAC5001-14 E INSTALLATION OF AXIALLY SWAGED HYDRAULIC FITTINGS

BAC5001-2 J PRESSURE TESTING OF TUBE AND DUCT ASSEMBLIES; AUTOFRETTAGE OF TUBE ASSEMBLIES

BAC5001-3 J TUBE BENDING

BAC5001-4 N FLARELESS TUBE AND FABRICATION

BAC5001-5 R COUPLING FERRULE DUCT END FABRICATION

BAC5001-6 M INSTALLATION OF TUBE ASSEMBLIES AND COMPONENTS

BAC5001-7 E INSTALLATION OF HOSE ASSEMBLIES

BAC5001-8 A FLARELESS TUBE END FABRICATION BITE – TYPE SLEEVES

BAC5001-9 D INSTALLATION OF COUPLINGS

BAC5002 V SWAGED CABLE ASSEMBLIES

BAC5004 P INSTALLATION OF PERMANENT FASTENERS

BAC5004-1 U SOLID RIVET INSTALLATION

BAC5004-2 AM PERMANENT STRAIGHT SHANK FASTENER INSTALLATION

BAC5004-3 J BLIND FASTENER INSTALLATION

BAC5004-4 A ONE SIDED INSTALLATION BOLTS – INSTALLATION AND INSPECTION

BAC5005 H MATERIAL SUBSTITUTIONS AND EQUILAVLENTS

BAC5008 V APPLICATION OF LUBRICANTS

BAC5009 AF BOLT AND NUT INSTALLATION

BAC5010 AB APPLICATION OF ADHESIVES

BAC5011 E APPLICATION OF RETAINING COMPOUNDS

BAC5018 N INSTALLATION OF SAFETYING DEVICES

BAC5019 Y CHROMIC ACID ANODIZING

BAC5019_DCN 1 DCNPSO-013193, CHROMIC ACID ANODIZING

BAC5030 P SMOOTHING AND FAIRING

BAC5032 G GRINDING OF CHROMIUM PLATE

BAC5034 T TEMPORARY PROTECTION OF PRODUCTION MATRIALS, PARTS AND ASSEMBLIES

BAC5034-1 L TEMPORARY PROTECTION OF OF PROTECTION MATERIALS, PARTS AND ASSEMBLIES WITH COATINGS

BAC5034-2 J TEMPORARY PROTECTION OF PRODUCTION MATERIALS, PARTS AND ASSEMBLIES WITH NONADHARENT FILM AND SHEET COVERINGS

BAC5034-3 E TEMPORARY PROTECTION OF PRODUCTION MATERIALS, PARTS AND ASSEMBLIES WITH PRESSURE SENSITIVE TAPE

BAC5034-4 P TEMPORARY PROTECTION OF PRODUCTION MATERIALS, PARTS AND ASSEMBLIES WITH PRESSURE SENSITIVE TAPE

BAC5040 D PROCESS SPECIFICATION FOR MANUFACTURE FROM STOCK, LUBRICATION, INSTALLATION, AND SIZING OF OIL-IMPREGNATED SINTERED METAL BEARINGS

BAC5047 M FLUID TIGHT FASTENER INSTALLATION

BAC5047-1 F FLUID TIGHT FASTENER INSTALLATION

BAC5047-2 G FLUID TIGHT FASTENER INSTALLATION IN FATIGUE RATED STRUCTURE

BAC5049 K DIMPLING AND COUNTERSINKING

BAC5058 D RIVETING IN TITANIUM

BAC5063 T FASTENER INSTALLATION IN COMPOSITE STRUCTURES

BAC5063-1 E SOLID RIVET INSTALLATION IN COMPOSITE STRUCTURES

BAC5063-2 F PERMANENT STRAIGHT SHANK FASTENER INSTALLATION IN COMPOSITE STRUCTURES

BAC5063-3 C BLIND FASTENER INSTALLATION IN COMPOSITE STRUCTURES

BAC5063-4 E BOLT AND NUT INSTALLATION IN COMPOSITE STRUCTURES

BAC5063-5 B MISCELLANEOUS FASTENER INSTALLATION IN COMPOSITE STRUCTURES

BAC5063-6 A ONE SIDED INSTALLATION BOLTS - INSTALLATION IN COMPOSITE STRUCTURES

BAC5063-7 L SLEEVED BOLT INSTALLATION IN COMPOSITE STRUCTURES

BAC5064 F INSTALLATION OF INSERTS, PANEL FASTENERS AND RELATED HARDWARE

BAC5114 E ENHANCED PROCESS CONTROL FOR CNC

BAC5114_QPL - ENHANCED PROCESS CONTROL FOR CNC MACHINING

BAC5117 AG ELECTRICAL BONDING

BAC5117-1 H ELECTRICAL BONDING OF RECEPTACLES

BAC5117-10 F ELECTRICAL BONDING-CLAMP INSTALLATION ON TUBES/CONDUIT

BAC5117-11 G ELECTRICAL BONDING - FITTING AND COUPLING INSTALLATION

BAC5117-12 D ELECTRICAL BONDING - BULKHEAD FITTING INSTALLATION

BAC5117-13 D ELECTRICAL BONDING OF FASTENERS TO CONDUCTIVE FINISHES ON COMPOSITES

BAC5117-14 D ELECTRICAL BONDING OF COMPOSITE PANELS

BAC5117-15 A BACS53F PREINSTALLED GROUND STUD INSTALLATION IN CARBON FIBER REINFORCED PLASTIC (CFRP)

BAC5117-16 D DUAL HOLE TERMINAL DIRECT GROUND STUD INSTALLATION

BAC5117-17 A ELECTRICAL BONDING OF CARBON FIBER REINFORCED PLASTIC (CFRP) STRUCTURE

BAC5117-18 C ELECTRICAL BONDING THROUGH FASTENER - CLEARANCE FIT HOLE

BAC5117-19 A ELECTRICAL BONDING THROUGH FASTENERS - INTERFERENCE FIT HOLE

BAC5117-2 K PREINSTALLED GROUND STUD INSTALLATION

BAC5117-20 E ELECTRICAL BONDING USING SLEEVED BOLTS

BAC5117-3 F STANDARD PREINSTALLED GROUND STUD INSTALLATION

BAC5117-4 J DIRECT GROUND STUD INSTALLATION

BAC5117-5 F TERMINAL INSTALLATION PREINSTALLED GROUND STUDS

BAC5117-6 M ELECTRICAL FAYING SURFACE BONDS

BAC5117-7 G DRIVEN RIVET ELECTRICAL BOND

BAC5117-8 F ELECTRICAL BONDING - GROUND BLOCK INSTALLATION

BAC5117-9 D ELECTRICAL BONDING - STATIC DISCHARGER ASSEMBLY INSTALLATION

BAC5300 N FORMING, STRAIGHTENING AND FITTING METAL PARTS

BAC5300-1 K SURFACE AND EDGE INTEGRITY OF METAL PARTS

BAC5300-2 K METAL PART FORMING, STRIGHTENING AND FITTING

BAC5306 M MARKINGS OF PANELS AND DIRECT SILKSCREENING

BAC5307 AE PART MARKING

BAC5307-1 E PART MARKING OF MACHINE READABLE INFORMATION WITH LABELS

BAC5308 J APPLICATION OF STENCIL AND INSIGNIA MARKINGS

BAC5308_DCN 1 DCNPSO-013824, APPLICATION OF STENCIL AND INSIGNIA MARKINGS

BAC5312 W APPLICATION OF PLASTIC FILM MARKERS

BAC5312_DCN - DCNPSO-013059, APPLICATION OF PLASTIC FILM MARKERS

BAC5316 W MANUFACTURE OF MARKERS AND PLACARDS

BAC5316_V_QPL - MANUFACTURE OF MARKERS AND PLACARDS

BAC5317 K FIBER REINFORCED COMPOSITE PARTS

BAC5317-1 J CARBON AND ARAMID FIBER REINFORCED COMPOSITE PARTS, 350 F (177C) CURE

BAC5317-2 K MANUFACTURE OF LOW TEMPERATURE AUTOCLAVE CURED EPOXY STRUCTURAL PARTS

BAC5317-3 K MANUFACTURING OF HIGH TEMPRATURE RESISTANT EPOXY STRUCTURAL PARTS

BAC5317-4 K ADVANCED COMPOSITE LAMINATE AND HONEYCOMB SANDWICH STRUCTURAL PARTS - 350 F (177 C) CURE

BAC5317-5 K MANUFACTURE OF ADVANCED COMPOSITE STRUCTURAL PARTS 250 F CURE

BAC5317-6 E MANUFACTURE OF PERFORATED CARBON FIBER REINFORCED PARTS, 350 F (177 C) CURE

BAC5317-7 B ADVANCED COMPOSITE LAMINATE AND HONEYCOMB SANDWICH STRUCTURAL PARTS - 350 F (177 C) CURE SELF-ADHESIVE PREPREG

BAC5325 P APPLICATION OF NONCHROMATED PRIMER ON COMPOSITE PLASTIC, TITANIUM AND CRES SURFACES

BAC5332 E INSTALLATION OF MOLDABLER PLASTIC SHIM

BAC5332_E_QPL B INSTALLATION OF MOLDABLE PLASTIC SHIM

BAC5333 B SUPERPLASTIC FORMING OF 2004 BARE AND ALCLAD ALUMINUM ALLOY SHEET

BAC5333_QPL - SUPERPLASTIC FORMING OF 2004 BARE AND ALCLAD ALUMINUM ALLOY SHEET

BAC5338 H ACID ETCH AND ELECTROCHEMICAL ETCH MARKING

BAC5361 J SEALING OF INTEGRAL FUEL TANK STRUCTURE FOR ELCROMAGNETIC EFFECTS

BAC5401 F STORAGE, ANDLING, ISSURANCE AND AGE CONTROL OF RUBBER OR RUBBER-LIKE MATERIALS

BAC5408 P VAPOR DEGREASING

BAC5423 Y PENETRANT METHODS OF INSPECTION

BAC5424 U MAGNETIC PARTICLE INSPECTION

BAC5430 N FABRICATION AND INSTALLATION OF RESIN BONDED LAMINATED SHIMS AND SOLID FILLERS

BAC5432 AJ CASTING AND POTTING WITH RESINS

BAC5435 AA BEARING INSTALLATION AND RETENTION

BAC5436 J ETCH INSPECTION OF GROUND OR MACHINED STEEL PARTS

BAC5439 J ULTRASONIC INSPECTION

BAC5439-1 A ULTRASONIC INSPECTION OF WELDS

BAC5439-2 D ULTRASONIC INSPECTION OF TUBING

BAC5444 H BONDING ASSEMBLY AID FOR SHIMS, FILLERS AND DETAILS

BAC5463 B QUALITY REQUIREMENTS FOR DETAIL PARTS MADE OF WROUGH FERROUS AND ALUMINUM ALLOYS

BAC5485 AD HANDLING OF ELECTRICAL/ELECTRONIC PARTS AND ASSEMBLIES

BAC5492 T MACHINING AND CUTTING TITANIUM

BAC5492_DCN 1 DCNPSO-012630, MACHINING AND CUTTING TITANIUM

BAC5504 AB INTEGRAL FUEL TANK STRUCTURE SEALING

BAC5514 AR COMMON BONDING REQUIREMENTS FOR STRUCTURAL ADHESIVES

BAC5514-510 C STRUCTURAL BONDING METAL-TO-METAL WITH ROOM TEMPERATURE CURING ADHESIVES

BAC5514-5101 W STRUCTURAL BONDING FOR 180 F SERVICE APPLICATION

BAC5514-5104 R STRUCTURAL BONDING WITH BMS5–104 ADHESIVES

BAC5514-5137 L STRUCTURAL BONDING WITH BMS5–137 ADHESIVES

BAC5514-542 AB STRUCTURAL BONDING METAL-TO-METAL WITH BMS5-42

BAC5514-551 AD STRUCTURAL BONDING WITH MODERATE TEMPERATURE CURING ADHESIVE (BMS5–51)

BAC5514-570 Y STRUCTURAL BONDING WITH BMS5–70

BAC5514-580 V STRUCTURAL BONDING WITH MODERATE TEMPERATURE CURING ADHESIVES (BMS5-80)

BAC5514-589 AA APPLICATION OF CORROSION INHIBITING ADHESIVE PRIMER

BAC5514-590 T BONDING WITH FOAMING ADHESIVES

BAC5555 V PHOSPHORIC ACID ANODIZING OF ALUMINUM FOR STRUCURAL BONDING

BAC5565 N VACUUM BAG AND MULTIPLE OPENING PRESS PROCESS FOR PHENOLIC SANDWICH PANELS AND LAMINATES

BAC5571 H RIVET-BONDING WITH STRUCTURAL ADHESIVES

BAC5572 H NON-STRUCTURAL INTERIOR NOMEX HONEYCOMB CORE SANDWICH PANELS AND LAMINATES USING KEVLAR

BAC5578 L MANUFACTURE OF ADVANCED CARBON FIBER REINFORCED ADVANCED COMPOSITE STRUCTURE WITH TOUGHENED EPOXY SYSTEMS

BAC5602 AH HEAT TREATMENT OF ALUMINUM ALLOYS

BAC5603 A FABRIC SURFACE COVERING AND FINSIHING

BAC5611 B HEAT TREATMENT OF COPPER AND COPPER ALLOYS

BAC5613 V HEAT TREATMENT OF TITANIUM AND TITANIUM ALLOYS

BAC5613_QPL - QUALIFIED PROCESSOR LIST FOR BAC 5613_V

BAC5616 K HEAT TREATMENT OF NICKEL-BASE & COBALT-BASE ALLOYS

BAC5617 W HEAT TREATMENT OF ALLOY STEELS

BAC5618 F CARBURIZING AND NITRIDING OF STEELS

BAC5619 L HEAT TREATMENT OF CORROSION RESISTANT STEEL

BAC5621 M TEMPERATURE CONTROL FOR PROCESSING OF MATERIALS

BAC5625 F SURFACE TREATMENTS FOR FERROUS ALLOYS

BAC5626 C COLORED CHEMICAL CONVERSION COATING FOR ALUMINUM

BAC5629 F APPLICATION OF URETHANE EXTERIOR COATINGS

BAC5631 A PRECISION CLEANING OF PROPULSION TUBING SYSTEMS

BAC5632 E BORIC ACID - SULFURIC ACID ANODIZNG

BAC5636 H SUPPERPLASTIC FORMING OF TITANIUM ALLOY SHEET

BAC5636_QPL E SUPERPLASTIC FORMING OF TITANIUM ALLOY SHEET

BAC5637 F ZINC-NICKEL ALLOY PLATING

BAC5640 B NITRIDING OF STEEL

BAC5641 C CARBURIZING OF CARBON AND ALLOY STEELS

BAC5642 A HOT ISOSTATIC PRESSING (HIP) OF CASTINGS

BAC5647 B ASSEMBLY OF CIRCULAR JOINTS BY ELECTROMAGNETIC COMPRESSION FORMING

BAC5648 - MACHINING OF COPPER BERYLLIUM ALLOYS

BAC5650 E HARDNESS TESING

BAC5651 D EDDY CURRENT ELECTRICAL CONDUCTIVITY INSPECTION

BAC5652 B INSPECTION OF CASTINGS

BAC5653 A BARKHAUSEN INSPECTION FOR THEMAL DAMAGE IN STEELS

BAC5656 E ABRASIVE WATERJET CUTTING FOR METALS AND METAL-COMPOSITE HYBRIDS

BAC5665 D APPLICATION OF SOL-GEL CONVERSION COATINGS ON CORROSION RESISTANT ALLOYS

BAC5701 R CADMIUM PLATING

BAC5705 N APPLICATION OF FLOOR COVERING MATERIALS

BAC5706 N APPLICATION OF ORGANIC FINISHES

BAC5709 W HARD CHROMIUM PLATING

BAC5709_QPL B QUALIFIED PROCESSOR LIST - HARD CHROMIUM PLATING

BAC5710 AE APPLICATION OF SPECIAL PURPOSE COATINGS

BAC5715 F SLIVER PLATING

BAC5718 J LOW HYDROGEN EMBRITTLEMENT CADMIUM PLATING

BAC5718_QPL A LOW HYDROGEN EMBRITTLEMENT CADMIUM PLATING

BAC5719 AB CHEMICAL CONVERSION COATINGS FOR ALUMINUM & ALUMINUM ALLOYS

BAC5722 F COPPER PLATING

BAC5725 J STRIPPING ORGANIC MATERIALS

BAC5730 U SHOT PEENING

BAC5730-1 D SHOT PEEN FORMING

BAC5730-2 D SHOT PEENING - SELF CONTAINED

BAC5736 AC APPLICATION OF CHEMICAL & SOLVENT RESISTANT FINISHES

BAC5741 B APPLICATION OF A BUNA A TYPE COATING TO INTEGRAL FUEL TANK

BAC5744 J MANUAL CLEANING (COLD ALKALINE, SOLVENT EMULSION AND FOAM CLEANERS)

BAC5746 M NICKEL PLATING (ELECTRODEPOSITED)

BAC5746_QPL B NICKEL PLATING (ELECTRODEPOSITED)

BAC5748 V ABRASIVE CLEANING, DEBURRING & FINISHING

BAC5749 Y ALKALINE CLEANING

BAC5750 V SOLVENT CLEANING

BAC5751 M CLEANING, DESCALING AND SURFACE PREPARATION OF FERROUS ALLOYS

BAC5753 AA CLEANING, DESCALING AND SURFACE PREPARATION OF TITANIUM AND TITANIUM ALLOYS

BAC5755 AH APPLICATION OF DECORATIVE FINISHES

BAC5756 K APPLICATION OF HEAT-TREAT PROTECTIVE COATINGS

BAC5758 L CLEANING, DETAILING AND SURFACE PREPARATION OF NICKEL AND COBALT BASE ALLOYS

BAC5759 E CHEMICAL MILLING OF STEEL, NICKEL, AND COBALT ALLOYS

BAC5760 H MANUFACTURE AND ASSEMBLY OF CIRCUIT BOARDS

BAC5761 E GOLD PLATING

BAC5762 F THE MANUFACTURE OF ETCHED CIRCUITS (PRINTED CIRCUIT BOARDS WITHOUT PLATED-THROUGH HOLES)

BAC5762-4 C MANUFACTURED OF NON-THRU-HOLE PLATED CIRCIUT BOARDS FOR COMMERCIAL AIRPLANES

BAC5763 L EMULSION CLEANING AND AQUEOUS DEGREASING

BAC5764 C NONSKID COATING

BAC5765 AA CLEANING AND DEOXIDIZING ALUMINUM ALLOYS

BAC5766 D STEAM CLEANING

BAC5768 G MANDREL COLD WORKING OF HOLES IN ALUMINUM

BAC5769 G CLEANING, DESCALING AND SURFACE PREPARATION OF MAGNESIUM ALLOYS

BAC5770 G CLEANING, DESCALING AND SURFACE PREPARATION OF COPPER AND COPPER ALLOYS

BAC5771 J STRIPPING INORGANIC FINISHES

BAC5772 Y CHEMICAL MILLING ALUMINUM ALLOYS

BAC5772_QPL Y CHEMICAL MILLING ALUMINUM ALLOYS

BAC5786 N ETCH CLEANING OF ALUMINUM ALLOYS

BAC5793 AB APPLICATION OF CORROSION RESISTANT FINISH FOR INTEGRAL FUEL TANKS

BAC5804 AH LOW HYDROGEN EMBRITTLEMENT CADMIUM-TITANIUM ALLOY PLATING

BAC5804_QPL - LOW HYDROGEN EMBRITTLEMENT CADMIUM-TITANIUM ALLOY PLATING

BAC5807 P APPLICATION OF HIGH TEMPERATURE EPOXY PRIMER

BAC5811 W APPLICATION OF BONDED SOLID FILM LUBRICANTS

BAC5811_W_QPL C APPLICATION OF BONDED SOLID FILM LUBRICANTS

BAC5814 B APPLICATION OF BONDED SOLID LUBRICANTS FOR HIGH TEMPERATURE SERVICE

BAC5814_QPL A APPLICATION OF BONDED SOLID LUBRICANTS FOR HIGH TEMPERATURE SERVICE

BAC5821 F HARD ANODIZING

BAC5837 AA PREPARING EXTERIOR PLASTIC SURFACES FOR PAINT

BAC5840 H APPLICATION OF HEAT AND CORROSION RESISTANT INORGANIC COATINGS

BAC5842 K CHEMICAL MILLING TITANIUM

BAC5842_QPL D CHEMICAL MILLING TITANIUM

BAC5845 V APPLICATION OF POLYURETHANE ENAMEL

BAC5849 P BRUSH PLATING, ANODIZING AND ELECTROCHEMICAL ETCHING

BAC5851 H APPLICATION OF THERMAL SPRAY COATINGS

BAC5851_QPL N APPLICATION OF THERMAL SPRAY COATINGS

BAC5854 M LOW HYDROGREN EMBRITTLEMENT STYLUS CADMIUM PLATING

BAC5855 D GRINDING AND MACHINING OF THERMAL SPRAYED COATINGS

BAC5861 E APPLICATION OF PHOSPHATE-FLUORIDE COATING TO TITANIUM ALLOYS

BAC5875 T FABRICATION OF ALUMINUM MARKERS AND ALUMINUM AND PLASTIC APPLIQUES

BAC5877 L APPLICATION OF ORGANIC CORROSION INHIBITING COMPOUNDS

BAC5882 P APPLICATION OF URETHANE COMPATIBLE PRIMER

BAC5884 E ANODIZING OF ALUMINUM ALLOYS

BAC5896 E APPLICATION OF ALIPHATIC ISOCYANATE POLYURETHANE ENAMEL

BAC5901 G CERTIFICATION OF WELD SETTINGS FOR MACHINE FUSION WELDING

BAC5915 M RADIOLOGIC INSPECTION

BAC5915-1 F RADIOGRAPHIC INSPECTION (FILM)

BAC5915-2 F RADIOSCOPIC INSPECTION (REAL-TIME)

BAC5945 K FUSION WELDING OF GROUND HANDLING AND WEAPONS SUPPORT EQUIPMENT - STEEL

BAC5946 AC TEMPER INSPECTION OF ALUMINUM ALLOYS

BAC5946_DCN 1 DCNPSO-013448, TEMPER INSPECTION OF ALUMINUM ALLOYS

BAC5948 D FUSION WELDING OF ALUMINUM ALLOYS FOR WEAPON SUPPORT EQUIPMENT

BAC5951 E GLASS BEAD PEENING

BAC5962 E QUALIFICATION AND CERTIFICATION OF WELDERS AND WELDING OPERATORS

BAC5963 D EDDY CURRENT INSPECTION FOR DISCONTINUITIES

BAC5969 F ELECTRICAL DISCHARGE MACHINING

BAC5973 G SLEEVE COLD WORKING OF HOLES IN ALUMINUM STRUCTURE

BAC5974 R FUSION WELDING OF GIRTH JOINTS SYSTEMS TUBING

BAC5975 R FUSION WELDING OF METALS

BAC5980 F NONDESTRUCTIVE INSPECTION OF COMPOSITE PARTS AND STRUCTURES

BACB10CK R BEARING, ROLLER, SINGLE ROW, SELF-ALIGNING

BACB10CN P BEARING, PLAIN SPHERICAL, BRONZE RACE, NARROW, STAKING GROOVE

BACB10ES AA BEARING, SPHERICAL, NARROW RING, SELF LUBRICATED LINER, CLAMPED INSTALLATION

BACB10FA Y BEARING, SPHERICAL, WIDE RING, SELF LUBRICATED LINER, SEALED, CLAMPED INSTALLATION

BACB10FB AN BEARING, SPHERICAL, NARROW RING, SELF LUBRICATED LINER, SEALED, CLAMPED INSTALLATION

BACB10FH R BEARING,SPHERICAL, WIDE RING

BACB10HP F BEARING, ROD END, PLAIN SPHERICAL, SELF LUBRICATED, EXTERNAL THREAD

BACB10HS G BEARING, STUDDED TRACK ROLLER, SINGLE ROW NEEDLE, SEALED, UNCROWNED AND CROWNED, CRES AND CREN

BACB10JV F BEARING, SPHERICAL, NARROW RING, COPPER-NICKEL-TIN BALL

BACB28AK R BUSHING, PLAIN (FOR CLAMPED INSTALLATION)

BACB28AP W BUSHING, FLANGED, UNDESIZE BORE, NOMINAL AND OVERSIZE OD (FOR CLAMPED INSTALLATION)

BACB28AT Y BUSHING, FLANGED, UNDERSIZE BORE, NOMINAL AND OVERSIZE OD (FOR UNCLAMPED INSTALLATION )

BACB28AU AA BUSHING, OVERSIZE FLANGE, UNDERSIZE BORE (FOR UNCLAMPED INSTALLATION)

BACB28AW T BUSHING, PLAIN, UNDERSIZE BORE (FOR UNCLAMPED NESTED INSTALLATION)

BACB28AZ T BUSHING, FLANGED, NOMINAL AND OVERSIZE FLANGE THICKNESS, LINED UNDERSIZE BORE, NOMINAL AND OVERSIZE OD (FOR UNCLAMPED INSTALLATION)

BACB28X AT BUSHING, FLANGED, NOMINAL SIZE BORE

BACB30BH M BOLT, SHEAR, THIN HEX HEAD, SHORT THREAD, CORROSION & HEAT RESISTANT

BACB30BL N BOLT, HEXAGON (FINE OR COARSE THREADS)

BACB30FM AY BOLT, PROTRUDING HEAD, HEX DRIVE, 95 KSI SHEAR

BACB30FN BH BOLT, 100 DEG SHEAR HEAD, HEX DRIVE, 95 KSI SHEAR

BACB30FQ AP BOLT, 100 DEG SHEAR HEAD, HEX DRIVE, 95 KSI SHEAR 0156 OVERSIZE SHANK

BACB30G - BOLT,SHEAR, 12–POINT HEAD,125 KSI SHEAR, 450 F

BACB30GU E BOLT, SHEAR, 12–POINT HEAD, 125 KSI SHEAR, 450 F

BACB30LE BE BOLT, 12 POINT HEAD, 200 KSI MIN TENSILE, A286 CRES (NOMINAL AND OVERSIZE)

BACB30LH AL BOLT, 100 DEG HEAD, CROSS RCESS, 95 KSI SHEAR, SHORT THREAD, A286 (NOMINAL AND OVERSIZE)

BACB30LM BK BOLT, HEX HEAD, 160 KSI MIN TENSILE, LONG THREAD, A286, SELF-LOCKING, NONLOCKING (NOMINAL AND OVERSIZE)

BACB30MC AL BOLT, PROTRUDING HEAD, HEX DRIVE, TENSION, .0156 OVERSIZE SHANK

BACB30MR BL BOLT, 12 POIMT HEAD, 160 KSI MIN TENSILE, 95 KSI MIN SHEAR, 6A-4V TITANIUM

BACB30MY BA BOLT, PROTRUDING HEAD, HEX DRIVE, 95 KSI SHEAR, 6A1-4V TITANIUM (NOMINAL AND OVERSIZE)

BACB30NM BE BOLT, HEX HEAD, 160 KSI MIN TENSILE, LONG THREAD, 6A1-4V TITANIUM, NONLOCKING AND SELF-LOCKING (NOMINAL AND OVERSIZE)

BACB30NN BA BOLT, 100 DEG. HEAD, CROSS RECESS, 160 KSI MIN. TENSILE, LONG THREAD, 6A1-4V TITANIUM (NOMINAL AND OVERSIZE)

BACB30NR AV BOLT, HEX HEAD, 95 KSI SHEAR, SHORT THREAD, 6A1-4V TITANIUM (NOMINAL AND OVERSIZE)

BACB30NT AL BOLT, PAN HEAD, CROSS RECESS, SHORT THREAD, 6AL-4V TITANIUM

BACB30NW BC BOLT, 100 DEG REDUCED SHEAR HEAD, HEX DRIVE, 95 KSI SHEAR, 6AL-4V TITANIUM (NOMINAL AND OVERSIZE)

BACB30NX BH BOLT, PROTRUDING HEAD, HEX DRIVE, 95 KSI SHEAR, 6

BACB30NY BL BOLT, 100 DEG TENSION HEAD, HEX DRIVE, 160 KSI MIN TENSILE, 6AL-4V TITANIUM (NOMINAL AND OVERSIZE)

BACB30PW AG BOLT, HEX HEAD, SHOULDER, A286 CRES, LONG THREAD, SELF-LOCKING AND NONLOCKING

BACB30US BK BOLT, 12 POINT HEAD, 220 KSI MIN TENSILE, 125 KSI MIN SHEAR, NICKEL ALLOY 718 (NOMINAL AND OVERSIZE)

BACB30UU AV BOLT, 12 POINT HEAD, SHORT THREAD, CLOSE TOLERANCE NICKEL ALLOY 718, 125 KSI MINIMUM SHEAR (NOMINAL AND OVERSIZE)

BACB30VF Y BOLT, 100 DEG. REDUCED HEAD, CROSS RECESS, 95 KSI SHEAR, SHORT THREAD, 6AL-4V TITANIUM

BACB30VT AR BOLT, PROTRUDING HEAD, HEX DRIVE, 95 KSI SHEAR, 6AL-4V TITANIUM, LIGHTWEIGHT, NOMINAL AND OVERSIZE

BACB30VU AG BOLT, 100 DEG. REDUCED SHEAR HEAD, HEX DRIVE, 95 KSI SHEAR, 6AL-4V TITANIUM, LIGHTWEIGHT

BACB30VW N BOLT, BLIND, PULL TYPE, HIGH STRENGTH, PROTRUDING HEAD

BACB30VX P BLIND, PULL TYPE, HIGH STRENGTH, 100 DEGREE FLUSH HEAD ( NOMINAL AND OVERSIZE)

BACB30XD P BOLT, 100 DEG. SHEAR HEAD, CROSS RECESS

BACB30XT R BOLT, LOCK, 100 DEG HEAD, CLOSE TOLERANCE, 95 KSI SHEAR, TITANIUM, LIGHTWEIGHT

BACB30YK R BOLT, PROTRUDING TENSION HEAD, HEX DRIVE, 125 KSI SHEAR, NICKEL ALLOY 718 (NOMINAL AND OVERSIZE)

BACB30YM N BOLT, 100 DEG TENSION HEAD, HEX DRIVE, 125 KSI SHEAR, NICKEL ALLOY 718 (NOMINAL AND

BACB30YN J BOLT, 100 DEG REDUCED SHEAR HEAD, HEX DRIVE, 125 KSI SHEAR, NICKEL ALLOY 718 (NOMINAL AND OVERSIZE)

BACB30YP AA BOLT, CLOSE TOLERANCE, 100 DEG. REDUCED SHEAR DOME HEAD, HEX DRIVE, 95 KSI SHEAR, 6AL-4V TITANIUM, LIGHTWEIGHT

BACB30ZE H BOLT, 100 DEG. REDUCED HEAD, CROSS RECESS, SHORT THD., CLOSE TOL., CRED, SELF-LOCKING AND NON-LOCKING (NOMINAL AND OVERSIZE)

BACC10KG K CLAMP, COUPLING, V-BAND, QUICK RELEASE

BACC13AT C CABLE ASSEMBLY, SAFETY, CRES CABLE, CRES FERRULE

BACC15AY C CLIP, PAX FLOOR BEAM

BACC30AB AF COLLAR, PRELOAD, SHEAR, A286 CRES, 450 F AND 900 F (NOMINAL AND OVERSIZE)

BACC30BH AC COLLAR, PRELOAD, TENSION, FORGED, CRES

BACC30BK J COLLAR, SHEAR, LOCKBOLT, REVERSIBLE, TI PIN, LIGHTWEIGHT

BACC30BL M COLLAR, PRELOAD, SHEAR, 7075-T73 ALUMIUM ALLOY (FOR LIGHTWEIGHT HEX DRIVE SHEAR BOLTS)

BACC30BU M COLLAR ASSEMBLY, PRELOAD, SHEAR, REDUCED HEX, SELF-ALIGNING, 300 SERIES CRES (FOR LIGHTWEIGHT, HEX DRIVE SHEAR BOLTS)

BACC30CP L COLLAR, PRELOAD, TENSION, 17-4PH CORROSION RESISTANT STEEL (NOMINAL AND

BACC30M AF COLLAR, PRELOAD, SHEAR, 2024-T6 ALUMINUM ALLOY (FOR HEX DRIVE SHEAR BOLTS, STANDARD OR .0156 OVERSIZE)

BACC47FJ N CONTACT, ELECTRICAL CONNECTOR, PIN, REMOVEABLE, CRIMP TYPE

BACC47FK P CONTACT, ELECTRICAL CONNECTOR, SOCKET, CRIMP REMOVABLE

BACC50AN B MODULE, ELECTRICAL, GROUND BLOCK, TERMINAL JUNCTION SYSTEM

BACD2003 D BEADS, MINOR STIFFENING

BACD2007 V DRAW FORMED TUBING TEE

BACD2074 BG FASTENER CODES & SYMBOLS

BACD2079 E HELICAL COIL INSERT, HOLE DETAIL

BACD2085 F INSERTS AND STUDS, KEY LOCKED, HOLE DETAIL

BACD2097 AA SURFACE TEXTURE (US CUSTOMARY & METRIC)

BACD40P K DUCT, AIR, FLEXIBLE, ANNULAR CONVOLUTED, GASPER, 100 PERCENT

BACF3AA - FILLER, TAPERED, 6AL-4V TITANIUM ALLOY

BACF3F AG FILLER, FLAT, RECTANGULAR, ALUMINUM ALLOY

BACI12AE H INSERT, SCREW THREAD, COARSE AND FINE, SCREW-LOCKING, HELICAL COIL, CRES

BACJ40AP - JUMPER ASSEMBLY, BONDING, ELECTRICAL, INSULATED, 12 AWG

BACM14H F MOUNT, NUT, PLATE, SELF-LOCKING, FLOATING, RIGHT ANGLE, GLASS EPOXY, ADHESIVE BONDED, 350 F

BACN10BL D NUT-SELF-LOCKING CIRCULAR GANG CHANNEL 3/4 NOMINAL SPACING - 82 DEG. CSK

BACN10GH AA NUT, SPACE PLATE, TWO LUG, LIGHT DUTY (THREADS IN SMALL END)

BACN10HR BU NUT, SELF-LOCKING, 12 POINT, 220 KSI TENSILE, HIGH RELIABILITY, 450 F AND 900 F

BACN10JA AJ NUT, PLATE, SELF-LOCKING, ONE LUG, FLOATING, LOW HEIGHT, 160 KSI, 450 F AND 900 F

BACN10JB AE NUT, PLATE, SELF-LOCKING, ONE LUG, FLOATING, LOW HEIGHT, 160 KSI, 450F & 900F

BACN10JC BC NUT, SELF-LOCKING, HEX, LOW HEIGHT, 450 DEG. F AND 900 DEG. F.

BACN10JD U NUT, CASTELLATED, HEX, 80 KSI, 125 KSI AND 160 KSI, 450 DEG. F AND 900 DEG. F

BACN10JN AE NUT, PLATE, SELF-LOCKING TWO LUG, FLOATING, PLAIN BASE, 450 F AND 900 F

BACN10JP AB NUT, PLATE, SELF-LOCKING, MINIATURE, PLAIN BASE, 450 F AND 900 F

BACN10JR AE NUT, PLATE, SELF-LOCKING, TWO LUG, PLAIN, FLOATING AND CSK, 450 F AND 900 F

BACN10JT T NUT, PLATE, SELF-LOCKING, SELF-AGLIGNING, 450 DEG. F AND 900 DEG. F

BACN10KE AM NUT, PLATE, SELF-LOCKING , FLOATING, 450 DEG. F AND 900 DEG. F

BACN10KF U NUT, PLATE, SELF-LOCKING, CORNER TYPE, PLAIN OR CSK BASE, 450 DEG. F AND 900 DEG. F

BACN10KH M NUT, PLATE, SELF-LOCKING, ONE LUG, FLOATING . SIDE BY SIDE RIVET HOLES, 450 F AND 900 F

BACN10TL Y NUT, SPACER PLATE, LIGHT DUTY

BACN10YK AH NUT, GANG CHANNEL, SELF-LOCKING, VARIABLE CBORE, CRES REMOVABLE NUT

BACN10YR T NUT, SELF-LOCKING, REDUCED HEX, LOW HEIGHT, A286 CRES, 450F AND 900F

BACN10YT W NUT, SELF-LOCKING, HEXAGON, COUNTERBORED, CRES

BACN10ZV G NUT, SELF-LOCKING, HEXAGON, COUNTERBORED, ALUMINUM

BACN10ZZ L NUT ASSEMBLY, SELF-LOCKING, HEXAGON, SELF-ALIGNING COUNTERBORED, ALUMINUM

BACN11AJ C NUT, SELF-LOCKING, HEXAGON, COUNTERBORED, CRES (FOR LIGHTWEIGHT HEX DRIVE BOLTS)

BACN11BH G NUT, SELF-LOCKING, REDUCED HEXAGON, COUNTERBORED, 3AL-2.5V TITANIUM

BACN11CC A NUT,

BACN11N L NUT, SELF-LOCKING, CASTELLATED, HEX, LOW (80 KSI) AND HIGH (125 KSI) HEIGHT, A286 CRES

BACN11P K NUT, PLATE, SELF-LOCKING, FLOATING, SPRING LOADED, A286 NUT ELEMENT

BACN11Z W NUT, SELF-LOCKING, 12 POINT, 180 KSI TENSILE, 450 F AND 900 F

BACP18BC D PIN, COTTER (SPLIT)

BACP18BE B PIN, SPRING, SLOTTED AND COILED

BACP20AX N PLUG, PERMANENT, DRILL PASSAGE

BACR14CW C TERMINATOR, DATABUS, 120 OHMS

BACR15BA BB RIVET, 100 DEG. PRECISION HEAD, CLOSE TOLERANCE SHANK

BACR15BB BB RIVET, UNIVERSAL HEAD, CLOSE TOLERANCE SHANK

BACR15CE BH RIVET, 100 DEG. SHEAR HEAD.

BACR15DN R RIVET, SOLID, UNIVERSAL HEAD, ALUMINUM ALLOY, SEALING

BACR15DR AJ RIVET, BLIND, NONSTRUCTURAL (PULL THRU TYPE)

BACR15FP AC RIVET, BLIND, 100 DEG FLUSH HEAD, LOCKED STEM, SEF-PLUGGING

BACR15FT AL RIVET, MODIFIED UNIVERSAL HEAD, CLOSE TOLERANCE SHANK

BACR15GE D RIVET, BLIND, 100 DEG FLUSH HEAD, LOCKED STEM, SELF

BACR15GF M RIVET, 100 DEGREE PRECISION SHEAR HEAD

BACS12ER AU SCREW, 100 DEG HEAD, CROSS RECESS, FULL THREADED, 6AL-4V TITANIUM

BACS12ER AU SCREW, 100 DEG HEAD, CROSS RECESS, FULL THREADED, 6AL-4V TITANIUM

BACS12FA AV SCREW, WASHER HEAD, CROSS RECESS, FULL THREADED, 6AL-4V TITANIUM

BACS12FA AV SCREW, WASHER HEAD, CROSS RECESS, FULL THREADED, 6AL-4V TITANIUM

BACS12GU T SCREW, HEX HEAD WITH CROSS RECESS, TITANIUM, 160 KSI

BACS13DJ A SLEEVE, INSULATION, SEALING, HEAT SHRINK

BACS13DK B SPLICE, SHIELDED, NICKEL PLATED, SOLDER, FLEXIBLE, HEAT SHRINK

BACS13DL A SEALING INSERT

BACS21DZ M STUD, INTERNAL THREAD, ADHESIVE BONDED

BACS31V C SUPPORT, ASSEMBLY, DUCT, 4 CLIP SNAP-ON

BACS31W E SUPPORT, TUBE, THREADED STUD

BACS40R AM SHIM, LAMINATED, ALUMINUM ALLOY, CRES AND TITANIUM, SURFACE BONDED

BACS40V G SHIM, LAMINATED, POLYIMIDE, SQUARE AND RECTANGULAR

BACS53B R STUD, GROUND, ELECTRICAL (35 AMPERE)

BACW10AU V WASHER, NUT BASE, SELF-ALIGNING, 450 DEG. F

BACW10BN R WASHER, PLAIN OR COUNTERSUNK (NOMINAL, .0156 AND .0312 OVERSIZE) ALLOY STEEL, ALUMINUM ALLOY AND A286 CRES

BACW10BP AH WASHER, PLAIN AND COUNTERSUNK, NOMINAL, .0156 AND .0312 OVERSIZE) ALLOY STEEL AND CRES

BACW10CA AF WASHER, SELF-ALIGNING, 8 DEGREE MAXIMUM MISALIGNMENT, (350 F, 600 F AND 900 F) 180 KSI

BACW10P FP WASHER, FLAT, MISCELLANEOUS

BDS-100 C DIMENSIONING AND TOLERANCING

BDS-1055 M BOEING DRAFTING STANDARD - STANDARD NOTES - APL CODES AND TEXT

BDS-1062 E BOEING DRAFTING STANDARD - DIMENSIONING AND TOLERANCING

BDS-1090-1 B DRAWING METHODS - UNDIMENSIONED

BDS-205 D ALTERED AND SELECTED ITEM DRAWINGS

BDS-206 E CONTROL DRAWINGS

BDS-5030 F BOEING DRAFTING STANDARD - CATIA DATASET NAMING CONVENTION

BMS0-PREF D PREFACE

BMS001PREF F PREFACE - BOEING MATERIAL SPECIFICATION

BMS1-57 N SILICONE RUBBER, BMS3-11 RESISTANT, HIGH PHYSICAL PROPERTIES

BMS1-57_QPL D QPL, SILICONE RUBBER, BMS3-11 RESISTANT, HIGH PHYSICAL PROPERTIES

BMS1-60 J SPECIALTY TYPE SPONGE RUBBER, CLOSED CELL

BMS1-60_QPL D QPL, SPECIALTY TYPE SPONGE RUBBER, CLOSED CELL

BMS1-72 G SILICONE RUBBER, FIRE RETARDANT, FOR AIRCRAFT INTERIORS

BMS1-72_QPL F SILICONE RUBBER, FIRE RETARDANT, FOR AIRCRAFT INTERIORS

BMS10-101 C URETHANE COATINGS FOR INTEGRAL FUEL TANKS

BMS10-103 D NONCHROMATED PRIMER FOR COMPOSITES

BMS10-103_QPL C QPL TO BMS10-103_D, NONCHROMATED PRIMER FOR COMPOSITES

BMS10-11 AD CHEMICAL & SOLVENT RESISTANT FINISH

BMS10-11_QPL A QPL, CHEMICAL & SOLVENT RESISTANT FINISH

BMS10-128 A SOL-GEL CONVERSION COATING FOR PAINT APPLICATIONS

BMS10-128_A_QPL C SOL-GELQPL - CONVERSION COATING FOR PAINT APPLICATIONS

BMS10-146 B LOW FRICTION, ABRASION RESISTANT COATING

BMS10-146_DCN 1 DCNPSO_002523, LOW FRICTION, ABRASION RESISTANT COATING

BMS10-146_QPL - LOW FRICTION, ABRASION RESISTANT COATING

BMS10-20 R CORROSION RESISTANT FINISH FOR INTEGRAL FUEL TANKS

BMS10-20_QPL - QPL, CORROSION RESISTANT FINISH FOR INTEGRAL FUEL TANKS

BMS10-20_DCN 1 DCNPSO_014045_01, CORROSION RESISTANT FINISH FOR INTEGRAL FUEL TANKS

BMS10-55 F INTERIOR DECORATIVE WATER EMULSION PAINTS

BMS10-60 AA PROTECTIVE ENAMEL

BMS10-60_QPL C PROTECTIVE ENAMEL

BMS10-67 N THERMAL SPRAY POWDERS

BMS10-67_QPL A QPL, THERMAL SPRAY POWDERS

BMS10-79 T URETHANE COMPATIBLE, CORROSION RESISTANT PRIMER

BMS10-79_QPL - QPL, URETHANE COMPATIBLE, CORROSION RESISTANT PRIMER

BMS10-83 R INTERIOR DECORATIVE URETHANE PAINT SYSTEM

BMS10-83_QPL - INTERIOR DECORATIVE URETHANE PAINT SYSTEM

BMS10-85 W ALUMINUM PIGMENTED COATING FOR FASTENERS

BMS10-85_QPL B ALUMINUM PIGMENTED COATING FOR FASTENERS

BMS10-86 T TEFLON FILLED COATING

BMS10-86_QPL - TEFLON FILLED COATING

BMS11-7 J CLEANING SOLVENT, PRE-SEALING

BMS11-7_QPL A CLEANING SOLVENT, PRE-SEALING

BMS11-9 G METHYL PROPYL KETONE

BMS11-9_QPL - QPL TO BMS11-9_G, METHYL PROPYL KETONE

BMS14-4 K PROTECTIVE COATING, INORGANIC, HEAT, WEATHER AND OIL RESISTANT

BMS15-12 M ALKALINE REMOVABLE TEMPORARY PROTECTIVE COATINGS AND COATING REMOVERS

BMS15-12_QPL F ALKALINE REMOVABLE TEMPORARY PROTECTIVE COATINGS AND COATING REMOVERS

BMS15-20 A PRESATURED WIPERS

BMS15-5 H WIPER, ABSORBENT, PROCESS CLEANING

BMS20-2 C GENERAL REQUIREMENTS FOR ALUMINUM ALLOY SHEET AND PLATE

BMS3-11 P HYDRAULIC FLUID, FIRE RESISTANT

BMS3-11_QPL - QPL, HYDRAULIC FLUID, FIRE RESISTANT

BMS3-24 B GREASE, AIRCRAFT: BALL AND ROLLER BEARING, WIDE TEMPERATURE RANGE

BMS3-29 B ADVANCED ORGANIC CORROSION INHIBITING COMPOUNDS

BMS3-29_QPL - QPL, ADVANCED ORGANIC CORROSION INHIBITING COMPOUNDS

BMS3-33 C GREASE, AIRCRAFT, GENERAL PURPOSE

BMS3-33_C_QPL A QPL, GREASE, AIRCRAFT, GENERAL PURPOSE

BMS5-109 D ROOM TEMPERATURE CURING TWO PART EPOXY ADHESIVES

BMS5-109_QPL C QPL, ROOM TEMPERATURE CURING TWO PART EPOXY

BMS5-126 H ADHESIVE, EPOXY POLYAMIDE, 2 COMPONENT

BMS5-126_QPL G QPL, ADHESIVE, EPOXY POLYAMIDE, 2 COMPONENT

BMS5-14 J ADHESIVE - SYNTHETIC RUBBER, BUNA-N

BMS5-14_QPL - QPL, ADHESIVE - SYNTHETIC RUBBER, BUNA-N

BMS5-141 A ADHESIVE, ROOM TEMPERATURE CURE, HIGH TEMPERATURE RESISTANT MODERATE PEEL STRENGTH, LOW OUTGASSING

BMS5-141_QPL D QPL, ADHESIVE, ROOM TEMPERATURE CURE, HIGH TEMPERATURE RESISTANT MODERATE PEEL STRENGTH, LOW OUTGASSING

BMS5-16 G TWO PART HOLE FILLING COMPOUND

BMS5-16_QPL A TWO PART HOLE FILLING COMPOUND

BMS5-26 V INTEGRAL FUEL TANK SEALANT

BMS5-28 AR HONEYCOMB EDGE FILLING AND POTTING COMPOUND

BMS5-28_QPL B HONEYCOMB EDGE FILLING AND POTTING COMPOUND

BMS5-42 V STRUCTURAL ADHESIVE FOR METAL-TO-METAL ASSEMBLIES-350 F CURE

BMS5-42_QPL B STRUCTURAL ADHESIVE FOR METAL-TO-METAL ASSEMBLIES-350 F CURE

BMS5-44 N TEMPERATURE-RESISTANT, FULL, PRESSURE, AND WEATHER SEALANT

BMS5-44_QPL A TEMPERATURE-RESISTANT, FULL, PRESSURE, AND WEATHER SEALANT

BMS5-45 M FUEL TANK SEALANT

BMS5-45_M_QPL A FUEL TANK SEALANT

BMS5-63 N FIREWALL SEALANT, HYDRAULIC FLUID RESISTANT

BMS5-63_QPL A QPL, FIREWALL SEALANT, HYDRAULIC FLUID RESISTANT

BMS5-7 G ADHESIVE, NEOPRENE BASE

BMS5-7_QPL B ADHESIVE, NEOPRENE BASE

BMS5-92 L ADHESIVE, MODIFIED EPOXY FOR GENERAL PURPOSE USE

BMS5-95 U PRESSURE AND ENVIRONMENTAL SEALANT - CHROMATE TYPE

BMS5-95_QPL - QPL, PRESSURE AND ENVIRONMENTAL SEALANT - CHROMATE TYPE

BMS7-122 E CONSUMABLE ELECTRODE VACUUM ARC REMELTED 4330 MODIFIED (AMS 6411) STEEL

BMS7-122_DCN 1 DCNPSO_013161, CONSUMABLE ELECTRODE VACUUM ARC REMELTED 4330 MODIFIED (AMS 6411) STEEL

BMS7-180 Y 7075 ALUMINUM ALLOY EXTRUSIONS - OBSOLETE

BMS7-186 M ALUMINUM ALLOY FORGINGS

BMS7-194 Y HIGH STRENGTH, STRESS CORROSION RESISTANT 7050 ALUMINUM ALLOY PLATE

BMS7-214 U HIGH STRENGTH, STRESS CORROSION RESISTANT ALUMINUM ALLOY FORGINGS

BMS7-214_QPL D QPL, HIGH STRENGTH, STRESS CORROSION RESISTANT ALUMINUM ALLOY FORGINGS

BMS7-232 D HIGH STRENGTH FATIGUS TOLERANT, STRESS CORROSION RESISTANT 7050 ALUMINUM ALLOY PLATE

BMS7-232_QPL - QPL, HIGH STRENGTH FATIGUS TOLERANT, STRESS CORROSION RESISTANT 7050 ALUMINUM ALLOY PLATE

BMS7-240 J 15-5PH (UNS S15500) SHEET, PLATE, AND STRIP

BMS7-247 J TITANIUM 6AL-4V FORGING, PREMIUM QUALITY

BMS7-247_QPL C QPL, TITANIUM 6AL-4V FORGING, PREMIUM QUALITY

BMS7-26 R STEEL BAR, FORGING STOCK, AND TUBING - 4340 MODIFIED

BMS7-26_QPL - QPL, STEEL BAR, FORGING STOCK, AND TUBING - 4340 MODIFIED

BMS7-260 N TITANIUM 10V-3Fe-3A1 FORGED BLOCK/BAR AND DIE

BMS7-260_QPL C QPL, TITANIUM 10V-3Fe-3A1 FORGED BLOCK/BAR AND DIE

BMS7-269 H TITANIUM ALLOY 6AI-4V FORGINGS, BETA ANNEALED

BMS7-28 G STEEL BARS, RODS AND FORGING STOCK (4340)

BMS7-302 C HIGH FORMABILITY7075-0 BARE AND ALCLAD ALUMINUM SHEET

BMS7-306 K HIGH STRENGTH, CORROSION RESISTANT ALUMINUM ALLOY EXTRUSIONS, 7150-T7751X

BMS7-306_QPL C QPL - HIGH STRENGTH, CORROSION RESISTANT ALUMINUM ALLOY EXTRUSIONS, 7150-T7751X

BMS7-323 E HIGH STRENGTH FATIGUE TOLERANT, STRESS CORROSION RESISTANT 7050 ALUMINUM ALLOY PLATE

BMS7-323_QPL H QPL, HIGH STRENGTH FATIGUE TOLERANT, STRESS CORROSION RESISTANT 7050 ALUMINUM ALLOY PLATE

BMS7-335 N RESIN BONDED LAMINATED SHIM STOCK

BMS7-335_QPL - RESIN BONDED LAMINATED SHIM STOCK

BMS7-348 G THICK SECTION TITANIUM 6AL-4V FORGED BLOCK

BMS7-348_QPL - THICK SECTION TITANIUM 6AL-4V FORGED BLOCK

BMS7-360 H TITANIUM 5AI-5V-3Mo-3Cr DIE FORGINGS AND BARS

BMS7-360_QPL C TITANIUM 5AI-5V-3Mo-3Cr DIE FORGINGS AND BARS

BMS7-370 A ALUMINUM ALLOY FORGINGS, THICK SECTION, HIGH STRENGTH, HIGH FRACTURE TOUGHNESS, STRESS CORROSION RESISTANT

BMS7-370_QPL B ALUMINUM ALLOY FORGINGS, THICK SECTION, HIGH STRENGTH, HIGH FRACTURE TOUGHNESS, STRESS CORROSION RESISTANT

BMS7-381 D HIGH STRENGTH, DAMAGE TOLERANT, CORROSION RESISTANT 7XXX -T7651 ALUMINUM ALLOY PLATE

BMS7-398 - 12Cr-11Ni CORROSION RESISTANT STEEL BAR, WIRE, FORGINGS, AND FORGING STOCK (BILLET), 220 TO 240 KSI AND 240 TO 260 KSI TENSILE ULTIMATE STRENGTH CAPABLE

BMS7-398_QPL A 12Cr-11Ni CORROSION RESISTANT STEEL BAR, WIRE, FORGINGS, AND FORGING STOCK (BILLET), 220 TO 240 KSI AND 240 TO 260 KSI TENSILE ULTIMATE STRENGTH CAPABLE

BMS7-404 - HIGH DAMAGE TOLERANT ALUMINUM COPPER LITHIUM SHEET AND PLATE

BMS7-404_QPL A HIGH DAMAGED TOLERANT ALUMINUM COPPER LITHIUM SHEET AND PLATE

BMS8-124 AE NONMETALLIC HONEYCOMB CORE

BMS8-124_QPL - QPL, NONMETALLIC HONEYCOMB CORE

BMS8-139 N GLASS FABRIC PREIMPREGNATED HIGH-TEMPERATURE-RESISTANCE EPOXY RESIN

BMS8-139_QPL B QPL, GLASS FABRIC PREIMPREGNATED HIGH-TEMPERATURE-RESISTANCE EPOXY RESIN

BMS8-245 N ADHESIVE FOR COMPOSITE BONDING (350 F CURE)

BMS8-343 G POLYMER COATED FABRIC, FLAME RESISTANT, FLEXIBLE CARGO LINER

BMS8-343_QPL E QPL, POLYMER COATED FABRIC, FLAME RESISTANT, FLEXIBLE CARGO LINER

BMS8-39 AF FLEXIBLE URETHANE FOAM

BMS8-39_QPL - QPL, FLEXIBLE URETHANE FOAM

BPS-B-80SUP F BEARING, ROLLER, AIRFRAME

BPS-B-82 L BEARING, PLAIN SPHERICAL

BPS-F-142 C FITTINGS, HYDRAULIC, PERMANENT JOINT

BPS-F-142SUP M FITTINGS, HYDRAULIC, PERMANENT JOINT

BPS-F-67 AV FASTENERS, HEX-DRIVE BOLTS

BPS-F-68 AT FASTENER, PRELOAD COLLARS

BPS-F-68SUP R FASTENER, PRELOAD COLLARS

BPS-F-69 BK FASTENERS, EXTERNALLY THREADED

BPS-N-70 AV NUT, SELF-LOCKING

BPS-R-259 B TERMINATOR, DATABUS

BSS001PREF G PREFACE - BOEING SPECIFICATION SUPPORT STANDARD

BSS7011 C GUIDELINES FOR THE APPLICATION OF PAINT

BSS7012 B MANUFACTURE OF SILKSCREENS

BSS7015 - DIMENSIONAL CONTROL OF CASTINGS & FORGINGS

BSS7022 A PROCEDURES AND EQUIPMENT FOR MEASUREMENT OF FASTENER HOLES

BSS7023 AU MANUFACTURING FACILITIES WITH APPROVED OPERATING PROCEDURES FOR MANUFACTURING PROCESS CONTROL DOCUMENTS

BSS7023_DCN 1 DCNPSO-012249, MANUFACTURING FACILITIES WITH APPROVED OPERATING PROCEDURES FOR MANUFACTURING PROCESS CONTROL DOCUMENTS

BSS7039 D LIQUID PENETRANT INSPECTION

BSS7040 C MAGNETIC PARTICLE INSPECTION

BSS7048 D EDDY CURRENT INSPECTION, DISCONTINUITIES

BSS7055 B ULTRASONIC INSPECTION, WROUGHT PRODUCTS

BSS7084 A PRE-APPROVED STATISTICAL SAMPLING PLANS

BSS7100 R ALTERNATIVES DOCUMENT - PROCESS, MATERIALS AND PARTS

BSS7219 E INTERGRANULAR ATTACK, TEST METHOD

BSS7221 H HARDNESS, TEST METHOD - OBSOLETE

BSS7225 L ADHESION, TAPE TEST

BSS7267 D APPLICATION TIME

BSS7278 D TACK-FREE TIME TESTING OF SEALANTS

BSS7286 F STATISTICAL PROCESS CONTROL OF DESIGNATED ENGINEERING CHARACTERISTICS

BSS7350 F ROCKWELL HARDNESS TESTING PROCEDURES

BSS7351 G EDDY CURRENT ELECTRICAL CONDUCTIVITY - DIRECT READING METHOD

BSS7600 Y PERSONNEL CERTIFICATION, GENERAL REQUIREMENTS

BSS7604 AK SEALING OPERATIONS, PERSONNEL CERTIFICATION FOR

BSS7617 T ELECTRICAL BONDING AND GROUNDING, PERSONNEL CERTIFICATION FOR

BSS7621 F HYDROGEN DETECTION INSTRUMENT OPERATOR, PERSONNEL CERTIFICATION FOR

BSS7630 G SHOT PEENING OPERATIONS, PERSONNEL CERTIF.

BSS7632 F INSTALLATION OF MOLDABLE PLASTIC SHIM, PERSONNEL CERTIFICATION FOR

BSS7646 E HARDNESS TESTING OF METALS, PERSONNEL CERTIFICATION FOR

BSS7649 G STYLUS OR BRUSH PLATING, ANODIZING, AND ELECTRO-CHEMICAL ETCHING, PERSONNEL CERTIFICATION FOR

BSS7649_DCN 1 DCNPSO-012185, STYLUS OR BRUSH PLATING, ANODIZING, AND ELECTRO-CHEMICAL ETCHING, PERSONNEL CERTIFICATION FOR

BSS7650 J POTTING OF ELECTRIC CONNECTORS, PERSONNEL CERTIFICATION FOR

BSS7650_DCN 1 DCNPSO_002606, POTTING OF ELECTRIC CONNECTORS, PERSONNEL CERTIFICATION FOR

BSS7675 K VISUAL WELD INSPECTORS/EXAMINERS, PERSONNEL CERTIFICATION FOR

BSS7698 K NONDESTRUCTIVE INSPECTION, PERSONNEL CERTIF. FOR

BSS7698_DCN 1 DCNPSO_006166, NONDESTRUCTIVE INSPECTION, PERSONNEL CERTIF. FOR

D-590-PREFACE V D-590 PART STANDARDS PREFACE

D2-5000 CH PROTECTIVE FINISH CODES

D31013-0 K BOEING MACHINE FIXTURES AND DRILL JIGS TOOL DESIGN DOCUMENT

D31013-1 F INTRODUCTION - MACHINE FIXTURES AND DRILL JIGS

D31041-0 P BOEING MASTER TOOLING DESIGN DOCUMENT (GAGES)

D31041-1 K GLOSSARY OF MASTER TOOLING TERMINOLOGY

D31041-2 G GAGING PROCESS

D31041-3 H MASTER TOOLING IDENTIFICATION CODES

D31041-4 M MASTER TOOL DESIGN CONSIDERATION

D31041-5 L INFORMATION AND INSPECTION REQUIRED ON MASTER TOOLING DRAWINGS

D31062-1 N PORTABLE WORK PLATFORM AND LADDER STAND DESIGN CRITERIA

D31081-0 F CLASS "A" DIES TOOL DESIGN DOCUMENT

D31084-0 H BOEING HYDROFORM DIES (HDF) TOOL DESIGN DOCUMENT

D32012-0 L BOEING NON-DESIGN BLANKING TOOLS (BT) DOCUMENT

D32014-1 J BOEING NON-DESIGN ASSEMBLY JIGS DOCUMENT (EXCEPT WICHITA RENTON AND 777)

D32041-0 M BOEING HYDROPRESS FORMING TOOLS DOCUMENT

D32042-0 K BOEING STRETCHFORM BLOCK (STFB) AND POSTFORM BLOCK (FB) TOOLING DOCUMENT

D32043-0 E BOEING ROUTER BOARD (RB) TOOLING DOCUMENT - CANCELLED

D32061-35 AA COUNTERSINKING SHEEET METAL PARTS

D32081-1 H TOOLING FABRICATION

D32082-0 L BOEING TRIMMING TOOLS DOCUMENT

D32082-1 H GLOSSARY OF SHAPING AND TRIMMING TERMINOLOGY

D32121-0 J BOEING FLEXIBLE TOOLING DOCUMENT

D33011-21 CR CRITICAL CHARACTERISTICS ON 737 TOOLING DRAWINGS

D33041-0 AY BOEING TOOL IDENTIFICATION CODES

D33041-13 AY ALPHABETICAL LISTING OF TOOL CODES

D33041-3 T NON-CONTRACTUAL TOOL CODES (2) - SPECIAL TEST EQUIPMENT

D33101-0 CJ BOEING UTILITY TOOLS (UT) CATALOG

D33101-25 CE TRUNNIONS, STRUCTURE, AND MISCELLANEOUS (UT-7281 THRU UT 7323)

D33101-3 CC MISCELLANEOUS UT'S (UT-2392 THRU UT-2400)

D33101-36 BW STRAP CLAMP COMPONENTS (UT -7816 THRU UT -7826)

D33101-38 CD CABLES, CORDS, AND STRAPS (UT-7838 THRU UT-7860)

D33101-39 CA OPTICAL TOOLING ACCESSORIES (UT-7934 THRU UT-7946)

D33101-4 CB ASSORTED TOOL IDENTIFICATION TAGS (UT-6899 THRU UT-6904-R-C)

D33144-0 E BOEING OPERATORS GUIDE FOR OPTICAL TOOLING SETUPS

D33181-0 DC TOOLING PROCEDURE STANDARDS

D33200-0 AB BOEING SUPPLIER'S TOOLING DOCUMENT

D33200-1 AT BOEING SUPPLIER'S TOOLING

D33200-2 AA SELLER-OWNED TOOLING REQUIREMENTS

D37521-1 K SUPPLIERS' PART PROTECTION GUIDE PHILADELPHIA

D37522-1 M INTRODUCTION TO MATERIAL HANDLING, PRODUCT PACKAGING, STORAGE, AND SHIPPING SUPPORT

D37522-6 AE SUPPLIER PACKAGING

D6-5000 BU SPECIAL COMMERCIAL AIRPLANE COMPANY FINISH CODES

MS20257SUP B HINGE, CONTINUOUS

MS21141SUP A FASTENER, BLIND, HIGH STRENGTH, FULL TYPE, POSITIVE MECHANICAL LOCK, PROTRUDING HEAD, CORROSION RESISTING STEEL, 95 K.S.I.

NASM 20073SUP A BOLT, MACHINE, AIRCRAFT, DRILLED HEAD, FINE THREAD

NASM 21044SUP B NUT, SELF-LOCKING, HEXAGON, REGULAR HEIGHT, 250 DEG F, 125 KSI FTU AND 60 KSI FTU

NASM 21134SUP C BOLT, TENSION, STEEL, 180 KSI Ftu, 450 DEGREE F EXTERNAL WRENCHING, SPLINE DRIVE, FLANGED

QPP4761 C QUALITY PROCESSING PROCEDURE - HEAT TREATMENT OF BOEING PART NUMBER 144A1610-3/-4/--7/-8/-15/-16 FORGING, MLG BEAM SUPPORT FITTING - STA 716.3

STB2047 E HOLES SLOTTED AND NOTCHED, PIERCED

NOT TO BE DISCLOSED

INFORMATION CONTAINED HEREIN IS SUBMITTED IN CONFIDENCE OR PRIVILEGED AND IS EXEMPT FROM DISCLOSURE UNDER THE FREEDOM OF INFORMATION ACT (5 U.S.C. 552) BY REASON OF THE EXEMPTIONS IN SEC. 552(B)(3) -- BY

You might also like

- Astm D 1265Document5 pagesAstm D 1265Jorge Kovach Alvarado50% (2)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Syllabus 1styearDocument40 pagesSyllabus 1styearAjayaHSNo ratings yet

- Id Number Title Year OrganizationDocument46 pagesId Number Title Year Organizationcrm100% (1)

- Schneider Electric-Technical CodeDocument42 pagesSchneider Electric-Technical CodeElica ElectricNo ratings yet

- 220kV Busbar & Bus Coupler Control & Relay Panel - 07.09.18Document49 pages220kV Busbar & Bus Coupler Control & Relay Panel - 07.09.18Guru Mishra100% (1)

- Chardon Cross Reference Chart PDFDocument3 pagesChardon Cross Reference Chart PDFEng BruccyNo ratings yet

- Chardon Cross Reference ChartDocument3 pagesChardon Cross Reference ChartEng BruccyNo ratings yet

- BS EN 1011-3-2000 - Recommendations For Arc Welding of Stainless Steels PDFDocument25 pagesBS EN 1011-3-2000 - Recommendations For Arc Welding of Stainless Steels PDF0502ravi100% (1)

- Bass& BacDocument24 pagesBass& BacsreeramNo ratings yet

- REVISION: AN: Airbus - Maintained Specification ReportDocument9 pagesREVISION: AN: Airbus - Maintained Specification ReportSergeyNo ratings yet

- Transmital Log - ACTIVE1Document40 pagesTransmital Log - ACTIVE1Hafeez AhmedNo ratings yet

- REVISION: M: Boeing/Spirit - Maintained Specification ReportDocument21 pagesREVISION: M: Boeing/Spirit - Maintained Specification ReportMASOUDNo ratings yet

- No Document NumberDocument15 pagesNo Document NumberArmawan 99No ratings yet

- Bridge Plug-Cement RetainerDocument7 pagesBridge Plug-Cement RetainerhabibimarioNo ratings yet

- Pasta MC PKG - No DISCIPLINA Tag - No Tag - Description Form - Sheet ConcatenadoDocument11 pagesPasta MC PKG - No DISCIPLINA Tag - No Tag - Description Form - Sheet ConcatenadoDieizon KummerNo ratings yet

- Weekly Progress Report: Pertamina Phe Onwj LTD Pipeline Replacement & Topside ModificationDocument9 pagesWeekly Progress Report: Pertamina Phe Onwj LTD Pipeline Replacement & Topside ModificationElias EliasNo ratings yet

- Option-2-Piping Support Structural BOQDocument12 pagesOption-2-Piping Support Structural BOQMaqsood Ibn Shaikhul ArfeenNo ratings yet

- 1833-301-02 DeleteDocument3 pages1833-301-02 DeleteIveel PurevdorjNo ratings yet

- B013578 Electrical Schematics ED3005Document57 pagesB013578 Electrical Schematics ED3005SantiagoNo ratings yet

- Mip Bohler PipelineDocument32 pagesMip Bohler PipelineDaniel StuparekNo ratings yet

- M10676-Bom Rev-B - KyDocument18 pagesM10676-Bom Rev-B - KykanarendranNo ratings yet

- 6112-12-BW2 Wrapper Material ElectricoDocument8 pages6112-12-BW2 Wrapper Material ElectricoPlasmodiums clansNo ratings yet

- EI Erection Tender Additional Work Silo, ConvDocument18 pagesEI Erection Tender Additional Work Silo, ConvSaurabh Kumar SinghNo ratings yet

- Balance Works (U&O)Document3 pagesBalance Works (U&O)Amresh KumarNo ratings yet

- AK-0-EE-IP-01-001 - Arrangement Plan of Excitation AC&DC Bus-Duct - FCDDocument57 pagesAK-0-EE-IP-01-001 - Arrangement Plan of Excitation AC&DC Bus-Duct - FCDrajbharath.pNo ratings yet

- Perda No 4 Tahun 2011Document66 pagesPerda No 4 Tahun 2011Kelink Hari PrasetyoNo ratings yet

- CHARDON Part Number Reference Chart Elastimold Part Number Description Elastimold Cooper TEDocument3 pagesCHARDON Part Number Reference Chart Elastimold Part Number Description Elastimold Cooper TEErnesto Pieruccini RamirezNo ratings yet

- Weekly Progress Report: Pertamina Phe Onwj LTD Pipeline Replacement & Topside ModificationDocument6 pagesWeekly Progress Report: Pertamina Phe Onwj LTD Pipeline Replacement & Topside ModificationElias EliasNo ratings yet

- Tamil Nadu Generation and Distribution Corporation LTDDocument23 pagesTamil Nadu Generation and Distribution Corporation LTDMinh TríNo ratings yet

- Purchase Order Requisition R-1910-0318 Rev 0Document27 pagesPurchase Order Requisition R-1910-0318 Rev 0AnaNo ratings yet

- TgsgtubeDocument33 pagesTgsgtubechilukamariNo ratings yet

- E Pipe & Fittings With SampleDocument138 pagesE Pipe & Fittings With Samplep4p7 projectsNo ratings yet

- 200 A Loadbreak Connectors: 25 KV Posi-Break Elbow and CapDocument19 pages200 A Loadbreak Connectors: 25 KV Posi-Break Elbow and CapCARHUAMACA PASCUAL mhNo ratings yet

- P021.46 DB54 Mat Mech 001Document115 pagesP021.46 DB54 Mat Mech 001p4p7 projectsNo ratings yet

- Wig 1000 P DS 0002.0.appDocument8 pagesWig 1000 P DS 0002.0.appzodhhashoNo ratings yet

- Option-1-Piping Support Structural BOQ PDFDocument12 pagesOption-1-Piping Support Structural BOQ PDFMaqsood Ibn Shaikhul ArfeenNo ratings yet

- 2227 Valerus Drawing List r6Document6 pages2227 Valerus Drawing List r6Avi NashNo ratings yet

- MOS-0570-5685619-00 CombinedDocument11 pagesMOS-0570-5685619-00 Combinedarmsarabia01No ratings yet

- Apator Disconecting FUSEDocument26 pagesApator Disconecting FUSEAnonymous yugocxnNo ratings yet

- ListDocument3 pagesListprabhutheniNo ratings yet

- Wir Piping Update April 26 2018Document10 pagesWir Piping Update April 26 2018jaymarNo ratings yet

- MTOCO001008Document8 pagesMTOCO001008Mohamed Rizk100% (1)

- Standard Const Material SpecDocument320 pagesStandard Const Material SpecElin IrhamnaNo ratings yet

- PVC Conduits, Fittings & Accessories PDFDocument70 pagesPVC Conduits, Fittings & Accessories PDFHaytham BafoNo ratings yet

- Ga & Boq - LDB PanelDocument3 pagesGa & Boq - LDB PanelrinkukachhelaNo ratings yet

- BWB - PRIME Approval List: AIRBUS INDUSTRIES: WWW - Flugzeuggalvanik.deDocument8 pagesBWB - PRIME Approval List: AIRBUS INDUSTRIES: WWW - Flugzeuggalvanik.deVIJAY YADAVNo ratings yet

- Copie de Standards Check ListDocument7 pagesCopie de Standards Check ListAbakar MahamatNo ratings yet

- F 400 Sewer Materials and Structures: Section No. Subject DateDocument56 pagesF 400 Sewer Materials and Structures: Section No. Subject DateAbdulRahman SharifNo ratings yet

- 1833-307-02 DeleteDocument3 pages1833-307-02 DeleteIveel PurevdorjNo ratings yet

- Welding Consumables For Pipeline ConstructionDocument32 pagesWelding Consumables For Pipeline ConstructionElias KapaNo ratings yet

- Ductile Iron Fittings CatalogueDocument12 pagesDuctile Iron Fittings Catalogueramkesh rathaurNo ratings yet

- Index SPFN 2010Document14 pagesIndex SPFN 2010NeozaqeNo ratings yet

- A I B T B V: N Ntroduction TO U ECH ALL AlvesDocument51 pagesA I B T B V: N Ntroduction TO U ECH ALL AlvesvankarpNo ratings yet

- 18th July MTA#024 Rev.01 - Scope of SupplyDocument5 pages18th July MTA#024 Rev.01 - Scope of Supplyمحمد اصدNo ratings yet

- Base PortafusibleDocument6 pagesBase PortafusiblePablito AteNo ratings yet

- Saep 310Document38 pagesSaep 310paul cafeNo ratings yet

- Suprajit Price List Sep-2021Document36 pagesSuprajit Price List Sep-2021Manish ChandNo ratings yet

- Pressure Seal Check ValvesDocument18 pagesPressure Seal Check ValvesthomasnafNo ratings yet

- Apron Electrical Works: Subject Items Unit Qty. Brand Name Delivery Status MSRDocument5 pagesApron Electrical Works: Subject Items Unit Qty. Brand Name Delivery Status MSRayhanarmanNo ratings yet

- Natural Gas System Line & Valve List: I.P.D.CDocument10 pagesNatural Gas System Line & Valve List: I.P.D.CepbamdadNo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Advances in Ceramic Armor XFrom EverandAdvances in Ceramic Armor XJerry C. LaSalviaNo ratings yet

- 14 September 2009: Subsea Challenges in Deep PanukeDocument22 pages14 September 2009: Subsea Challenges in Deep Panukeharan2000No ratings yet

- Architectural - Sheet Metal - CollieDocument42 pagesArchitectural - Sheet Metal - CollieWissam AlameddineNo ratings yet

- Corrosion On Stainless SteelDocument3 pagesCorrosion On Stainless SteelMondayNo ratings yet

- Ice Melt Buyer'S Guide Ice Melt Buyer'S GuideDocument7 pagesIce Melt Buyer'S Guide Ice Melt Buyer'S GuidelyndondrNo ratings yet

- Magnesium AlloyDocument22 pagesMagnesium AlloyPrethev100% (1)

- 1995-Microbes Onboard ShipsDocument43 pages1995-Microbes Onboard ShipsAnakin SkywalkerNo ratings yet

- API-570-Exam-100-Q (계산문제 정리할수 있는 문제) PDFDocument23 pagesAPI-570-Exam-100-Q (계산문제 정리할수 있는 문제) PDFasNo ratings yet

- 2011 Syllabi New 22.08.2013Document295 pages2011 Syllabi New 22.08.2013invincible_shalin6954No ratings yet

- Bearing For Clean EnviromentDocument14 pagesBearing For Clean Enviromentصالح سميرNo ratings yet

- Superhydrophobic CoatingDocument28 pagesSuperhydrophobic CoatingAldrei Zamm Recamadas100% (1)

- Corrosion of Metals in Marine Environments An OverviewDocument23 pagesCorrosion of Metals in Marine Environments An OverviewGustavo VicierraNo ratings yet

- ACI PRC-201.1-08 Guide For Conducting A Visual Inspection of Concrete in ServiceDocument19 pagesACI PRC-201.1-08 Guide For Conducting A Visual Inspection of Concrete in ServiceGikoNo ratings yet

- 2 e Lech Tro ChemistryDocument39 pages2 e Lech Tro ChemistryrahmaNo ratings yet

- 16 PTIRecommendationsforStayCableDesignTestingandInstallationDocument23 pages16 PTIRecommendationsforStayCableDesignTestingandInstallationBeratErtekin100% (1)

- The Indian Institute of WeldingDocument10 pagesThe Indian Institute of WeldingSandeep MohantyNo ratings yet

- Engineering Failure Analysis: Jivan Kumar, Swati Biswas, M.D. Ganeshachar, S.N. Narendra Babu, S. RamachandraDocument12 pagesEngineering Failure Analysis: Jivan Kumar, Swati Biswas, M.D. Ganeshachar, S.N. Narendra Babu, S. RamachandraAgy RandhikoNo ratings yet

- Concrete ProjectionDocument28 pagesConcrete ProjectionMooneer El AssaadNo ratings yet

- Hempel Coating Reference Handbook GBDocument145 pagesHempel Coating Reference Handbook GBGerardo Castillo100% (2)

- Cap 9. Aplicaciones de MA en Recubrimiento PDFDocument67 pagesCap 9. Aplicaciones de MA en Recubrimiento PDFEduardo LozanoNo ratings yet

- Zink Phosphate ZP 10Document5 pagesZink Phosphate ZP 10Shamshir ChemicalsNo ratings yet

- Strut Technical DataDocument15 pagesStrut Technical DataJOFRANo ratings yet

- Penguard Primer: Technical Data SheetDocument5 pagesPenguard Primer: Technical Data SheetRekhis OussamaNo ratings yet

- 2007gates Hyd Cat10-10-07Document598 pages2007gates Hyd Cat10-10-07jaysx5No ratings yet

- Demo UdsDocument15 pagesDemo UdsvesselengineerNo ratings yet

- G2593R9Document21 pagesG2593R9TanaNo ratings yet

- Corrossion Control of Underwater PilesDocument23 pagesCorrossion Control of Underwater Pilesvaradha s nairNo ratings yet

- Designing Concrete For Exposure To SeawaterDocument3 pagesDesigning Concrete For Exposure To SeawaterSaeedNo ratings yet