Professional Documents

Culture Documents

Experiment 4 Data Sheet 2 Group 5 and 6

Experiment 4 Data Sheet 2 Group 5 and 6

Uploaded by

Gabriel Ford MedinaCopyright:

Available Formats

You might also like

- Flexural Buckling ExampleDocument8 pagesFlexural Buckling ExampleDubu DubuNo ratings yet

- SNI 4658-2008-Pelek Kategori LDocument2 pagesSNI 4658-2008-Pelek Kategori LDimazNugraha100% (1)

- NDE Procedures: Authorized byDocument4 pagesNDE Procedures: Authorized byEdAlm100% (1)

- BHMH - Al Alloy - 2014 T6 Iss - 01Document4 pagesBHMH - Al Alloy - 2014 T6 Iss - 01Beni hidayatullahNo ratings yet

- Process Variable Effect On The Strength of Autoclave-Bonded Film Adhesive JointsDocument22 pagesProcess Variable Effect On The Strength of Autoclave-Bonded Film Adhesive Joints呆猫DemooNo ratings yet

- Projek Sarjana Muda 1 (SMJ 4912) 10 MAY 2009: Universiti Technology Malaysia Faculti Kejuruteraan MekanikalDocument24 pagesProjek Sarjana Muda 1 (SMJ 4912) 10 MAY 2009: Universiti Technology Malaysia Faculti Kejuruteraan MekanikalKamarul NizamNo ratings yet

- Analysis of Metallurgical Properties of Al-Sio2 Composite MaterialDocument7 pagesAnalysis of Metallurgical Properties of Al-Sio2 Composite MaterialPandu SetiawanNo ratings yet

- Aluminum 7005-T6, 7005-T63, and 7005-T6351Document3 pagesAluminum 7005-T6, 7005-T63, and 7005-T6351Dule JovanovicNo ratings yet

- E16 8 2Document4 pagesE16 8 2Branko FerenčakNo ratings yet

- International Journal of Research Publication and ReviewsDocument7 pagesInternational Journal of Research Publication and ReviewsBasavaraj G LNo ratings yet

- 6061 T6 MaterialDocument2 pages6061 T6 Materialtravis8zimmermannNo ratings yet

- 2021-2022 - Example Exam Aircraft Structures 2 - New Setup of ExamDocument10 pages2021-2022 - Example Exam Aircraft Structures 2 - New Setup of ExamLeonardo Elez DraganNo ratings yet

- Plastic Deformation in Tensile Testing: Renewable Energy Equipment DesignDocument17 pagesPlastic Deformation in Tensile Testing: Renewable Energy Equipment DesignNoman AhmedNo ratings yet

- AluminiumHE15 PropertiesDocument3 pagesAluminiumHE15 PropertiesPrashanthNo ratings yet

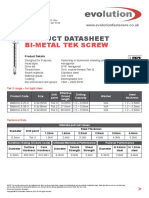

- Metal Tek ScrewDocument2 pagesMetal Tek ScrewAmin SalahNo ratings yet

- BF02323554Document7 pagesBF02323554Fernando CruzNo ratings yet

- Main Tunnel First CheckDocument9 pagesMain Tunnel First CheckDara HajebiNo ratings yet

- Welding ProcesssDocument9 pagesWelding ProcesssPANKAJ SINGH NEGINo ratings yet

- 1 s2.0 S2214785318301767 MainDocument8 pages1 s2.0 S2214785318301767 MainJames CarterNo ratings yet

- 1792 Effect of Antimony Addition Relative To Microstructure and Mechanical Properties of Continous Cast Lead AlloyDocument7 pages1792 Effect of Antimony Addition Relative To Microstructure and Mechanical Properties of Continous Cast Lead Alloynaeem akramNo ratings yet

- Assignment 4 Vasilii BogdanDocument9 pagesAssignment 4 Vasilii BogdanRenzil ColacoNo ratings yet

- 13IJMPERDJUN201913Document6 pages13IJMPERDJUN201913TJPRC PublicationsNo ratings yet

- Analysis of Die Angle in Deep Drawing Process Using FEMDocument5 pagesAnalysis of Die Angle in Deep Drawing Process Using FEMEduardoNo ratings yet

- Test Data Sheet: Date of Sampling Date of TestingDocument5 pagesTest Data Sheet: Date of Sampling Date of TestingChandan MondalNo ratings yet

- Ampco 45: Technical Data SheetDocument2 pagesAmpco 45: Technical Data Sheetmarceloalves.dsNo ratings yet

- Stress Analysis of Multi-Layered Hybrid Composite Pipes Subjected To Internal PressureDocument13 pagesStress Analysis of Multi-Layered Hybrid Composite Pipes Subjected To Internal PressureAFZAL M BAKSHINo ratings yet

- Comparison in Deformation and Fracture Behavior of Magnesium During Equal Channel Angular Pressing by Experimental and Numerical MethodsDocument4 pagesComparison in Deformation and Fracture Behavior of Magnesium During Equal Channel Angular Pressing by Experimental and Numerical Methodskamel touilebNo ratings yet

- Optimization of Process Parameters of Friction Stir Welding of Aa 6082-T6 Using Grey Based Taguchi MethodDocument8 pagesOptimization of Process Parameters of Friction Stir Welding of Aa 6082-T6 Using Grey Based Taguchi MethodTJPRC PublicationsNo ratings yet

- Aluminum 7175 T736Document3 pagesAluminum 7175 T736TylerLALA100% (1)

- FB 07 STC 098 en 01 - PPD-200X30X5Document2 pagesFB 07 STC 098 en 01 - PPD-200X30X5c_passerino6572No ratings yet

- The Behavior of AZ31 Magnesium Alloy SheDocument6 pagesThe Behavior of AZ31 Magnesium Alloy SheLidia SantanaNo ratings yet

- Properties Alupex A2 Catalog 2017Document1 pageProperties Alupex A2 Catalog 2017singhmohinderpal53No ratings yet

- Spcolumn V6.00 Computer Program For The Strength Design of Reinforced Concrete Sections All Rights ReservedDocument5 pagesSpcolumn V6.00 Computer Program For The Strength Design of Reinforced Concrete Sections All Rights ReservedKhandaker Khairul AlamNo ratings yet

- S 45 CDocument1 pageS 45 CFahmi IrmanshahNo ratings yet

- Naik 2018 IOP Conf. Ser.: Mater. Sci. Eng. 338 012039Document7 pagesNaik 2018 IOP Conf. Ser.: Mater. Sci. Eng. 338 012039muru0105No ratings yet

- Effect of Rotating Ring Inclination On Single Metal Sealing PerformanceDocument5 pagesEffect of Rotating Ring Inclination On Single Metal Sealing PerformanceerpublicationNo ratings yet

- Experimental Seismic Performance Evaluation of Bridge PiersDocument6 pagesExperimental Seismic Performance Evaluation of Bridge Piersaizaz ahmadNo ratings yet

- A21 Ex Rect eDocument1 pageA21 Ex Rect ededosimoesNo ratings yet

- SkyCiv Beam Summary Report - xJ84Dll1l0ngWWBTLe4P0EM8QNfw48R0Document7 pagesSkyCiv Beam Summary Report - xJ84Dll1l0ngWWBTLe4P0EM8QNfw48R0Bastian David Castro BastiasNo ratings yet

- Compression Characterization of High-Modulus Carbon FibersDocument15 pagesCompression Characterization of High-Modulus Carbon FibersManx. E1geNo ratings yet

- Machining Performance Enhancement of Brass C360 Alloy Using Taguchi Based Grey Relational Analysis MethodDocument10 pagesMachining Performance Enhancement of Brass C360 Alloy Using Taguchi Based Grey Relational Analysis MethodTJPRC PublicationsNo ratings yet

- Informe de Análisis de Estrés NESTLEDocument11 pagesInforme de Análisis de Estrés NESTLERafael CalleNo ratings yet

- Experiment 4 Report Sheet Group Number 3 1 (Added)Document6 pagesExperiment 4 Report Sheet Group Number 3 1 (Added)Lenard SusanoNo ratings yet

- HYBRIDJOINTSDocument12 pagesHYBRIDJOINTSJohn Robert Dizon GabrielNo ratings yet

- Bolt Depot - Bolt Grade Markings and Strength ChartDocument2 pagesBolt Depot - Bolt Grade Markings and Strength ChartSandeep SNo ratings yet

- 2024-T3 ASM Material Data Sheet PDFDocument2 pages2024-T3 ASM Material Data Sheet PDFAnonymous mq0U43UsPNo ratings yet

- NZTM Q06A G250 ZM275 Gal NZ SteelDocument1 pageNZTM Q06A G250 ZM275 Gal NZ SteelĐoàn Thế MinhNo ratings yet

- SkyCiv Beam Summary Report - QnNAa8jdrnyXqvzc2dpxdNapwURwnLnXDocument7 pagesSkyCiv Beam Summary Report - QnNAa8jdrnyXqvzc2dpxdNapwURwnLnXBastian David Castro BastiasNo ratings yet

- Aac 500, Aac 1267, Acsr 60Document5 pagesAac 500, Aac 1267, Acsr 60Rahmat IzaiziNo ratings yet

- 74948-Article Text-169595-1-10-20120319Document10 pages74948-Article Text-169595-1-10-20120319Santosh PatelNo ratings yet

- MESP 130400-01 Technical Specification For Catenary Wire Hard-Drawn Copper 37/2.5 181mmDocument7 pagesMESP 130400-01 Technical Specification For Catenary Wire Hard-Drawn Copper 37/2.5 181mm4493464No ratings yet

- Prediction and Optimization of End Milling Process Parameters of LM24 Aluminium Alloy Based MMCDocument4 pagesPrediction and Optimization of End Milling Process Parameters of LM24 Aluminium Alloy Based MMCerpublicationNo ratings yet

- Effect of Laser Beam Welding Parameters On Microstructure and Properties of Duplex Stainless SteelDocument9 pagesEffect of Laser Beam Welding Parameters On Microstructure and Properties of Duplex Stainless Steelnaresh1272No ratings yet

- Mumbai - Maharashtra Email: Sandeep@vivant - in - Mobile: 72195 61918Document1 pageMumbai - Maharashtra Email: Sandeep@vivant - in - Mobile: 72195 61918Abhinav VarmaNo ratings yet

- Modeling and Optimization of Tensile Shear Strength of Titanium:Aluminum Dissimilar Welded ComponentDocument11 pagesModeling and Optimization of Tensile Shear Strength of Titanium:Aluminum Dissimilar Welded Componentaw1228818No ratings yet

- Full Factorial DesignDocument6 pagesFull Factorial DesignterNo ratings yet

- The Influence of Welding Ampere Range To ST-40 Shear Strength With Butt JointDocument6 pagesThe Influence of Welding Ampere Range To ST-40 Shear Strength With Butt Jointgangdukuh251No ratings yet

- Test 2 Compression Test of Low Carbon Steel and Cast IronDocument10 pagesTest 2 Compression Test of Low Carbon Steel and Cast IronJakaria IslamNo ratings yet

- Ampco 8: Technical Data SheetDocument2 pagesAmpco 8: Technical Data SheetdedosimoesNo ratings yet

- Drainage Pit Slab Cover 1 - v6Document13 pagesDrainage Pit Slab Cover 1 - v6ma.shaheNo ratings yet

- Physics - 61 - Week - 5 - Exercises and Solved Problems PDFDocument2 pagesPhysics - 61 - Week - 5 - Exercises and Solved Problems PDFSebastian SmytheNo ratings yet

- Kinetics (Gjjkkkgty)Document5 pagesKinetics (Gjjkkkgty)Chrysler Kane DepnagNo ratings yet

- The Ocean CurrentsDocument10 pagesThe Ocean CurrentsAdiNo ratings yet

- Anti-Gravity Micro MachineDocument21 pagesAnti-Gravity Micro MachineSandip PingaleNo ratings yet

- Killer Python Science Experiment TemplateDocument3 pagesKiller Python Science Experiment TemplateRob MilneNo ratings yet

- Dynamic Analysis of Loads and Stresses in Connecting RodsDocument10 pagesDynamic Analysis of Loads and Stresses in Connecting RodsJuan Pablo Cano MejiaNo ratings yet

- Suggested Fabrication Procedures For 20Cb-3® (Alloy 20) Stainless UNS N08020 PDFDocument55 pagesSuggested Fabrication Procedures For 20Cb-3® (Alloy 20) Stainless UNS N08020 PDFWhoNo ratings yet

- Optical Cavity Resonator PDFDocument4 pagesOptical Cavity Resonator PDFIjaz TalibNo ratings yet

- Experimental and Numerical Investigations On Seismic Responses of Reinforced Concrete Structures Considering Strain Rate EffectDocument15 pagesExperimental and Numerical Investigations On Seismic Responses of Reinforced Concrete Structures Considering Strain Rate EffectIon SococolNo ratings yet

- Latj 201190020Document4 pagesLatj 201190020Siddharth JhambNo ratings yet

- RefractionDocument15 pagesRefractionSudharsan Gupta Sudhir100% (1)

- Applied Physics On Spectros PDFDocument71 pagesApplied Physics On Spectros PDFKaskus FourusNo ratings yet

- L2 - TECCO Techdoc-Summary 2020 screen-ENDocument36 pagesL2 - TECCO Techdoc-Summary 2020 screen-ENRodrigo MorgadoNo ratings yet

- Bending Vs BucklingDocument8 pagesBending Vs BucklingPacha Khan KhogyaniNo ratings yet

- متابعة صيانة التكييف المركزيDocument52 pagesمتابعة صيانة التكييف المركزيRomou Alsaaq100% (1)

- Bio Lab Report 1Document2 pagesBio Lab Report 1fatin sofeaNo ratings yet

- Fag Deep Groove Ball BearingsDocument12 pagesFag Deep Groove Ball BearingsmkhotmaleNo ratings yet

- (IND) Eutech Plus Series FamilyDocument12 pages(IND) Eutech Plus Series FamilyIntan NevianitaNo ratings yet

- Powder DiffractionDocument9 pagesPowder DiffractionGary TrumpNo ratings yet

- 410 Types PDFDocument18 pages410 Types PDFGökhan ÇiçekNo ratings yet

- Metkon Mobiprep PDFDocument4 pagesMetkon Mobiprep PDFRepresentaciones y Distribuciones FALNo ratings yet

- Refraction of Light at Curved SurfacesDocument28 pagesRefraction of Light at Curved SurfacesAshutosh GourNo ratings yet

- LAB NO 4... Balistic PendulumDocument11 pagesLAB NO 4... Balistic PendulumShayan AliNo ratings yet

- HVAC Characteristics of Air TranscriptDocument20 pagesHVAC Characteristics of Air TranscriptEmad Mohamed Sofy AminNo ratings yet

- Thermodynamics of Portland Cement Clinkering: Theodore Hanein, Fredrik P. Glasser, Marcus BannermanDocument9 pagesThermodynamics of Portland Cement Clinkering: Theodore Hanein, Fredrik P. Glasser, Marcus BannermanBenNo ratings yet

- Tugas Metrologi IndustriDocument7 pagesTugas Metrologi IndustriMegi Yulistin100% (1)

- DLP For Different Types of LubricantDocument6 pagesDLP For Different Types of LubricantPADILLA MARIA.MICHAELANo ratings yet

- Combined Hardening and Softening Constitutive Model of Plasticity: Precursor To Shear Slip Line FailureDocument13 pagesCombined Hardening and Softening Constitutive Model of Plasticity: Precursor To Shear Slip Line FailureNaida AdemovicNo ratings yet

Experiment 4 Data Sheet 2 Group 5 and 6

Experiment 4 Data Sheet 2 Group 5 and 6

Uploaded by

Gabriel Ford MedinaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Experiment 4 Data Sheet 2 Group 5 and 6

Experiment 4 Data Sheet 2 Group 5 and 6

Uploaded by

Gabriel Ford MedinaCopyright:

Available Formats

Experiment 4: Mechanical Properties of Metals

Name: Date Performed: November 6, 2023

Mañana, Kimberly L.

Medina, Nica Cassandra S.

Micosa, Prince Joben M.

Morena, Windelyn G.

Olpenda, Kristine Dale P.

Frank Lloyd Irasga

Chzanne Manalo

Yanna Angelique Lorenzo

Samantha Librando

Gonzaga, John Gabriel

Course/Section: CHMO31L - B07 Date Submitted: November 11, 2023

Group No: 5 and 6 Instructor: Prof. Edgar Magas

REPORT SHEET

Experiment 4

MECHANICAL PROPERTIES OF METALS

RESULTS AND INTERPRETATIONS

A. Dimensions of the test specimens.

Initial dimensions (mm) Final dimensions (mm)

Material

Trial 1 Trial 2 Trial 3 Trial 1 Trial 2 Trial 3

Steel

L 224 mm - - 236 mm - -

A 31.67 - - 7.07 - -

mm2 mm2

d 6.35 mm - 3 mm - -

Copper

L 208.5 - - 218.5 - -

mm mm

A 31.17 - - 6.16 - -

mm2 mm2

d 6.3 mm - - 2.8 mm - -

Aluminum

L 217 mm - - 232 mm - -

CHM031L. Chemistry for Engineers Laboratory Page 4-1

No part of this laboratory manual may be reproduced without the written permission of the College of Arts and

Science, Malayan Colleges Laguna.

Experiment 4: Mechanical Properties of Metals

A 29.22 - - 7.07 - -

mm2 mm2

d 6.1 mm - - 3 mm - -

*d = diameter; L = length; A = area

STEEL

CHM031L. Chemistry for Engineers Laboratory Page 4-2

No part of this laboratory manual may be reproduced without the written permission of the College of Arts and

Science, Malayan Colleges Laguna.

Experiment 4: Mechanical Properties of Metals

COPPER

ALUMINUM

CHM031L. Chemistry for Engineers Laboratory Page 4-3

No part of this laboratory manual may be reproduced without the written permission of the College of Arts and

Science, Malayan Colleges Laguna.

Experiment 4: Mechanical Properties of Metals

1. Plot the stress versus strain. Make sure to attach the graphs in your laboratory report. Use

this plot to determine the (a) proportional limit stress, (b) elastic limit stress, (c) upper yield

stress and lower yield stress, (d) ultimate stress, and (e) fracture stress. Make sure to label

the plot properly with these points. In the case that the upper and lower yield stresses are

not well-defined, plot the 0.2% offset line on the graph so that 0.2% offset yield stress can be

determined.

C. Summary of the observations on tested specimens at various loads.

Upper Lower 0.2%

Elastic Ultimate Fracture

Proportional Yield Yield Offset

Material Limit Stress Stress

Limit (MPa) Point Point Yield

(MPa) (MPa) (MPa)

(MPa) (MPa) (MPa

Steel 246 347 NA NA 509 531 305

CHM031L. Chemistry for Engineers Laboratory Page 4-4

No part of this laboratory manual may be reproduced without the written permission of the College of Arts and

Science, Malayan Colleges Laguna.

Experiment 4: Mechanical Properties of Metals

Upper Lower 0.2%

Elastic Ultimate Fracture

Proportional Yield Yield Offset

Material Limit Stress Stress

Limit (MPa) Point Point Yield

(MPa) (MPa) (MPa)

(MPa) (MPa) (MPa

Copper 115 287 NA NA 269 314 174

CHM031L. Chemistry for Engineers Laboratory Page 4-5

No part of this laboratory manual may be reproduced without the written permission of the College of Arts and

Science, Malayan Colleges Laguna.

Experiment 4: Mechanical Properties of Metals

Upper Lower 0.2%

Elastic Ultimate Fracture

Proportional Yield Yield Offset

Material Limit Stress Stress

Limit (MPa) Point Point Yield

(MPa) (MPa) (MPa)

(MPa) (MPa) (MPa

Aluminum 46 96 NA NA 149 183 93

CHM031L. Chemistry for Engineers Laboratory Page 4-6

No part of this laboratory manual may be reproduced without the written permission of the College of Arts and

Science, Malayan Colleges Laguna.

Experiment 4: Mechanical Properties of Metals

2. Calculate the nominal fracture stress, actual fracture stress, % reduction in area, %

eleongation, ductility, and modulus of elasticity (slope of the graph on the limit of

proportionality).

D. Properties of tested specimens obtained from stress-strain graph.

Nominal Fracture Actual Fracture % Reduction

Material % Elongation Ductility

Stress (MPa) Stress (MPa) in Area

Steel 305 MPa 1366.24 MPa 77.68% 5.36% 3.5

Copper 174 MPa 789.37 MPa 80.24% 4.80% 0.14

Aluminum 93 MPa 384.36 MPa 75.80% 6.91% 8.4

E. Comparison of the literature and experimental values.

Modulus of Elasticity Yield Stress Ultimate Stress

Material Value

(MPa) (MPa) (MPa)

Literature 200000 MPa 250 MPa 400 MPa

Steel Observed 82000 MPa 509 MPa 531 MPa

% Error -59% 103.6% 32.75%

Literature 117000 MPa 70 MPa 220 MPa

Copper Observed 57500 MPa 269 MPa 314 MPa

% Error -50.85% 284.29% 42.73%

Literature 69000 MPa 95 MPa 110 MPa

Aluminum Observed 46000 MPa 149 MPa 183 MPa

% Error -33.33% 56.84% 66.36%

Note: Make sure to specify the reference for the literature values of modulus of elasticity, yield

stress, and ultimate stress.

Compare the experimental values with the literature values. Specify the factors causing the

difference in the values, if there is.

- The data presented above demonstrates the variation in modulus elasticity, with the literature

values for each of the three materials being higher than the experimental values. The various

forms of atomic bonding that these kinds of materials have directly correlated with differences

CHM031L. Chemistry for Engineers Laboratory Page 4-7

No part of this laboratory manual may be reproduced without the written permission of the College of Arts and

Science, Malayan Colleges Laguna.

Experiment 4: Mechanical Properties of Metals

in modulus values amongst metals. However, the three materials' observed data sets' yield stress

and ultimate stress were higher than the values found in previous studies. Numerous approaches

have been put forth to calculate the yield stress; nevertheless, it has been shown that, depending

on the technique and sample handling, differences of more than one order of magnitude may

occur

Calculation (show all solutions):

Area, reduction, and elongation:

CHM031L. Chemistry for Engineers Laboratory Page 4-8

No part of this laboratory manual may be reproduced without the written permission of the College of Arts and

Science, Malayan Colleges Laguna.

Experiment 4: Mechanical Properties of Metals

Nominal fracture Stress and Actual Fracture Stress:

CHM031L. Chemistry for Engineers Laboratory Page 4-9

No part of this laboratory manual may be reproduced without the written permission of the College of Arts and

Science, Malayan Colleges Laguna.

Experiment 4: Mechanical Properties of Metals

CHM031L. Chemistry for Engineers Laboratory Page 4-10

No part of this laboratory manual may be reproduced without the written permission of the College of Arts and

Science, Malayan Colleges Laguna.

Experiment 4: Mechanical Properties of Metals

Ductility:

CHM031L. Chemistry for Engineers Laboratory Page 4-11

No part of this laboratory manual may be reproduced without the written permission of the College of Arts and

Science, Malayan Colleges Laguna.

Experiment 4: Mechanical Properties of Metals

Modulus of Elasticity:

Yield Stress:

CHM031L. Chemistry for Engineers Laboratory Page 4-12

No part of this laboratory manual may be reproduced without the written permission of the College of Arts and

Science, Malayan Colleges Laguna.

Experiment 4: Mechanical Properties of Metals

Ultimate stress:

CHM031L. Chemistry for Engineers Laboratory Page 4-13

No part of this laboratory manual may be reproduced without the written permission of the College of Arts and

Science, Malayan Colleges Laguna.

Experiment 4: Mechanical Properties of Metals

POST-LABORATORY QUESTIONS

1. Compare the mechanical properties of the materials tested. Briefly discuss the reason

behind the observations.

- The materials used in the experiment exhibit the same results since they are all

subjected to tensile strength. Even so, the force needed in order for them to achieve

elasticity and plasticity are different as we see in the data gathered in the experiment.

2. Which among the tested materials is the stiffest? Briefly explain.

- Based on the results of the experimentation, we can say that among the materials used

in the experiment, steel rod is the stiffest since more force is required to break it in

comparison to other materials (copper and aluminum).

3. Differentiate between yield point and yield strength on a stress-strain curve. Which gives

the more accurate indication of a material`s fitness for a particular tensile application?

- The yield point is the point at which a material changes from being elastic to becoming

plastic. The yield strength is the amount of stress at which the plastic phase ends, and the

elastic phase begins. The maximal extent of elastic behavior is represented by the

constant known as yield strength. In conclusion yield strength provides a more precise

indication of a material's suitability for a given tensile application because it indicates the

precise stress the material can withstand, allowing the selection of the right tensile

application.

CHM031L. Chemistry for Engineers Laboratory Page 4-14

No part of this laboratory manual may be reproduced without the written permission of the College of Arts and

Science, Malayan Colleges Laguna.

Experiment 4: Mechanical Properties of Metals

4. Distinguish between the proportional limit and the elastic limit for each material. Which

is the more important indicator of a material’s mechanical behaviour.

- Based on the material list the elastic limit is the point at which a material first begins to

deform permanently, while the proportional limit is the point of which a material’s

deformation becomes non-linear. The elastic limit is a more important indicator of a

material's mechanical behavior because it represents the maximum stress that can be

applied without causing permanent deformation.

5. Differentiate brittle and ductile materials in terms of degree of plastic deformation.

- brittle materials are those that exhibit little or no plastic deformation before they

fracture. they usually fracture at or near their field stress. ductile materials are those that

undergo significant plastic deformation before they fracture. They usually have a large

yield stress and can be deformed under stress without fracture.

6. What is effect of temperature on yield and tensile strengths, and ductility?

- tensile and yield strengths generally increase slightly as temperatures are reduced and

decrease at a progressive rate as temperatures increase. Ductility decreases uniformly

with decreasing temperature and increases with increasing temperature.

CHM031L. Chemistry for Engineers Laboratory Page 4-15

No part of this laboratory manual may be reproduced without the written permission of the College of Arts and

Science, Malayan Colleges Laguna.

Experiment 4: Mechanical Properties of Metals

REFERENCES (cite the references that you used)

Callister, W. D. & Rethwisch, D. G. (2016). Fundamentals of materials science and engineering: An

integrated approach (5th ed.). Wiley Global Education, USA.

“Young’s Modulus, Tensile Strength and Yield Strength Values for Some Materials.”

Www.engineeringtoolbox.com, www.engineeringtoolbox.com/young-modulus-

d_417.html?fbclid=IwAR2JEtdQlGc1smLrICiqo1Yh_nnlwE2k_4HMJKJe3SWH9Pn2gdbUk0AR3So.

Accessed 11 Nov. 2023.

CHM031L. Chemistry for Engineers Laboratory Page 4-16

No part of this laboratory manual may be reproduced without the written permission of the College of Arts and

Science, Malayan Colleges Laguna.

You might also like

- Flexural Buckling ExampleDocument8 pagesFlexural Buckling ExampleDubu DubuNo ratings yet

- SNI 4658-2008-Pelek Kategori LDocument2 pagesSNI 4658-2008-Pelek Kategori LDimazNugraha100% (1)

- NDE Procedures: Authorized byDocument4 pagesNDE Procedures: Authorized byEdAlm100% (1)

- BHMH - Al Alloy - 2014 T6 Iss - 01Document4 pagesBHMH - Al Alloy - 2014 T6 Iss - 01Beni hidayatullahNo ratings yet

- Process Variable Effect On The Strength of Autoclave-Bonded Film Adhesive JointsDocument22 pagesProcess Variable Effect On The Strength of Autoclave-Bonded Film Adhesive Joints呆猫DemooNo ratings yet

- Projek Sarjana Muda 1 (SMJ 4912) 10 MAY 2009: Universiti Technology Malaysia Faculti Kejuruteraan MekanikalDocument24 pagesProjek Sarjana Muda 1 (SMJ 4912) 10 MAY 2009: Universiti Technology Malaysia Faculti Kejuruteraan MekanikalKamarul NizamNo ratings yet

- Analysis of Metallurgical Properties of Al-Sio2 Composite MaterialDocument7 pagesAnalysis of Metallurgical Properties of Al-Sio2 Composite MaterialPandu SetiawanNo ratings yet

- Aluminum 7005-T6, 7005-T63, and 7005-T6351Document3 pagesAluminum 7005-T6, 7005-T63, and 7005-T6351Dule JovanovicNo ratings yet

- E16 8 2Document4 pagesE16 8 2Branko FerenčakNo ratings yet

- International Journal of Research Publication and ReviewsDocument7 pagesInternational Journal of Research Publication and ReviewsBasavaraj G LNo ratings yet

- 6061 T6 MaterialDocument2 pages6061 T6 Materialtravis8zimmermannNo ratings yet

- 2021-2022 - Example Exam Aircraft Structures 2 - New Setup of ExamDocument10 pages2021-2022 - Example Exam Aircraft Structures 2 - New Setup of ExamLeonardo Elez DraganNo ratings yet

- Plastic Deformation in Tensile Testing: Renewable Energy Equipment DesignDocument17 pagesPlastic Deformation in Tensile Testing: Renewable Energy Equipment DesignNoman AhmedNo ratings yet

- AluminiumHE15 PropertiesDocument3 pagesAluminiumHE15 PropertiesPrashanthNo ratings yet

- Metal Tek ScrewDocument2 pagesMetal Tek ScrewAmin SalahNo ratings yet

- BF02323554Document7 pagesBF02323554Fernando CruzNo ratings yet

- Main Tunnel First CheckDocument9 pagesMain Tunnel First CheckDara HajebiNo ratings yet

- Welding ProcesssDocument9 pagesWelding ProcesssPANKAJ SINGH NEGINo ratings yet

- 1 s2.0 S2214785318301767 MainDocument8 pages1 s2.0 S2214785318301767 MainJames CarterNo ratings yet

- 1792 Effect of Antimony Addition Relative To Microstructure and Mechanical Properties of Continous Cast Lead AlloyDocument7 pages1792 Effect of Antimony Addition Relative To Microstructure and Mechanical Properties of Continous Cast Lead Alloynaeem akramNo ratings yet

- Assignment 4 Vasilii BogdanDocument9 pagesAssignment 4 Vasilii BogdanRenzil ColacoNo ratings yet

- 13IJMPERDJUN201913Document6 pages13IJMPERDJUN201913TJPRC PublicationsNo ratings yet

- Analysis of Die Angle in Deep Drawing Process Using FEMDocument5 pagesAnalysis of Die Angle in Deep Drawing Process Using FEMEduardoNo ratings yet

- Test Data Sheet: Date of Sampling Date of TestingDocument5 pagesTest Data Sheet: Date of Sampling Date of TestingChandan MondalNo ratings yet

- Ampco 45: Technical Data SheetDocument2 pagesAmpco 45: Technical Data Sheetmarceloalves.dsNo ratings yet

- Stress Analysis of Multi-Layered Hybrid Composite Pipes Subjected To Internal PressureDocument13 pagesStress Analysis of Multi-Layered Hybrid Composite Pipes Subjected To Internal PressureAFZAL M BAKSHINo ratings yet

- Comparison in Deformation and Fracture Behavior of Magnesium During Equal Channel Angular Pressing by Experimental and Numerical MethodsDocument4 pagesComparison in Deformation and Fracture Behavior of Magnesium During Equal Channel Angular Pressing by Experimental and Numerical Methodskamel touilebNo ratings yet

- Optimization of Process Parameters of Friction Stir Welding of Aa 6082-T6 Using Grey Based Taguchi MethodDocument8 pagesOptimization of Process Parameters of Friction Stir Welding of Aa 6082-T6 Using Grey Based Taguchi MethodTJPRC PublicationsNo ratings yet

- Aluminum 7175 T736Document3 pagesAluminum 7175 T736TylerLALA100% (1)

- FB 07 STC 098 en 01 - PPD-200X30X5Document2 pagesFB 07 STC 098 en 01 - PPD-200X30X5c_passerino6572No ratings yet

- The Behavior of AZ31 Magnesium Alloy SheDocument6 pagesThe Behavior of AZ31 Magnesium Alloy SheLidia SantanaNo ratings yet

- Properties Alupex A2 Catalog 2017Document1 pageProperties Alupex A2 Catalog 2017singhmohinderpal53No ratings yet

- Spcolumn V6.00 Computer Program For The Strength Design of Reinforced Concrete Sections All Rights ReservedDocument5 pagesSpcolumn V6.00 Computer Program For The Strength Design of Reinforced Concrete Sections All Rights ReservedKhandaker Khairul AlamNo ratings yet

- S 45 CDocument1 pageS 45 CFahmi IrmanshahNo ratings yet

- Naik 2018 IOP Conf. Ser.: Mater. Sci. Eng. 338 012039Document7 pagesNaik 2018 IOP Conf. Ser.: Mater. Sci. Eng. 338 012039muru0105No ratings yet

- Effect of Rotating Ring Inclination On Single Metal Sealing PerformanceDocument5 pagesEffect of Rotating Ring Inclination On Single Metal Sealing PerformanceerpublicationNo ratings yet

- Experimental Seismic Performance Evaluation of Bridge PiersDocument6 pagesExperimental Seismic Performance Evaluation of Bridge Piersaizaz ahmadNo ratings yet

- A21 Ex Rect eDocument1 pageA21 Ex Rect ededosimoesNo ratings yet

- SkyCiv Beam Summary Report - xJ84Dll1l0ngWWBTLe4P0EM8QNfw48R0Document7 pagesSkyCiv Beam Summary Report - xJ84Dll1l0ngWWBTLe4P0EM8QNfw48R0Bastian David Castro BastiasNo ratings yet

- Compression Characterization of High-Modulus Carbon FibersDocument15 pagesCompression Characterization of High-Modulus Carbon FibersManx. E1geNo ratings yet

- Machining Performance Enhancement of Brass C360 Alloy Using Taguchi Based Grey Relational Analysis MethodDocument10 pagesMachining Performance Enhancement of Brass C360 Alloy Using Taguchi Based Grey Relational Analysis MethodTJPRC PublicationsNo ratings yet

- Informe de Análisis de Estrés NESTLEDocument11 pagesInforme de Análisis de Estrés NESTLERafael CalleNo ratings yet

- Experiment 4 Report Sheet Group Number 3 1 (Added)Document6 pagesExperiment 4 Report Sheet Group Number 3 1 (Added)Lenard SusanoNo ratings yet

- HYBRIDJOINTSDocument12 pagesHYBRIDJOINTSJohn Robert Dizon GabrielNo ratings yet

- Bolt Depot - Bolt Grade Markings and Strength ChartDocument2 pagesBolt Depot - Bolt Grade Markings and Strength ChartSandeep SNo ratings yet

- 2024-T3 ASM Material Data Sheet PDFDocument2 pages2024-T3 ASM Material Data Sheet PDFAnonymous mq0U43UsPNo ratings yet

- NZTM Q06A G250 ZM275 Gal NZ SteelDocument1 pageNZTM Q06A G250 ZM275 Gal NZ SteelĐoàn Thế MinhNo ratings yet

- SkyCiv Beam Summary Report - QnNAa8jdrnyXqvzc2dpxdNapwURwnLnXDocument7 pagesSkyCiv Beam Summary Report - QnNAa8jdrnyXqvzc2dpxdNapwURwnLnXBastian David Castro BastiasNo ratings yet

- Aac 500, Aac 1267, Acsr 60Document5 pagesAac 500, Aac 1267, Acsr 60Rahmat IzaiziNo ratings yet

- 74948-Article Text-169595-1-10-20120319Document10 pages74948-Article Text-169595-1-10-20120319Santosh PatelNo ratings yet

- MESP 130400-01 Technical Specification For Catenary Wire Hard-Drawn Copper 37/2.5 181mmDocument7 pagesMESP 130400-01 Technical Specification For Catenary Wire Hard-Drawn Copper 37/2.5 181mm4493464No ratings yet

- Prediction and Optimization of End Milling Process Parameters of LM24 Aluminium Alloy Based MMCDocument4 pagesPrediction and Optimization of End Milling Process Parameters of LM24 Aluminium Alloy Based MMCerpublicationNo ratings yet

- Effect of Laser Beam Welding Parameters On Microstructure and Properties of Duplex Stainless SteelDocument9 pagesEffect of Laser Beam Welding Parameters On Microstructure and Properties of Duplex Stainless Steelnaresh1272No ratings yet

- Mumbai - Maharashtra Email: Sandeep@vivant - in - Mobile: 72195 61918Document1 pageMumbai - Maharashtra Email: Sandeep@vivant - in - Mobile: 72195 61918Abhinav VarmaNo ratings yet

- Modeling and Optimization of Tensile Shear Strength of Titanium:Aluminum Dissimilar Welded ComponentDocument11 pagesModeling and Optimization of Tensile Shear Strength of Titanium:Aluminum Dissimilar Welded Componentaw1228818No ratings yet

- Full Factorial DesignDocument6 pagesFull Factorial DesignterNo ratings yet

- The Influence of Welding Ampere Range To ST-40 Shear Strength With Butt JointDocument6 pagesThe Influence of Welding Ampere Range To ST-40 Shear Strength With Butt Jointgangdukuh251No ratings yet

- Test 2 Compression Test of Low Carbon Steel and Cast IronDocument10 pagesTest 2 Compression Test of Low Carbon Steel and Cast IronJakaria IslamNo ratings yet

- Ampco 8: Technical Data SheetDocument2 pagesAmpco 8: Technical Data SheetdedosimoesNo ratings yet

- Drainage Pit Slab Cover 1 - v6Document13 pagesDrainage Pit Slab Cover 1 - v6ma.shaheNo ratings yet

- Physics - 61 - Week - 5 - Exercises and Solved Problems PDFDocument2 pagesPhysics - 61 - Week - 5 - Exercises and Solved Problems PDFSebastian SmytheNo ratings yet

- Kinetics (Gjjkkkgty)Document5 pagesKinetics (Gjjkkkgty)Chrysler Kane DepnagNo ratings yet

- The Ocean CurrentsDocument10 pagesThe Ocean CurrentsAdiNo ratings yet

- Anti-Gravity Micro MachineDocument21 pagesAnti-Gravity Micro MachineSandip PingaleNo ratings yet

- Killer Python Science Experiment TemplateDocument3 pagesKiller Python Science Experiment TemplateRob MilneNo ratings yet

- Dynamic Analysis of Loads and Stresses in Connecting RodsDocument10 pagesDynamic Analysis of Loads and Stresses in Connecting RodsJuan Pablo Cano MejiaNo ratings yet

- Suggested Fabrication Procedures For 20Cb-3® (Alloy 20) Stainless UNS N08020 PDFDocument55 pagesSuggested Fabrication Procedures For 20Cb-3® (Alloy 20) Stainless UNS N08020 PDFWhoNo ratings yet

- Optical Cavity Resonator PDFDocument4 pagesOptical Cavity Resonator PDFIjaz TalibNo ratings yet

- Experimental and Numerical Investigations On Seismic Responses of Reinforced Concrete Structures Considering Strain Rate EffectDocument15 pagesExperimental and Numerical Investigations On Seismic Responses of Reinforced Concrete Structures Considering Strain Rate EffectIon SococolNo ratings yet

- Latj 201190020Document4 pagesLatj 201190020Siddharth JhambNo ratings yet

- RefractionDocument15 pagesRefractionSudharsan Gupta Sudhir100% (1)

- Applied Physics On Spectros PDFDocument71 pagesApplied Physics On Spectros PDFKaskus FourusNo ratings yet

- L2 - TECCO Techdoc-Summary 2020 screen-ENDocument36 pagesL2 - TECCO Techdoc-Summary 2020 screen-ENRodrigo MorgadoNo ratings yet

- Bending Vs BucklingDocument8 pagesBending Vs BucklingPacha Khan KhogyaniNo ratings yet

- متابعة صيانة التكييف المركزيDocument52 pagesمتابعة صيانة التكييف المركزيRomou Alsaaq100% (1)

- Bio Lab Report 1Document2 pagesBio Lab Report 1fatin sofeaNo ratings yet

- Fag Deep Groove Ball BearingsDocument12 pagesFag Deep Groove Ball BearingsmkhotmaleNo ratings yet

- (IND) Eutech Plus Series FamilyDocument12 pages(IND) Eutech Plus Series FamilyIntan NevianitaNo ratings yet

- Powder DiffractionDocument9 pagesPowder DiffractionGary TrumpNo ratings yet

- 410 Types PDFDocument18 pages410 Types PDFGökhan ÇiçekNo ratings yet

- Metkon Mobiprep PDFDocument4 pagesMetkon Mobiprep PDFRepresentaciones y Distribuciones FALNo ratings yet

- Refraction of Light at Curved SurfacesDocument28 pagesRefraction of Light at Curved SurfacesAshutosh GourNo ratings yet

- LAB NO 4... Balistic PendulumDocument11 pagesLAB NO 4... Balistic PendulumShayan AliNo ratings yet

- HVAC Characteristics of Air TranscriptDocument20 pagesHVAC Characteristics of Air TranscriptEmad Mohamed Sofy AminNo ratings yet

- Thermodynamics of Portland Cement Clinkering: Theodore Hanein, Fredrik P. Glasser, Marcus BannermanDocument9 pagesThermodynamics of Portland Cement Clinkering: Theodore Hanein, Fredrik P. Glasser, Marcus BannermanBenNo ratings yet

- Tugas Metrologi IndustriDocument7 pagesTugas Metrologi IndustriMegi Yulistin100% (1)

- DLP For Different Types of LubricantDocument6 pagesDLP For Different Types of LubricantPADILLA MARIA.MICHAELANo ratings yet

- Combined Hardening and Softening Constitutive Model of Plasticity: Precursor To Shear Slip Line FailureDocument13 pagesCombined Hardening and Softening Constitutive Model of Plasticity: Precursor To Shear Slip Line FailureNaida AdemovicNo ratings yet