Professional Documents

Culture Documents

Ulfide Blackening - Technical Bulletin CAN-04, 3-21-08

Ulfide Blackening - Technical Bulletin CAN-04, 3-21-08

Uploaded by

Irwan RestyoCopyright:

Available Formats

You might also like

- C. M. Hoke Refining Precious Metal Wastes Screen Readable December 2013Document384 pagesC. M. Hoke Refining Precious Metal Wastes Screen Readable December 2013Alexandru Vlad0% (1)

- Gold Recovery InstructablesDocument34 pagesGold Recovery Instructablesflorigrig0% (1)

- Answer Sheet Day2Document5 pagesAnswer Sheet Day2Marian Gaylle AntonioNo ratings yet

- Fish CanningDocument22 pagesFish Canningnehha100% (1)

- The Taming of the Screwcap: Its origins, evolution and FutureFrom EverandThe Taming of the Screwcap: Its origins, evolution and FutureNo ratings yet

- White Rust White Paper 200531Document6 pagesWhite Rust White Paper 200531mario fisgaNo ratings yet

- Antibacterial SilverDocument26 pagesAntibacterial SilverJAI SURYANo ratings yet

- Stable GlazesDocument8 pagesStable Glazesdamjan_mariničNo ratings yet

- How To Remove Gold From Plated Materials Including Electronics, Computer, Telecommunication and Other ScrapDocument5 pagesHow To Remove Gold From Plated Materials Including Electronics, Computer, Telecommunication and Other ScrapMike Meuser100% (7)

- Making A Colloidal Silver GeneratorDocument5 pagesMaking A Colloidal Silver Generatorsanyu33333No ratings yet

- BCME StressCorrosion enDocument14 pagesBCME StressCorrosion enmichael_george291616100% (1)

- A Pocket Guide To Can DefectsDocument16 pagesA Pocket Guide To Can DefectsMelissa D. BernardinoNo ratings yet

- PerfMatrix Test Report TemplateDocument23 pagesPerfMatrix Test Report TemplatemohanmotupalliNo ratings yet

- Gold Recovery Correctly - 12 StepsDocument25 pagesGold Recovery Correctly - 12 Stepsjuan9gonzalez_9No ratings yet

- Nguyên nhân gây phồng vỏ hộpDocument34 pagesNguyên nhân gây phồng vỏ hộpHồng Đinh ThịNo ratings yet

- Code of Practice For The Prevention and Reduction of Inorganic Tin Contamination in Canned FoodsDocument14 pagesCode of Practice For The Prevention and Reduction of Inorganic Tin Contamination in Canned FoodsNuc LeusNo ratings yet

- This Should Also Never Be Attempted IndoorsDocument11 pagesThis Should Also Never Be Attempted IndoorsezrentsNo ratings yet

- Antibacterial SilverDocument4 pagesAntibacterial SilverARCUSNo ratings yet

- Rust Chemistry: How Does Rust Form?Document2 pagesRust Chemistry: How Does Rust Form?Maksuda HossainNo ratings yet

- Mitigation/Reduction StrategyDocument2 pagesMitigation/Reduction StrategyShaira DaleNo ratings yet

- Step 1: SAFETY FIRST, Always.: This Should Also Never Be Attempted IndoorsDocument5 pagesStep 1: SAFETY FIRST, Always.: This Should Also Never Be Attempted IndoorskeethanNo ratings yet

- Bronze DiseaseDocument25 pagesBronze DiseaseŽeljko SlijepčevićNo ratings yet

- Wegemt 20Th Graduate School Fishing Vessel Technology: InnavesDocument36 pagesWegemt 20Th Graduate School Fishing Vessel Technology: InnavesJuan SilvaNo ratings yet

- Chemc1000v2 Manual SampleDocument9 pagesChemc1000v2 Manual Sampleankara271828No ratings yet

- Bacteriological Considerations: 1N Canning FoodDocument6 pagesBacteriological Considerations: 1N Canning FoodRuth Febrina Sondang AritonangNo ratings yet

- 5 Common Misconceptions Lyo1Document3 pages5 Common Misconceptions Lyo1Apar DholakiaNo ratings yet

- ShellDocument5 pagesShellTe Amo GuidNo ratings yet

- SDSSODALIGHTDocument5 pagesSDSSODALIGHTFátima Julieta García AguilarNo ratings yet

- It's Not A Cleaning HouseDocument6 pagesIt's Not A Cleaning HouseFIGJPNo ratings yet

- Felix Franks Freeze-Drying of Pharmaceuticals and Biopharmaceuticals Principles and Practice 2007 PDFDocument211 pagesFelix Franks Freeze-Drying of Pharmaceuticals and Biopharmaceuticals Principles and Practice 2007 PDFAudrey Novita ArijantoNo ratings yet

- Ritar Msds Gel PDFDocument8 pagesRitar Msds Gel PDFHanks EpphNo ratings yet

- Spore StainDocument3 pagesSpore StainShaezarah MohamudallyNo ratings yet

- Wet Storage Staining On Galvanized Steel 4 2 2013Document5 pagesWet Storage Staining On Galvanized Steel 4 2 2013Calvin TehNo ratings yet

- Tin CanDocument6 pagesTin CanJohn Robert GonzalesNo ratings yet

- University of Santo Tomas College of Education Department of Food Technology AY 2020-2021 FT7410L Food Processing LaboratoryDocument20 pagesUniversity of Santo Tomas College of Education Department of Food Technology AY 2020-2021 FT7410L Food Processing LaboratoryMARIELLA CZES FAJARDONo ratings yet

- 20tips Purchasing Bio ReactorDocument8 pages20tips Purchasing Bio Reactorglq223No ratings yet

- Forensics Lab 8.2 - Revealing Latent Fingerprints Using Iodine Fuming - Make - DIY Projects and Ideas For MakersDocument6 pagesForensics Lab 8.2 - Revealing Latent Fingerprints Using Iodine Fuming - Make - DIY Projects and Ideas For MakersPortia HermosaNo ratings yet

- Paper 10 - Catalyst CatastrophesDocument16 pagesPaper 10 - Catalyst CatastrophesArsalan QadirNo ratings yet

- Solvent Extraction of Iodine From SeaweedDocument3 pagesSolvent Extraction of Iodine From SeaweedKeiran GarraghanNo ratings yet

- Practical 2 - Sulphate Analysis - 2018Document6 pagesPractical 2 - Sulphate Analysis - 2018Abbie ZiyechNo ratings yet

- The Teacher's Guide: To The Corrosion ToolkitDocument42 pagesThe Teacher's Guide: To The Corrosion ToolkitCiceroNo ratings yet

- Ceramic Assignment - EdrineDocument8 pagesCeramic Assignment - EdrineL edrineNo ratings yet

- Some Think Coolants or Other Contamination Do Not Harm The Quenchant. This Perception Couldn't Be Farther From The TruthDocument2 pagesSome Think Coolants or Other Contamination Do Not Harm The Quenchant. This Perception Couldn't Be Farther From The TruthAlex SandroNo ratings yet

- MSDS AgNO3Document2 pagesMSDS AgNO3rizqi wulandariNo ratings yet

- Food Cans Manufacturing: Food Packaging FST-4041 BS-final YearDocument22 pagesFood Cans Manufacturing: Food Packaging FST-4041 BS-final YearSONIA NABINo ratings yet

- MSDS Magnesium Chloride Hexahydrate FlakesDocument6 pagesMSDS Magnesium Chloride Hexahydrate FlakesRodrigo Ramos100% (1)

- ICI SAFETY NEWSLETTER No 59 PDFDocument5 pagesICI SAFETY NEWSLETTER No 59 PDFИванов ИванNo ratings yet

- Pharmaceutical Packaging TechnologyDocument9 pagesPharmaceutical Packaging TechnologyEditor IJTSRDNo ratings yet

- Term Paper FinalDocument4 pagesTerm Paper FinalPhilipNo ratings yet

- Lna Msds Quicklime 2012-3Document5 pagesLna Msds Quicklime 2012-31No ratings yet

- English of Miss LelyDocument15 pagesEnglish of Miss LelyshomaniaNo ratings yet

- 2 - Storage Guidelines For Prepainted Metal - FinalDocument12 pages2 - Storage Guidelines For Prepainted Metal - FinaljariasvazquezNo ratings yet

- Health WarningDocument6 pagesHealth WarningkeethanNo ratings yet

- Kill JarsDocument2 pagesKill JarsakosijemueldilayNo ratings yet

- Cautionary Tale 02 Hydrogen Embrittlement PDFDocument2 pagesCautionary Tale 02 Hydrogen Embrittlement PDFstevemwilliamsNo ratings yet

- Cleaning Red PhosphorousDocument5 pagesCleaning Red PhosphorousLood Totalno50% (2)

- U.S. Army Improvised Munitions HandbookFrom EverandU.S. Army Improvised Munitions HandbookRating: 3 out of 5 stars3/5 (4)

- Laboratory Manual of Glass-BlowingFrom EverandLaboratory Manual of Glass-BlowingRating: 5 out of 5 stars5/5 (1)

- Section Cutting and Staining: A practical introduction to histological methods for students and practitionersFrom EverandSection Cutting and Staining: A practical introduction to histological methods for students and practitionersNo ratings yet

- Instruction Manual For DODGE Para-Flex High Speed and Flywheel CouplingsDocument2 pagesInstruction Manual For DODGE Para-Flex High Speed and Flywheel CouplingsJonNo ratings yet

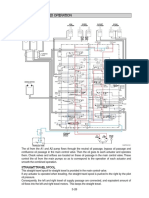

- DC ChopperDocument63 pagesDC ChopperMalyaj SrivastavaNo ratings yet

- MalconSunscreen BrochureDocument2 pagesMalconSunscreen Brochuremosaic09No ratings yet

- Slapdriver Interference Screwdriver SystemDocument8 pagesSlapdriver Interference Screwdriver SystemFreddy Churata SuriNo ratings yet

- CE6015 Tall BuildingsDocument13 pagesCE6015 Tall BuildingsShan Cv0% (1)

- Design of Vertical Lift Service Gates Salarond Barrage: 1.0 Technical DetailsDocument23 pagesDesign of Vertical Lift Service Gates Salarond Barrage: 1.0 Technical DetailsRanjeet Singh MoreyNo ratings yet

- Liquid Cargo HandlingDocument4 pagesLiquid Cargo HandlingMartin ZagarNo ratings yet

- Auto Reclosing SchemeDocument3 pagesAuto Reclosing SchemeShah Aizat Razali100% (1)

- Rotulas IKODocument8 pagesRotulas IKOAgustín TorresNo ratings yet

- Importance of Highway EngineeringDocument1 pageImportance of Highway EngineeringPrincess Gupo TañasNo ratings yet

- Group 5 Combined Operation: 1. OutlineDocument9 pagesGroup 5 Combined Operation: 1. OutlineالمهندسوليدالطويلNo ratings yet

- DMM-III Assignment TestDocument2 pagesDMM-III Assignment TestSaibabu SoloNo ratings yet

- Method Statement - DuctingDocument8 pagesMethod Statement - Ductingkptl6185No ratings yet

- Norsok M101 Rev.5 2011Document62 pagesNorsok M101 Rev.5 2011Elzo2000No ratings yet

- Modern Atomic TheoryDocument28 pagesModern Atomic TheorySai TendoNo ratings yet

- UFO - technology ХАКЕРСКИЙ МАНУАЛDocument419 pagesUFO - technology ХАКЕРСКИЙ МАНУАЛBogdan Litvinov100% (1)

- Arm MmuDocument56 pagesArm MmuSuhas Rohit PaiNo ratings yet

- McDougal Space v2Document20 pagesMcDougal Space v2FSpace PublicationsNo ratings yet

- TallBuilding BrochureDocument6 pagesTallBuilding BrochureSonny AndalisNo ratings yet

- Boiler Shutdown ActivitiesDocument13 pagesBoiler Shutdown ActivitiesMohammad salmanNo ratings yet

- AMS 2368 C-2012 - Eng.Document6 pagesAMS 2368 C-2012 - Eng.TetianaNo ratings yet

- Gaa 24350 Aw11 Ii PDFDocument22 pagesGaa 24350 Aw11 Ii PDFEvgeniy100% (1)

- Chapter 5 The Preliminary MethodDocument31 pagesChapter 5 The Preliminary MethodF1013 ShamimiNo ratings yet

- ACULASER - C4100 Parts CatalogDocument35 pagesACULASER - C4100 Parts CatalogMarco CatenaNo ratings yet

- Lateral Stability of Reinforced Concrete Columns Under Axial Reversed Cyclic Tension and CompressionDocument10 pagesLateral Stability of Reinforced Concrete Columns Under Axial Reversed Cyclic Tension and CompressionMirellaNo ratings yet

- Spherical Pressure VesselDocument4 pagesSpherical Pressure VesselYetkin Erdoğan0% (1)

- Sheet Metal Forming Simulation Suite: Pam-Stamp 2GDocument2 pagesSheet Metal Forming Simulation Suite: Pam-Stamp 2GKrishna VamsiNo ratings yet

- Vistapro User Guide: 6.0Document40 pagesVistapro User Guide: 6.0Pedro QuintalNo ratings yet

- Name: Poon Jun Yu ID: 00011200 Lecture Name: DR - Mustafar Bin Sudin Program:DMTDocument8 pagesName: Poon Jun Yu ID: 00011200 Lecture Name: DR - Mustafar Bin Sudin Program:DMTJash LiewNo ratings yet

Ulfide Blackening - Technical Bulletin CAN-04, 3-21-08

Ulfide Blackening - Technical Bulletin CAN-04, 3-21-08

Uploaded by

Irwan RestyoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ulfide Blackening - Technical Bulletin CAN-04, 3-21-08

Ulfide Blackening - Technical Bulletin CAN-04, 3-21-08

Uploaded by

Irwan RestyoCopyright:

Available Formats

1600 South Jackson Street

Seattle, Washington 98144

Phone 206-323-3540

Fax 206-323-3543 SETTING THE STANDARD IN SEAFOOD SAFETY

SULFIDE BLACKENING

Technical Bulletin CAN-04

Occasionally, an unsightly black deposit forms in canned seafoods, usually on the headspace surfaces

or along the side seam of the can interior. This discoloration is often referred to as iron sulfide

blackening. This term is a misnomer in that the deposit actually consists of a complex mixture of iron

compounds: oxides, hydroxides, carbonates and sulfides.

While no simple explanation of the phenomena is possible, a number of conditions may contribute to

the problem. These include:

1. Condition of can interior. If the code is too deeply embossed, damage to tinplate may occur.

New code dies, with their sharper edges, present a particular problem. Use them carefully. Don't mix

old and new dies.

Scratches on the can interior are a focal point for sulfide blackening. Store tin so that damage does not

take place.

2. Cooling after retorting. While it may get somewhat worse on long storage, our experience

has been that most sulfide blackening develops during the retorting and post retort cooling steps.

Retorting times and temperatures cannot be shortened or lowered, but post retort cooling can be

speeded up.

Efficient cooling of the canned product, post retort, reduces the chances of sulfide blackening

discoloration and also of product scorching.

3. Vacuum and headspace. Sulfide blackening is mostly a headspace phenomenon, with iron-

oxygen reactions playing an important part. The goal is to eliminate as much oxygen from the can as

possible by reducing the volume of the headspace and by pulling as high a vacuum as practical.

4. Delays during production. After butchering, the various canning steps should be completed

as quickly as possible. Our experience has been that the fresher the raw product the fewer the

problems. Delays may alter headspace gas composition, product pH, color, appearance, etc. and these

may contribute to the formation of sulfide blackening.

The technical representatives of your can supplier have had extensive experience with corrosion

problems. They should be consulted on the types of can and procedures necessary to provide adequate

protection.

Sulfide blackening discoloration does not, by itself, present a health hazard to the consumer.

Consumers, however, do not know this fact, nor can they be expected to know it. When they see black

stains in a can, they are concerned. The fact that this condition is harmless does not decrease the

importance of attempting to prevent this problem.

Revision Date: 3-21-08

Supersedes: SPA Tech. Bulletin No. 18, 1-23-08

www.spa-food.org

You might also like

- C. M. Hoke Refining Precious Metal Wastes Screen Readable December 2013Document384 pagesC. M. Hoke Refining Precious Metal Wastes Screen Readable December 2013Alexandru Vlad0% (1)

- Gold Recovery InstructablesDocument34 pagesGold Recovery Instructablesflorigrig0% (1)

- Answer Sheet Day2Document5 pagesAnswer Sheet Day2Marian Gaylle AntonioNo ratings yet

- Fish CanningDocument22 pagesFish Canningnehha100% (1)

- The Taming of the Screwcap: Its origins, evolution and FutureFrom EverandThe Taming of the Screwcap: Its origins, evolution and FutureNo ratings yet

- White Rust White Paper 200531Document6 pagesWhite Rust White Paper 200531mario fisgaNo ratings yet

- Antibacterial SilverDocument26 pagesAntibacterial SilverJAI SURYANo ratings yet

- Stable GlazesDocument8 pagesStable Glazesdamjan_mariničNo ratings yet

- How To Remove Gold From Plated Materials Including Electronics, Computer, Telecommunication and Other ScrapDocument5 pagesHow To Remove Gold From Plated Materials Including Electronics, Computer, Telecommunication and Other ScrapMike Meuser100% (7)

- Making A Colloidal Silver GeneratorDocument5 pagesMaking A Colloidal Silver Generatorsanyu33333No ratings yet

- BCME StressCorrosion enDocument14 pagesBCME StressCorrosion enmichael_george291616100% (1)

- A Pocket Guide To Can DefectsDocument16 pagesA Pocket Guide To Can DefectsMelissa D. BernardinoNo ratings yet

- PerfMatrix Test Report TemplateDocument23 pagesPerfMatrix Test Report TemplatemohanmotupalliNo ratings yet

- Gold Recovery Correctly - 12 StepsDocument25 pagesGold Recovery Correctly - 12 Stepsjuan9gonzalez_9No ratings yet

- Nguyên nhân gây phồng vỏ hộpDocument34 pagesNguyên nhân gây phồng vỏ hộpHồng Đinh ThịNo ratings yet

- Code of Practice For The Prevention and Reduction of Inorganic Tin Contamination in Canned FoodsDocument14 pagesCode of Practice For The Prevention and Reduction of Inorganic Tin Contamination in Canned FoodsNuc LeusNo ratings yet

- This Should Also Never Be Attempted IndoorsDocument11 pagesThis Should Also Never Be Attempted IndoorsezrentsNo ratings yet

- Antibacterial SilverDocument4 pagesAntibacterial SilverARCUSNo ratings yet

- Rust Chemistry: How Does Rust Form?Document2 pagesRust Chemistry: How Does Rust Form?Maksuda HossainNo ratings yet

- Mitigation/Reduction StrategyDocument2 pagesMitigation/Reduction StrategyShaira DaleNo ratings yet

- Step 1: SAFETY FIRST, Always.: This Should Also Never Be Attempted IndoorsDocument5 pagesStep 1: SAFETY FIRST, Always.: This Should Also Never Be Attempted IndoorskeethanNo ratings yet

- Bronze DiseaseDocument25 pagesBronze DiseaseŽeljko SlijepčevićNo ratings yet

- Wegemt 20Th Graduate School Fishing Vessel Technology: InnavesDocument36 pagesWegemt 20Th Graduate School Fishing Vessel Technology: InnavesJuan SilvaNo ratings yet

- Chemc1000v2 Manual SampleDocument9 pagesChemc1000v2 Manual Sampleankara271828No ratings yet

- Bacteriological Considerations: 1N Canning FoodDocument6 pagesBacteriological Considerations: 1N Canning FoodRuth Febrina Sondang AritonangNo ratings yet

- 5 Common Misconceptions Lyo1Document3 pages5 Common Misconceptions Lyo1Apar DholakiaNo ratings yet

- ShellDocument5 pagesShellTe Amo GuidNo ratings yet

- SDSSODALIGHTDocument5 pagesSDSSODALIGHTFátima Julieta García AguilarNo ratings yet

- It's Not A Cleaning HouseDocument6 pagesIt's Not A Cleaning HouseFIGJPNo ratings yet

- Felix Franks Freeze-Drying of Pharmaceuticals and Biopharmaceuticals Principles and Practice 2007 PDFDocument211 pagesFelix Franks Freeze-Drying of Pharmaceuticals and Biopharmaceuticals Principles and Practice 2007 PDFAudrey Novita ArijantoNo ratings yet

- Ritar Msds Gel PDFDocument8 pagesRitar Msds Gel PDFHanks EpphNo ratings yet

- Spore StainDocument3 pagesSpore StainShaezarah MohamudallyNo ratings yet

- Wet Storage Staining On Galvanized Steel 4 2 2013Document5 pagesWet Storage Staining On Galvanized Steel 4 2 2013Calvin TehNo ratings yet

- Tin CanDocument6 pagesTin CanJohn Robert GonzalesNo ratings yet

- University of Santo Tomas College of Education Department of Food Technology AY 2020-2021 FT7410L Food Processing LaboratoryDocument20 pagesUniversity of Santo Tomas College of Education Department of Food Technology AY 2020-2021 FT7410L Food Processing LaboratoryMARIELLA CZES FAJARDONo ratings yet

- 20tips Purchasing Bio ReactorDocument8 pages20tips Purchasing Bio Reactorglq223No ratings yet

- Forensics Lab 8.2 - Revealing Latent Fingerprints Using Iodine Fuming - Make - DIY Projects and Ideas For MakersDocument6 pagesForensics Lab 8.2 - Revealing Latent Fingerprints Using Iodine Fuming - Make - DIY Projects and Ideas For MakersPortia HermosaNo ratings yet

- Paper 10 - Catalyst CatastrophesDocument16 pagesPaper 10 - Catalyst CatastrophesArsalan QadirNo ratings yet

- Solvent Extraction of Iodine From SeaweedDocument3 pagesSolvent Extraction of Iodine From SeaweedKeiran GarraghanNo ratings yet

- Practical 2 - Sulphate Analysis - 2018Document6 pagesPractical 2 - Sulphate Analysis - 2018Abbie ZiyechNo ratings yet

- The Teacher's Guide: To The Corrosion ToolkitDocument42 pagesThe Teacher's Guide: To The Corrosion ToolkitCiceroNo ratings yet

- Ceramic Assignment - EdrineDocument8 pagesCeramic Assignment - EdrineL edrineNo ratings yet

- Some Think Coolants or Other Contamination Do Not Harm The Quenchant. This Perception Couldn't Be Farther From The TruthDocument2 pagesSome Think Coolants or Other Contamination Do Not Harm The Quenchant. This Perception Couldn't Be Farther From The TruthAlex SandroNo ratings yet

- MSDS AgNO3Document2 pagesMSDS AgNO3rizqi wulandariNo ratings yet

- Food Cans Manufacturing: Food Packaging FST-4041 BS-final YearDocument22 pagesFood Cans Manufacturing: Food Packaging FST-4041 BS-final YearSONIA NABINo ratings yet

- MSDS Magnesium Chloride Hexahydrate FlakesDocument6 pagesMSDS Magnesium Chloride Hexahydrate FlakesRodrigo Ramos100% (1)

- ICI SAFETY NEWSLETTER No 59 PDFDocument5 pagesICI SAFETY NEWSLETTER No 59 PDFИванов ИванNo ratings yet

- Pharmaceutical Packaging TechnologyDocument9 pagesPharmaceutical Packaging TechnologyEditor IJTSRDNo ratings yet

- Term Paper FinalDocument4 pagesTerm Paper FinalPhilipNo ratings yet

- Lna Msds Quicklime 2012-3Document5 pagesLna Msds Quicklime 2012-31No ratings yet

- English of Miss LelyDocument15 pagesEnglish of Miss LelyshomaniaNo ratings yet

- 2 - Storage Guidelines For Prepainted Metal - FinalDocument12 pages2 - Storage Guidelines For Prepainted Metal - FinaljariasvazquezNo ratings yet

- Health WarningDocument6 pagesHealth WarningkeethanNo ratings yet

- Kill JarsDocument2 pagesKill JarsakosijemueldilayNo ratings yet

- Cautionary Tale 02 Hydrogen Embrittlement PDFDocument2 pagesCautionary Tale 02 Hydrogen Embrittlement PDFstevemwilliamsNo ratings yet

- Cleaning Red PhosphorousDocument5 pagesCleaning Red PhosphorousLood Totalno50% (2)

- U.S. Army Improvised Munitions HandbookFrom EverandU.S. Army Improvised Munitions HandbookRating: 3 out of 5 stars3/5 (4)

- Laboratory Manual of Glass-BlowingFrom EverandLaboratory Manual of Glass-BlowingRating: 5 out of 5 stars5/5 (1)

- Section Cutting and Staining: A practical introduction to histological methods for students and practitionersFrom EverandSection Cutting and Staining: A practical introduction to histological methods for students and practitionersNo ratings yet

- Instruction Manual For DODGE Para-Flex High Speed and Flywheel CouplingsDocument2 pagesInstruction Manual For DODGE Para-Flex High Speed and Flywheel CouplingsJonNo ratings yet

- DC ChopperDocument63 pagesDC ChopperMalyaj SrivastavaNo ratings yet

- MalconSunscreen BrochureDocument2 pagesMalconSunscreen Brochuremosaic09No ratings yet

- Slapdriver Interference Screwdriver SystemDocument8 pagesSlapdriver Interference Screwdriver SystemFreddy Churata SuriNo ratings yet

- CE6015 Tall BuildingsDocument13 pagesCE6015 Tall BuildingsShan Cv0% (1)

- Design of Vertical Lift Service Gates Salarond Barrage: 1.0 Technical DetailsDocument23 pagesDesign of Vertical Lift Service Gates Salarond Barrage: 1.0 Technical DetailsRanjeet Singh MoreyNo ratings yet

- Liquid Cargo HandlingDocument4 pagesLiquid Cargo HandlingMartin ZagarNo ratings yet

- Auto Reclosing SchemeDocument3 pagesAuto Reclosing SchemeShah Aizat Razali100% (1)

- Rotulas IKODocument8 pagesRotulas IKOAgustín TorresNo ratings yet

- Importance of Highway EngineeringDocument1 pageImportance of Highway EngineeringPrincess Gupo TañasNo ratings yet

- Group 5 Combined Operation: 1. OutlineDocument9 pagesGroup 5 Combined Operation: 1. OutlineالمهندسوليدالطويلNo ratings yet

- DMM-III Assignment TestDocument2 pagesDMM-III Assignment TestSaibabu SoloNo ratings yet

- Method Statement - DuctingDocument8 pagesMethod Statement - Ductingkptl6185No ratings yet

- Norsok M101 Rev.5 2011Document62 pagesNorsok M101 Rev.5 2011Elzo2000No ratings yet

- Modern Atomic TheoryDocument28 pagesModern Atomic TheorySai TendoNo ratings yet

- UFO - technology ХАКЕРСКИЙ МАНУАЛDocument419 pagesUFO - technology ХАКЕРСКИЙ МАНУАЛBogdan Litvinov100% (1)

- Arm MmuDocument56 pagesArm MmuSuhas Rohit PaiNo ratings yet

- McDougal Space v2Document20 pagesMcDougal Space v2FSpace PublicationsNo ratings yet

- TallBuilding BrochureDocument6 pagesTallBuilding BrochureSonny AndalisNo ratings yet

- Boiler Shutdown ActivitiesDocument13 pagesBoiler Shutdown ActivitiesMohammad salmanNo ratings yet

- AMS 2368 C-2012 - Eng.Document6 pagesAMS 2368 C-2012 - Eng.TetianaNo ratings yet

- Gaa 24350 Aw11 Ii PDFDocument22 pagesGaa 24350 Aw11 Ii PDFEvgeniy100% (1)

- Chapter 5 The Preliminary MethodDocument31 pagesChapter 5 The Preliminary MethodF1013 ShamimiNo ratings yet

- ACULASER - C4100 Parts CatalogDocument35 pagesACULASER - C4100 Parts CatalogMarco CatenaNo ratings yet

- Lateral Stability of Reinforced Concrete Columns Under Axial Reversed Cyclic Tension and CompressionDocument10 pagesLateral Stability of Reinforced Concrete Columns Under Axial Reversed Cyclic Tension and CompressionMirellaNo ratings yet

- Spherical Pressure VesselDocument4 pagesSpherical Pressure VesselYetkin Erdoğan0% (1)

- Sheet Metal Forming Simulation Suite: Pam-Stamp 2GDocument2 pagesSheet Metal Forming Simulation Suite: Pam-Stamp 2GKrishna VamsiNo ratings yet

- Vistapro User Guide: 6.0Document40 pagesVistapro User Guide: 6.0Pedro QuintalNo ratings yet

- Name: Poon Jun Yu ID: 00011200 Lecture Name: DR - Mustafar Bin Sudin Program:DMTDocument8 pagesName: Poon Jun Yu ID: 00011200 Lecture Name: DR - Mustafar Bin Sudin Program:DMTJash LiewNo ratings yet