Professional Documents

Culture Documents

GV Sub Fig7050 3D

GV Sub Fig7050 3D

Uploaded by

Bryan STOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GV Sub Fig7050 3D

GV Sub Fig7050 3D

Uploaded by

Bryan STCopyright:

Available Formats

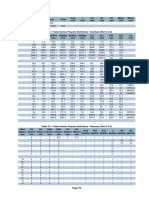

FITTINGS FOR GROOVED-END PIPE

FIG. 7050 3D

Long Radius Elbows

1. 3D long radius elbows are available in sizes up to 24". Sizes 4" and below 4. Bends to conform to above radii.

are provided with a 4" (101.6 mm) long integral tangent. Remaining sizes 5. C to E tolerances: 2" through 6" ± 1⁄8" (3.2 mm);

are provided with integral tangents with lengths equal to the nominal

8" through 16" ± 1⁄4" (6.4 mm);

pipe size. 18" through 24" + 3⁄8" (9.5 mm).

2. Grooved or plain-end available - specify choice on order. 6. All weights are approximate, based on calculated weight of pipe.

3. Material: standard wall steel pipe to ASTM A 53, Grade B.

(Other materials available on request).

O.D. O.D.

O.D.

O.D.

R O.D. O.D.

=3

D R=

3D R=

3D R=3

D R=3D R=3D

q Fig. 7050-3D, q Fig. 7057-3D, q Fig. 7051-3D, q Fig. 7058-3D, q Fig. 7052-3D, q Fig. 7053-3D,

90° Elbow 60° Elbow 45° Elbow 30° Elbow 221⁄2° Elbow 111⁄4° Elbow

FIGURE 7050-3D FIG. 7057-3D FIG. 7051-3D FIG. 7058-3D FIG. 7052-3D FIG. 7053-3D

90° ELBOW 60° ELBOW 45° ELBOW 30° ELBOW 221⁄2° ELBOW 111⁄4° ELBOW

Nominal Center Approx. Center Approx. Center Approx. Center Approx. Center Approx. Center Approx.

O.D.

Size to End Wt. Ea. to End Wt. Ea. to End Wt. Ea. to End Wt. Ea. to End Wt. Ea. to End Wt. Ea.

In./DN(mm) In./mm In./mm Lbs./Kg In./mm Lbs./Kg In./mm Lbs./Kg In./mm Lbs./Kg In./mm Lbs./Kg In./mm Lbs./Kg

2 2.375 10 5.3 71⁄2 4.3 61⁄2 3.9 53⁄4 3.4 51⁄4 3.2 41⁄2 2.8

50 60.3 254 2.4 191 2.0 165 1.8 146 1.5 133 1.5 114 1.3

1 1 1 1 1 3

2 ⁄2 2.875 11 ⁄2 9.5 8 ⁄4 7.7 7 ⁄4 6.7 6 5.8 5 ⁄2 5.3 4 ⁄4 4.6

65 73 292 4.3 210 3.5 184 3.0 152 2.6 140 2.4 121 2.1

3 3.500 13 14.0 91⁄4 11.0 73⁄4 9.5 61⁄2 8.0 53⁄4 7.3 5 6.2

80 88.9 330 6.4 235 5.0 197 4.3 165 3.6 146 3.3 127 2.8

31⁄2 4.000 141⁄2 18.6 10 14.4 81⁄2 12.3 63⁄4 10.2 6 9.2 5 7.6

90 101.6 368 8.4 254 6.5 216 5.6 171 4.6 152 4.2 127 3.4

4 4.500 16 24.1 11 18.5 9 15.7 71⁄4 12.8 61⁄2 11.4 51⁄4 9.3

100 114.3 406 10.9 279 8.4 229 7.1 184 5.8 165 5.2 133 4.2

5 5.563 20 40.9 133⁄4 31.3 111⁄4 26.5 9 21.8 8 19.4 61⁄2 15.8

125 141.3 508 18.6 349 14.2 286 12.0 229 9.9 203 8.8 165 7.2

6 6.625 24 63.7 161⁄2 48.8 131⁄2 41.3 103⁄4 33.9 91⁄2 30.1 73⁄4 24.6

150 168.3 610 28.9 419 22.1 343 18.7 273 15.4 241 13.7 197 11.2

8 8.625 32 127.8 22 97.9 18 82.9 141⁄2 68.0 123⁄4 60.5 101⁄2 49.3

200 219.1 813 58.0 559 44.4 457 37.6 368 30.8 324 27.4 267 22.4

10 10.750 40 226.4 271⁄4 173.4 221⁄2 146.9 18 120.5 16 107.2 13 87.3

250 273.1 1016 102.7 692 78.7 572 66.6 457 54.7 406 48.6 330 39.6

12 12.750 48 332.7 323⁄4 254.8 27 215.9 213⁄4 177.0 191⁄4 157.5 151⁄2 128.3

300 323.9 1219 150.9 832 115.6 686 97.9 552 80.3 489 71.4 394 58.2

14 14.000 56 427.3 381⁄4 327.3 311⁄2 227.3 251⁄4 227.3 221⁄2 202.3 181⁄4 164.8

350 355.6 1422 193.8 972 148.5 800 103.1 641 103.1 572 91.8 464 74.8

16 16.000 64 560.1 433⁄4 429.0 36 363.5 29 297.9 251⁄2 265.2 203⁄4 216.0

400 406.4 1626 254.1 1111 194.6 914 164.9 737 135.1 648 120.3 527 98.0

18 18.000 72 710.7 491⁄4 544.4 401⁄2 461.3 321⁄2 378.1 283⁄4 336.5 23.35 274.1

450 457.2 1829 322.4 1251 246.9 1029 209.2 826 171.5 730 152.6 593 124.3

20 20.000 80 879.3 543⁄4 673.5 45 540.7 36 467.8 32 416.3 26 339.2

500 508 2032 398.8 1391 305.5 1143 245.3 914 212.2 813 188.8 660 153.9

24 24.000 96 1270.3 651⁄2 973.0 533⁄4 824.4 431⁄4 675.7 381⁄4 601.4 31 490.0

600 609.6 2438 576.2 1664 441.3 1365 373.9 1099 304.1 972 272.8 787 222.3

PROJECT INFORMATION APPROVAL STAMP

Project: q Approved

Address: q Approved as noted

Contractor: q Not approved

Engineer: Remarks:

Submittal Date:

Notes 1:

Notes 2:

GL-7.12

FITTINGS FOR GROOVED-END PIPE

NSF/ANSI 61

Gruvlok fittings are available through 24" nominal pipe

For Listings/Approval Details and Limitations,

size in a variety of styles. Use the Fitting Size Table to visit our website at www.anvilintl.com or

contact an Anvil® Sales Representative.

convert nominal pipe size to corresponding pipe O.D.

Galvanized Gruvlok Fittings are

These fittings are designed to provide minimum NSF-61 and Low Lead Approved

pressure drop and uniform strength.

Depending on styles and size, Gruvlok fittings are

provided in various materials including ductile iron,

forged steel or fabricated steel.

Pressure ratings of Gruvlok standard fittings conform to

those of Fig. 7001 Gruvlok coupling.

FLOW DATA – FRICTIONAL RESISTANCE MATERIAL SPECIFICATIONS

(EXPRESSED AS EQUIVALENT STRAIGHT PIPE)

CAST FITTINGS:

Nom. Pipe Wall Elbow Tee

O.D. Ductile iron conforming to ASTM A 536, Grade 65-45-12

Size Thickness 90° 45° Branch Run

Malleable iron conforming to ASTM A 47

In./DN(mm) In./mm In./mm Ft./m Ft./m Ft./m Ft./m

FABRICATED FITTINGS:

1 1.315 0.133 1.7 0.9 4.4 1.7

25 33.4 3.4 0.5 0.3 1.3 0.5 1-12" Carbon steel, Schedule 40, conforming to ASTM A 53, Grade B

11⁄4 1.660 0.140 2.3 1.2 5.8 2.3 14-24" Carbon steel, 0.375 wall, conforming to ASTM A 53, Grade B

32 42.2 3.6 0.7 0.4 1.8 0.7

11⁄2 1.900 0.145 2.7 1.3 6.7 2.7 COATINGS:

40 48.3 3.7 0.8 0.4 2.0 0.8 Rust inhibiting paint – Color: ORANGE (standard)

2 2.375 0.154 3.4 1.7 8.6 3.4 Hot Dipped Zinc Galvanized conforming to ASTM A 153 (optional)

50 60.3 3.9 1.0 0.5 2.6 1.0

21⁄2 2.875 0.203 4.1 2.1 10.3 4.1 Other Colors Available (IE: RAL3000 and RAL9000)

65 73.0 5.2 1.2 0.6 3.1 1.2

3 O.D. 2.996 0.197 4.3 2.2 10.8 4.3

76.1 76.1 5.0 1.3 0.7 3.3 1.3

3 3.500 0.216 5.1 2.6 12.8 5.1

80 88.9 5.5 1.6 0.8 3.9 1.6 FITTING SIZE

41⁄4 O.D. 4.250 0.220 6.4 3.2 16.1 6.4

108.0 108.0 5.6 2.0 1.0 4.9 2.0 Nominal Nominal

O.D. O.D.

4 4.500 0.237 6.7 3.4 16.8 6.7 Size Size

100 114.3 6.0 2.0 1.0 5.1 2.0

In./DN(mm) In./mm In./DN(mm) In./mm

51⁄4 O.D. 5.236 0.248 8.0 4.0 20.1 8.0

133.0 133.0 6.3 2.4 1.2 6.1 2.4 1 1.315 5 5.563

51⁄2 O.D. 5.500 0.248 8.3 4.2 20.9 8.3 25 33.4 140 141.3

139.7 139.7 6.3 2.5 1.3 6.4 2.5 11⁄4 1.660 61⁄4 O.D. 6.259

5 5.563 0.258 8.4 4.2 21.0 8.4 32 42.4 159.0 159.0

125 141.3 6.6 2.6 1.3 6.4 2.6 11⁄2 1.900 61⁄2 O.D. 6.500

61⁄4 O.D. 6.259 0.280 9.7 4.9 24.3 9.7 40 48.3 165.1 165.1

159.0 159.0 7.1 3.0 1.5 7.4 3.0 2 2.375 6 6.625

61⁄2 O.D. 6.500 0.280 10.0 5.0 24.9 10.0 50 60.3 150 168.3

165.1 165.1 7.1 3.0 1.5 7.6 3.0 21⁄2 2.875 8 8.625

6 6.625 0.280 10.1 5.1 25.3 10.1 65 73.0 200 219.1

150 168.3 7.1 3.1 1.6 7.7 3.1

3 O.D. 2.996 10 10.750

8 8.625 0.322 13.3 6.7 33.3 13.3

200 219.1 8.2 4.1 2.0 10.1 4.1 76.1 76.1 250 273.0

10 10.750 0.365 16.7 8.4 41.8 16.7 3 3.500 12 12.750

250 273.1 9.3 5.1 2.6 12.7 5.1 80 88.9 300 323.9

12 12.750 0.375 20.0 10.0 50.0 20.0 31⁄2 4.000 14 14.000

300 323.9 9.5 6.1 3.0 15.2 6.1 90 101.6 350 355.6

14 14.000 0.375 22.2 17.7 64.2 22.9 41⁄4 O.D. 4.250 16 16.000

350 355.6 9.5 6.8 5.4 19.6 7.0 108.0 108.0 400 406.4

16 16.000 0.375 25.5 20.4 73.9 26.4 4 4.500 18 18.000

400 406.4 9.5 7.8 6.2 22.5 8.0 100 114.3 450 457.2

18 18.000 0.375 28.9 23.1 87.2 31.1 51⁄4 O.D. 5.236 20 20.000

450 457.2 9.5 8.8 7.0 26.6 9.5 133.0 133.0 500 508.0

20 20.000 0.375 32.2 25.7 97.3 34.8 51⁄2 O.D. 5.500 24 24.000

500 508.0 9.5 9.8 7.8 29.7 10.6 139.7 139.7 600 609.6

24 24.000 0.375 38.9 31.1 113.0 40.4

600 609.6 9.5 11.9 9.5 34.4 12.3 The Fitting Size Chart is used to determine the

O.D. of the pipe that the fittings is to be used with.

For the reducing tee and branches, use the value that is corresponding to the branch Gruvlok Fittings are identified by either the Nominal

size. For example: for 6" x 6" x 3" tee, the branch value of 3" is 12.8 ft (3.9). size in inches or the Pipe O.D. in/mm.

GL-11.16

You might also like

- PDM ColumbiaDocument20 pagesPDM ColumbiaAlex Bravo100% (8)

- Hdpe Pipe Weight & Dimensional Chart As Per Is: 4984:2016Document1 pageHdpe Pipe Weight & Dimensional Chart As Per Is: 4984:2016Procurement ACPL92% (25)

- 10 Drill String DesignDocument102 pages10 Drill String DesignDanian Primasatrya100% (2)

- Pipe's Wall Thickness: ASTM A312, A358, A778, A53, A106, API 5L ASME/ANSI B36.19 B36.10Document1 pagePipe's Wall Thickness: ASTM A312, A358, A778, A53, A106, API 5L ASME/ANSI B36.19 B36.10Theodosios StergiouNo ratings yet

- How To Calculate CBR Value Using DCPT Result On SiteDocument5 pagesHow To Calculate CBR Value Using DCPT Result On SiteMartin100% (1)

- Finite Element Analysis of Aircraft WingDocument17 pagesFinite Element Analysis of Aircraft WingSai Rahul100% (1)

- Layher Allround Industri Stillas 2015 - Engelsk - Utskrift.2Document68 pagesLayher Allround Industri Stillas 2015 - Engelsk - Utskrift.2cosmin todoran100% (1)

- Instruction Manual WARTSILLADocument458 pagesInstruction Manual WARTSILLAEmilio Portela100% (7)

- Long Radius Steel Elbows - 3D, 5D and 6D: Product DescriptionDocument3 pagesLong Radius Steel Elbows - 3D, 5D and 6D: Product Descriptionbadesharamk100% (2)

- Vinidex PE Pipe Capability MatrixDocument1 pageVinidex PE Pipe Capability Matrixgusloh100% (1)

- Vinidex Capability & Pe100 Polyethylene Pipe Dimensions: (Based On AS/NZS 4130)Document1 pageVinidex Capability & Pe100 Polyethylene Pipe Dimensions: (Based On AS/NZS 4130)Christopher Kenneth ChoaNo ratings yet

- E-17 Model l60-6d Wrought 6d 60o ElbowDocument4 pagesE-17 Model l60-6d Wrought 6d 60o ElbowmohdNo ratings yet

- E-17 MODEL L60-6D WROUGHT 6D 60o ELBOW PDFDocument4 pagesE-17 MODEL L60-6D WROUGHT 6D 60o ELBOW PDFAnand GNo ratings yet

- Pipe Bends Specification PDFDocument4 pagesPipe Bends Specification PDFToniNo ratings yet

- E-17 MODEL L60-6D WROUGHT 6D 60o ELBOW PDFDocument4 pagesE-17 MODEL L60-6D WROUGHT 6D 60o ELBOW PDFKikist ErsNo ratings yet

- Elbows - Long Radius, 3D, 5D, 6D PDFDocument4 pagesElbows - Long Radius, 3D, 5D, 6D PDFzinha_al100% (1)

- E-17 Model l60-6d Wrought 6d 60o ElbowDocument4 pagesE-17 Model l60-6d Wrought 6d 60o ElbowAdil AlaliNo ratings yet

- 5d Bend-Dimensions - E-17 Model l60-6d Wrought 6d 60o ElbowDocument4 pages5d Bend-Dimensions - E-17 Model l60-6d Wrought 6d 60o Elbowjacob thangamNo ratings yet

- Structural PDFDocument5 pagesStructural PDFrouhoNo ratings yet

- Steel Pipe Dimensions ChartDocument1 pageSteel Pipe Dimensions ChartERIC GERARDNo ratings yet

- 管径计算表Document11 pages管径计算表Ascend032No ratings yet

- Pipe Wall ThicknessDocument1 pagePipe Wall ThicknessFurkan Burak MuhammedNo ratings yet

- Pipe's Wall Thickness: ASTM A312, A358, A778, A53, A106, API 5L ASME/ANSI B36.19 B36.10Document1 pagePipe's Wall Thickness: ASTM A312, A358, A778, A53, A106, API 5L ASME/ANSI B36.19 B36.10Mohamed BencharifNo ratings yet

- Pipe & FlangeDocument8 pagesPipe & FlangeAbhiyan Anala ArvindNo ratings yet

- Pipe's Wall Thickness: ASTM A312, A358, A778, A53, A106, API 5L ASME/ANSI B36.19 B36.10Document1 pagePipe's Wall Thickness: ASTM A312, A358, A778, A53, A106, API 5L ASME/ANSI B36.19 B36.10Kagira Drawing SoltuionNo ratings yet

- Pipe's Wall Thickness: ASTM A312, A358, A778, A53, A106, API 5L ASME/ANSI B36.19 B36.10Document1 pagePipe's Wall Thickness: ASTM A312, A358, A778, A53, A106, API 5L ASME/ANSI B36.19 B36.10Theodosios StergiouNo ratings yet

- HDPE Pipe Flow RatesDocument2 pagesHDPE Pipe Flow Ratesalaa sadikNo ratings yet

- Pipe's Wall Thickness: ASTM A312, A358, A778, A53, A106, API 5L ASME/ANSI B36.19 B36.10Document1 pagePipe's Wall Thickness: ASTM A312, A358, A778, A53, A106, API 5L ASME/ANSI B36.19 B36.10Scribd meNo ratings yet

- Pipes & Fittings Sizes - WeightDocument5 pagesPipes & Fittings Sizes - Weightjohnijohn5No ratings yet

- DN Nominal Pipe Size Chart Metric MMDocument1 pageDN Nominal Pipe Size Chart Metric MMteguh.setionoNo ratings yet

- DN Nominal Pipe Size Chart Metric MMDocument1 pageDN Nominal Pipe Size Chart Metric MMNguyên Bùi50% (2)

- Ansi Pipe DimensionsDocument2 pagesAnsi Pipe Dimensionsgmascini9893No ratings yet

- Ansi B36.10 Carbon Steel / Alloy Steel / Seamless Pipe Weight Perkg/Mtr Astm Pipe Schedule - Wall Wall Thickness Millimetere - WT Weights in KG./MTRDocument3 pagesAnsi B36.10 Carbon Steel / Alloy Steel / Seamless Pipe Weight Perkg/Mtr Astm Pipe Schedule - Wall Wall Thickness Millimetere - WT Weights in KG./MTRSURAJ PANDEYNo ratings yet

- Pipe Dimensions Chart Rev Jan 2012Document1 pagePipe Dimensions Chart Rev Jan 2012eljammalNo ratings yet

- Pipe's Wall Thickness: ASTM A312, A358, A778, A53, A106, API 5L ASME/ANSI B36.19 B36.10Document6 pagesPipe's Wall Thickness: ASTM A312, A358, A778, A53, A106, API 5L ASME/ANSI B36.19 B36.10Nuta AnghelacheNo ratings yet

- OD Wall Thickness (MM) SS CS DN NPS SCH 5S SCH 10S SCH 40S SCH 80S SCH 10 SCH 20 SCH 30 SCH 40 STD SCH 60 Nominal Pipe SizeDocument2 pagesOD Wall Thickness (MM) SS CS DN NPS SCH 5S SCH 10S SCH 40S SCH 80S SCH 10 SCH 20 SCH 30 SCH 40 STD SCH 60 Nominal Pipe SizeAmirul AsyrafNo ratings yet

- Pipe (OK)Document1 pagePipe (OK)Black AutumnNo ratings yet

- 5364 Gv-Sub-Fig7050 Fig7051 Fig7052Document2 pages5364 Gv-Sub-Fig7050 Fig7051 Fig7052Bryan STNo ratings yet

- Tabel NPS Dan SCH Pipa Carbon - Stainless SteelDocument3 pagesTabel NPS Dan SCH Pipa Carbon - Stainless SteelAdhi Erlangga0% (1)

- Pipe Data SheetDocument2 pagesPipe Data SheetsparkletsharjahNo ratings yet

- Pipe Dimensions Chart Rev Jan 2012Document1 pagePipe Dimensions Chart Rev Jan 2012Thomas CalvinNo ratings yet

- Tanques Toro FullDocument16 pagesTanques Toro FullNoreVillalobosPalacioNo ratings yet

- HDPE Pipe Dimensions and Pressure Ratings1 - P.E.S CoDocument2 pagesHDPE Pipe Dimensions and Pressure Ratings1 - P.E.S CoJGon100% (1)

- Design Properties For Metric Hex Bolts (Typical Coarse Pitch Thread)Document4 pagesDesign Properties For Metric Hex Bolts (Typical Coarse Pitch Thread)scarto08No ratings yet

- Industrial Hydraulic - 20Document1 pageIndustrial Hydraulic - 20Hoanh Hai NguyenNo ratings yet

- DuctileIronPipeDesign2013Document1 pageDuctileIronPipeDesign2013Ozan AtıcıNo ratings yet

- Hdpe Pipe Chart1Document3 pagesHdpe Pipe Chart1BENJAMIN UNALANNo ratings yet

- Steel Core Rope Chart (Customer)Document1 pageSteel Core Rope Chart (Customer)chx6sprrvcNo ratings yet

- Carbon Steel / Alloy Steel / Seamless Pipe: Download SpecificationDocument2 pagesCarbon Steel / Alloy Steel / Seamless Pipe: Download SpecificationSreenubabu Kandru100% (1)

- Din 126-2Document1 pageDin 126-2Safi Zabihullah SafiNo ratings yet

- Input Parameter Valve and Flange: Fluid Density (KG/M) Insulation Density (KG/M)Document8 pagesInput Parameter Valve and Flange: Fluid Density (KG/M) Insulation Density (KG/M)ranjitkumar1977No ratings yet

- ECF 2 C@3ÿCG?ÿ9?C3G5Dÿ5@D@2 Chg1: Stuvwÿ Ytz (Sÿ - ) Zÿ S Zvtÿ Tuÿ ) Yu) Ÿ S - ZDocument21 pagesECF 2 C@3ÿCG?ÿ9?C3G5Dÿ5@D@2 Chg1: Stuvwÿ Ytz (Sÿ - ) Zÿ S Zvtÿ Tuÿ ) Yu) Ÿ S - ZAmirNo ratings yet

- Stainless Steel Pipes Dimension (Schedule, Wall Tickness & Weight)Document1 pageStainless Steel Pipes Dimension (Schedule, Wall Tickness & Weight)Senthil KumarNo ratings yet

- Determination of Adequacy of Blanching Hardcopy - RemovedDocument32 pagesDetermination of Adequacy of Blanching Hardcopy - Removeddoublesyaa28No ratings yet

- Grooved-End Fittings: Model 901 Short Radius 90 Elbow 7111 45 Elbow 903 Short Radius TEEDocument1 pageGrooved-End Fittings: Model 901 Short Radius 90 Elbow 7111 45 Elbow 903 Short Radius TEEZaira LorenaNo ratings yet

- Df FS Qúltima Qa Máxima B Fa máxima L Q A Vol Wsuelo Q Q (Z+S) Qfinal 〖𝜸′〗 - 𝑬𝒇𝒆𝒄𝒕𝒊𝒗𝒐Document3 pagesDf FS Qúltima Qa Máxima B Fa máxima L Q A Vol Wsuelo Q Q (Z+S) Qfinal 〖𝜸′〗 - 𝑬𝒇𝒆𝒄𝒕𝒊𝒗𝒐Carlos Rios PoiconNo ratings yet

- Line Sizing Spreadsheets-GeneralDocument8 pagesLine Sizing Spreadsheets-GeneralFavoriteNo ratings yet

- Pipe Wall ThicknessDocument1 pagePipe Wall ThicknessBasheer BarakahNo ratings yet

- Pipe Dimensions Chart Rev Jan 2012Document1 pagePipe Dimensions Chart Rev Jan 2012snake13No ratings yet

- Illustrated Guide to Door Hardware: Design, Specification, SelectionFrom EverandIllustrated Guide to Door Hardware: Design, Specification, SelectionNo ratings yet

- Introducing Autodesk Maya 2015: Autodesk Official PressFrom EverandIntroducing Autodesk Maya 2015: Autodesk Official PressNo ratings yet

- Tabla Roscas Taladros1Document1 pageTabla Roscas Taladros1Bryan STNo ratings yet

- Catalogo New Star Air SystemDocument100 pagesCatalogo New Star Air SystemBryan STNo ratings yet

- IM-3043-6D-703-002 Rev.0Document1 pageIM-3043-6D-703-002 Rev.0Bryan STNo ratings yet

- Cilindros YaleDocument92 pagesCilindros YaleBryan STNo ratings yet

- R2094 0.3 Module Anti Backlash GearsDocument1 pageR2094 0.3 Module Anti Backlash Gearsmu.loa91No ratings yet

- Piping Schedule ChartDocument2 pagesPiping Schedule ChartNaveen Chandar Emmer100% (2)

- W5330NDocument2 pagesW5330NMursia CiaNo ratings yet

- Operating Instructions: For The WABCO Diagnostic Controller With Program Card ABS/ASR (ATC) D 446 300 732 0Document26 pagesOperating Instructions: For The WABCO Diagnostic Controller With Program Card ABS/ASR (ATC) D 446 300 732 0Weidong ZhangNo ratings yet

- Home Assignment-5 - (Assignment Problems) Chapter-6Document2 pagesHome Assignment-5 - (Assignment Problems) Chapter-6Rounak MajumdarNo ratings yet

- MD TTM50A Service ManualDocument49 pagesMD TTM50A Service ManualAlexandru Diaconu100% (1)

- Scania 12-M SeriesDocument64 pagesScania 12-M Seriesw6r50% (2)

- PP Push-Fit Drainage Solutions Catalogue: "Superior German Quality"Document31 pagesPP Push-Fit Drainage Solutions Catalogue: "Superior German Quality"holoNo ratings yet

- VARIO GT 24 Standard PanelsDocument57 pagesVARIO GT 24 Standard PanelsdonnyervinNo ratings yet

- 1 Grey, 8A Red: Visible Dry-Method Magnetic ParticlesDocument2 pages1 Grey, 8A Red: Visible Dry-Method Magnetic ParticlesaravindanNo ratings yet

- Ic Lab 6Document4 pagesIc Lab 6Md Mehbub SamratNo ratings yet

- Bentone HC: Key PropertiesDocument2 pagesBentone HC: Key PropertiesLluís FontNo ratings yet

- Surface Hardening enDocument20 pagesSurface Hardening enanhntran4850No ratings yet

- PT Process General Training DocumentDocument37 pagesPT Process General Training Documentjanardhan bhawarNo ratings yet

- Alcohol To Jet Atj Inglés PDFDocument10 pagesAlcohol To Jet Atj Inglés PDFJorge EsquerreNo ratings yet

- Safety Operations On Medium Voltage Switch GearDocument3 pagesSafety Operations On Medium Voltage Switch GearpecampbeNo ratings yet

- 12 THDocument205 pages12 THthamaraibala9788No ratings yet

- Metals PresentationDocument15 pagesMetals Presentationsujit_sekharNo ratings yet

- Masterroc FLC 100: Description and PropertiesDocument3 pagesMasterroc FLC 100: Description and Propertiesrobin rezkNo ratings yet

- ETM RetrofitDocument10 pagesETM RetrofitjonniebravoNo ratings yet

- Auto Components - August 2015 PDFDocument44 pagesAuto Components - August 2015 PDFArun Raj PillaiNo ratings yet

- Jobaid3 Inspection Checklist For Masonry ConstructionDocument3 pagesJobaid3 Inspection Checklist For Masonry Constructionrmm99rmm99No ratings yet

- Road RollersDocument29 pagesRoad RollersThomas Wayne100% (1)

- Value Stream MappingDocument101 pagesValue Stream MappingTanbir KuhelNo ratings yet

- Filter MeshDocument38 pagesFilter MeshTuấn VũNo ratings yet

- Industrial Training On RdsoDocument24 pagesIndustrial Training On RdsoPrakhar AwasthiNo ratings yet