Professional Documents

Culture Documents

TS - 72-100-A (5) Apollo

TS - 72-100-A (5) Apollo

Uploaded by

Andres Felipe Gonzalez UrbeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TS - 72-100-A (5) Apollo

TS - 72-100-A (5) Apollo

Uploaded by

Andres Felipe Gonzalez UrbeCopyright:

Available Formats

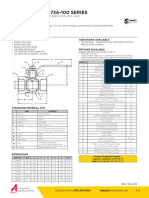

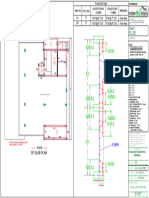

72-1xx-A SERIES

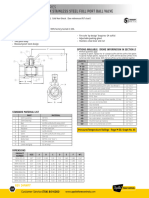

CARBON STEEL HIGH PRESSURE BALL VALVE

Female NPT Thread, 3000 CWP (psig), Cold Non-Shock Body rating. (See referenced P/T chart)

150 psig Saturated Steam.

Vacuum Service to 29 inches Hg.

MSS SP-110 Compliant.

FEATURES VARIATIONS AVAILABLE

• Forged body design • 72-140 Series (316 SS Ball & Stem. NACE MR0175 (2000) &

• Reinforced seats MR0103 (2003) compliant)

• Fire safe “by design” (requires -24 suffix)

• Zinc phosphate corrosion protection OPTIONS AVAILABLE

• Adjustable packing gland (MORE INFORMATION IN SECTION J)

• Full port • Minimum quantities apply

• To specify an option, replace the “01” standard suffix with the suffix of the option.

• Blowout-proof stem design EXP. NO. SCALE: DRN: DATE: CHKD: APP'D: NO. REV. • To specify multiple options, replace the “01” suffix with the desired suffixes in the

• Heavy duty lever R

NAME: numerical order shown below. NOTE: Not all suffixes can be combined together.

MAT'L:

(SUFFIX) OPTION SIZES

NOTE: This drawing and the subject matter disclosed therein is the property of Conbraco Industries, Inc. and is not to be

copied, used, appropriated or disclosed to others without the expressed written permission of Conbraco Industries, Inc. REV. CHANGE DESCRIPTION ECN NO. BY DATE

-01 Standard Configuration All

-02- Stem Grounded All

9 E

-04- 2-1/4” Stem Extension (Carbon Steel, Zinc Plated) 1” to 1-1/2”

2 -07- Steel Tee Handle 1/2” to 1-1/2”

7 1 -08- 90º Reversed Stem All

11 8

-10- SS Lever & Nut 1-1/2” to 2”

3

D -14- Side Vented Ball (Uni-Directional) All

-21- UHMWPE Trim (Non-PTFE) All

-24- Graphite Packing (Fire Safe “By Design”) All

A -27- Latch Lock Handle All

-45- Less Lever & Nut All

-49- No Lubrication. Assembled Dry All

10 -52- Two Tack Welds All

6 5

4 -53- Three Tack Welds All

B -56- Multifill Seats & Packing All

C -60- Static Grounded Ball & Stem All

250# Steam Trim (MPTFE Seats & Packing)

-64- All

Use with 316 SS Ball & Stem Variation

-65- Multi Fill Seats & Graphite Packing All

STANDARD MATERIAL LIST -67- Cleaned for Industrial Gas All

PART MATERIAL -78- Delrin Seats, Graphite Packing All

1 Lever and grip Steel, zinc plated w/vinyl -79- Nylon Seats, Graphite Packing All

2 Stem A108-Carbon Steel -UA- AIS (American Iron & Steel) Compliant All

3 Stem bearing RPTFE

4 Retainer seal RPTFE Pressure/Temperature Ratings - Page M-15, Graph No. 15

5 Seat (2) RPTFE

ASTM A108, Carbon Steel, Chrome Plated VALVE RATING:

6 Ball

or ASTM A276, Type 316 Stainless Steel The lowest rating determines the valve’s practical pressure limitation.

7 Gland nut A108-Carbon Steel Review the pressure-temperature rating for the valve’s seat and the

valve’s body.

8 Stem packing MPTFE

9 Lever nut Steel, zinc plated

10 Body A105-Carbon Steel

11 Retainer A108-Carbon Steel

DIMENSIONS

PART NO. SIZE A B C D E WT.

72-103-01A 1/2" 0.62 1.40 2.78 2.09 4.76 1.65

72-104-01A 3/4" 0.81 1.83 3.66 2.27 4.76 2.87

72-105-01A 1" 1.00 1.99 3.98 2.94 7.76 4.68

72-106-01A 1-1/4” 1.25 2.20 4.45 3.17 7.76 7.52

72-107-01A 1-1/2” 1.50 2.59 5.09 3.36 7.76 10.62

72-108-01A 2" 2.00 2.91 5.76 4.21 9.91 17.41

REV. 18JUL19

Customer Service (704) 841-6000 industrial.apollovalves.com A-11

FLOW DATA

FLOW DATA

The listed Cv “factors” are derived from actual flow testing, at Apollo’s Pageland, South Carolina factory. These tests were completed using standard

“off the shelf” valves with no special preparation and utilizing standard schedule 40 pipe. It should be understood that these factors are for the valve

only and also include the connection configuration. The flow testing is done utilizing water as a fluid media and is a direct statement of the gallons of

water flowed per minute with a 1 psig pressure differential across the valve/connection unit. Line pressure is not a factor. Because the Cv is a factor, the

formula can be used to estimate flow of most media for valve sizing.

√ √

FLOW OF LIQUID ∆P FLOW OF GAS (∆P) (P2)

Q = CV Q = 1360 CV

SpGr (SpGr) (T)

or ∆P = (Q) (SpGr) or ∆P = 5.4 x 10 (SpGr) (T) (Q)2

2 -7

(Cv)2 (Cv)2 (P2)

WHERE: WHERE:

• Q = Flow in US gpm • Q = Flow in SCFH

• ∆P = Pressure drop (psig) • ∆P = Pressure drop (psig)

• SpGr = Specific gravity at flowing temperature • SpGr = Specific gravity (based on air = 1.0)

• Cv = Valve constant • P2 = Outlet pressure–psia (psig + 14.7)

• T = (temp. °F + 460)

• Cv = Valve constant

CAUTION: The gas equation shown, is valid at very low pressure drop ratios.

The gas equation is NOT valid when the ratio of pressure drop (∆P) to inlet

pressure (P1) exceeds 0.02.

NOTE: Only use the gas equation shown if (P1-P2)/P1 is less than 0.02.

CV FACTORS FOR APOLLO VALVES (CONTINUED ON M-4)

SIZE (IN.)

VALVE

1/4 3/8 1/2 3/4 1 1.25 1.5 2 2.5 3 4 6 8 10 12

70B-140 Series 8.4 7.2 15 30 43 48 84 108 190 370 670 -- -- -- --

70-100/200 Series 8.4 7.2 15 30 43 48 84 108 190 370 670 -- -- -- ---

70-300/400 Series -- -- 15 30 43 48 84 108 -- -- -- -- -- -- --

70-600 Series 2.3 4.5 5.4 12 14 21 34 47 -- -- -- -- -- -- --

70-800 Series 8.4 7.2 15 30 43 48 84 -- -- -- -- -- -- -- --

71-AR Series -- -- -- 30 43 48 84 108 190 370 -- -- -- -- --

71-100/200 Series -- -- -- 30 43 48 84 108 190 370 -- -- -- -- --

72-100/900 Series -- -- 26 48 65 125 170 216 -- -- -- -- -- -- --

72-1xx-A/72-9xx-A Series -- -- 26 48 65 125 170 245 -- -- -- -- -- -- --

73A-100 Series 8.4 7.2 15 30 43 48 84 108 -- -- -- -- -- -- --

73-300/400 Series -- -- 26 48 65 125 170 216 -- -- -- -- -- -- --

74-100 Series 8.4 7.2 15 30 43 48 84 108 190 370 670 -- -- -- --

75-100 Series 8.4 7.2 15 30 43 48 84 108 190 370 670 -- -- -- --

76-AR Series 8.4 7.2 15 30 43 48 84 108 190 370 670 -- -- -- --

76F-100 Series 8.1 15 15 51 68 125 177 389 -- -- -- -- -- -- --

76FJ-100 Series 8.1 15 15 51 68 125 177 389 -- -- -- -- -- -- --

76FK-100 Series 8.1 15 15 51 68 125 177 389 -- -- -- -- -- -- --

76-100 Series 8.4 7.2 15 30 43 48 84 108 190 370 -- -- -- -- --

76-300/400 Series -- -- 26 48 65 125 170 216 -- -- -- -- -- -- --

76-600 Series 2.3 4.5 5.4 12 14 21 34 47 -- -- -- -- -- -- --

76J-100 Series 8.4 7.2 15 30 43 48 84 108 190 370 -- -- -- -- --

76J-AR Series 8.4 7.2 15 30 43 48 84 108 190 370 670 -- -- -- --

76K-100 Series 8.4 7.2 15 30 43 48 84 108 190 370 -- -- -- -- --

76K-AR Series 8.4 7.2 15 30 43 48 84 108 190 370 670 -- -- -- --

7K-100 Series -- -- 15 51 68 125 177 389 503 -- -- -- -- -- --

77-AR Series 8.1 15 15 51 68 -- 177 389 -- -- -- -- -- -- --

REV. 21APR17

Customer Service (704) 841-6000 industrial.apollovalves.com M-3

FLOW DATA

FOR APOLLO BALL VALVES

CV FACTORS FOR APOLLO VALVES (CONTINUED FROM M-3)

SIZE (IN.)

VALVE

1/4 3/8 1/2 3/4 1 1.25 1.5 2 2.5 3 4 6 8 10 12

77C-100/200 Series 4.5 7.2 16 36 68 125 177 389 503 -- -- -- -- -- --

77D-140 Series 4.5 7.2 16 36 68 125 177 389 -- -- -- -- -- -- --

77D-640 Series -- -- -- 11 24 35 -- -- -- -- -- -- -- -- --

77G-UL Series 4.5 7.2 16 36 68 125 177 389 503 -- -- -- -- -- --

77W Series -- -- 16 36 68 125 177 389 -- -- -- -- -- -- --

77-100/200 Series 8.1 15 15 51 68 125 177 389 503 -- -- -- -- -- --

79 Series 8.5 8.5 9.8 32 44 66 148 218 440 390 -- -- -- -- --

80 Series 8.4 7.2 15 30 43 48 84 108 190 370 -- -- -- -- --

82-100/200 Series 8.1 14 26 51 68 120 170 376 510 996 1893 -- -- -- --

83A/83B Series 8.1 14 26 51 68 120 170 376 -- -- -- -- -- -- --

83R-100/200 Series -- -- -- -- -- -- 170 376 -- 996 1893 -- -- -- --

86A/86B Series 8.1 14 26 51 68 120 170 376 -- -- -- -- -- -- --

86R-100/200 Series -- -- -- -- -- -- 170 376 -- 996 1893 -- -- -- --

87A-100 Series -- -- -- -- -- -- 86 104 234 375 673 1099 1902 3890 --

87A-200 Series -- -- 15 19 75 -- 195 410 545 1021 2016 4837 9250 15170 22390

87A-700 Series -- -- -- -- -- -- 86 104 234 375 673 1099 1902 3890 --

87A-900 Series -- -- 15 19 75 -- 195 410 545 1021 2016 4837 9250 15170 22390

87A-F00 Series -- -- -- -- 75 -- 195 410 545 1021 2016 4837 -- -- --

87B-100 Series -- -- -- -- -- -- -- -- -- 375 673 1099 1902 3890 --

87J-100 Series -- -- -- -- -- -- 86 104 234 375 673 1099 1902 3890 --

87J-200 Series -- -- 15 19 75 -- 195 410 545 1021 2016 4837 9250 15170 22390

87J-700 Series -- -- -- -- -- -- 86 104 234 375 673 1099 1902 3890 --

87J-900 Series -- -- 15 19 75 -- 195 410 545 1021 2016 4837 9250 15170 22390

87K-100 Series -- -- -- -- -- -- 86 104 234 375 673 1099 1902 3890 --

87K-200 Series -- -- 15 19 75 -- 195 410 545 1021 2016 4837 9250 15170 22390

87K-700 Series -- -- -- -- -- -- 86 104 234 375 673 1099 1902 3890 --

87K-900 Series -- -- 15 19 75 -- 195 410 545 1021 2016 4837 9250 15170 22390

88A-100 Series -- -- -- -- -- -- 86 104 234 375 673 1099 1902 3890 --

88A-200 Series -- -- 15 19 75 -- 195 410 545 1021 2016 4837 9250 15170 22390

88A-700 Series -- -- -- -- -- -- 86 104 234 375 673 1099 1902 3890 --

88A-900 Series -- -- 15 19 75 -- 195 410 545 1021 2016 4837 9250 15170 22390

88A-F00 Series -- -- -- -- 75 -- 195 410 545 1021 2016 4837 -- -- --

88B-100 Series -- -- -- -- -- -- -- -- -- 375 673 1099 1902 3890 --

89-100 Series 8.4 7.2 15 30 43 48 84 108 190 370 -- -- -- -- --

9A-100 Series 8.3 6.7 5.7 10 16 25 40 62 -- -- -- -- -- -- --

90-100 Series 8.3 6.7 5.7 10 16 25 40 62 -- -- -- -- -- -- --

92-100 Series 8.3 6.7 5.7 10 16 25 40 62 -- -- -- -- -- -- --

93-100 Series 8.3 6.7 5.7 10 16 25 40 62 -- -- -- -- -- -- --

94A-100/200 Series 6 7 19 34 50 104 268 309 629 1018 1622 -- -- -- --

96-100 Series 8.3 6.7 5.7 10 16 25 40 62 -- -- -- -- -- -- --

399-100 Series 8.4 7.2 15 30 43 48 84 108 190 370 -- -- -- -- --

489-100 Series 8.4 7.2 15 30 43 48 84 108 190 370 -- -- -- -- --

M-4 Customer Service (704) 841-6000 industrial.apollovalves.com

PRESSURE/TEMPERATURE RATINGS

ENGINEERING DATA

3000 CWP (CS) ASTM A216-WCB OR ASTM A105 OR ASTM A108 GRAPH 15

REFRIGERATION VALVE GRAPH 16

Customer Service (704) 841-6000 industrial.apollovalves.com M-15

You might also like

- Valvula de Bola ApolloDocument4 pagesValvula de Bola ApolloLeonardo Diego Avila HuaringaNo ratings yet

- Val Bola Pollo 2000wog 2pza Mod 73aDocument5 pagesVal Bola Pollo 2000wog 2pza Mod 73akimberly quispe mendozaNo ratings yet

- Apollo Super Duplex Stainless Steel Full Port Ball Valve 76FK-100-A TSDocument4 pagesApollo Super Duplex Stainless Steel Full Port Ball Valve 76FK-100-A TSgeneraljomoNo ratings yet

- Apollo Stainless Steel Full Port Ball Valve 76F-100-A TSDocument4 pagesApollo Stainless Steel Full Port Ball Valve 76F-100-A TSjhonny sanchezNo ratings yet

- FlowPak - V725 - ANSI - English Veersion Free For Client PDFDocument12 pagesFlowPak - V725 - ANSI - English Veersion Free For Client PDFMisael Castillo CamachoNo ratings yet

- 72-100 SERIES: Carbon Steel High Pressure Ball ValveDocument4 pages72-100 SERIES: Carbon Steel High Pressure Ball ValveEdinsonNo ratings yet

- V-Series Precision Tube: General ConfigurationDocument198 pagesV-Series Precision Tube: General ConfigurationBYRON ENRIQUE AGUILERA CHIMARRONo ratings yet

- Submittal Data Information Flanged In-Line Air Separator - 125 Psi Submittal Data Information Flanged In-Line Air Separator - 125 PsiDocument1 pageSubmittal Data Information Flanged In-Line Air Separator - 125 Psi Submittal Data Information Flanged In-Line Air Separator - 125 PsiRaul RamirezNo ratings yet

- Equipment Definition: Component LiteratureDocument4 pagesEquipment Definition: Component LiteratureAbbas AkbarNo ratings yet

- SXLSXHDocument11 pagesSXLSXHJuan carlos 200797No ratings yet

- Tsubaki Power Lock Ad N SeriesDocument5 pagesTsubaki Power Lock Ad N SeriesRizal IephoNo ratings yet

- IJ Data-Sheet PDFDocument1 pageIJ Data-Sheet PDFdakidofdaboomNo ratings yet

- RotexDocument50 pagesRotexliyuping200809No ratings yet

- En Bayard Penstock L110BDocument2 pagesEn Bayard Penstock L110Bshjnbe18No ratings yet

- Apollo LD14102BE10A Data SheetDocument2 pagesApollo LD14102BE10A Data SheetJacobs San RomanNo ratings yet

- Apollo LD14102BE10A Data SheetDocument2 pagesApollo LD14102BE10A Data SheetJacobs San RomanNo ratings yet

- STW Stilling WellDocument2 pagesSTW Stilling WellROGELIO QUIJANONo ratings yet

- Order Online TodDocument4 pagesOrder Online Todj8164322No ratings yet

- TS PR Residential SeriesDocument2 pagesTS PR Residential SeriesGégé di TPNo ratings yet

- Low-Profile SMT Header: TMM 1 SMDocument1 pageLow-Profile SMT Header: TMM 1 SMRaghav AdhikariNo ratings yet

- Disc o Flex - RATHI PDFDocument28 pagesDisc o Flex - RATHI PDFSACHIN PATELNo ratings yet

- Submittal Data Information Flanged In-Line Air Separator - 125 PsiDocument1 pageSubmittal Data Information Flanged In-Line Air Separator - 125 PsiAkiles VaesaNo ratings yet

- 76-500 SERIES: FeaturesDocument5 pages76-500 SERIES: FeaturesHung NguyenNo ratings yet

- DFT Inc - SCV CheckDocument2 pagesDFT Inc - SCV Checkedo_tapia_urNo ratings yet

- 1100 MSDocument1 page1100 MSAhmed RamzyNo ratings yet

- Samtec Connector - MaleDocument1 pageSamtec Connector - MaleMRousstiaNo ratings yet

- Welding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Document1 pageWelding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Mohammad Mehdi Jafari100% (2)

- 113AR CompressedDocument2 pages113AR CompressedAbdul RahmanNo ratings yet

- Sub-D Feedthroughs: Three Versions For Different Technical RequirementsDocument2 pagesSub-D Feedthroughs: Three Versions For Different Technical RequirementsDeaNo ratings yet

- 1100 MRDocument1 page1100 MRAhmed RamzyNo ratings yet

- With Clamping Hub: PropertiesDocument1 pageWith Clamping Hub: Propertiesmiguel.cruzNo ratings yet

- Wafer Type Butterfly Valve Z 411-A Wafer Type Butterfly Valve Z 411-ADocument4 pagesWafer Type Butterfly Valve Z 411-A Wafer Type Butterfly Valve Z 411-ANguyen Quang NamNo ratings yet

- CELDA LCD-100K DatasheetDocument2 pagesCELDA LCD-100K DatasheetJOSENo ratings yet

- Piping DimensionDocument58 pagesPiping DimensionmohammadabdulrobifarezaNo ratings yet

- WPQ Cinasa 01-2022Document1 pageWPQ Cinasa 01-2022Erick VazquezNo ratings yet

- 05-42 SSLFH-X Seismic SeriesDocument2 pages05-42 SSLFH-X Seismic Seriesjonathan watsonNo ratings yet

- Bourns LMNPLPDocument2 pagesBourns LMNPLPJc Valve RecordNo ratings yet

- Demco Butterfly ValveDocument35 pagesDemco Butterfly ValveJairo PuentesNo ratings yet

- Torsiflex-I Disc Couplings: For General Purpose ApplicationsDocument8 pagesTorsiflex-I Disc Couplings: For General Purpose Applicationsmarcelo castilloNo ratings yet

- Instructions For Use: GB GB GBDocument2 pagesInstructions For Use: GB GB GBnotaloka43No ratings yet

- R1100-Metal Dome Type - Selling Price - 410 QARDocument1 pageR1100-Metal Dome Type - Selling Price - 410 QARabdulrahman elmograbiNo ratings yet

- Ez Arc Brochure-14Document2 pagesEz Arc Brochure-14Shalom AvadovNo ratings yet

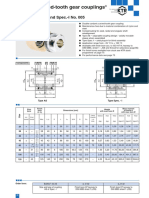

- Bowex Curved-Tooth Gear Couplings: Type As No. 004 and Spec.-I No. 005Document1 pageBowex Curved-Tooth Gear Couplings: Type As No. 004 and Spec.-I No. 005Mauricio Ariel H. OrellanaNo ratings yet

- DriveTechnology p174 p193 Steel Laminae CouplingsDocument20 pagesDriveTechnology p174 p193 Steel Laminae CouplingsNhật Quang PhạmNo ratings yet

- General Data: Pictures May Not Show Every (All) Optional Feature (S) On Actual BitDocument1 pageGeneral Data: Pictures May Not Show Every (All) Optional Feature (S) On Actual BitDaniel NavarroNo ratings yet

- CAT-5322 SS-2001 Abort StationDocument2 pagesCAT-5322 SS-2001 Abort StationEliud RodriguezNo ratings yet

- Multi-Set II Drop-In AnchorsDocument5 pagesMulti-Set II Drop-In AnchorsReinel OrjuelaNo ratings yet

- E McqaDocument19 pagesE McqaTháiSơnTrầnNo ratings yet

- ZIMM Miniature 01 UK (Aug-10) PDFDocument12 pagesZIMM Miniature 01 UK (Aug-10) PDFhepcomotionNo ratings yet

- BTL5 EX KatalogiDocument13 pagesBTL5 EX KatalogimunjaNo ratings yet

- CPE5-013 MA4 ProductSheetDocument4 pagesCPE5-013 MA4 ProductSheetAjmal ArshadNo ratings yet

- SF SlabDocument1 pageSF SlabVijaya RajuNo ratings yet

- 72-100 Series: Carbon Steel High Pressure Ball ValveDocument4 pages72-100 Series: Carbon Steel High Pressure Ball ValvevictorNo ratings yet

- Vm4D / Vm4Sd: High Performance Vane MotorDocument2 pagesVm4D / Vm4Sd: High Performance Vane Motorluisxxx1No ratings yet

- MLX9042x Product Flyer MelexisDocument2 pagesMLX9042x Product Flyer Melexisvinoth1983mu6050No ratings yet

- NSSBCHM Activity 16 LabDocument4 pagesNSSBCHM Activity 16 Labsad asdNo ratings yet

- CGL PRE 2023 English All SetsDocument314 pagesCGL PRE 2023 English All Setskumarmohit0203No ratings yet

- GrandStream GXV-3175 - User Manual EnglishDocument130 pagesGrandStream GXV-3175 - User Manual Englishซิสทูยู ออนไลน์No ratings yet

- Lingerie Insight February 2011Document52 pagesLingerie Insight February 2011gab20100% (2)

- Al-Naji2018 Article AnEfficientMotionMagnificationDocument16 pagesAl-Naji2018 Article AnEfficientMotionMagnificationAhmed El-ShafeiNo ratings yet

- I) H3C - MSR3600 - Datasheet PDFDocument15 pagesI) H3C - MSR3600 - Datasheet PDFSON DANG LAMNo ratings yet

- System Analysis & Design in A Changing World Chapter 13 Problems and ExercisesDocument8 pagesSystem Analysis & Design in A Changing World Chapter 13 Problems and ExercisesbriandonaldNo ratings yet

- 11 RECT TANK 4.0M X 3.0M X 3.3M H - Flocculator PDFDocument3 pages11 RECT TANK 4.0M X 3.0M X 3.3M H - Flocculator PDFaaditya chopadeNo ratings yet

- Have Something Done EXERCISESDocument3 pagesHave Something Done EXERCISEScarlos laredoNo ratings yet

- Portable Boring MachineDocument2 pagesPortable Boring Machinesexmanijak100% (1)

- Lifting Lug Design Calculation Report: Page 1 of 6Document6 pagesLifting Lug Design Calculation Report: Page 1 of 6maniaxpdfNo ratings yet

- Synchro Studio 8: Getting Started and What's New in Version 8Document35 pagesSynchro Studio 8: Getting Started and What's New in Version 8Fernando Luis FerrerNo ratings yet

- Lab Manual DLD LabDocument113 pagesLab Manual DLD Labqudratullah ehsan0% (1)

- STS Week 4 S&T and Nation-Building Part 2 PDFDocument40 pagesSTS Week 4 S&T and Nation-Building Part 2 PDFLawrence YusiNo ratings yet

- Your Re'sume' CritiqueDocument9 pagesYour Re'sume' CritiqueMark Richard Hilbert (Rossetti)No ratings yet

- UntitledDocument58 pagesUntitledArun KumarNo ratings yet

- Ques Risk and Return & CAPM (S-17Revised)Document6 pagesQues Risk and Return & CAPM (S-17Revised)Najia SiddiquiNo ratings yet

- Pressure Relief Valve Scenario Summary: General Job DataDocument6 pagesPressure Relief Valve Scenario Summary: General Job DatajorgekarlosprNo ratings yet

- Parts of The House and FurnitureDocument1 pageParts of The House and FurnitureJOSE MARIA ARIGUZNAGA ORDUÑANo ratings yet

- QuadEquations PPT Alg2Document16 pagesQuadEquations PPT Alg2Kenny Ann Grace BatiancilaNo ratings yet

- Gen Bio 1 Le Week 1 - Quarter 2Document7 pagesGen Bio 1 Le Week 1 - Quarter 2Cassy Joy Rellama100% (1)

- Solid State MCQ & CsaDocument10 pagesSolid State MCQ & Csashivansh upadhyay100% (1)

- Biology Online TextbookDocument2 pagesBiology Online TextbookMicaela DavisNo ratings yet

- History: The History of The Hospitality Industry Dates All The WayDocument10 pagesHistory: The History of The Hospitality Industry Dates All The WaySAKET TYAGINo ratings yet

- GN No 333 Public Procurement (Amendment) Regulations, 2016Document45 pagesGN No 333 Public Procurement (Amendment) Regulations, 2016imran hameerNo ratings yet

- Mfx2550 Field Engineering ManualDocument415 pagesMfx2550 Field Engineering ManualJoeNo ratings yet

- Pugh Method Example-2Document4 pagesPugh Method Example-2Shaikh AkhlaqueNo ratings yet

- 15 To 21 OctoberDocument16 pages15 To 21 OctoberpratidinNo ratings yet

- GeoseaDocument9 pagesGeoseaArthur WakashimasuNo ratings yet

- UntitledDocument22 pagesUntitledMoniNo ratings yet