Professional Documents

Culture Documents

Installation and T&C of Fm200 System

Installation and T&C of Fm200 System

Uploaded by

er.arun.kumar.s92Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation and T&C of Fm200 System

Installation and T&C of Fm200 System

Uploaded by

er.arun.kumar.s92Copyright:

Available Formats

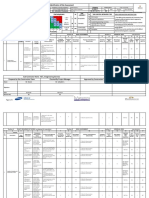

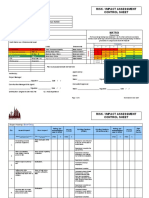

Al Sahel Contracting Company LLC Doc. Ref.

FM-10031

Revision 03

RISK / IMPACT ASSESSMENT Date Jan-2018

LOCATION / PROJECT JOB NO. ASSESSMENT NO.

POTENTIAL HAZARDS / CONDITIONS TO BE CONSIDERED

Deep Excavations Storage / Lay Down Area Fall from Height Fire Risk Noise Young Persons

Demolition Confined Spaces Slips / Tripping Noise / Dust / Vibration VDU Expectant Mothers

Plant / Machinery Working Platforms/Ladders Fuel Storage Fumes Ergonomics S/C Workers

Lifting Operations Manual Handling Storage / Lay Down Area Traffic High Winds General Public / Visitors

Buried / Overhead Services COSHH Ground Conditions Smoke Adverse Weather Others

TASK:

Evaluation of Residual

Potential Hazards / Normal / Abnormal / Hazard Effect Who or What Might be Risk/Impact Control Measures or Risk/Impact Level Control /

No. Activity OHS or E Status

Aspect Emergency / Harm Harmed Recovery Measures Influence

S L R/I S L R/I

1 5 1 5 5 1 5

2 5 2 10 5 2 10

3 5 3 15 5 3 15

4 - -

5 - -

FOLLOWING STEPS TO BE FOLLOWED WHILE EVALUATING THE HAZARDS AND RISK FOR EACH ACTIVITY.

SEVERITY OF CONSEQUENCES LIKELIHOOD / PROBABILITY HIERARCHY OF CONTROLS MATRIX

DESCRIPTION SCALE LIKELIHOOD / PROBABILITY SCALE SL. # DESCRIPTION If the severity/Impect rating lies between 5 to 25, then

ELIMINATION

corrective actions needs to be taken by concerned

FATALITY / CATASTROPHIC 5 ALMOST CERTAIN 5 1

persons with documentary evidence

4 LIKELY 4 2 SUBSTITUTION LIKELIHOOD / PROBABILITY (L)

.

MAJOR HEALTH IMPACT / INJURY, DAMAGE TO COMMUNITY*

SQ

N

ENGINEERING CONTROL 1 2 3 4 5

O

MINOR INJURY / MODERATE 3 POSSIBLE 3 3

C

FIRST AID / MINOR 2 UNLIKELY 2 4 SIGNAGE/WARNING/ADMIN. CONTROLS 1 1 2 3 4 5

SEVERITY

NEGLIGIBLE / INSIGNIFICANT 1 RARE 1 5 PPE'S 2 2 4 6 8 10

* Major health impact, damage to community, major asset loss, or major injury (damaging, disabling illness). 3

(S)

3 6 9 12 15

COLOUR CODE RISK or IMPACT LEVEL / RATING MEASURES TO BE TAKEN 4 4 8 12 16 20

RED EXTREME 15-25 & special cases WORK CANNOT PROCEED, ENGINEERING MEASURES REQUIRED 5 5 10 15 20 25

ORANGE HIGH 10-12 IMMEDIATE CORRECTION MEASURES REQUIRED R = S X L WHERE: R / I = RISK / IMPECT RATING

YELLOW MEDIUM 4-9 REVIEW REQUIRED FOR ADDITIONAL MEASURES S = SEVERITY

GREEN LOW 1-4 NO ACTION REQUIRED OR ACCEPTABLE RISK/IMPACT L = LIKELIHOOD / PROBABILITY

Final Assessment: Provided that there are no deviations from control measures, the residual risk assumed is low. Supplementary measures should include using the correct PPE and safety Tool Box Talk to

ensure that all workers are fully aware of the control measures.

Updated on:

Revision No.:

Assessed By: Verified By (PROJECT MANAGER) Approved By (CLIENT / CONSULTANT)

Name: Name: Name:

Signature: Signature: Signature:

Date/Time: Date/Time: Date/Time:

Al Sahel Contracting Company LLC Doc. Ref. FM-10031

Revision 03

RISK / IMPACT ASSESSMENT Date Jan-2018

LOCATION / PROJECT JOB NO. ASSESSMENT NO.

POTENTIAL HAZARDS / CONDITIONS TO BE CONSIDERED

Deep Excavations Storage / Lay Down Area Fall from Height Fire Risk Noise Young Persons

Demolition Confined Spaces Slips / Tripping Noise / Dust / Vibration VDU Expectant Mothers

Plant / Machinery Working Platforms/Ladders Fuel Storage Fumes Ergonomics S/C Workers

Lifting Operations Manual Handling Storage / Lay Down Area Traffic High Winds General Public / Visitors

Buried / Overhead Services COSHH Ground Conditions Smoke Adverse Weather Others

TASK:

Evaluation of Residual

Potential Hazards / Normal / Abnormal / Hazard Effect Who or What Might be Risk/Impact Control Measures or Risk/Impact Level Control /

No. Activity OHS or E Status

Aspect Emergency / Harm Harmed Recovery Measures Influence

S L R/I S L R/I

1 5 1 5 5 1 5

2 5 2 10 5 2 10

3 5 3 15 5 3 15

4 4 3 12 -

5 - -

FOLLOWING STEPS TO BE FOLLOWED WHILE EVALUATING THE HAZARDS AND RISK FOR EACH ACTIVITY.

SEVERITY OF CONSEQUENCES LIKELIHOOD / PROBABILITY HIERARCHY OF CONTROLS MATRIX

DESCRIPTION SCALE LIKELIHOOD / PROBABILITY SCALE SL. # DESCRIPTION If the severity/Impect rating lies between 5 to 25, then

ELIMINATION

corrective actions needs to be taken by concerned

FATALITY / CATASTROPHIC 5 ALMOST CERTAIN 5 1

persons with documentary evidence

4 LIKELY 4 2 SUBSTITUTION LIKELIHOOD / PROBABILITY (L)

.

MAJOR HEALTH IMPACT / INJURY, DAMAGE TO COMMUNITY*

SQ

N

ENGINEERING CONTROL 1 2 3 4 5

O

MINOR INJURY / MODERATE 3 POSSIBLE 3 3

C

FIRST AID / MINOR 2 UNLIKELY 2 4 SIGNAGE/WARNING/ADMIN. CONTROLS 1 1 2 3 4 5

SEVERITY

NEGLIGIBLE / INSIGNIFICANT 1 RARE 1 5 PPE'S 2 2 4 6 8 10

* Major health impact, damage to community, major asset loss, or major injury (damaging, disabling illness). 3

(S)

3 6 9 12 15

COLOUR CODE RISK or IMPACT LEVEL / RATING MEASURES TO BE TAKEN 4 4 8 12 16 20

RED EXTREME 15-25 & special cases WORK CANNOT PROCEED, ENGINEERING MEASURES REQUIRED 5 5 10 15 20 25

ORANGE HIGH 10-12 IMMEDIATE CORRECTION MEASURES REQUIRED R = S X L WHERE: R / I = RISK / IMPECT RATING

YELLOW MEDIUM 4-9 REVIEW REQUIRED FOR ADDITIONAL MEASURES S = SEVERITY

GREEN LOW 1-4 NO ACTION REQUIRED OR ACCEPTABLE RISK/IMPACT L = LIKELIHOOD / PROBABILITY

Final Assessment: Provided that there are no deviations from control measures, the residual risk assumed is low. Supplementary measures should include using the correct PPE and safety Tool Box Talk to

ensure that all workers are fully aware of the control measures.

Updated on:

Revision No.:

Assessed By: Verified By (PROJECT MANAGER) Approved By (CLIENT / CONSULTANT)

Name: Name: Name:

Signature: Signature: Signature:

Date/Time: Date/Time: Date/Time:

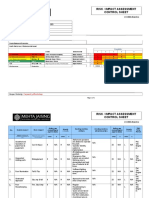

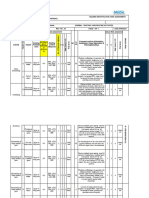

RISK ASSESSMENT-INSTALLATION AND T&C OF FM200 SYSTEM

VIDA 1-4 AT BLOCKK(B+G+9F+R) HOTEL, SERVICED&BRANDED APARTMENTS, PLOT NO:763,

LOCATION / PROJECT

MUWAILAH, SHARJAH, UAE

JOB NO. J-374 ASSESSMENT NO.

POTENTIAL HAZARDS / CONDITIONS TO BE CONSIDERED

Deep Excavations Storage / Lay Down Area Fall from Height Fire Risk Noise Young Persons

Demolition Confined Spaces Slips / Tripping Noise / Dust / Vibration VDU Expectant Mothers

Plant / Machinery Working Platforms/Ladders Fuel Storage Fumes Ergonomics S/C Workers

Lifting Operations Manual Handling Storage / Lay Down Area Traffic High Winds General Public / Visitors

Buried / Overhead Services COSHH Ground Conditions Smoke Adverse Weather Others

TASK: INSTALLATION OF FM 200 SYSTEM

Evaluation of Residual

Legal Requirements Normal /

Hazard Effect / Who or What Risk/Impact Risk/Impact Level

No. Activity Potential Hazards / Aspect OHS or E Abnormal / Control Measures or Recovery Measures Status Control / Influence

Harm Might be Harmed

Emergency

Yes / No If Yes, Provide the Ref. S L R/I S L R/I

1 Transportation & Delivery YES DMCOP *Collisions involving delivery OHS NORMAL Serious injuries Drivers, 4 3 12 *Designatedpathways, implement speed 1 4 4 ALARP CONTROL

of Materials at site chapter 20 vehicles, other site vehicles, or pedestrians, limits, provide training for drivers.

(offloading) pedestrians other road

*Injuries related to manual lifting, users,Workers *Provide mechanical aids (cranes, forklifts),

carrying, and unloading of involved,Work training on proper lifting techniques,and

materials. ers in the minimize manual handling where possible.

*Objects falling from delivery vicinity, *Use barricades and

vehicles during unloading warning signs, enforce restricted access

*Risks associated with the use of zones, secure materials properly during

forklifts, cranes, or other transport inside the site. *Proper

machinery during unloading. labeling and documentation, employee

*Exposure to hazardous materials training on handling hazardous materials,

during transportation and emergency response plans. *Ensure proper

unloading supervision for the task. *Makesure the

equipment is certified and operator is

competent for the operation. * Use

proper personal protective equipment (PPE)

2 Pre-installation procedure No *Risks associated with working OHS NORMAL Serious Workers 4 3 12 *Ensure that power sources are properly shut 1 4 4 ALARP CONTROL

of FM200 system with electrical systems during the injuries/Minor involved in off before installation

installation process. injuries task ,tresspass *Use

*The system operates under ers and appropriate PPE for confined space work.

pressure, and there is a risk of Foreman

pressure-related incidents during *Use appropriate tools and

installation. equipment to conduct pressure tests

*Exposure to the clean agent according to manufacturer specifications.

(FM200) during installation. *Ensure that

*Risks associated with the workers have and use appropriate PPE,

handling and movement of heavy including gloves, masks, goggles, and other

equipment and cylinders. necessary protective gear.

*Poor ventilation during

installation can lead to the

accumulation of gases or fumes.

*The installation

process may involve hot work or

activities that could pose a fire

risk.

< FORM NO.: FM-10031 | REV.: 04 | DATE: Apr-2022 >

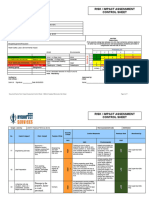

TASK: INSTALLATION OF FM 200 SYSTEM

Evaluation of Residual

Legal Requirements Normal /

Hazard Effect / Who or What Risk/Impact Risk/Impact Level

No. Activity Potential Hazards / Aspect OHS or E Abnormal / Control Measures or Recovery Measures Status Control / Influence

Harm Might be Harmed

Emergency

Yes / No If Yes, Provide the Ref. S L R/I S L R/I

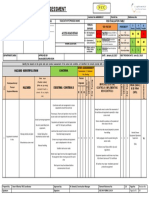

3 Shifting of Pipes through YES DM *Improper handling OHS NORMAL Back Injury/ Workers 3 3 9 *Ensure workers involve in manual handling 1 3 3 ALARP CONTROL

manual handling COP,CHAPT *Unclear route Muscle strains/ involved in shall receive a training of proper handling

ER 7 * Obstructed access Slip and trip/ task ,tresspass technique.

* Lack of training Pinch-points ers and * Unfit personnel are not allowed to

* Heavy load Fatigue/ Foreman manually handle the pipes.

* Unsecured grip Crushed body *Avoid manual handling if possible.

* Unfit personnel parts *Use mechanical handling aid

* Using inappropriate PPE equipment such as pallet trolley whenever

possible.

* Clear access routes .

*Use suitable non-slip hand gloves.

*Regular rest breaks on high temperature and

humidity atmospheric condition.

4 Painting of pipes YES DM E NORMAL Irritation, 4 3 12 *Use respiratory protection, ensure adequate 1 3 3 ALARP CONTROL

in the designated painting COP,CHAPT * Exposure to paint and solvents dizziness, and Painters, ventilation

areas/Workshop ER 18 can lead to skin irritation, headaches./slip supervisors, *Keep the painting area well-

respiratory issues, and other and fall and other ventilated, avoid open flames, and have

health problems. hazards/ workers in the firefighting equipment, such as fire

* Inhaling paint fumes can cause musculoskeletal vicinity. extinguishers, readily available *Keep

respiratory irritation, dizziness, injuries/ the work area clean, use non-slip floor

and headaches. coatings, and provide proper signage. Ensure

*Combustible paints and solvents workers wear appropriate footwear.

pose a fire hazard, especially in *Provide lifting aids, train workers in

the presence of ignition sources. proper lifting techniques, and implement

* Wet or spilled paint on the floor ergonomic practices. Use mechanical lifting

can create slip and fall hazards. devices when feasible. *Implement

* Lifting and maneuvering pipes dust control measures, and provide training

can lead to musculoskeletal on the proper use of protective equipment.

injuries. *

The use of power tools and *Store paints and solvents in designated

equipment can result in high noise areas, following manufacturer guidelines.

levels, leading to hearing damage. Train workers on safe handling practices

*Dust from surface preparation (chemical store). *Provide comprehensive

and paint application can be training for workers on hazard recognition,

harmful to the respiratory system. proper use of equipment, and emergency

response procedures.

*Conduct regular inspections of safety

measures to identify and address potential

issues promptly.

< FORM NO.: FM-10031 | REV.: 04 | DATE: Apr-2022 >

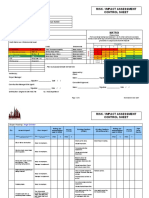

TASK: INSTALLATION OF FM 200 SYSTEM

Evaluation of Residual

Legal Requirements Normal /

Hazard Effect / Who or What Risk/Impact Risk/Impact Level

No. Activity Potential Hazards / Aspect OHS or E Abnormal / Control Measures or Recovery Measures Status Control / Influence

Harm Might be Harmed

Emergency

Yes / No If Yes, Provide the Ref. S L R/I S L R/I

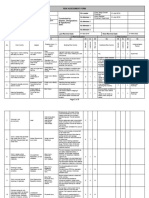

5 Threading of GI pipes YES DM *Risks associated with the OHS NORMAL Slips, Workers 3 3 9 *Provide comprehensive training for workers 1 3 3 ALARP CONTROL

using threading machine COP,CHAPT moving parts of the threading trips,Cuts, Performing the on the safe operation of threading machines,

ER 18 machine, such as rotating dies and abrasions, or Threading,Sup including hazard recognition, emergency

gears posses chances for crush ervisors and procedures, and the proper use of personal

entanglement *Lifting, injuries,muscul Managers,Adj protective equipment.

positioning, and maneuvering of oskeletal acent Workers *Conduct regular inspections of the

heavy pipes can lead to injuries, threading machine, tools, and safety

musculoskeletal injuries. including equipment to identify and address potential

*Electrical components of the strains and issues promptly ensure the machine is tagged

threading machine pose a risk of sprains,mild using the monthly colour code.

electric shock shocks,burns to *Develop and communicate an

*Exposure to cutting fluids or the skin,kin emergency response plan that includes

lubricants may cause skin irritation, procedures for machine malfunctions,

irritation or respiratory issues. dermatitis electrical issues, and other potential

emergencies. *Ensure that

threading dies and cutting tools are in good

condition and properly secured. Train

workers on the safe handling and storage of

tools *Maintain a

clean and organized workspace to minimize

tripping hazards and facilitate safe movement

around the threading machine

6 Grooving of pipes using YES DMCOP,CH *Risks associated with the OHS NORMAL Slips, Workers 3 3 9 *Provide comprehensive training for workers 1 3 3 ALARP CONTROL

Pipe Grooving APTER 18 moving parts of the threading trips,Cuts, Performing the on the safe operation of grooving machines,

Machine machine, such as rotating dies and abrasions, or grooving,Supe including hazard recognition, emergency

gears posses chances for crush rvisors and procedures, and the proper use of personal

entanglement *Lifting, injuries,muscul Managers,Adj protective equipment.

positioning, and maneuvering of oskeletal acent Workers *Conduct regular inspections of the grooving

heavy pipes can lead to injuries, machine, tools, and safety equipment to

musculoskeletal injuries. including identify and address potential issues

*Electrical components of the strains and promptly,ensure the machine is tagged using

threading machine pose a risk of sprains,mild the monthly colour code. *Develop and

electric shock shocks,burns to communicate an emergency response plan

*Exposure to cutting fluids or the skin,kin that includes procedures for machine

lubricants may cause skin irritation, malfunctions, electrical issues, and other

irritation or respiratory issues. dermatitis potential emergencies. *Train

workers on the safe handling and storage of

tools *Maintain a

clean and organized workspace to minimize

tripping hazards and facilitate safe movement

around the threading machine

< FORM NO.: FM-10031 | REV.: 04 | DATE: Apr-2022 >

TASK: INSTALLATION OF FM 200 SYSTEM

Evaluation of Residual

Legal Requirements Normal /

Hazard Effect / Who or What Risk/Impact Risk/Impact Level

No. Activity Potential Hazards / Aspect OHS or E Abnormal / Control Measures or Recovery Measures Status Control / Influence

Harm Might be Harmed

Emergency

Yes / No If Yes, Provide the Ref. S L R/I S L R/I

7 Cutting of pipes to its YES DMCOP,CH *Risks associated with moving OHS NORMAL Cuts, abrasions, Workers 3 3 9 *Provide machine guards to prevent contact 1 3 3 ALARP CONTROL

desired length by the use of APTER 14 parts of the pipe cutting machine, or crushing Performing the with moving parts.

pipe cutting machine including blades. injuries Cutting,Worke *Ensure proper maintenance and inspection

*Lifting, positioning, and rs Handling of the cutting machine is done and tagged

maneuvering pipes can lead to Materials,Elec with the monthly color code.

musculoskeletal injuries. tricians,Adjace *Train workers on safe machine operation.

*Operation of the cutting machine nt *Provide workers with appropriate PPE,

can generate high noise levels. Workers,Super including gloves and eye protection.

*Cutting metal pipes can produce visors and *Implement regular cleaning procedures to

sharp metallic shavings Managers remove metal shavings from the work area.

*Electrical components of the

cutting machine pose a risk of

electric shock.

8 Mounting of FM200 No *Manual Handling and OHS NORMAL Cuts, Workers 3 3 9 *Provide comprehensive training on safe 1 3 3 ALARP CONTROL

cylinder Ergonomic Hazards abrasions, or Mounting mounting procedures, the use of equipment,

*Falling Hazards impact Cylinders,Sup and hazard recognition.

*Pinch Points and injuries,Muscul ervisors and *Provide appropriate PPE, including gloves,

Crush Hazards *Manual Handling oskeletal Managers,Wor safety glasses, fall protection equipment, and

of Tools *Chemical Exposure injuries, falls, kers Handling respiratory protection if needed.

*Fire Hazards pinch points, Tools,Adjacen *Use mechanical lifting aids or equipment to

crush injuries, t Workers minimize manual handling risks.

chemical *Implement fall protection measures like

exposure safety harness

*Implement machine guarding to prevent

pinch points and crush injuries.

*Ensure that tools and equipment used for

mounting are in good condition and suitable

for the task.

*Follow proper procedures for handling

lubricants, cleaning agents, or any chemicals

used in the mounting process.

*Eliminate or control ignition sources and

have firefighting equipment readily

available.

*Promote effective communication among

workers, supervisors, and other stakeholders

regarding safety procedures and potential

hazards

< FORM NO.: FM-10031 | REV.: 04 | DATE: Apr-2022 >

TASK: INSTALLATION OF FM 200 SYSTEM

Evaluation of Residual

Legal Requirements Normal /

Hazard Effect / Who or What Risk/Impact Risk/Impact Level

No. Activity Potential Hazards / Aspect OHS or E Abnormal / Control Measures or Recovery Measures Status Control / Influence

Harm Might be Harmed

Emergency

Yes / No If Yes, Provide the Ref. S L R/I S L R/I

9 Working at height using YES DMCOP,CH *The risk of person falling from OHS NORMAL Minor sprains Workers on 4 3 12 *Install guardrails, toe boards, & use 1 3 3 ALARP CONTROL

aluminium mobile APTER 8 heights while working on the and fractures to the personal fall arrest systems to prevent falls.

scaffolding in installing scaffolding or fatalities Scaffolding,W *Regularly inspect the scaffolding for

pipes and fittings for water *The scaffolding may collapse orkers Below ensuring its complete inspected and tagged.

spray system. due to instability or improper the *Secure tools and prevent falling objects

assembly *Tools, equipment, or Scaffolding,Ot *Adhere to weight limits and avoid

materials may fall from the her workers in overloading the scaffolding

scaffolding *Inadequate access the *Provide training for the team involved in

and egress points to the vicinity,Forem the activity regarding scaffolding asfety and

scaffolding ans and safe wok at height teachnique,

supervisors

10 Removal of scrap pipes and YES DMCOP,CH *Trip and Slip Hazard OHS/E NORMAL Strains, sprains, Workers 3 2 6 *Implement regular housekeeping 3 1 3 ALARP CONTROL

clearing the workplace. APTER 8 *Sharp Edges and Protrusions and other Removing procedures to keep the workplace clean and

(Housekeeping) *Improperly stacked or stored musculoskeletal Scrap organized *Train workers on proper stacking

scrap pipes may fall causing injuries,Injuries Pipes,Other and storage procedures for scrap pipes

injuries caused by sharp Workers in the *Conduct regular inspections of the work

*stains from excess oils and objects, Area area to identify and address potential

shellac protruding hazards. *Ensure surfaces are slip-resistant,

*Insufficient personal protective materials,Skin and promptly clean up spills or debris

equipment (PPE) may increase the irritation,

risk of injuries respiratory

issues,slip &trip

FOLLOWING STEPS TO BE FOLLOWED WHILE EVALUATING THE HAZARDS AND RISK FOR EACH ACTIVITY.

SEVERITY OF CONSEQUENCES LIKELIHOOD / PROBABILITY HIERARCHY OF CONTROLS MATRIX

LIKELIHOOD /

DESCRIPTION SCALE SCALE SL. # DESCRIPTION

PROBABILITY If the severity/Impact rating lies between 5 to 25, then corrective actions

FATALITY / CATASTROPHIC 5 ALMOST CERTAIN 5 1

needs to be taken by concerned persons with documentary evidence

ELIMINATION

MAJOR HEALTH IMPACT / INJURY, DAMAGE TO COMMUNITY* 4 LIKELY 4 2 SUBSTITUTION LIKELIHOOD / PROBABILITY (L)

.

SQ

MINOR INJURY / MODERATE

N

3 POSSIBLE 3 3 ENGINEERING CONTROL 1 2 3 4 5

O

C

FIRST AID / MINOR 2 UNLIKELY 2 4 1 1 2 3 4 5

SIGNAGE/WARNING/ADMIN. CONTROLS

SEVERITY (S)

NEGLIGIBLE / INSIGNIFICANT 1 RARE 1 5 2 4 6 8 10

PPE'S 2

* Major health impact, damage to community, major asset loss, or major injury (damaging, disabling illness). 3 3 6 9 12 15

COLOUR CODE RISK or IMPACT LEVEL / RATING MEASURES TO BE TAKEN 4 4 8 12 16 20

RED EXTREME 15-25 & special cases WORK CANNOT PROCEED, ENGINEERING MEASURES REQUIRED 5 5 10 15 20 25

ORANGE HIGH 10-12 IMMEDIATE CORRECTION MEASURES REQUIRED R=SXL WHERE: R / I = RISK / IMPACT RATING

YELLOW MEDIUM 5-9 REVIEW REQUIRED FOR ADDITIONAL MEASURES S = SEVERITY

< FORM NO.: FM-10031 | REV.: 04 | DATE: Apr-2022 >

TASK: INSTALLATION OF FM 200 SYSTEM

Evaluation of Residual

Legal Requirements Normal /

Hazard Effect / Who or What Risk/Impact Risk/Impact Level

No. Activity Potential Hazards / Aspect OHS or E Abnormal / Control Measures or Recovery Measures Status Control / Influence

Harm Might be Harmed

Emergency

Yes / No If Yes, Provide the Ref. S L R/I S L R/I

GREEN LOW 1-4 NO ACTION REQUIRED OR ACCEPTABLE RISK/IMPACT L = LIKELIHOOD / PROBABILITY

Final Assessment: Provided that there are no deviations from control measures, the residual risk assumed is low. Supplementary measures should include using the correct PPE and safety Tool Box Talk to ensure that all workers are fully

aware of the control measures.

Updated on: 11/20/2023 Revision no. 0

Assessed By: Verified By: Approved By:

Name: Arunkumar Subash Name: Nimer Fares Name:

Signature: Signature: Signature:

Date/Time: 11/20/2023 Date/Time: 11/20/2023 Date/Time:

< FORM NO.: FM-10031 | REV.: 04 | DATE: Apr-2022 >

You might also like

- RA 024 Risk Assessment - Precast Concrete WorksDocument14 pagesRA 024 Risk Assessment - Precast Concrete Worksthomson78% (9)

- Soft Landscaping ROW Area Risk AssessmentDocument11 pagesSoft Landscaping ROW Area Risk AssessmentSIBIN100% (3)

- Epoxy PaintingDocument4 pagesEpoxy PaintingSaleem BashaNo ratings yet

- Thyssenkrupp Elevator Qatar: Risk AssessmentDocument5 pagesThyssenkrupp Elevator Qatar: Risk AssessmentMahran Mastouri100% (4)

- RA-LBC-007 Risk Assessment Concrete WorksDocument8 pagesRA-LBC-007 Risk Assessment Concrete Worksjones100% (1)

- Hazard Identification & Risk Assessment Theatre 01-06-17 02 (01.12.17) 08Document6 pagesHazard Identification & Risk Assessment Theatre 01-06-17 02 (01.12.17) 08sachin vaish100% (1)

- LDM 2 Wellness Massage K To 12 Curriculum Guide To MelcDocument2 pagesLDM 2 Wellness Massage K To 12 Curriculum Guide To MelcChi de la Torre67% (6)

- 05 - RISK ASSESSMENT-Winch MechineDocument3 pages05 - RISK ASSESSMENT-Winch Mechine287100% (1)

- 04 - RISK ASSESSMENT CradleDocument5 pages04 - RISK ASSESSMENT Cradle287100% (4)

- Understanding Culture, Society, and Politics: Second QuarterDocument12 pagesUnderstanding Culture, Society, and Politics: Second QuarterRene Rey B. Sulapas85% (13)

- Steel YardDocument6 pagesSteel YardAtiq ShaikhNo ratings yet

- Hoist Erection Operation & Maintenance Work - R0 - 30.09.2017Document6 pagesHoist Erection Operation & Maintenance Work - R0 - 30.09.2017Nikhil Manjrekar100% (2)

- Risk Assesment - MobilisationDocument7 pagesRisk Assesment - Mobilisationشاز إياسNo ratings yet

- Risk / Impact Assessment Control Sheet: CC/EHS/RA/014 ContractDocument4 pagesRisk / Impact Assessment Control Sheet: CC/EHS/RA/014 Contractsaurabh juwatkarNo ratings yet

- 022 - Compressed Gas Cylinder - HandlingDocument3 pages022 - Compressed Gas Cylinder - HandlingAbhijit JanaNo ratings yet

- RA LBC 007 Risk Assessment Concrete WorksDocument8 pagesRA LBC 007 Risk Assessment Concrete WorksMohammad Al Masa'dehNo ratings yet

- Hansvahini Auto Interior Pvt. LTD: Hazard Identification and Risk AssessmentDocument6 pagesHansvahini Auto Interior Pvt. LTD: Hazard Identification and Risk AssessmentAtul SharmaNo ratings yet

- Risk / Impact Assessment Control Sheet: Severity Rating: MatrixDocument7 pagesRisk / Impact Assessment Control Sheet: Severity Rating: MatrixSaim AliNo ratings yet

- 06-She-ra-06-Bulk Earthworks Ra Rev01Document12 pages06-She-ra-06-Bulk Earthworks Ra Rev01Mlungisi MadlalaNo ratings yet

- 01 WI HSE 001 - Risk Assessment BridgesDocument8 pages01 WI HSE 001 - Risk Assessment BridgesMisbah Ul Haq LabeedNo ratings yet

- Risk / Impact Assessment Control Sheet: MatrixDocument3 pagesRisk / Impact Assessment Control Sheet: MatrixJonathan Kat BucasasNo ratings yet

- SS RA - 013 Foundation and Ground Shuttering Form and Rebar WorksDocument6 pagesSS RA - 013 Foundation and Ground Shuttering Form and Rebar WorksSn AhsanNo ratings yet

- Screeding WorksDocument2 pagesScreeding WorksSaleem Basha100% (1)

- Risk / Impact Assessment Control Sheet: MatrixDocument4 pagesRisk / Impact Assessment Control Sheet: MatrixSaim AliNo ratings yet

- HIRA TECHNOX Rev 04Document12 pagesHIRA TECHNOX Rev 04jogender kumarNo ratings yet

- Mobile CranesDocument5 pagesMobile CranesSAYED100% (1)

- F01 - HiraDocument1 pageF01 - Hiradeeptanwar1997No ratings yet

- CMI-TRCP (04.29) T.C MachineDocument2 pagesCMI-TRCP (04.29) T.C Machine김순혁No ratings yet

- RA - Work at HeightsDocument4 pagesRA - Work at HeightsEtienne NWNo ratings yet

- Annex 2 HIRADEC FormatDocument9 pagesAnnex 2 HIRADEC Formatamit100% (1)

- Eme-D-062 Underwater Diving OperationsDocument3 pagesEme-D-062 Underwater Diving Operationslatish salianNo ratings yet

- Risk / Impact Assessment Control Sheet: MatrixDocument3 pagesRisk / Impact Assessment Control Sheet: MatrixMithun RajNo ratings yet

- Hvac WorksDocument4 pagesHvac WorksSaleem BashaNo ratings yet

- Risk / Impact Assessment Control Sheet: 000 Y N Y NDocument19 pagesRisk / Impact Assessment Control Sheet: 000 Y N Y NeDtutors. inNo ratings yet

- SS RA - 010 Lean Concrete Pouring 1Document8 pagesSS RA - 010 Lean Concrete Pouring 1Sn AhsanNo ratings yet

- RA 021 Risk Assessment - Installation of External Landscape Lighting WorksDocument13 pagesRA 021 Risk Assessment - Installation of External Landscape Lighting Worksthomson50% (2)

- BSD - 016 Block MachineDocument4 pagesBSD - 016 Block MachineZakkaudin KhanNo ratings yet

- BSD - 022 Compressed Gas Cylinder - HandlingDocument3 pagesBSD - 022 Compressed Gas Cylinder - HandlingZakkaudin KhanNo ratings yet

- Thyssenkrupp Elevator Qatar: Risk AssessmentDocument5 pagesThyssenkrupp Elevator Qatar: Risk AssessmentMahran MastouriNo ratings yet

- BSD - 005 Arc WeldingDocument3 pagesBSD - 005 Arc WeldingZakkaudin KhanNo ratings yet

- Risk / Impact Assessment Control Sheet: MatrixDocument3 pagesRisk / Impact Assessment Control Sheet: MatrixMithun RajNo ratings yet

- Painting WorksDocument3 pagesPainting WorksSaleem Basha100% (1)

- BSD - 019 Bulk EarthworksDocument3 pagesBSD - 019 Bulk EarthworksZakkaudin KhanNo ratings yet

- 007 Assembly of Elements BoilermakerDocument3 pages007 Assembly of Elements BoilermakerBorislav VulicNo ratings yet

- BSD - 008 Back FillingDocument3 pagesBSD - 008 Back FillingZakkaudin KhanNo ratings yet

- RA FormatDocument12 pagesRA FormatShibinNo ratings yet

- Al Qooz Contracting LLC: Hazard Identification and Risk AssesmentDocument8 pagesAl Qooz Contracting LLC: Hazard Identification and Risk Assesmentشاز إياس100% (1)

- Risk / Impact Assessment Control Sheet: MatrixDocument2 pagesRisk / Impact Assessment Control Sheet: MatrixNiraNo ratings yet

- Ep Hira Safety and EnvDocument77 pagesEp Hira Safety and EnvEdwin Otniel LumbantoruanNo ratings yet

- 5.#hiradec - CWPDocument7 pages5.#hiradec - CWPPankaj PandeyNo ratings yet

- JHA For Pipe Scrap Loading and UnloadingDocument5 pagesJHA For Pipe Scrap Loading and Unloadingkunnar corrosionNo ratings yet

- Using Hand Drill (WS)Document2 pagesUsing Hand Drill (WS)John KalvinNo ratings yet

- Sec Ehvpd Risk Assessment: Hazard Identification Control Risk Reduction Action PlanDocument1 pageSec Ehvpd Risk Assessment: Hazard Identification Control Risk Reduction Action PlanSn AhsanNo ratings yet

- JSA M005 Personnel Transfer Rev1Document2 pagesJSA M005 Personnel Transfer Rev1aadamekNo ratings yet

- RMH-RA-GP-1001-Marking Penetration, Support Bracket Location (Reviewed 01042019)Document3 pagesRMH-RA-GP-1001-Marking Penetration, Support Bracket Location (Reviewed 01042019)Kumar sssssNo ratings yet

- RA 020 Risk Assessment - Risk Assessment - Installation of Cables in Ducts & TrenchesDocument11 pagesRA 020 Risk Assessment - Risk Assessment - Installation of Cables in Ducts & Trenchesthomson100% (2)

- HIRA-Underground WaterproofingDocument5 pagesHIRA-Underground WaterproofingBhagat DeepakNo ratings yet

- 002 - RA For Chemical HandlingDocument5 pages002 - RA For Chemical HandlingJacqueline CKNo ratings yet

- AVN-MAR-PIP-RA-003 - R0 - Installation of Drain Line Below HelipadDocument3 pagesAVN-MAR-PIP-RA-003 - R0 - Installation of Drain Line Below HelipadtaufikNo ratings yet

- Cerebral Amyloid AngiopathyDocument2 pagesCerebral Amyloid AngiopathyPaolo Giordano100% (1)

- URIKAR - The Most Advanced & Powerful Percussion Massager With AI Chip For Daily Stress Relief and Workout RecoveryDocument2 pagesURIKAR - The Most Advanced & Powerful Percussion Massager With AI Chip For Daily Stress Relief and Workout RecoveryPR.comNo ratings yet

- I. Background: Eko Nugraha PutraDocument9 pagesI. Background: Eko Nugraha PutraDwi Fitriyana PutriNo ratings yet

- Drlee - Restless Leg SyndromeDocument1 pageDrlee - Restless Leg SyndromeSouheila MniNo ratings yet

- TVL CSS G11-Q1-DW10Document2 pagesTVL CSS G11-Q1-DW10charmaine jornadalNo ratings yet

- Safety Training Plan ExampleDocument2 pagesSafety Training Plan ExampleBilly Billy100% (1)

- Filipino Nurses For GermanyDocument6 pagesFilipino Nurses For GermanyRose Dyan Petallo Plandano50% (4)

- Unit 8.2 - Planning Final (1-9-2019)Document23 pagesUnit 8.2 - Planning Final (1-9-2019)Josephine TorresNo ratings yet

- Hamburguer StoryDocument8 pagesHamburguer StoryOrianny LealNo ratings yet

- Extra Exam Practice 7: Read The Text and Answer The Questions That FollowDocument2 pagesExtra Exam Practice 7: Read The Text and Answer The Questions That Followana100% (2)

- Harshal GawasDocument3 pagesHarshal GawasAnonymous T2Dy9X4FmNo ratings yet

- Accident Prevention Plan FINALDocument74 pagesAccident Prevention Plan FINALsakrakirfanNo ratings yet

- 60-SGC-HSE-F-007 Task Risk Assesement - Rev00 (En+Az) - ApprovedDocument11 pages60-SGC-HSE-F-007 Task Risk Assesement - Rev00 (En+Az) - ApprovedРашад ИбрагимовNo ratings yet

- DextroseDocument1 pageDextroseAdrianne BazoNo ratings yet

- Respiratory and Circulatory Systems: Activity Sheet No. 1Document7 pagesRespiratory and Circulatory Systems: Activity Sheet No. 1alexNo ratings yet

- 39.full Violin and Its Effects ArticleDocument8 pages39.full Violin and Its Effects ArticleROMCNo ratings yet

- Perfectionism A Challenging But WorthwhileDocument27 pagesPerfectionism A Challenging But WorthwhileAna Luiza Ferreira PsiNo ratings yet

- WAC 110 - 60A CHAPTER - FMDocument28 pagesWAC 110 - 60A CHAPTER - FMroger degreeNo ratings yet

- CASE STUDY - 5 Mercy's Big Data Project Aims To Boost OperationsDocument3 pagesCASE STUDY - 5 Mercy's Big Data Project Aims To Boost Operations7ossam AbduNo ratings yet

- TCS BPS Hiring: Reporting Time Date of Test Test TimingDocument2 pagesTCS BPS Hiring: Reporting Time Date of Test Test TimingYuvan NaveenNo ratings yet

- Lift Plan-Wilco Extenral StairsDocument25 pagesLift Plan-Wilco Extenral StairsEdgar ChecaNo ratings yet

- Cochrane LibraryDocument59 pagesCochrane LibraryMadalina BocaNo ratings yet

- IET The Chartered Engineer StandardDocument6 pagesIET The Chartered Engineer StandardNg Chee PengNo ratings yet

- Trường Thcs Giảng Võ Tổ Ngoại Ngữ: NĂM HỌC 2021-2022Document5 pagesTrường Thcs Giảng Võ Tổ Ngoại Ngữ: NĂM HỌC 2021-2022khanhvan nguyenNo ratings yet

- Abnormal Psychology 5th Ed by Gerald C Davidson-177-216Document40 pagesAbnormal Psychology 5th Ed by Gerald C Davidson-177-216bella swanNo ratings yet

- Active Recreation (Fitness) : 1. Grade Level - 10 2. Subject - Physical EducationDocument5 pagesActive Recreation (Fitness) : 1. Grade Level - 10 2. Subject - Physical EducationKyno NakpilNo ratings yet

- Principles of Control & PreventionDocument26 pagesPrinciples of Control & PreventionArcher ArtilleryNo ratings yet

- Test - Inter 1Document5 pagesTest - Inter 1HONGAN_ANHONG1No ratings yet