Professional Documents

Culture Documents

Liu 2017

Liu 2017

Uploaded by

MAYERLI MAMANI GARCIAOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Liu 2017

Liu 2017

Uploaded by

MAYERLI MAMANI GARCIACopyright:

Available Formats

Angewandte

A Journal of the Gesellschaft Deutscher Chemiker

International Edition Chemie www.angewandte.org

Accepted Article

Title: Selective electrochemical reduction of CO2 to ethanol on B and N

codoped nanodiamond

Authors: Yanming Liu, Yujing Zhang, Kai Chen, Xie Quan, Xinfei Fan,

Yan Su, Shuo Chen, Huimin Zhao, Yaobin Zhang, Hongtao

Yu, and Michael R. Hoffmann

This manuscript has been accepted after peer review and appears as an

Accepted Article online prior to editing, proofing, and formal publication

of the final Version of Record (VoR). This work is currently citable by

using the Digital Object Identifier (DOI) given below. The VoR will be

published online in Early View as soon as possible and may be different

to this Accepted Article as a result of editing. Readers should obtain

the VoR from the journal website shown below when it is published

to ensure accuracy of information. The authors are responsible for the

content of this Accepted Article.

To be cited as: Angew. Chem. Int. Ed. 10.1002/anie.201706311

Angew. Chem. 10.1002/ange.201706311

Link to VoR: http://dx.doi.org/10.1002/anie.201706311

http://dx.doi.org/10.1002/ange.201706311

Angewandte Chemie International Edition 10.1002/anie.201706311

COMMUNICATION

Selective electrochemical reduction of CO2 to ethanol on B and N

codoped nanodiamond

Yanming Liu,# Yujing Zhang,# Kai Cheng, Xie Quan,* Xinfei Fan, Yan Su, Shuo Chen, Huimin Zhao,

Yaobin Zhang, Hongtao Yu, and Michael R. Hoffmann

Abstract: Electrochemical reduction of CO2 to ethanol, a clean and morphology,[5] exposed surface facet[6] or surface

[7]

renewable liquid fuel with high heating value, is an attractive strategy functionalization of metals. Although metals exhibit competent

for global warming mitigation and resource utilization. However, activity, they often undergo easy deactivation or poor selectivity

converting CO2 to ethanol remains great challenge due to the low for high energy density products. Transition metal oxides and

activity, poor product selectivity and stability of electrocatalysts. Here, chalcogenides (e.g. Co3O4) have also been explored for

B and N codoped nanodiamond (BND) was reported as an efficient electrocatalytic CO2 reduction.[8] Their primary products are

and stable electrode for selective reduction of CO2 to ethanol. Good limited to CO or HCOO- with maximum Faradic efficiency of 60.0-

ethanol selectivity was achieved on BND with high Faradaic efficiency 85.1%. Recently, carbon based nanomaterials[9] such as B doped

of 93.2% (-1.0 V vs RHE), which overcame the limitation of low diamond (BDD), N doped carbon nanotubes and graphene have

selectivity for multicarbon or high heating value fuels. Its superior been proposed as promising electrocatalysts for CO2 reduction

performance was mainly originated from the synergistic effect of B due to their earth abundant component, good activity and

and N codoping, high N content and overpotential for hydrogen durability, which reduce CO2 to CO, HCHO or HCOO- with

evolution. The possible pathway for CO2 reduction revealed by DFT maximum Faradic efficiency of 74.0-87.0%. Although notable

computation was CO2 → *COOH → *CO → *COCO → *COCH2OH progress has been achieved, there remains a major challenge to

→ *CH2OCH2OH → CH3CH2OH. develop durable electrocatalysts that can efficiently and

selectively convert CO2 to high heating value fuels, especially that

with multicarbon such as CH3CH2OH.

The world-wide utilization of fossil fuels deplete feasible fossil

B and N codoped diamond (BND) is a potential electrocatalyst

fuel sources and produce large amount of CO2. Electrocatalytic

with good stability. B and N doping regulate the electronic

reduction of CO2 to fuels or other chemicals can reduce CO2

structure of diamond,[10] which enable to form defect-induced

accumulation in atmosphere and alleviate energy crisis, which is

active sites for CO2 reduction. BND has a more negative H2

a promising method for carbon recycling if powered by renewable

evolution potential than the electrocatalysts mentioned above,

energy sources. Electrocatalytic CO2 reduction can yield a variety

which is more favorable for CO2 reduction with higher Faradic

of products, including CO, HCOO-, HCHO, CH3COO-, CH3OH,

efficiency. These properties make BND an attractive alternative

CH3CH2OH, CH4, etc. However, CH3CH2OH is preferred product

electrocatalyst for CO2 reduction. N doped diamond (NDD)

because it is a clean and renewable liquid fuel with high heating

preferentially reduces CO2 to C2 product CH3COO-,[11] while the

value (-1366.8 kJ/mol, higher than -283.0~-890.4 kJ/mol for

main product reported for BDD is HCHO.[9b] Given the observed

others listed above). It is also an important raw material for

synergistic effect of B and N codoping on electrocatalytic activity

organic chemicals and disinfectants. Industrial production of

of carbon nanomaterials,[10a,12] codoped BND may afford better

CH3CH2OH consumes large amount of agricultural feedstocks or

electrocatalytic performance than BDD and NDD, and convert

ethylene. Thus, there is a pressing need to find efficient

CO2 to highly reduced product. Moreover, CO2 reduction

electrocatalysts that can selectively convert CO2 to CH3CH2OH.

performance of BND can be tuned by altering its chemical

Homogeneous metal-ligand complex and heterogeneous

composition. However, electrocatalytic CO2 reduction on BND

electrocatalysts have been reported for CO2 reduction.[1] Metals[2]

and the impact of codoping with B and N on CO2 reduction have

and metal alloys[3] have been found to be active for

never been reported before. Herein, BND was explored for

electrocatalytic reduction of CO2, where product selectivity and

electrocatalytic reduction of CO2. The effect of codoped B and N

efficiency could be tailored by controlling particle size, [4]

on CO2 reduction performance was elucidated by experiments

combined with density function theory (DFT) calculation.

[*] Dr. Y. M. Liu, Y. J. Zhang, Prof. X. Quan, Dr. X. F. Fan, Dr. S. Chen, Prof. BND electrodes were prepared by depositing BND film on Si

H. M. Zhao, Prof. Y.B Zhang, Dr. H. T. Yu substrate using hot filament chemical vapor deposition method

Key Laboratory of Industrial Ecology and Environmental Engineering with a gas mixture of CH4/B2H6/N2/H2 that had 2.5% CH4. BNDs

(Ministry of Education), Faculty of Chemical, Environmental and

with the same B2H6 content (12.5%) but different N2 levels (2.5%,

Biological Science and Technology

Dalian University of Technology, Dalian 116024, China 5.0% and 10.0%) were prepared, which are denoted as BND1,

E-mail: quanxie@dlut.edu.cn BND2 and BND3, respectively. The surface morphology of

Dr. Y. Su, Prof. J. J. Zhao prepared BND electrodes was characterized by SEM images

School of Physics and Opto-Electronic Technology

(Figure 1a-c), which show BND films are composed of pyramidal

Dalian University of Technology, Dalian 116024, China

Prof. M. R. Hoffmann nanoparticles that cover the entire substrates. Well-faceted

Linde+Robinson Laboratories diamond crystals with clear edges and corners are observed on

California Institute of Technology, California 91125, United States BND1. When N content of BND is increased, twin crystals appear

[#] These authors contributed equally to this work.

on the grain boundaries of BND2 and BND3.

Supporting information for this article is given via a link at the end of the

document.

This article is protected by copyright. All rights reserved.

Angewandte Chemie International Edition 10.1002/anie.201706311

COMMUNICATION

a b c example, at -1.1 V, the measured production rate of CH3CH2OH

is 9.3 times, 17.5 times, 51.0 times as large as that of CH3OH,

and 11.4 times, 16.1 times, 12.9 times as large as that of HCOO -

for BND1, BND2 and BND3, respectively. Moreover, CH3CH2OH

production rate is significantly increased as potential negatively

500 nm 500 nm 500 nm

shifted from -0.8 V to -1.1 V (decrease at -1.1 V due to competition

d e from H2 evolution), while CH3OH and HCOO- production rates

-1 -1

1220 cm 1320 cm

BND3 (111)

(220)

(311) Intensity (a.u.) remain low in the range of potential applied. The CH 3CH2OH

BND3

Intensity (a.u.)

production rate of BND2 is higher than that of BND1 under any

BND2 BND2 potential applied, and lower than that of BND3 at -0.8~-1.0 V,

BND1 BND1

which indicates increasing N content of BND to some extent can

facilitate CH3CH2OH production. At -1.1~-1.2 V, BND2 has a

20 40 60 80 100 900 1200 1500

-1

1800 slightly higher CH3CH2OH production rate than BND3, which may

2 theta (deg.) Raman Shift (cm )

be attributed to more energy is consumed for H2 evolution on

Figure 1. SEM images of (a) BND1, (b) BND2 and (c) BND3 along with their

BND3 than on BND2 (Figure S2).

corresponding (d) XRD and (e) Raman spectra.

1

Current density (mA cm )

-2

0

-1 Ar

The XRD spectra (Figure 1d) of BNDs display three CO2

-2

characteristic diffraction peaks at 43.9°, 75.3° and 91.5°, which 1

0

are assigned to (111), (220) and (311) facets of cubic diamond. -1 Ar

As revealed by peak intensity, the main facet is (111) for BND1, -2 CO2

1

while the main facet for BND2 and BND3 is (220), indicating the 0

increased N content alters the crystal growth direction of BND -1 Ar

-2 CO2

under the conditions applied (details in supporting information). In

the Raman spectra (Figure 1e), peaks around 1220 cm -1 and -1.2 -0.8 -0.4 0.0

Potential (V vs. RHE)

1315-1320 cm-1 appear on each of the BNDs. The peak located

at 1220 cm-1 can be attributed to polyacetylene generated at the Figure 2. Linear sweep voltammograms of BND1, BND2 and BND3 in Ar or

grain boundary of nanocrystalline diamond. The peak around CO2 saturated 0.1 M NaHCO3 solution (scan rate 100 mV s-1).

1315-1320 cm-1 corresponds to sp3 bonded carbon, which is the

characteristic peak of diamond. X-ray photoelectron spectroscopy 90

a 90 b

(XPS) analysis demonstrates B and N are doped into the diamond 72

C2H5OH C2H5OH

72

Rate (g h cm )

CH3OH CH3OH

lattice (Figure S1). The B contents of BND1, BND2 and BND3 are

-2

Rate (g h cm )

- -

-2

54 HCOO HCOO

54

-1

similar (2.4 at.%, 2.4 at.%, 2.5 at.%), while their N contents

-1

increase gradually (3.1 at.%, 3.6 at.%, 4.9 at.%). 36 36

Linear sweep voltammograms of BNDs were measured to 18 18

probe their electrocatalytic activity for CO2 reduction. As

0 0

presented in Figure 2, the current density in CO2 saturated -1.2 -1.1 -1.0 -0.9 -0.8 -1.2 -1.1 -1.0 -0.9 -0.8

solution (jCO2) is greater than that in Ar saturated solution (jAr) for Potential (V vs RHE) Potential (V vs RHE)

90 100

each BND when potential is more negative than threshold value, c d

HCOO

-

Faradaic efficiency (%)

C2H5OH CH3OH

manifesting that the three BNDs are active for electrocatalytic 72

CH3OH

80

C2H5OH

Rate (g h cm )

-2

reduction of CO2. At the same applied potential, BND3 exhibits 54 HCOO

-

60

-1

the highest net current density for CO2 reduction (jCO2-jAr) at

36 40

potential from -0.6 V to -1.0 V, followed by BND2. The onset

potential for CO2 reduction is -0.6 V for BND3, much more positive 18 20

than those for BND2 (-0.7 V) and BND1 (-0.9 V). It is notable that

0 0

as the N content of BND increases, BND is more active for -1.2 -1.1 -1.0 -0.9 -0.8 -1.2 -1.1 -1.0 -0.9 -0.8

Potential (V vs RHE) Potential (V vs RHE)

electrocatalytic CO2 reduction in terms of both onset potential and 100 100

e f

current density (at -0.6 V to -1.0 V). In addition, BNDs present

Faradaic efficiency (%)

Faradaic efficiency (%)

80 80

very negative potential for H2 evolution (-1.0~-1.1 V), on which

CO2 reduction can outcompete proton reduction even at potential 60

-

60 -

HCOO HCOO

as negative as -1.1 V. Its high overpotential for H2 evolution is CH3OH CH3OH

40 40 C2H5OH

C2H5OH

favorable for improving CO2 reduction efficiency.

To confirm the occurrence of CO2 reduction on BNDs and 20 20

explore their reduction products, CO2 electrolysis was performed 0 0

-1.2 -1.1 -1.0 -0.9 -0.8 -1.2 -1.1 -1.0 -0.9 -0.8

on BNDs at applied potentials ranging from -0.8 to -1.2 V. The Potential (V vs RHE) Potential (V vs RHE)

detected products of CO2 reduction are CH3CH2OH, CH3OH and

HCOO- on BND1, BND2 and BND3 (Figure 3a-c). Interestingly, Figure 3. Production rates of CH3CH2OH, CH3OH and HCOO- on (a) BND1, (b)

BND2 and (c) BND3 in CO2 saturated 0.1 M NaHCO3 solution, and

all three BNDs preferentially convert CO 2 to CH3CH2OH, for

corresponding Faradaic efficiencies on (d) BND1, (e) BND2 and (f) BND3.

This article is protected by copyright. All rights reserved.

Angewandte Chemie International Edition 10.1002/anie.201706311

COMMUNICATION

Achieving high Faradaic efficiency is still a great challenge for morphology and dopant content, identical crystal structure and

electrocatalytic reduction of CO2, especially for producing high dominated facet, the main factors contributing to the high activity

heating value fuels such as CH3CH2OH. Here, Faradaic efficiency and selectivity for CH3CH2OH on BND could be the synergetic

for CO2 reduction on BNDs was determined to further evaluate effect of B and N codoping. Both NDD and BND preferentially

their performance (Figure 3d-f). As expected, the Faradaic convert CO2 to C2 product, which suggests doping N into

efficiency for CH3CH2OH is much higher than those for CH3OH diamond may be key for effective C-C coupling reaction. CO2

and HCOO- on BNDs under any potential applied. It increases reduction on N doped graphitic carbon materials is reported to

gradually as potential is shifted from -0.8 V to -1.0 V, and then yield either HCOOH or CO.[9c,9d] Thus, the high CH3CH2OH

decreases at more negative potentials which may be due to selectivity of BND appears to be correlated to the intrinsic property

competition from H2 evolution reaction (Figure S1). The maximum of codoped diamond.

Faradaic efficiency for CH3CH2OH achieved on BND3 is 93.2% at Both CH3CH2OH production rate and current efficiency of BNDs

-1.0 V, which is 3107.7 times as great as that for CH3OH and 69.6 are in the order of BND3> BND2> BND1 before H2 evolution

times as great as that for HCOO-. It illustrates BND presents very occurred (Figure 3). As the three BNDs have the same crystal

high efficiency and selectivity for CH3CH2OH, which is the highest structure, similar morphology and B content, it can be deduced

among electrocatalysts reported to date.[5a,13] The Faradaic that the enhanced CH3CH2OH production performance of BND

efficiencies for CH3CH2OH follows the order BND1<BND2<BND3, may be originated from its increased N content and/or altered

elucidating that higher N content of BND is favorable for main facet (during BND preparation, its main facet changes from

converting CO2 to CH3CH2OH. (111) to (220) with increased N content). BND3 is more active

The durability of BND3 for electrocatalytic reduction of CO 2 was than BND2 for CH3CH2OH production and both of their main facet

evaluated by running 16 consecutive CO2 reduction experiments is (220), demonstrating the increased N content is responsible for

with each run lasting for 3 h at -1.0 V. As shown in Figure 4a, enhanced CH3CH2OH production performance of BND3. As high

Faradaic efficiency for CH3CH2OH keeps around 93.2% during 16 N content will also promote H2 evolution, a balance between N

sequential CO2 reduction experiments, which illustrates the high content and H2 evolution is crucial for achieving good CO2

durability of BND for electrocatalytic reduction of CO2. reduction performance on BND. Meanwhile, DFT computation is

employed to probe the impact of (111) and (220) facets for the

-

100 a b HCOO CH OH C H OH 3preferential production of CH3CH2OH. As shown in Figure S7,

2 5

100

Faradaic efficiency (%)

HCHO CH COOH

Faradaic efficiency (%)

80 CO2 reduction is more favorable on (111) facet than (220) facet

80

with much lower reaction free energy, which suggests altered

60

60 facet may be not the main factor contributing to the superior

40 40 performance of BND for CH3CH2OH production.

20 20 Figure 5a shows the free energy diagram of possible pathways

0 0

for CO2 reduction on (111) facet of BND. The multi-electron

0 4 8

Cycle

12 16 NDD BDD BND1 BND2 BND3

reduction of CO2 to CH3CH2OH proceeds as follows: CO2 →

*COOH → *CO → *COCO → *COCOH → *COCHOH →

Figure 4. (a) Faradaic efficiencies for CH3CH2OH during 16 consecutive runs *COCH2OH → *CHOCH2OH → *CH2OCH2OH → CH3CH2OH.

for CO2 reduction on BND3 at -1.0 V, (b) Faradaic efficiencies for CO2 reduction

Interestingly, two neighboring CO* species can easily link

on NDD, BDD, BND1, BND2 and BND3 at -1.0 V.

together (*CO → *COCO) with reaction free energy of -3.32 eV,

indicating C-C coupling reaction occurs easily on BND, which is

In order to further probe CO2 reduction activity of BNDs, their one of the reason that BND has much higher CH3CH2OH

performance was compared to singly doped BDD and NDD. SEM selectivity over C1 product. In addition, the free energy for the

images show BDD film and NDD film are uniform with well-faceted elementary reaction and overall process of CH3CH2OH

diamond crystals (Figure S3). Both BDD and NDD are cubic production is negative, which illustrates reducing CO2 to

diamond dominated by (111) facet (Figure S4). XPS shows BDD CH3CH2OH is thermodynamically favorable on BND. Meanwhile,

has the same B content as BND1 and BND2 (2.4 at.%), and NDD the synergetic effect of B and N codoping for CH 3CH2OH

has the same N content as BND2 (3.6 at.%, slightly higher than production also can be revealed by DFT analysis. Figure 5b

3.1 at.% of BND1). Their linear sweep voltammograms (Figure S5) shows the energetically favorable configuration associated with

reveals both BDD and NDD are active for CO2 reduction and the elementary step of CO2 reduction at diamond (111) surface, which

net current density of BND2 for CO2 reduction is much higher than was explored from possible structures. At first, the doped B atom

those of BDD and NDD, indicating co-doping significantly may enhance CO2 capture by bonding with one O atom of

enhances CO2 reduction activity. The main products for absorbed CO2 (*CO2). In the subsequent *CO2 reduction process

electrocatalytic CO2 reduction are HCHO/HCOOH for BDD, which proceeds through addition of H, H preferentially adsorbs at

whereas they are CH3COOH/HCOOH for NDD (Figure S6). doped N atom before diffusion into *CO2. The doped N can

Despite their generation of lower heating value products relative facilitate *H transfer in the elementary reactions involving

to CH3CH2OH produced on BNDs, the Faradaic efficiency for hydrogenation, taking the reaction *COCO → *COCOH for

HCHO (53.9%)/HCOOH (26.1%) production on BDD, CH3COOH example, the energy barrier is 2.74 eV when H is transferred from

(62.4%)/HCOOH (24.7%) production on NDD is much lower than the top C atom of diamond (without N doping), while it is 0.89 eV

those of CH3CH2OH generation on BNDs, which are 83.3%, 88.8% for H transferred from N atom. Meanwhile, B atom also plays an

and 93.2% for BND1, BND2 and BND3, respectively (Figure 4b). important role by forming B-O bond in the reactions *COOH →

Considering that BDD, NDD and BND1 have the similar *CO and *COCHOH → *COCH2OH → *CHOCH2OH →

This article is protected by copyright. All rights reserved.

Angewandte Chemie International Edition 10.1002/anie.201706311

COMMUNICATION

*CH2OCH2OH, which can promote these elementary reactions. [1] a) J. Qiao, Y. Liu, F. Hong, J. Zhang, Chem. Soc. Rev. 2014, 43, 631-675;

Both experimental and DFT results imply that the synergetic effect b) D. D. Zhu, J. L. Liu, S. Z. Qiao, Adv. Mater. 2016, 28, 3423-3452; c) S.

Gao, Y. Lin, X. Jiao, Y. Sun, Q. Luo, W. Zhang, D. Li, J. Yang, Y. Xie,

of B and N codoping is crucial for CH3CH2OH production on BND.

Nature 2016, 529, 68-71; d) X. Nie, M. R. Esopi, M. J. Janik, A. Asthagiri,

1 Angew. Chem. Int. Ed. 2013, 52, 2459-2462; Angew. Chem. 2013, 125,

a

2519-2522.

0

CO2 [2] a) K. P. Kuhl, T. Hatsukade, E. R. Cave, D. N. Abram, J. Kibsgaard, T. F.

*CO

Jaramillo, J. Am. Chem. Soc. 2014, 136, 14107-14113; b) A. Loiudice, P.

Free energy (eV)

*CH2OCH2OH

Lobaccaro, E. A. Kamali, T. Thao, B. H. Huang, J. W. Ager, R. Buonsanti,

-1 CH3CH2OH

Angew. Chem. Int. Ed. 2016, 55, 5789-5792; Angew. Chem. 2016, 128,

*COOH

*CHOCH2OH

5883-5886; c) J. Medina-Ramos, R. C. Pupillo, T. P. Keane, J. L. DiMeglio,

-2 J. Rosenthal, J. Am. Chem. Soc. 2015, 137, 5021-5027; d) X. Min, M. W.

*COCH2OH

Kanan, J. Am. Chem. Soc. 2015, 137, 4701-4708; e) K. P. Kuhl, E. R. Cave,

-3 *COCHOH D. N. Abram, T. F. Jaramillo, Energy Environ. Sci. 2012, 5, 7050-7059; f)

*COCO *COCOH

H. Xiao, T. Cheng, W. A. Goddard, J. Am. Chem. Soc. 2017, 139, 130-136.

-4 [3] S. Zhang, P. Kang, M. Bakir, A. M. Lapides, C. J. Dares, T. J. Meyer, Proc.

Reaction coordinate

Natl. Acad. Sci. USA 2015, 112, 15809-15814.

b

[4] a) R. Reske, H. Mistry, F. Behafarid, B. Roldan Cuenya, P. Strasser, J. Am.

Chem. Soc. 2014, 136, 6978-6986; b) D. Gao, H. Zhou, J. Wang, S. Miao,

F. Yang, G. Wang, J. Wang, X. Bao, J. Am. Chem. Soc. 2015, 137, 4288-

4291.

[5] a) M. Ma, K. Djanashvili, W. A. Smith, Angew. Chem. Int. Ed. 2016, 55,

6680-6684; Angew. Chem. 2016, 128, 6792-6796; b) M. Liu, Y. Pang, B.

Zhang, P. De Luna, O. Voznyy, J. Xu, X. Zheng, C. T. Dinh, F. Fan, C. Cao,

F. P. de Arquer, T. S. Safaei, A. Mepham, A. Klinkova, E. Kumacheva, T.

Filleter, D. Sinton, S. O. Kelley, E. H. Sargent, Nature 2016, 537, 382-386;

c) Y. Li, F. Cui, M. B. Ross, D. Kim, Y. Sun, P. Yang, Nano Lett. 2017, 17,

Figure 5. (a) Free energy diagrams for CO2 reduction on (111) facet of BND,

1312-1317.

(b) Energetically favorable structures for elementary steps of CO2 reduction on

[6] H. Won da, H. Shin, J. Koh, J. Chung, H. S. Lee, H. Kim, S. I. Woo, Angew.

(111) facet of BND (gray = C, pink = B, blue = N, red = O, white = H).

Chem. Int. Ed. 2016, 55, 9297-9300; Angew. Chem. 2016, 128, 9443-9446 .

[7] Z. Cao, D. Kim, D. Hong, Y. Yu, J. Xu, S. Lin, X. Wen, E. M. Nichols, K.

Efficient and selective electrochemical reduction of CO 2 to Jeong, J. A. Reimer, P. Yang, C. J. Chang, J. Am. Chem. Soc. 2016, 138,

CH3CH2OH has been achieved on BND with CH3CH2OH 8120-8125.

production rate one order of magnitude higher than those of minor [8] a) F. Li, S. F. Zhao, L. Chen, A. Khan, D. R. MacFarlane, J. Zhang, Energy

products. The Faradaic efficiency for CH3CH2OH was 93.2%, Environ. Sci. 2016, 9, 216-223; b) S. Gao, X. Jiao, Z. Sun, W. Zhang, Y.

Sun, C. Wang, Q. Hu, X. Zu, F. Yang, S. Yang, L. Liang, J. Wu, Y. Xie,

significantly enhanced relative to values reported for other

Angew. Chem. Int. Ed. 2016, 55, 698-702; Angew. Chem. 2016, 128, 708-

electrocatalysts. Experimental analysis coupled with DFT 712.

calculation indicated the high activity and selectivity of BND for [9] a) B. Kumar, M. Asadi, D. Pisasale, S. Sinha-Ray, B. A. Rosen, R. Haasch,

CH3CH2OH production mainly originated from the synergetic J. Abiade, A. L. Yarin, A. Salehi-Khojin, Nat. Commun. 2013, 4, 3819; b) K.

effect of B and N codoping and fine balance between N content Nakata, T. Ozaki, C. Terashima, A. Fujishima, Y. Einaga, Angew. Chem.

and H2 evolution potential. The preferred pathway obtained from Int. Ed. 2014, 53, 871-874; Angew. Chem. 2014, 126, 890-893; c) J. Wu,

DFT computation was CO2 →*COOH → *CO → *COCO M. Liu, P. P. Sharma, R. M. Yadav, L. Ma, Y. Yang, X. Zou, X. D. Zhou, R.

Vajtai, B. I. Yakobson, J. Lou, P. M. Ajayan, Nano Lett. 2016, 16, 466-470;

→*COCH2OH →*CH2OCH2OH → CH3CH2OH, where *COCO

d) S. Zhang, P. Kang, S. Ubnoske, M. K. Brennaman, N. Song, R. L. House,

formation occurred easily on BND. This work provides new insight

J. T. Glass, T. J. Meyer, J. Am. Chem. Soc. 2014, 136, 7845-7848; e) X. C.

into converting CO2 to high heating value C2 products such as Wang, K. Maeda, A. Thomas, K. Takanabe, G. Xin, J. M. Carlsson, K.

CH3CH2OH by carbon based electrodes. Domen, M. Antonietti, Nat. Mater. 2009, 8, 76-80.

[10] a) Y. Liu, S. Chen, X. Quan, H. Zhao, H. Yu, Y. Zhang, J. Mater. Chem. A

2013, 1, 14706-14712; b) T. Yokoya, T. Nakamura, T. Matsushita, T. Muro,

Y. Takano, M. Nagao, T. Takenouchi, H. Kawarada, T. Oguchi, Nature

Acknowledgements

2005, 438, 647-650.

[11] Y. M. Liu, S. Chen, X. Quan, H. T. Yu, J. Am. Chem. Soc. 2015, 137, 11631-

This work was supported by National Natural Science Foun- 11636.

dation of China (NO. 21590813 and NO. 21437001) and the Pro- [12] Y. Zheng, Y. Jiao, L. Ge, M. Jaroniec, S. Z. Qiao, Angew. Chem. Int. Ed.

gramme of Introducing Talents of Discipline to Universi-ties 2013, 52, 3110-3116; Angew. Chem. 2013, 125, 3192-3198.

(B13012). [13] a) J. Wu, S. Ma, J. Sun, J. I. Gold, C. Tiwary, B. Kim, L. Zhu, N. Chopra, I.

N. Odeh, R. Vajtai, A. Z. Yu, R. Luo, J. Lou, G. Ding, P. J. Kenis, P. M.

Ajayan, Nat. Commun. 2016, 7, 13869; b) D. Raciti, K. J. Livi, C. Wang,

Keywords: CO2 reduction • doped diamond • electrocatalysis •

Nano Lett. 2015, 15, 6829-6835.

ethanol • heterogeneous catalysis

This article is protected by copyright. All rights reserved.

Angewandte Chemie International Edition 10.1002/anie.201706311

COMMUNICATION

Entry for the Table of Contents

COMMUNICATION

Efficient and selective electrochemical Y. M. Liu, Y. J. Zhang, K. Chen, X. Quan,*

reduction of CO2 to ethanol was X. F. Fan, Y. Su, S. Chen, H. M. Zhao, Y.

achieved on nonmetallic B and N B. Zhang, H. T. Yu, M. R. Hoffmann

codoped nanodiamond. The

synergistic effect of B/N codoping, N C2H5OH Page No. – Page No.

content and H2 evolution potential were

Selective electrochemical reduction of

used as key factors for tailoring ethanol C2H5OH

CO2 to ethanol on B and N codoped

selectivity. These factors and

nanodiamond

uncovered CO2 reduction mechanism 2CO2 + 9H2O + 12e– → C2H5OH + 12OH−

is valuable for converting CO2 to

multicarbon or high heating value fuels.

This article is protected by copyright. All rights reserved.

You might also like

- Limestone: Lime: 20 KG: Kgmole PGDocument16 pagesLimestone: Lime: 20 KG: Kgmole PGPauline Ortilla100% (1)

- Degradation Study On Tin - and Bismuth-Based Gas-Diffusion Electrodes During Electrochemical CO2 Reduction in Highly Alkaline MediaDocument10 pagesDegradation Study On Tin - and Bismuth-Based Gas-Diffusion Electrodes During Electrochemical CO2 Reduction in Highly Alkaline MediagrizzopitonNo ratings yet

- Electrochemical Reduction of CO Catalyzed by Metal NanocatalystsDocument12 pagesElectrochemical Reduction of CO Catalyzed by Metal NanocatalystsaliNo ratings yet

- Electrocatalytic Reduction of CO Into Useful Chemicals-A Brief ReviewDocument19 pagesElectrocatalytic Reduction of CO Into Useful Chemicals-A Brief ReviewJayarama ANo ratings yet

- Syngas NatcommunDocument9 pagesSyngas NatcommunrmramsundarNo ratings yet

- Catalysts 12 00403 v2Document33 pagesCatalysts 12 00403 v2Châu Tinh TổNo ratings yet

- 1 s2.0 S2213343722020449 MainDocument13 pages1 s2.0 S2213343722020449 MainDaniel MontalvoNo ratings yet

- Improved Methanol Yield and Selectivity From CO2 Hydrogenation Using A Novel Cu-ZnO-ZrO2 Catalyst Supported On Mg-Al Layered Double Hydroxide (LDH)Document8 pagesImproved Methanol Yield and Selectivity From CO2 Hydrogenation Using A Novel Cu-ZnO-ZrO2 Catalyst Supported On Mg-Al Layered Double Hydroxide (LDH)Nguyễn TuânNo ratings yet

- Selective CO2 Reduction On 2D Mesoporous Bi NanosheetsDocument6 pagesSelective CO2 Reduction On 2D Mesoporous Bi NanosheetsSantosh Srinivas NNo ratings yet

- The Design Aspects of Metal Complexes in CO2 Reduction A Mini ReviewDocument5 pagesThe Design Aspects of Metal Complexes in CO2 Reduction A Mini ReviewInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 1 s2.0 S1385894724004571 MainDocument14 pages1 s2.0 S1385894724004571 MainanushathampiNo ratings yet

- Reactores 2Document19 pagesReactores 2Ariday BeltránNo ratings yet

- AJNM - Volume 3 - Issue 2 - Pages 93-102Document10 pagesAJNM - Volume 3 - Issue 2 - Pages 93-102Hùng TrầnNo ratings yet

- Photoreduction, Maida PDFDocument8 pagesPhotoreduction, Maida PDF'Sebastian OrtizNo ratings yet

- 2018, CO2 Capture and Electro-Conversion Into Valuable Organic Products A Batch and Continuous StudyDocument13 pages2018, CO2 Capture and Electro-Conversion Into Valuable Organic Products A Batch and Continuous StudyRitesh PatidarNo ratings yet

- Varela Et Al-2018-Advanced Energy MaterialsDocument36 pagesVarela Et Al-2018-Advanced Energy MaterialsHarshithNo ratings yet

- Bimetallic CatalystDocument6 pagesBimetallic CatalystAkundi VsjNo ratings yet

- Applied Catalysis B: EnvironmentalDocument9 pagesApplied Catalysis B: EnvironmentalElson OliveiraNo ratings yet

- Expeerimental DtatDocument10 pagesExpeerimental DtatGeorge FuryNo ratings yet

- Trabajo 2 Segundo SemestreDocument11 pagesTrabajo 2 Segundo SemestreSergio AlejandroNo ratings yet

- A Carbon Efficient Bicarbonate Electrolyzer - 2023 - XDocument18 pagesA Carbon Efficient Bicarbonate Electrolyzer - 2023 - Xalvaro david torresNo ratings yet

- N and P DoppéDocument8 pagesN and P DoppétahaNo ratings yet

- Synergistic Effect of MgH2 Doping With Ni and Carbon N 2022 International JoDocument15 pagesSynergistic Effect of MgH2 Doping With Ni and Carbon N 2022 International JoPrashant HNo ratings yet

- Production of Hydrogen by Thermal Methane Splitting in A Nozzle-Type Laboratory-Scale Solar ReactDocument11 pagesProduction of Hydrogen by Thermal Methane Splitting in A Nozzle-Type Laboratory-Scale Solar ReactMohammed AlShammasiNo ratings yet

- Bio-Ethanol Ni - MG - Al (Ni1 - Ni3)Document13 pagesBio-Ethanol Ni - MG - Al (Ni1 - Ni3)posidontubeNo ratings yet

- Electrochemical Reduction of Co TO Methane in Methanol at Low TemperatureDocument2 pagesElectrochemical Reduction of Co TO Methane in Methanol at Low TemperatureHassaanNo ratings yet

- 7 8 2022 s40145-022-0619-xDocument13 pages7 8 2022 s40145-022-0619-xicpsdt.cuetNo ratings yet

- Feliz 2021 J. Phys. D Appl. Phys. 54 334003Document16 pagesFeliz 2021 J. Phys. D Appl. Phys. 54 334003Hoang Phuong NguyenNo ratings yet

- Uamerica 23 01.196Document16 pagesUamerica 23 01.196Rimy Cruz GambaNo ratings yet

- Azine-Based Covalent Organic Frameworks As Metal-Free Visible Light Photocatalysts For CO2 Reduction With H2ODocument32 pagesAzine-Based Covalent Organic Frameworks As Metal-Free Visible Light Photocatalysts For CO2 Reduction With H2OJam imtiazNo ratings yet

- ChemSusChem - 2016 - Schlager - Electrochemical Reduction of Carbon Dioxide To Methanol by Direct Injection of ElectronsDocument5 pagesChemSusChem - 2016 - Schlager - Electrochemical Reduction of Carbon Dioxide To Methanol by Direct Injection of ElectronsliviuNo ratings yet

- Nanomaterials 13 00506 v2Document18 pagesNanomaterials 13 00506 v2sripantNo ratings yet

- Journal of Environmental Chemical Engineering: 2 2 Yan Resing Dias, Oscar W. Perez-LopezDocument8 pagesJournal of Environmental Chemical Engineering: 2 2 Yan Resing Dias, Oscar W. Perez-Lopezfarah al-sudaniNo ratings yet

- 1 s2.0 S2213343722005838 MainDocument14 pages1 s2.0 S2213343722005838 Mainpattanapon.kNo ratings yet

- Solid State Ionics: Tae Ho Shin, Jae-Ha Myung, Khan M. Naeem, Cristian Savaniu, John T.S. IrvineDocument4 pagesSolid State Ionics: Tae Ho Shin, Jae-Ha Myung, Khan M. Naeem, Cristian Savaniu, John T.S. Irvinedennisitty01No ratings yet

- Electrochimica ActaDocument6 pagesElectrochimica ActacomsianNo ratings yet

- Graphene Oxide As A Promising Photocatalyst For CO2 To MethanolDocument7 pagesGraphene Oxide As A Promising Photocatalyst For CO2 To MethanolJose FERNANDEZ ADELLNo ratings yet

- 1 s2.0 S0926337321001995 MainDocument28 pages1 s2.0 S0926337321001995 MainmariaapliakaNo ratings yet

- 1 s2.0 S1385894723009713 MainDocument9 pages1 s2.0 S1385894723009713 MainherayatiNo ratings yet

- Applied Catalysis B: Environment and EnergyDocument12 pagesApplied Catalysis B: Environment and Energydr.shakeri2209No ratings yet

- Bore Ribo On 2018Document8 pagesBore Ribo On 2018Hêny CarlênicNo ratings yet

- Electrocatalytic Production of C3-C4 Compounds by Conversion of CO On A Chloride-Induced Bi-Phasic Cu O-Cu CatalystDocument5 pagesElectrocatalytic Production of C3-C4 Compounds by Conversion of CO On A Chloride-Induced Bi-Phasic Cu O-Cu CatalystAsifHasanliNo ratings yet

- On The General Mechanism of Photocatalytic Reduction of CO2Document10 pagesOn The General Mechanism of Photocatalytic Reduction of CO2alejandro sifuentes clementeNo ratings yet

- Journal of Environmental Chemical Engineering: 2 2 Chao Qu, Da-Wei LiangDocument8 pagesJournal of Environmental Chemical Engineering: 2 2 Chao Qu, Da-Wei LiangMM afsahiNo ratings yet

- Dang 2019Document8 pagesDang 2019Maria Rita TomazNo ratings yet

- Energies: CO Utilization Technologies: A Techno-Economic Analysis For Synthetic Natural Gas ProductionDocument18 pagesEnergies: CO Utilization Technologies: A Techno-Economic Analysis For Synthetic Natural Gas Productionayiep1202No ratings yet

- Novel Highly Active Carbon Supported Ternary Pdnibi Nanoparticles As Anode Catalyst For The Alkaline Direct Ethanol Fuel CellDocument11 pagesNovel Highly Active Carbon Supported Ternary Pdnibi Nanoparticles As Anode Catalyst For The Alkaline Direct Ethanol Fuel CellFabricio CarrilloNo ratings yet

- 2021 - Hu - Ni, W2C and WC SpeciesDocument16 pages2021 - Hu - Ni, W2C and WC SpeciesArmonistasNo ratings yet

- 7171 Oxyfuel Combustion For Below Zero CO2 EmissionsDocument462 pages7171 Oxyfuel Combustion For Below Zero CO2 EmissionsJoão13@No ratings yet

- 21-H2 CO2 Polymer Electrolyte Fuel Cell PT Ru C CathodeDocument8 pages21-H2 CO2 Polymer Electrolyte Fuel Cell PT Ru C Cathodeee20b044No ratings yet

- Zou 2019Document7 pagesZou 2019sheraz ahmadNo ratings yet

- Catalysts 12 00363Document32 pagesCatalysts 12 00363Khalid RashidNo ratings yet

- Journal of Industrial and Engineering Chemistry: A. Loder, M. Siebenhofer, S. LuxDocument12 pagesJournal of Industrial and Engineering Chemistry: A. Loder, M. Siebenhofer, S. Luxfarah al-sudaniNo ratings yet

- S027288422102722XDocument9 pagesS027288422102722Xahmad.faizal.2005136No ratings yet

- Benamor 2018 IOP Conf. Ser.: Mater. Sci. Eng. 458 012063Document9 pagesBenamor 2018 IOP Conf. Ser.: Mater. Sci. Eng. 458 012063Hatef ShabanianNo ratings yet

- 1 s2.0 S0959652621014104 MainextDocument24 pages1 s2.0 S0959652621014104 MainextNafees VakilNo ratings yet

- CO2 Splitting To Carbon - Ceria - Nat CommunDocument8 pagesCO2 Splitting To Carbon - Ceria - Nat CommunherayatiNo ratings yet

- JASEM ISSN 1119-8362: Keywords: Cobalt Greenhouse Gases Hydrogen Reforming Neodymium (III) OxideDocument6 pagesJASEM ISSN 1119-8362: Keywords: Cobalt Greenhouse Gases Hydrogen Reforming Neodymium (III) OxideOsariemen Angela EdokpayiNo ratings yet

- High-Entropy Intermetallics On Ceria As Ef Ficient Catalysts For The Oxidative Dehydrogenation of Propane Using CODocument10 pagesHigh-Entropy Intermetallics On Ceria As Ef Ficient Catalysts For The Oxidative Dehydrogenation of Propane Using COEtherNo ratings yet

- Carbon Dioxide Thermodynamic Properties Handbook: Covering Temperatures from -20° to 250°C and Pressures up to 1000 BarFrom EverandCarbon Dioxide Thermodynamic Properties Handbook: Covering Temperatures from -20° to 250°C and Pressures up to 1000 BarNo ratings yet

- Carcinogens Mutagens and TeratogensDocument14 pagesCarcinogens Mutagens and TeratogensGC Photo StateNo ratings yet

- Acetylene MsdsDocument15 pagesAcetylene MsdsfouedNo ratings yet

- Worksheet Mass SpectrometryDocument7 pagesWorksheet Mass SpectrometryMinh Thy Nguyen LeNo ratings yet

- Brosur Decontamination Kits CBRN ProtectionDocument2 pagesBrosur Decontamination Kits CBRN ProtectionFrilia Elfani PutriNo ratings yet

- J Foodchem 2017 09 080Document10 pagesJ Foodchem 2017 09 080Theo MartinezNo ratings yet

- DOMO Series: Part 1: General RequirementsDocument1 pageDOMO Series: Part 1: General RequirementsZulioTZNo ratings yet

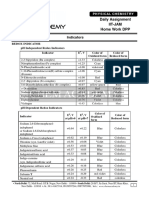

- Chem Academy: Daily Assignment Iit-Jam Home Work DPPDocument3 pagesChem Academy: Daily Assignment Iit-Jam Home Work DPPjkc collegeNo ratings yet

- SCIENCE-9 Q1 W6-W7 Mod5 ADM-1-photosythesisDocument42 pagesSCIENCE-9 Q1 W6-W7 Mod5 ADM-1-photosythesisJB Dar100% (1)

- Astm F2620-11Document21 pagesAstm F2620-11Gianfranco Niquín100% (3)

- NSM 3-5 ManualDocument23 pagesNSM 3-5 Manualatamed32No ratings yet

- Gel Electrophoresis and Alternative Tracking DyeDocument3 pagesGel Electrophoresis and Alternative Tracking DyeAnime GangNo ratings yet

- Afico Liner CatalogueDocument4 pagesAfico Liner CatalogueChris SolonNo ratings yet

- Cbjescpu 27Document13 pagesCbjescpu 27chilledyt243No ratings yet

- Joining of Carbon Fibre Reinforced Polymer CFRP Composites and Aluminium AlloyDocument72 pagesJoining of Carbon Fibre Reinforced Polymer CFRP Composites and Aluminium AlloySorina gNo ratings yet

- The Effects of Different Debittering Methods On The Production of Lupin Bean Snack From BitterDocument16 pagesThe Effects of Different Debittering Methods On The Production of Lupin Bean Snack From BitterMalak BattahNo ratings yet

- Transformation of Sentences (Part-4)Document4 pagesTransformation of Sentences (Part-4)Nishinath Chondro GainNo ratings yet

- Experiment No. 5: ObjectDocument5 pagesExperiment No. 5: ObjectDarshil GalaiyaNo ratings yet

- Starch Fatty EsteresDocument6 pagesStarch Fatty EsteresRobertaSouzaNo ratings yet

- Cuckow 1949Document6 pagesCuckow 1949Thai NghNo ratings yet

- Alamsyah Et Al., 2008Document6 pagesAlamsyah Et Al., 2008Luana BouvieNo ratings yet

- 7.3 Salt Preparation PPQ - SDocument10 pages7.3 Salt Preparation PPQ - SWu YiruiNo ratings yet

- Bello Zon CDVC Part 1 English Proinent ClO2 GenDocument48 pagesBello Zon CDVC Part 1 English Proinent ClO2 GenPaul IvanNo ratings yet

- Aldol InstrDocument7 pagesAldol Instrmed jrNo ratings yet

- Assignment - 01: Department of Mechanical Engineering National University of Technology Machine Design II (ME-3442)Document1 pageAssignment - 01: Department of Mechanical Engineering National University of Technology Machine Design II (ME-3442)Muscle TVNo ratings yet

- Mil PRF 7808LDocument18 pagesMil PRF 7808LLuca LombardiNo ratings yet

- General Biology NotesDocument2 pagesGeneral Biology NotesjeayNo ratings yet

- Soap and DetergentDocument24 pagesSoap and DetergentCik Tiem Ngagiman80% (10)

- M1062E01-Biossays 240 Series-181207-1Document2 pagesM1062E01-Biossays 240 Series-181207-1Luana ZuffoNo ratings yet

- 2 LetuchijDocument5 pages2 LetuchijshahinNo ratings yet