Professional Documents

Culture Documents

AAC Block 516

AAC Block 516

Uploaded by

Sanjay Kumar Gouda Sanju0 ratings0% found this document useful (0 votes)

13 views3 pagesThe document summarizes common types of cracks in AAC block masonry structures and provides mitigation measures. It lists 5 types of cracks:

1) Structural movements due to load settlement, thermal expansion, or moisture changes. Mitigation includes delaying partitions and using bond beams.

2) Floor deformation and movement. Mitigation is embedding steel wires in mortar joints.

3) Ceiling deflection and movement. Mitigation includes separating walls from ceilings or forming cuts.

4) Deflection of structural abutments. Mitigation is using slip joints.

5) Wall movement from temperature and moisture changes. Mitigation includes specifying moisture limits, adding reinforcement, and providing control joints.

Original Description:

516

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document summarizes common types of cracks in AAC block masonry structures and provides mitigation measures. It lists 5 types of cracks:

1) Structural movements due to load settlement, thermal expansion, or moisture changes. Mitigation includes delaying partitions and using bond beams.

2) Floor deformation and movement. Mitigation is embedding steel wires in mortar joints.

3) Ceiling deflection and movement. Mitigation includes separating walls from ceilings or forming cuts.

4) Deflection of structural abutments. Mitigation is using slip joints.

5) Wall movement from temperature and moisture changes. Mitigation includes specifying moisture limits, adding reinforcement, and providing control joints.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

13 views3 pagesAAC Block 516

AAC Block 516

Uploaded by

Sanjay Kumar Gouda SanjuThe document summarizes common types of cracks in AAC block masonry structures and provides mitigation measures. It lists 5 types of cracks:

1) Structural movements due to load settlement, thermal expansion, or moisture changes. Mitigation includes delaying partitions and using bond beams.

2) Floor deformation and movement. Mitigation is embedding steel wires in mortar joints.

3) Ceiling deflection and movement. Mitigation includes separating walls from ceilings or forming cuts.

4) Deflection of structural abutments. Mitigation is using slip joints.

5) Wall movement from temperature and moisture changes. Mitigation includes specifying moisture limits, adding reinforcement, and providing control joints.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

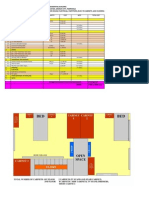

AAC Block Manufacturing Process Flow Chart

AAC Block Masonry – Crack -Causes -Mitigation Measures

Sl.no Type of Crack Reason Mitigation

A In the case of framed structures, erection of

partitions and panel walls shall be delayed

wherever possible until the frame has taken

up, as much as possible, any deformation

Cracks may occur due to alterations in length, occurring due to structural movements.

Structural Movements curvature or orientation of the structural Cracks in partition walls may occur at the

members enclosing a wall or partition due to corners of door frames and window frames at

load settlement, thermal expansion or changes lintel level or sill level. It may, therefore, be

in moisture content. desirable to provide a nominal reinforced

concrete bond beam (see Fig. 1) at sill level

and vertical reinforced concrete stud at either

side of vertical members of frames which may

in addition provide sufficient anchorage for

the holdfast.

The floor upon which a partition is built may This may be achieved by embedding wires of

deflect under load brought upon it after it is minimum 3 mm diameter mild steel or

built. Where such deflections tend to create galvanized steel or welded wire fabric strip in

B Floor deformation

non-continuous bearing, the partition shall be bed joints in cement mortar 1: 2 after every

and movement strong enough to span between the points of 900 mm to 1200 mm height.

least floor deflection or shall be capable of

adapting itself to the altered conditions of

support without cracking.

To avoid cracking as a result of such

deflection, the partition wall shall be separated

A ceiling above a partition wall may deflect from the ceiling by a gap or by a layer of

C Ceiling deflection and

under loads applied after its erection, or resilient material or lean mortar. Where this

movement through thermal or other movements. cannot be done as in the case of plastered

finishes, the risk of cracking may be

diminished by forming a cut between the

ceiling plaster and the wall plaster.

Type of Crack Reason Mitigation

D Deflection or Walls, columns or other structural elements In order to avoid cracking of walls or partitions

movement of against which a wall or partition abuts may as a result of such movements, a slip joint shall

deflect or move because of load, settlement, be provided where possible, preferably packed

structural abutments -

shrinkage or thermal effects with a resilient material or lean mortar.

E Control of Wall Cracking in concrete masonry walls is often due There are three methods of controlling

Movement to tensile stresses which develop when wall cracking in concrete masonry structures:

movements accompanying temperature and a) Specifying a limit on the moisture content

Accompanying

moisture change are restrained by other of masonry units at the time of delivery and

Temperature and elements of the building, or when concrete construction, b) Incorporating steel

Moisture Changes masonry places restraint on the movement of reinforcement either in the form of nominal

adjoining elements. bond beams or horizontal joint reinforcement.

c) Providing control joints to accommodate

the movement

Figure -1 – Nominal Reinforced concrete Bond Beam at Sill Level.

You might also like

- Classification of Shear WallDocument23 pagesClassification of Shear WallShivkamal50% (2)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- UnderpinningDocument58 pagesUnderpinningZoeyHakim100% (1)

- INFILLSDocument26 pagesINFILLSShah Nawaz KhanNo ratings yet

- Control Joints For Concrete Masonry Walls - Empirical Method: TEK 10-2CDocument8 pagesControl Joints For Concrete Masonry Walls - Empirical Method: TEK 10-2CWissam AlameddineNo ratings yet

- Chapter9-Masonry Walls Under Lateral LoadsDocument37 pagesChapter9-Masonry Walls Under Lateral Loadsreadcc.nepalNo ratings yet

- Tek 10-02C1Document8 pagesTek 10-02C1albertoxinaNo ratings yet

- Seismic Response of Wood-Frame Construction: Part B: The Role of Wood-Framed DiaphragmsDocument4 pagesSeismic Response of Wood-Frame Construction: Part B: The Role of Wood-Framed Diaphragmsrmm99rmm99No ratings yet

- Damages and RepairDocument25 pagesDamages and RepairNikil ShetNo ratings yet

- Ce 113 - Concrete Pavement Behavior and CharacteristicsDocument12 pagesCe 113 - Concrete Pavement Behavior and CharacteristicsJacob John100% (3)

- Link Beam Schedule-ModelDocument19 pagesLink Beam Schedule-ModelJohnson SambranoNo ratings yet

- Construction JointDocument1 pageConstruction JointAbbas FarisNo ratings yet

- Blast Protection For Facade's Part 3Document7 pagesBlast Protection For Facade's Part 3psychotrackerNo ratings yet

- Wall Frame Structures - Draft 27-2-2014Document23 pagesWall Frame Structures - Draft 27-2-2014Muhammad Ahsan NadeemNo ratings yet

- Low Retaining Walls: RightDocument4 pagesLow Retaining Walls: Rightgusyahri001No ratings yet

- Seismic Response of Concrete & Masonry Buildings: Part C: The Role of Shear Walls and FramesDocument4 pagesSeismic Response of Concrete & Masonry Buildings: Part C: The Role of Shear Walls and Framesrmm99rmm99No ratings yet

- Design of Monolithic Concrete Ground FloorsDocument13 pagesDesign of Monolithic Concrete Ground FloorsЕгор ШигинNo ratings yet

- Assignment 3 (Infill Wall)Document6 pagesAssignment 3 (Infill Wall)Mahmoud AlbhaisiNo ratings yet

- Capacity Design of Infilled Frame Structures: Francisco J CRISAFULLI, Athol J CARR and Robert PARKDocument8 pagesCapacity Design of Infilled Frame Structures: Francisco J CRISAFULLI, Athol J CARR and Robert PARKDebby KrisnandiNo ratings yet

- Module 4 Singapore Structural Steel Society 2001Document29 pagesModule 4 Singapore Structural Steel Society 2001joyce burhanNo ratings yet

- Strength of Materials II - 4C - Dams & Retaining Walls - Analysis & Conditions of Stability of Retaining WallsDocument12 pagesStrength of Materials II - 4C - Dams & Retaining Walls - Analysis & Conditions of Stability of Retaining WallsEdwin KaranjqNo ratings yet

- Building Advisory Notice 13 14 Technical Specification C1 - 11 Performance of External Walls in FireDocument3 pagesBuilding Advisory Notice 13 14 Technical Specification C1 - 11 Performance of External Walls in FiretkaluarlgpmNo ratings yet

- 4 Joints in BuildingsDocument18 pages4 Joints in BuildingsDipeshNo ratings yet

- Study of Cracks in Buildings: January 2009Document15 pagesStudy of Cracks in Buildings: January 2009sharathr22No ratings yet

- Study of Cracks in Buildings: January 2009Document15 pagesStudy of Cracks in Buildings: January 2009meetNo ratings yet

- TEK 03-2A Grouting Concrete Masonry WallsDocument6 pagesTEK 03-2A Grouting Concrete Masonry WallsjerryNo ratings yet

- Concrete Construction Article PDF - Detailing Shelf AnglesDocument2 pagesConcrete Construction Article PDF - Detailing Shelf AnglesFarid RezaeianNo ratings yet

- Masonry Control Joints (TEK - 10-02B) PDFDocument4 pagesMasonry Control Joints (TEK - 10-02B) PDFCesar RjszvlNo ratings yet

- Shear Strength and Compressive Strength of Reinforced Perforated Clay Block MasonryDocument23 pagesShear Strength and Compressive Strength of Reinforced Perforated Clay Block MasonryEmil SánchezNo ratings yet

- Shear Wall ApplicationsDocument10 pagesShear Wall ApplicationsArian AhmedNo ratings yet

- Gas Insulated Switchgear (GIS) Building Concrete Cracks CausesDocument8 pagesGas Insulated Switchgear (GIS) Building Concrete Cracks CausesmohamedNo ratings yet

- Common Construction PT Issues ArticleDocument4 pagesCommon Construction PT Issues ArticleUdom RithNo ratings yet

- 13 - Chapter 5 PDFDocument12 pages13 - Chapter 5 PDFbharathikrishnaNo ratings yet

- "Post Tensioning": Abgao, Alvin MDocument3 pages"Post Tensioning": Abgao, Alvin MAce JokerNo ratings yet

- CIP 6 - Joints in Concrete Slabs On GradeDocument2 pagesCIP 6 - Joints in Concrete Slabs On GradeBalaji_Rajaman_2280No ratings yet

- Civil Equaltion PDFDocument2 pagesCivil Equaltion PDFBalaji_Rajaman_2280No ratings yet

- CMAA MovementDocument9 pagesCMAA MovementalbertoxinaNo ratings yet

- Retrofit Group StudyDocument30 pagesRetrofit Group StudyDivith B SannakkiNo ratings yet

- Study of Cracks in BuildingsDocument15 pagesStudy of Cracks in BuildingsZEC LIMITEDNo ratings yet

- Lintel Design and DetailingDocument4 pagesLintel Design and Detailingxuanlinh_nguyen8063100% (1)

- TN 30 Cladding Subject To EarthquakesDocument5 pagesTN 30 Cladding Subject To Earthquakesj.prolovic.savicNo ratings yet

- Earthquake Resistant BuildingsDocument10 pagesEarthquake Resistant BuildingssolairajaNo ratings yet

- Tek 14-23Document15 pagesTek 14-23nemogudanadjemidNo ratings yet

- Tek 10-01aDocument8 pagesTek 10-01aJUAN JOSE LariosNo ratings yet

- Retaining Walls and Steep Reinforced Slopes: 730.01 GeneralDocument32 pagesRetaining Walls and Steep Reinforced Slopes: 730.01 GeneralMina AdlyNo ratings yet

- Learning Outcome 4 Retaining WallsDocument9 pagesLearning Outcome 4 Retaining WallsChris FindlayNo ratings yet

- EQTip 23Document2 pagesEQTip 23sunilaanserNo ratings yet

- PrecaastDocument25 pagesPrecaastRahul AnandNo ratings yet

- TOS 6 MergedDocument130 pagesTOS 6 MergedAnuja JadhavNo ratings yet

- RC III Ch-3 - Reinforced Concrete WallsDocument11 pagesRC III Ch-3 - Reinforced Concrete WallsJo Yohannes100% (1)

- TOS 6 Unit 1 Retaining Walls ContinuedDocument11 pagesTOS 6 Unit 1 Retaining Walls ContinuedDaniSh PathAnNo ratings yet

- Fet Ci Lecture Notes Prof Kmoin Seismic Retrofit Techniques For Masonry Buildings An Overview PDFDocument59 pagesFet Ci Lecture Notes Prof Kmoin Seismic Retrofit Techniques For Masonry Buildings An Overview PDFArsalan MakhdoomiNo ratings yet

- Masonry IV PDFDocument40 pagesMasonry IV PDFBaraka GotoraNo ratings yet

- Metal Buildings and CMU WallsDocument4 pagesMetal Buildings and CMU WallsMattncigaNo ratings yet

- Concrete Retaining Walls: Important ConsiderationsDocument7 pagesConcrete Retaining Walls: Important Considerationsaditarian .pNo ratings yet

- Some Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910From EverandSome Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910No ratings yet

- The Modern Bricklayer - A Practical Work on Bricklaying in all its Branches - Volume III: With Special Selections on Tiling and Slating, Specifications Estimating, EtcFrom EverandThe Modern Bricklayer - A Practical Work on Bricklaying in all its Branches - Volume III: With Special Selections on Tiling and Slating, Specifications Estimating, EtcRating: 5 out of 5 stars5/5 (1)

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- Bridge BearingsDocument26 pagesBridge BearingsSanjay Kumar Gouda SanjuNo ratings yet

- Sanjaya Kumar GoudaDocument4 pagesSanjaya Kumar GoudaSanjay Kumar Gouda SanjuNo ratings yet

- Share Student Biodata-Wps OfficeDocument1 pageShare Student Biodata-Wps OfficeSanjay Kumar Gouda SanjuNo ratings yet

- APHYD17386810000018219Document5 pagesAPHYD17386810000018219Sanjay Kumar Gouda SanjuNo ratings yet

- PYBOM00349480000017265Document3 pagesPYBOM00349480000017265Sanjay Kumar Gouda SanjuNo ratings yet

- DLCPM00241540000032326Document2 pagesDLCPM00241540000032326Sanjay Kumar Gouda SanjuNo ratings yet

- Abutment & Pile FDN MCW FOR MNB 43+790 - Fixed 03.09.2020 PDFDocument79 pagesAbutment & Pile FDN MCW FOR MNB 43+790 - Fixed 03.09.2020 PDFAtanu AdhiakryNo ratings yet

- Spanish HOUSES in The PHILIPPINESDocument14 pagesSpanish HOUSES in The PHILIPPINESEirenne Phae RamilNo ratings yet

- Medina Ar-El-Pl-St PDFDocument14 pagesMedina Ar-El-Pl-St PDFdasmin anne depacaquiboNo ratings yet

- Example Assignment No.1 - Internal Wall FinishesDocument5 pagesExample Assignment No.1 - Internal Wall Finishesfaizsyam01No ratings yet

- คู่มือประกอบการใช้แบบมาตรฐาน ชุดเต็มDocument138 pagesคู่มือประกอบการใช้แบบมาตรฐาน ชุดเต็มdin dukNo ratings yet

- Secant Pile Wall ConstructionDocument5 pagesSecant Pile Wall Constructionsantanu mukherjeeNo ratings yet

- Buildings Structural Open Issues With TBC Remarks 25apr2013Document5 pagesBuildings Structural Open Issues With TBC Remarks 25apr2013niginpNo ratings yet

- Nadira BrochureDocument22 pagesNadira BrochureZanuriah Ahmad100% (1)

- Connection ScheduleDocument192 pagesConnection ScheduleNikitaBhattaraiAcharyaNo ratings yet

- Labour Only QuotationDocument1 pageLabour Only QuotationtinashemambarizaNo ratings yet

- Houses of Mountainous Region, NepalDocument13 pagesHouses of Mountainous Region, NepalManish50% (2)

- All in One ALE ReviewerDocument53 pagesAll in One ALE Reviewergulay yuo100% (1)

- Mood Boards: Studio Unit Lobby & Reception AtriumDocument6 pagesMood Boards: Studio Unit Lobby & Reception AtriumTiara OyardoNo ratings yet

- School Building DesignDocument42 pagesSchool Building DesignKawaii Crafts100% (4)

- Block 1Document17 pagesBlock 1andrie VonNo ratings yet

- Royal Government of Bhutan TRADITIONAL-ARCHITECTURE Guidelines PDFDocument49 pagesRoyal Government of Bhutan TRADITIONAL-ARCHITECTURE Guidelines PDFDhamma_Storehouse50% (2)

- Pengaruh - Model - Jembatan - Rangka - Batang - Berbahan - Stik Es KrimDocument12 pagesPengaruh - Model - Jembatan - Rangka - Batang - Berbahan - Stik Es Krimhqfq685No ratings yet

- Project Proposal and EstimationsDocument2 pagesProject Proposal and EstimationsEller-jed M. MendozaNo ratings yet

- Woodilee Phase 4 BrochureDocument32 pagesWoodilee Phase 4 BrochureMNo ratings yet

- Padmanabhapuram Palace & Unit - 5Document26 pagesPadmanabhapuram Palace & Unit - 5Priya Priya100% (1)

- Student On-The-Job-Training Weekly ReportDocument2 pagesStudent On-The-Job-Training Weekly ReportCherrylyn EstabilloNo ratings yet

- Design of Free Standing Brick Masonry WallDocument3 pagesDesign of Free Standing Brick Masonry Wallmumarbsc7244No ratings yet

- DSR 2016 in Ms ExcelDocument749 pagesDSR 2016 in Ms ExcelsaravananNo ratings yet

- Okotech Download BrochureDocument24 pagesOkotech Download BrochureMohd DaudNo ratings yet

- Terracotta Tile 2019 Company EditionDocument8 pagesTerracotta Tile 2019 Company EditionSiti ZulaikhaNo ratings yet

- Post Slab 3Document30 pagesPost Slab 3Md. Enzamul Hoque RahulNo ratings yet

- Lesson 3: Concept of Art Mediums of Visual ArtsDocument12 pagesLesson 3: Concept of Art Mediums of Visual ArtsRenalyn VacalNo ratings yet

- False Celling 1Document63 pagesFalse Celling 1Bijaya Raula100% (1)

- Universities of Leeds, Sheffield and York: Promoting Access To White Rose Research PapersDocument11 pagesUniversities of Leeds, Sheffield and York: Promoting Access To White Rose Research PapersAsep DayatNo ratings yet