Professional Documents

Culture Documents

Abstract of ASTM A153 A153M 2000

Abstract of ASTM A153 A153M 2000

Uploaded by

Jesse ChenCopyright:

Available Formats

You might also like

- ASTM A123-A123M-17 Hot Dip GalvanizingDocument9 pagesASTM A123-A123M-17 Hot Dip GalvanizingManuel Antonio Santos Vargas100% (2)

- ASTM A653-Standard Specification For Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by The Hot-Dip Process PDFDocument14 pagesASTM A653-Standard Specification For Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by The Hot-Dip Process PDFMOHAMAD NIZAMUDINNo ratings yet

- Astm A780Document4 pagesAstm A780Zuleima ulacio100% (3)

- RMO - KFUI UnderstandingDocument30 pagesRMO - KFUI Understandingmustaf100% (2)

- Astm A123-17Document9 pagesAstm A123-17TAEWARAT RAKRUANG0% (1)

- Astm A 153 - A 153M-09Document5 pagesAstm A 153 - A 153M-09Amr FathallaNo ratings yet

- Astm A153Document5 pagesAstm A153Gurkan100% (1)

- Astm A653 15 PDFDocument13 pagesAstm A653 15 PDFDaniel Vasquez100% (2)

- ASTM A90-13 Standard Test Method For Weight (Mass) of Coating On Iron and Steel Articles With Zinc or Zinc-Alloy CoatingsDocument5 pagesASTM A90-13 Standard Test Method For Weight (Mass) of Coating On Iron and Steel Articles With Zinc or Zinc-Alloy CoatingsGeorge YinNo ratings yet

- Astm A 780 - A 780M-09Document4 pagesAstm A 780 - A 780M-09Ramsi AnkziNo ratings yet

- A741Document3 pagesA741solrac4371100% (1)

- Astm A624Document5 pagesAstm A624Tri-Sure More Than ClosuresNo ratings yet

- Abstract of ASTM A153M 1995Document4 pagesAbstract of ASTM A153M 1995Jesse ChenNo ratings yet

- A153 PDFDocument4 pagesA153 PDFfernandoraiasaNo ratings yet

- A153a153m - 16 PDFDocument5 pagesA153a153m - 16 PDFHéctor BrunaNo ratings yet

- Zinc Coating (Hot-Dip) On Iron and Steel Hardware: Standard Specification ForDocument5 pagesZinc Coating (Hot-Dip) On Iron and Steel Hardware: Standard Specification ForMariela BelénNo ratings yet

- Astm A153Document5 pagesAstm A153Hanzel RodriguezNo ratings yet

- A153a153m 16Document5 pagesA153a153m 16Ralf JonesNo ratings yet

- Astm A 153pdfDocument4 pagesAstm A 153pdfrmsa17No ratings yet

- Zinc Coating (Hot-Dip) On Iron and Steel Hardware: Standard Specification ForDocument4 pagesZinc Coating (Hot-Dip) On Iron and Steel Hardware: Standard Specification FormarcoNo ratings yet

- Astm A 153 PDFDocument4 pagesAstm A 153 PDFmahmoud hegazy100% (5)

- Astm A153-A153m-05Document5 pagesAstm A153-A153m-05Nadhira100% (1)

- Zinc-5 % Aluminum (Hot-Dip) Coatings On Iron and Steel ProductsDocument6 pagesZinc-5 % Aluminum (Hot-Dip) Coatings On Iron and Steel ProductsDanZel Dan100% (1)

- Astm A 153 GalvanizadoDocument3 pagesAstm A 153 GalvanizadoVernon Jiménez FonsecaNo ratings yet

- Zinc Coating (Hot-Dip) On Iron and Steel Hardware: Standard Specification ForDocument5 pagesZinc Coating (Hot-Dip) On Iron and Steel Hardware: Standard Specification ForOscar Rodrigo LopezNo ratings yet

- Norma Astm A-123 InglesDocument8 pagesNorma Astm A-123 InglesMarilu' CrNo ratings yet

- Astm A153a153m-16Document5 pagesAstm A153a153m-16safak kahramanNo ratings yet

- Zinc Coating (Hot-Dip) On Iron and Steel Hardware: Standard Specification ForDocument4 pagesZinc Coating (Hot-Dip) On Iron and Steel Hardware: Standard Specification ForJONADHNo ratings yet

- Astm A711Document4 pagesAstm A711dneradNo ratings yet

- Astm A 123 - 2013Document8 pagesAstm A 123 - 2013JOSENo ratings yet

- Zinc Coating (Hot-Dip) On Iron and Steel Hardware: Standard Specification ForDocument5 pagesZinc Coating (Hot-Dip) On Iron and Steel Hardware: Standard Specification ForJithu KareemNo ratings yet

- Astm C-645Document7 pagesAstm C-645sabbirNo ratings yet

- Zinc Coating (Hot-Dip) On Iron and Steel Hardware: Standard Specification ForDocument5 pagesZinc Coating (Hot-Dip) On Iron and Steel Hardware: Standard Specification ForMd. Main UddinNo ratings yet

- A780 09Document4 pagesA780 09DuongthithuydungNo ratings yet

- ASTM A123 Galv. DFT RequirementDocument8 pagesASTM A123 Galv. DFT Requirementshoaib1985No ratings yet

- A653.1501849-1 - Hot Dipped Steel GalvanizationDocument13 pagesA653.1501849-1 - Hot Dipped Steel Galvanizationsubhaschandranath1No ratings yet

- A320A320MDocument8 pagesA320A320MJay GaneshNo ratings yet

- Norma A 153 (Ingles)Document4 pagesNorma A 153 (Ingles)Ivo GeceleNo ratings yet

- ASTM A153-03 - Zinc Coating (Hot-Dip) On Iron and Steel HardwareDocument4 pagesASTM A153-03 - Zinc Coating (Hot-Dip) On Iron and Steel HardwareMelissa SammyNo ratings yet

- A653A653MDocument13 pagesA653A653MfelipeNo ratings yet

- Zinc Alloy Thermo-Diffusion Coatings (TDC) On Steel Fasteners, Hardware, and Other ProductsDocument5 pagesZinc Alloy Thermo-Diffusion Coatings (TDC) On Steel Fasteners, Hardware, and Other ProductsSofia Yuli100% (1)

- 610 Winters Avenue, Paramus, NJ 07652: Ili Infodisk IncDocument5 pages610 Winters Avenue, Paramus, NJ 07652: Ili Infodisk IncDenny Angriawan NurcahyaNo ratings yet

- ASTM A320-A320M-05aDocument8 pagesASTM A320-A320M-05aNadhiraNo ratings yet

- C 955 - 03Document4 pagesC 955 - 03Tarek FennicheNo ratings yet

- A358/a358m 12Document8 pagesA358/a358m 12Maria Ivana100% (1)

- Astm A193 - 2009Document13 pagesAstm A193 - 2009Leonardo R. GonçalvesNo ratings yet

- Astm A90a90m - 13Document5 pagesAstm A90a90m - 13baskaran.marieNo ratings yet

- A 792 GalvalumeDocument5 pagesA 792 GalvalumeKapa SandeepNo ratings yet

- Alloy-Steel and Stainless Steel Bolting For High Temperature or High Pressure Service and Other Special Purpose ApplicationsDocument13 pagesAlloy-Steel and Stainless Steel Bolting For High Temperature or High Pressure Service and Other Special Purpose ApplicationsJohn HollandNo ratings yet

- Nonstructural Steel Framing Members: Standard Specification ForDocument6 pagesNonstructural Steel Framing Members: Standard Specification Forthienbinh.ngnNo ratings yet

- Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by The Hot-Dip ProcessDocument13 pagesSteel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by The Hot-Dip ProcessKannanNo ratings yet

- ASTM A 924 A924M - 2010aDocument12 pagesASTM A 924 A924M - 2010attilokkulNo ratings yet

- Astm B695-2004Document3 pagesAstm B695-2004alexis morales espinozaNo ratings yet

- A975-11 (Reapproved 2016)Document8 pagesA975-11 (Reapproved 2016)duongNo ratings yet

- Astm A 975-11Document8 pagesAstm A 975-11Otilia Chavez ChoqueNo ratings yet

- Steel Sheet and Strip, High-Strength, Low-Alloy, Hot-Rolled, and Steel Sheet, Cold-Rolled, High-Strength, Low-Alloy, With Improved FormabilityDocument3 pagesSteel Sheet and Strip, High-Strength, Low-Alloy, Hot-Rolled, and Steel Sheet, Cold-Rolled, High-Strength, Low-Alloy, With Improved FormabilitySinan ChenNo ratings yet

- A424A424M-09a Standard Specification For Steel, Sheet, For Porcelain EnamelingDocument3 pagesA424A424M-09a Standard Specification For Steel, Sheet, For Porcelain Enamelingtjt4779100% (1)

- Astm A320mDocument4 pagesAstm A320mSHYAM SINGHNo ratings yet

- Alloy/Steel Bolting Materials For Low-Temperature ServiceDocument8 pagesAlloy/Steel Bolting Materials For Low-Temperature ServiceMartuaHaojahanSaragihSidabutarNo ratings yet

- Astm F1941M 2007Document12 pagesAstm F1941M 2007Jesse ChenNo ratings yet

- Abstract of ASTM F880M 1990Document5 pagesAbstract of ASTM F880M 1990Jesse ChenNo ratings yet

- Astm F879M 1991Document5 pagesAstm F879M 1991Jesse ChenNo ratings yet

- Astm F836M 1997Document6 pagesAstm F836M 1997Jesse ChenNo ratings yet

- Abstract of ASTM F738M 1997Document12 pagesAbstract of ASTM F738M 1997Jesse ChenNo ratings yet

- Astm F837M 1991Document7 pagesAstm F837M 1991Jesse ChenNo ratings yet

- Abstract of ASTM F912M 1997Document6 pagesAbstract of ASTM F912M 1997Jesse ChenNo ratings yet

- Asme B18.11 2000Document8 pagesAsme B18.11 2000Jesse ChenNo ratings yet

- Astm A490m 1993Document5 pagesAstm A490m 1993Jesse ChenNo ratings yet

- Abstract of ASTM F835 2000Document7 pagesAbstract of ASTM F835 2000Jesse ChenNo ratings yet

- Asme B18.6.4 1998Document55 pagesAsme B18.6.4 1998Jesse ChenNo ratings yet

- Astm F738M 1997Document9 pagesAstm F738M 1997Jesse ChenNo ratings yet

- Abstract of ASTM F912 2000Document5 pagesAbstract of ASTM F912 2000Jesse ChenNo ratings yet

- Asme B18.8.1 2000Document7 pagesAsme B18.8.1 2000Jesse ChenNo ratings yet

- Abstract of ASTM F568M 1996Document12 pagesAbstract of ASTM F568M 1996Jesse ChenNo ratings yet

- Asme B18.6.3 2002Document56 pagesAsme B18.6.3 2002Jesse ChenNo ratings yet

- Abstract of ASTM F836M 1997Document8 pagesAbstract of ASTM F836M 1997Jesse ChenNo ratings yet

- Asme B18.8.6M 1995Document4 pagesAsme B18.8.6M 1995Jesse ChenNo ratings yet

- Asme B18.7 2007Document13 pagesAsme B18.7 2007Jesse ChenNo ratings yet

- Asme B18.9 1996Document8 pagesAsme B18.9 1996Jesse ChenNo ratings yet

- Asme B18.6.X 2002Document9 pagesAsme B18.6.X 2002Jesse ChenNo ratings yet

- Asme B18.8.4M 1994Document8 pagesAsme B18.8.4M 1994Jesse ChenNo ratings yet

- Asme B18.8.7M 1994Document6 pagesAsme B18.8.7M 1994Jesse ChenNo ratings yet

- Asme B18.2.8 1999Document3 pagesAsme B18.2.8 1999Jesse ChenNo ratings yet

- Asme B18.5.2.3M 1998Document7 pagesAsme B18.5.2.3M 1998Jesse ChenNo ratings yet

- Asme B18.6.2 1998Document9 pagesAsme B18.6.2 1998Jesse ChenNo ratings yet

- Asme B18.5 1998Document15 pagesAsme B18.5 1998Jesse ChenNo ratings yet

- Asme B18.2.3.10M 1996Document8 pagesAsme B18.2.3.10M 1996Jesse ChenNo ratings yet

- Asme B18.8.8M 1994Document6 pagesAsme B18.8.8M 1994Jesse ChenNo ratings yet

- Abstract of ASME B1.13M 1995Document26 pagesAbstract of ASME B1.13M 1995Jesse ChenNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument89 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- 02QDCQ5192Document9 pages02QDCQ5192Azwar ArifNo ratings yet

- VALVES - 28 - Butteryfly - PVC and CPVCDocument17 pagesVALVES - 28 - Butteryfly - PVC and CPVCAdditya ChoudhharyNo ratings yet

- Question Related To Post Weld Heat TreatmentDocument4 pagesQuestion Related To Post Weld Heat Treatmentg s b srinivasNo ratings yet

- Design No. R705: BXUVC.R705 Fire-Resistance RatingsDocument3 pagesDesign No. R705: BXUVC.R705 Fire-Resistance RatingsSimon BeaudoinNo ratings yet

- Brick CladdingDocument8 pagesBrick CladdingAnonymous PWdOlxYNo ratings yet

- Arc Welding Cracks SolidificationDocument3 pagesArc Welding Cracks SolidificationShaher YarNo ratings yet

- Bend Testing of Material For Ductility: Standard Test Methods ForDocument10 pagesBend Testing of Material For Ductility: Standard Test Methods Forsafak kahramanNo ratings yet

- Ilovepdf - Merged - 2023-02-28T013959.042Document22 pagesIlovepdf - Merged - 2023-02-28T013959.042Fernando Méndez De TovarNo ratings yet

- Ipd Products For Caterpillar C9 Engines: Ipdsteel™ Pistons & ComponentsDocument10 pagesIpd Products For Caterpillar C9 Engines: Ipdsteel™ Pistons & ComponentsfjaristizabalNo ratings yet

- Concrete Mix DesignDocument21 pagesConcrete Mix DesignfaheemqcNo ratings yet

- CENG 6302 Pavement Analysis and Design Chapter 7 Overview of RigidDocument22 pagesCENG 6302 Pavement Analysis and Design Chapter 7 Overview of RigidThe HackerNo ratings yet

- Proposal by Asfaw ADocument34 pagesProposal by Asfaw ABelachew ZelekeNo ratings yet

- Lecture1 Structures WU MASE101Document58 pagesLecture1 Structures WU MASE101hussain ghaziNo ratings yet

- Astm A 653Document13 pagesAstm A 653Anonymous LQdcbfAEYNNo ratings yet

- Conductive Cement / Ground Enhancing Material: San-Earth M5CDocument2 pagesConductive Cement / Ground Enhancing Material: San-Earth M5Cst. enchevNo ratings yet

- Design Guide: Injection MoldingDocument17 pagesDesign Guide: Injection MoldingVictor Villouta LunaNo ratings yet

- Pretreatment For Powder CoatingDocument15 pagesPretreatment For Powder Coatingsateeshsingh100% (1)

- Designer Brick Brochure WEBDocument28 pagesDesigner Brick Brochure WEBdirtapatroNo ratings yet

- Table of Standards: Approvals / CertificationsDocument4 pagesTable of Standards: Approvals / CertificationsShafeyAliKhanNo ratings yet

- BROSUR DC Neutral PlusDocument2 pagesBROSUR DC Neutral PlusMust DymNo ratings yet

- Gravi-Tech Product BulletinDocument2 pagesGravi-Tech Product BulletinKevin DrummNo ratings yet

- Standard Pipe DetailsDocument1 pageStandard Pipe DetailsJohn DanielNo ratings yet

- 3.032 Mechanical Behavior of Materials: Fall 2007Document3 pages3.032 Mechanical Behavior of Materials: Fall 2007engineerNo ratings yet

- Soil Nail BrochureDocument16 pagesSoil Nail BrochureericelijahNo ratings yet

- 616566Document2 pages616566Neem LalNo ratings yet

- Technical Circular No. 22-2020 Ashghal Approved Tests List No. 4-2020 PDFDocument179 pagesTechnical Circular No. 22-2020 Ashghal Approved Tests List No. 4-2020 PDFThe Keymaster100% (1)

- Window & Door Schedule: StudioDocument1 pageWindow & Door Schedule: StudioBatWing ZNo ratings yet

Abstract of ASTM A153 A153M 2000

Abstract of ASTM A153 A153M 2000

Uploaded by

Jesse ChenCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Abstract of ASTM A153 A153M 2000

Abstract of ASTM A153 A153M 2000

Uploaded by

Jesse ChenCopyright:

Available Formats

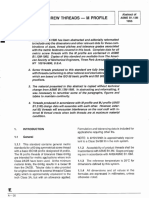

Abstract of

MATERIALS

ZINC COATING (HOT-DIP) ON IRON AND ASTM

A153/A153M

STEEL HARDWARE 2000

IFI NOTES:

1. ASTM A 153fA 153M is a specification developed through the proce.

dures of ASTM. A1531A153M is under the jurisdiction of ASTM

Committee A-5 on Metallic Coated Iron and Steel Products and is

the direct responsibility of its Subcommittee A05.13 on Structural

Shapes and Hardware Specifications.

2. A1531A153M covers hot-dip galvanizing of various forms of iron

and steel products, including fasteners. This abstract has been

editorially modified to eliminate those requirements and references

which specifically exclude fasteners . Also omitted are those re-

quirements dealing with sampling, Note 2 of Table 1, quality assur-

ance and inspection, a listing of applicable documents, and metric

(soft converted) equivalencies. For the omitted information, refer

to the complete A1531A153M.

The paragraph numbers throughout this abstract are those of ASTM

A153IAI53M·2000.

3. ASTM A 1531A 153M-2000 is abstracted with permission from the An-

nual Book of ASTM Standards, copyright American Society for Test-

ing and Materials, 100 Barr Harbor Drive, West Conshohocken, PA

19428·2959, U.S.A.

1. Scope ated with its use. It is the responsibility of the

user of this standard to establish appropriate

1.1 This specification covers zinc coatings safety and health practices and determine the

applied by the hot-dip process on iron and steel applicability of regulatory limitations prior to use.

hardware.

2. Referenced Documents

1.2 This document is intended to be appli-

cable to hardware items that are centrifuged or

(Refer to the complete specification , see

otherwise handled to remove excess galva niz-

page N-38.)

ing bath metal (free zinc). Coating thickness

grade requirements reflect th is.

3. Materials and Manufacture

NOTE i -If the galvanized material covered by this speci·

fication is bent or otherwise fabricated to the degree that

causes the zinc coatings to stretch or compre ss beyond 3.1 Steel or Iron - Ferrous articles to be hot-

the limit of elasticity, some cracking or flaking of the coat· dip zinc coated shaH conform to specifications

ing may occur. designated by the purchaser.

1.3 (See IFI Note 2.)

3.2 Zinc- The zinc used for the coating shaH

1.4 This standard does not purport to ad- conform to ASTM 86 and shall be at least equal

dress aI/ of the safety concerns, if any, associ- to the grade designated as ~ Prim e Western . ~

8 -230 © 2003 Industrial Fasteners Institute

Abstract of

ASTM ZINC COATING (HOT-DIP) ON IRON AND MATERIALS

A1 53/A153M

2000 STEEL HARDWARE

Table 1 Weight of Zinc Coating fo r Vario us Classes of Mate rial 2

Minimum Weigh t of Zin c Coating oz.Ift' of Surface ~

Cla ss of Material

Averag e of Specimens Tested · An y Ind ividual Specimen

Class C - Fasteners 0Yef' 3J8 in. In diameter aoo similar

12' 1.00

artides. Washers 3116 In. aoo 114 In. in ttlckness

Class D - Fasteners 318 In. am lIder In diameter. rivets, 0.85

100

nails aoo similar articles. Washers lIder 3116 In. in ltickness

• In the case of long pteCes, such as anchor rods and Similar articles over 5 ft, In length, the weight of coating shall be detemllned al

each end and the middle 01 the article. In no case shall individual measurements be below the minimum shown In the "An'1lndividual

Specimen' column .

• The number of specimens to be tested per order shall be as specified In Section 7.

NOTE 2 - Based upon mathematical calculations, 1 oz/ft' of zinc surface corresponds to an average coaUng thickness of 1.7 mil

(0.0017 In.). References to "coating thickness" or "coating thickness grade" throughout this standard are interchangeable with

......eight· in Table 1 in accordance with the calculation.

3.3 Coating Thickness Grade - The thick- would Interfere with function or as edge tears or spikes

that present a safety hazard because of their sharpness,

ness grades of the coating shall conform to the

are grounds for rejection under the terms of 5.1.

requirements prescribed in Table 1 for the ma-

terial category and thickness of material in which 4. 3 Steel that is cold worked may become

the article belongs. embrittled, depending on such factors as the type

(strength level, ag ing characteristics), thickness,

3.4 Th readed Articles - The zinc coating on

and degree of cold work. Galvanizing may ac-

threads shall not be subjected to a cutting, roil-

celerate em brittlement. Preca utio ns aga inst

ing, or finishing-tool operation, unless specifically

embrittlement shall be taken by the designer and

authorized by the purchaser. Threads in nuts

the fabricator. The precautions to fabricate prop-

may be tapped after galva nizing.

erly and prepare the material for galvanizing to

prevent embrittlement are described in ASTM

4. Workmanshi p, Finish, and Appearance

A1 43.

4.1 The zinc coated articles shall be free from NOTE 4 - low service temperatures increase the risk of

uncoated areas, blisters, flux deposits, dross brittle failure of all plain carbon steels Including those which

inclusions, and other types of projections that have been galvanized. This temperature embrittling effect

varies with type of steel. The expected service tempera-

would interfere with the intended use of the ar-

ture should thus be taken 1nto account when selecting steels

ticles or other defects not consistent with good for galvanizing.

galvanizing practice.

4.4 Malleable castings shall be of such com-

4.2 The zinc coating shall be smooth and position as will preclude the possibility that they

reasonably uniform in thickness. become embrittled by the galvanizing process,

NOTE 2 - Smoothness of surface Is a relative term. Mi- or they shaJJ be either cooled from the anneal,

nor roughness that does not interfere with the intended or subseq uently heat treated so as to immunize

use of the part, or roughness that is related to the as-re- them against embriltlement.

ceived (ungalvanized) surface condition of the part. shaH

not be grounds for rejection. 4.5 The zinc coating shall adhere tenaciously

NOTE 3 - Since this specification Is applicable to items to the surface of the basis metal (see Section 8).

that are centrifuged or otherwise handled to remove ex-

cess bath metal (see 1.2), Irregular coating distribution is 5. Sa mpling

not normally encountered. Drainage problems. which

manifest themselves as local excess coating thickness that (Refer to the complete specification.)

© 2003 Industrial Fasteners Institute 8 -231

Abstract of

MATERIALS

ZINC COATING (HOT-DIP) ON IRON AND ASTM

A153/A 153M

STEEL HARDWARE 2000

6. Test Methods 6.3 Embrittlement - Test for embrittlement

in accordance with Practice ASTM A143.

6.1 Tests shall be made to ensure that the

zinc coating is being furnished in accordance with 6.4 Adherence - Determine adherence of

this specification and as specified for the follow- the zinc coating to the surface of the base metal

ing: by cutting or prying with the point of a stout knife,

applied with considerable pressure in a manner

6.1. 1 Thickness of coating in 3.3.

tending to remove a portion of the coating . The

6.1.2 Fi nish and appearance in 4.1 and 4.2. adherence shall be considered inadequate if the

6.1.3 Embrittlement in 4.3 and 4.4. coating flakes off in the form of a layer or skin so

as to expose the base metal in advance of the

6.1.4 Adherence in 4.5. knife point. 0 0 not use testing carried out at

edges or corners (points of 'lowest coating ad-

6.2 Thickness of Coating:

herence) to determine adherence of coating .

6.2.1 The average weight of the zinc coating Likewise, do not use removal of small particles

may be determined by weighing specimens af- of the coating by paring or whittling to determine

ter pickling and drying and again after galvaniz- failure.

ing.

NOTE 5 - This method does not take Into account the

7. Inspection

weight of Iron reacted from the article that is incorporated

(Refer to the complete specification.)

Into the coa ting. It will thus underestimate coa ting weight

by up to approximately 10%. Base metal reactivity will

affect the extent of underestimation. 8. Rejection and Retest

6.2.2 In the case of materials inspected after (Refer to the complete speCification.)

galvanizing , the weight of coating may be deter-

mined by stripping one or more specimens in 9. Packag ing

accordance with ASTM A90/A90M , or the aver- 9.1 The supplier shall employ such methods

age thickness of coating may be determined with

of packaging zinc coated articles as may rea-

the use of a magnetic thickness gage in confor-

sonably be req uired to ensure their receipt by

mity with Practice ASTM E376.

the purchaser in satisfactory condition, with the

6.2.2.1 In the case of fasteners such as bolts, use to be made of the article being taken into

nuts, and screws, the determination of the thick- consideration.

ness of coating shall be made on a portion of 9.2 Zinc coated items should not be packed

the article that does not include any threads. in unventilated containers, especially if these are

6 .2.3 The thickness of coating may be deter- fabricated from unseasoned wood .

mined by cross section and optical measure-

ment. The thickness thus determined is a point 10. Certific ation

value . No less than five such measurements (Refer to the complete specification.)

shall be made at locations on the test article ,

which are as widely dispersed as practical, so 11 , Keywords

as to be representative of the whole surface of

the test article. The average of no less than five 11 .1 coatings, zinc; galvanized coatings; steel

such measurements is the specimen coating hardware, zinc coated; steel products. metallic

thickness. coated; zinc coatings, steel products.

8 -232 © 2003 Industrial Fasteners Institute

You might also like

- ASTM A123-A123M-17 Hot Dip GalvanizingDocument9 pagesASTM A123-A123M-17 Hot Dip GalvanizingManuel Antonio Santos Vargas100% (2)

- ASTM A653-Standard Specification For Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by The Hot-Dip Process PDFDocument14 pagesASTM A653-Standard Specification For Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by The Hot-Dip Process PDFMOHAMAD NIZAMUDINNo ratings yet

- Astm A780Document4 pagesAstm A780Zuleima ulacio100% (3)

- RMO - KFUI UnderstandingDocument30 pagesRMO - KFUI Understandingmustaf100% (2)

- Astm A123-17Document9 pagesAstm A123-17TAEWARAT RAKRUANG0% (1)

- Astm A 153 - A 153M-09Document5 pagesAstm A 153 - A 153M-09Amr FathallaNo ratings yet

- Astm A153Document5 pagesAstm A153Gurkan100% (1)

- Astm A653 15 PDFDocument13 pagesAstm A653 15 PDFDaniel Vasquez100% (2)

- ASTM A90-13 Standard Test Method For Weight (Mass) of Coating On Iron and Steel Articles With Zinc or Zinc-Alloy CoatingsDocument5 pagesASTM A90-13 Standard Test Method For Weight (Mass) of Coating On Iron and Steel Articles With Zinc or Zinc-Alloy CoatingsGeorge YinNo ratings yet

- Astm A 780 - A 780M-09Document4 pagesAstm A 780 - A 780M-09Ramsi AnkziNo ratings yet

- A741Document3 pagesA741solrac4371100% (1)

- Astm A624Document5 pagesAstm A624Tri-Sure More Than ClosuresNo ratings yet

- Abstract of ASTM A153M 1995Document4 pagesAbstract of ASTM A153M 1995Jesse ChenNo ratings yet

- A153 PDFDocument4 pagesA153 PDFfernandoraiasaNo ratings yet

- A153a153m - 16 PDFDocument5 pagesA153a153m - 16 PDFHéctor BrunaNo ratings yet

- Zinc Coating (Hot-Dip) On Iron and Steel Hardware: Standard Specification ForDocument5 pagesZinc Coating (Hot-Dip) On Iron and Steel Hardware: Standard Specification ForMariela BelénNo ratings yet

- Astm A153Document5 pagesAstm A153Hanzel RodriguezNo ratings yet

- A153a153m 16Document5 pagesA153a153m 16Ralf JonesNo ratings yet

- Astm A 153pdfDocument4 pagesAstm A 153pdfrmsa17No ratings yet

- Zinc Coating (Hot-Dip) On Iron and Steel Hardware: Standard Specification ForDocument4 pagesZinc Coating (Hot-Dip) On Iron and Steel Hardware: Standard Specification FormarcoNo ratings yet

- Astm A 153 PDFDocument4 pagesAstm A 153 PDFmahmoud hegazy100% (5)

- Astm A153-A153m-05Document5 pagesAstm A153-A153m-05Nadhira100% (1)

- Zinc-5 % Aluminum (Hot-Dip) Coatings On Iron and Steel ProductsDocument6 pagesZinc-5 % Aluminum (Hot-Dip) Coatings On Iron and Steel ProductsDanZel Dan100% (1)

- Astm A 153 GalvanizadoDocument3 pagesAstm A 153 GalvanizadoVernon Jiménez FonsecaNo ratings yet

- Zinc Coating (Hot-Dip) On Iron and Steel Hardware: Standard Specification ForDocument5 pagesZinc Coating (Hot-Dip) On Iron and Steel Hardware: Standard Specification ForOscar Rodrigo LopezNo ratings yet

- Norma Astm A-123 InglesDocument8 pagesNorma Astm A-123 InglesMarilu' CrNo ratings yet

- Astm A153a153m-16Document5 pagesAstm A153a153m-16safak kahramanNo ratings yet

- Zinc Coating (Hot-Dip) On Iron and Steel Hardware: Standard Specification ForDocument4 pagesZinc Coating (Hot-Dip) On Iron and Steel Hardware: Standard Specification ForJONADHNo ratings yet

- Astm A711Document4 pagesAstm A711dneradNo ratings yet

- Astm A 123 - 2013Document8 pagesAstm A 123 - 2013JOSENo ratings yet

- Zinc Coating (Hot-Dip) On Iron and Steel Hardware: Standard Specification ForDocument5 pagesZinc Coating (Hot-Dip) On Iron and Steel Hardware: Standard Specification ForJithu KareemNo ratings yet

- Astm C-645Document7 pagesAstm C-645sabbirNo ratings yet

- Zinc Coating (Hot-Dip) On Iron and Steel Hardware: Standard Specification ForDocument5 pagesZinc Coating (Hot-Dip) On Iron and Steel Hardware: Standard Specification ForMd. Main UddinNo ratings yet

- A780 09Document4 pagesA780 09DuongthithuydungNo ratings yet

- ASTM A123 Galv. DFT RequirementDocument8 pagesASTM A123 Galv. DFT Requirementshoaib1985No ratings yet

- A653.1501849-1 - Hot Dipped Steel GalvanizationDocument13 pagesA653.1501849-1 - Hot Dipped Steel Galvanizationsubhaschandranath1No ratings yet

- A320A320MDocument8 pagesA320A320MJay GaneshNo ratings yet

- Norma A 153 (Ingles)Document4 pagesNorma A 153 (Ingles)Ivo GeceleNo ratings yet

- ASTM A153-03 - Zinc Coating (Hot-Dip) On Iron and Steel HardwareDocument4 pagesASTM A153-03 - Zinc Coating (Hot-Dip) On Iron and Steel HardwareMelissa SammyNo ratings yet

- A653A653MDocument13 pagesA653A653MfelipeNo ratings yet

- Zinc Alloy Thermo-Diffusion Coatings (TDC) On Steel Fasteners, Hardware, and Other ProductsDocument5 pagesZinc Alloy Thermo-Diffusion Coatings (TDC) On Steel Fasteners, Hardware, and Other ProductsSofia Yuli100% (1)

- 610 Winters Avenue, Paramus, NJ 07652: Ili Infodisk IncDocument5 pages610 Winters Avenue, Paramus, NJ 07652: Ili Infodisk IncDenny Angriawan NurcahyaNo ratings yet

- ASTM A320-A320M-05aDocument8 pagesASTM A320-A320M-05aNadhiraNo ratings yet

- C 955 - 03Document4 pagesC 955 - 03Tarek FennicheNo ratings yet

- A358/a358m 12Document8 pagesA358/a358m 12Maria Ivana100% (1)

- Astm A193 - 2009Document13 pagesAstm A193 - 2009Leonardo R. GonçalvesNo ratings yet

- Astm A90a90m - 13Document5 pagesAstm A90a90m - 13baskaran.marieNo ratings yet

- A 792 GalvalumeDocument5 pagesA 792 GalvalumeKapa SandeepNo ratings yet

- Alloy-Steel and Stainless Steel Bolting For High Temperature or High Pressure Service and Other Special Purpose ApplicationsDocument13 pagesAlloy-Steel and Stainless Steel Bolting For High Temperature or High Pressure Service and Other Special Purpose ApplicationsJohn HollandNo ratings yet

- Nonstructural Steel Framing Members: Standard Specification ForDocument6 pagesNonstructural Steel Framing Members: Standard Specification Forthienbinh.ngnNo ratings yet

- Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by The Hot-Dip ProcessDocument13 pagesSteel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by The Hot-Dip ProcessKannanNo ratings yet

- ASTM A 924 A924M - 2010aDocument12 pagesASTM A 924 A924M - 2010attilokkulNo ratings yet

- Astm B695-2004Document3 pagesAstm B695-2004alexis morales espinozaNo ratings yet

- A975-11 (Reapproved 2016)Document8 pagesA975-11 (Reapproved 2016)duongNo ratings yet

- Astm A 975-11Document8 pagesAstm A 975-11Otilia Chavez ChoqueNo ratings yet

- Steel Sheet and Strip, High-Strength, Low-Alloy, Hot-Rolled, and Steel Sheet, Cold-Rolled, High-Strength, Low-Alloy, With Improved FormabilityDocument3 pagesSteel Sheet and Strip, High-Strength, Low-Alloy, Hot-Rolled, and Steel Sheet, Cold-Rolled, High-Strength, Low-Alloy, With Improved FormabilitySinan ChenNo ratings yet

- A424A424M-09a Standard Specification For Steel, Sheet, For Porcelain EnamelingDocument3 pagesA424A424M-09a Standard Specification For Steel, Sheet, For Porcelain Enamelingtjt4779100% (1)

- Astm A320mDocument4 pagesAstm A320mSHYAM SINGHNo ratings yet

- Alloy/Steel Bolting Materials For Low-Temperature ServiceDocument8 pagesAlloy/Steel Bolting Materials For Low-Temperature ServiceMartuaHaojahanSaragihSidabutarNo ratings yet

- Astm F1941M 2007Document12 pagesAstm F1941M 2007Jesse ChenNo ratings yet

- Abstract of ASTM F880M 1990Document5 pagesAbstract of ASTM F880M 1990Jesse ChenNo ratings yet

- Astm F879M 1991Document5 pagesAstm F879M 1991Jesse ChenNo ratings yet

- Astm F836M 1997Document6 pagesAstm F836M 1997Jesse ChenNo ratings yet

- Abstract of ASTM F738M 1997Document12 pagesAbstract of ASTM F738M 1997Jesse ChenNo ratings yet

- Astm F837M 1991Document7 pagesAstm F837M 1991Jesse ChenNo ratings yet

- Abstract of ASTM F912M 1997Document6 pagesAbstract of ASTM F912M 1997Jesse ChenNo ratings yet

- Asme B18.11 2000Document8 pagesAsme B18.11 2000Jesse ChenNo ratings yet

- Astm A490m 1993Document5 pagesAstm A490m 1993Jesse ChenNo ratings yet

- Abstract of ASTM F835 2000Document7 pagesAbstract of ASTM F835 2000Jesse ChenNo ratings yet

- Asme B18.6.4 1998Document55 pagesAsme B18.6.4 1998Jesse ChenNo ratings yet

- Astm F738M 1997Document9 pagesAstm F738M 1997Jesse ChenNo ratings yet

- Abstract of ASTM F912 2000Document5 pagesAbstract of ASTM F912 2000Jesse ChenNo ratings yet

- Asme B18.8.1 2000Document7 pagesAsme B18.8.1 2000Jesse ChenNo ratings yet

- Abstract of ASTM F568M 1996Document12 pagesAbstract of ASTM F568M 1996Jesse ChenNo ratings yet

- Asme B18.6.3 2002Document56 pagesAsme B18.6.3 2002Jesse ChenNo ratings yet

- Abstract of ASTM F836M 1997Document8 pagesAbstract of ASTM F836M 1997Jesse ChenNo ratings yet

- Asme B18.8.6M 1995Document4 pagesAsme B18.8.6M 1995Jesse ChenNo ratings yet

- Asme B18.7 2007Document13 pagesAsme B18.7 2007Jesse ChenNo ratings yet

- Asme B18.9 1996Document8 pagesAsme B18.9 1996Jesse ChenNo ratings yet

- Asme B18.6.X 2002Document9 pagesAsme B18.6.X 2002Jesse ChenNo ratings yet

- Asme B18.8.4M 1994Document8 pagesAsme B18.8.4M 1994Jesse ChenNo ratings yet

- Asme B18.8.7M 1994Document6 pagesAsme B18.8.7M 1994Jesse ChenNo ratings yet

- Asme B18.2.8 1999Document3 pagesAsme B18.2.8 1999Jesse ChenNo ratings yet

- Asme B18.5.2.3M 1998Document7 pagesAsme B18.5.2.3M 1998Jesse ChenNo ratings yet

- Asme B18.6.2 1998Document9 pagesAsme B18.6.2 1998Jesse ChenNo ratings yet

- Asme B18.5 1998Document15 pagesAsme B18.5 1998Jesse ChenNo ratings yet

- Asme B18.2.3.10M 1996Document8 pagesAsme B18.2.3.10M 1996Jesse ChenNo ratings yet

- Asme B18.8.8M 1994Document6 pagesAsme B18.8.8M 1994Jesse ChenNo ratings yet

- Abstract of ASME B1.13M 1995Document26 pagesAbstract of ASME B1.13M 1995Jesse ChenNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument89 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- 02QDCQ5192Document9 pages02QDCQ5192Azwar ArifNo ratings yet

- VALVES - 28 - Butteryfly - PVC and CPVCDocument17 pagesVALVES - 28 - Butteryfly - PVC and CPVCAdditya ChoudhharyNo ratings yet

- Question Related To Post Weld Heat TreatmentDocument4 pagesQuestion Related To Post Weld Heat Treatmentg s b srinivasNo ratings yet

- Design No. R705: BXUVC.R705 Fire-Resistance RatingsDocument3 pagesDesign No. R705: BXUVC.R705 Fire-Resistance RatingsSimon BeaudoinNo ratings yet

- Brick CladdingDocument8 pagesBrick CladdingAnonymous PWdOlxYNo ratings yet

- Arc Welding Cracks SolidificationDocument3 pagesArc Welding Cracks SolidificationShaher YarNo ratings yet

- Bend Testing of Material For Ductility: Standard Test Methods ForDocument10 pagesBend Testing of Material For Ductility: Standard Test Methods Forsafak kahramanNo ratings yet

- Ilovepdf - Merged - 2023-02-28T013959.042Document22 pagesIlovepdf - Merged - 2023-02-28T013959.042Fernando Méndez De TovarNo ratings yet

- Ipd Products For Caterpillar C9 Engines: Ipdsteel™ Pistons & ComponentsDocument10 pagesIpd Products For Caterpillar C9 Engines: Ipdsteel™ Pistons & ComponentsfjaristizabalNo ratings yet

- Concrete Mix DesignDocument21 pagesConcrete Mix DesignfaheemqcNo ratings yet

- CENG 6302 Pavement Analysis and Design Chapter 7 Overview of RigidDocument22 pagesCENG 6302 Pavement Analysis and Design Chapter 7 Overview of RigidThe HackerNo ratings yet

- Proposal by Asfaw ADocument34 pagesProposal by Asfaw ABelachew ZelekeNo ratings yet

- Lecture1 Structures WU MASE101Document58 pagesLecture1 Structures WU MASE101hussain ghaziNo ratings yet

- Astm A 653Document13 pagesAstm A 653Anonymous LQdcbfAEYNNo ratings yet

- Conductive Cement / Ground Enhancing Material: San-Earth M5CDocument2 pagesConductive Cement / Ground Enhancing Material: San-Earth M5Cst. enchevNo ratings yet

- Design Guide: Injection MoldingDocument17 pagesDesign Guide: Injection MoldingVictor Villouta LunaNo ratings yet

- Pretreatment For Powder CoatingDocument15 pagesPretreatment For Powder Coatingsateeshsingh100% (1)

- Designer Brick Brochure WEBDocument28 pagesDesigner Brick Brochure WEBdirtapatroNo ratings yet

- Table of Standards: Approvals / CertificationsDocument4 pagesTable of Standards: Approvals / CertificationsShafeyAliKhanNo ratings yet

- BROSUR DC Neutral PlusDocument2 pagesBROSUR DC Neutral PlusMust DymNo ratings yet

- Gravi-Tech Product BulletinDocument2 pagesGravi-Tech Product BulletinKevin DrummNo ratings yet

- Standard Pipe DetailsDocument1 pageStandard Pipe DetailsJohn DanielNo ratings yet

- 3.032 Mechanical Behavior of Materials: Fall 2007Document3 pages3.032 Mechanical Behavior of Materials: Fall 2007engineerNo ratings yet

- Soil Nail BrochureDocument16 pagesSoil Nail BrochureericelijahNo ratings yet

- 616566Document2 pages616566Neem LalNo ratings yet

- Technical Circular No. 22-2020 Ashghal Approved Tests List No. 4-2020 PDFDocument179 pagesTechnical Circular No. 22-2020 Ashghal Approved Tests List No. 4-2020 PDFThe Keymaster100% (1)

- Window & Door Schedule: StudioDocument1 pageWindow & Door Schedule: StudioBatWing ZNo ratings yet