Professional Documents

Culture Documents

Imp 290899-1561291928550)

Imp 290899-1561291928550)

Uploaded by

CIVIL ENGINEERINGOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Imp 290899-1561291928550)

Imp 290899-1561291928550)

Uploaded by

CIVIL ENGINEERINGCopyright:

Available Formats

Adaptive Network–Fuzzy Inferencing to Estimate Concrete

Strength Using Mix Design

S. Tesfamariam1 and H. Najjaran2

Abstract: Proportioning of concrete mixes is carried out in accordance with specified code information, specifications, and past expe-

riences. Typically, concrete mix companies use different mix designs that are used to establish tried and tested datasets. Thus, a model can

Downloaded from ascelibrary.org by University of Notre Dame on 08/24/14. Copyright ASCE. For personal use only; all rights reserved.

be developed based on existing datasets to estimate the concrete strength of a given mix proportioning and avoid costly tests and

adjustments. Inherent uncertainties encountered in the model can be handled with fuzzy based methods, which are capable of incorpo-

rating information obtained from expert knowledge and datasets. In this paper, the use of adaptive neuro-fuzzy inferencing system is

proposed to train a fuzzy model and estimate concrete strength. The efficiency of the proposed method is verified using actual concrete

mix proportioning datasets reported in the literature, and the corresponding coefficient of determination r2 range from 0.970–0.999.

Further, sensitivity analysis is carried out to highlight the impact of different mix constituents on the estimate concrete strength.

DOI: 10.1061/共ASCE兲0899-1561共2007兲19:7共550兲

CE Database subject headings: Fuzzy sets; Compressive strength; Concrete; Mixing; Strength.

Introduction in-place concrete is determined by the prevalent construction

quality. Hence, from batching to concrete placement, stringent

Concrete is one of the oldest materials in the construction indus- control has to be exercised as any deviation may compromise the

try. The concrete mix proportioning method has evolved from a structural integrity and durability of the structure. As shown in

simple arbitrary volumetric method 共1:2:3—Cement:Sand:Coarse Fig. 1, there is an infinite possibility of obtaining the desired mix

aggregate兲 to the present-day mass and absolute-volume method design specification, however, the desirable one is the one that

共ACI 211.1-91 2001兲. A four-step mix design procedure is illus- satisfies the design constraints at minimal cost.

The mix design involves a complex and nonlinear procedure

trated in Fig. 1. Step 1 entails specifying exposure condition,

that is influenced by the material interaction and culture of con-

workability of freshly mixed concrete, and strength and durability

struction quality. Hence, it is difficult to develop a comprehensive

requirements of hardened concrete. Once this is specified, Step 2

analytical model by considering all design variables. Typically,

follows code specified design procedures to satisfy minimum/

concrete mix companies have extensive records of their past mix

maximum requirements, i.e., maximum water cement ratio

proportions, which can be used to develop a model for the design

共w / c ratio兲, minimum 28 days specified strength 共f ⬘c 兲, minimum procedure. Automation of the mix proportioning can be carried

entrained air 共EA兲, maximum slump, and maximum coarse aggre- out with different soft computing techniques. Soft computing is a

gate 共CA兲. Step 3 entails computing the required unit water con- conglomerate of computing techniques that include fuzzy-based

tent, coarse aggregate and, consequently, the fine aggregate 共FA兲. methods, neuro-computing, genetic computing, probabilistic rea-

Finally, Step 4 specifies the final water, cement, coarse aggregate, soning, genetic algorithms, chaotic systems, belief networks, and

fine aggregate, and admixture content. Typically, the mix design learning theory 共Zadeh 1997兲. The soft computing techniques ef-

is verified in the laboratory through trial mix, and adjustments are fectively explore the relationship among independent and depen-

made accordingly. The final proportioning of the mix design has dent variables without any assumptions about the relationship

to be verified through the concrete mix made in the field, since 共e.g., a linear relationship兲 between the various variables.

variation may arise due to different mixers, pumping properties, Various authors have used a standard multilayer feedforward

and wall effect 共Neville 1997兲. Moreover, the quality of the final artificial neural network 共ANN兲 to predict the compressive

strength of concrete 共e.g., Lai and Serra 1997; Yeh 1998; Oh et al.

1

Technical Officer, Institute for Research in Construction, National 1999; Ni and Wang 2000; Hong-Guang and Ji-Zong 2000; Lee

Research Council of Canada, Ottawa, Canada K1A 0R6 共corresponding 2003; Kim et al. 2004; and Chiang and Yang 2005兲 where a

author兲. E-mail: Solomon.tesfamariam@nrc.ca back-propagation algorithm 共BPNN兲 is used to train the network

2

Assistant Professor, School of Engineering, Univ. of British existing datasets. Kim et al. 共2005兲 have further enhanced the

Columbia Okanagan, Kelowna, BC, Canada. E-mail: Homayoun. previously reported 共Kim et al. 2004兲 ANN using the probabilistic

Najjaran@ubc.ca neural network method to handle uncertainty and save computa-

Note. Associate Editor: Kamran M. Nemati. Discussion open until tional time. Jain et al. 共2005兲 forwarded further insight into the

December 1, 2007. Separate discussions must be submitted for individual

implementation and discussions on the efficiency of neural net-

papers. To extend the closing date by one month, a written request must

be filed with the ASCE Managing Editor. The manuscript for this paper work models for concrete mix.

was submitted for review and possible publication on December 16, The main advantage of using ANN is their flexibility and abil-

2005; approved on November 8, 2006. This paper is part of the Journal ity to model nonlinear relationships. However, the ANN models

of Materials in Civil Engineering, Vol. 19, No. 7, July 1, 2007. ©ASCE, have often been criticized for acting as a “black box.” The knowl-

ISSN 0899-1561/2007/7-550–560/$25.00. edge contained in an ANN model is maintained in the form of a

550 / JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / JULY 2007

J. Mater. Civ. Eng. 2007.19:550-560.

Fig. 2. Typical fuzzy membership functions

Downloaded from ascelibrary.org by University of Notre Dame on 08/24/14. Copyright ASCE. For personal use only; all rights reserved.

eling is explained briefly. Second, the implementation and deriva-

tion of an ANFIS based model is discussed. Third, ANFIS is used

to develop a FIS model for estimation of concrete strength. The

results are verified using actual concrete mix proportioning

datasets reported in the literature, and the corresponding coeffi-

cient of determination r2 are computed. Finally, sensitivity analy-

sis is carried out to highlight the impact of each mix constituents

on the estimate concrete strength.

Fig. 1. Concrete mix proportioning

Fuzzy Modeling Methods

Fuzzy logic was initially used to formulate linguistic information

weight matrix that is hard to interpret and can be misleading at 共Zadeh 1965兲. Later its potential to model complex multi-input-

times. In other words, the ANN models do not have the ability to multi-output systems, where classical mathematical methods

incorporate additional knowledge or expertise into the model. Al- failed, is realized. This is followed by the use of the FIS, also

though qualitative modeling methods can be used to capture known as fuzzy rule-based systems or fuzzy models, in control

human knowledge, such models will naturally suffer from subjec- and modeling problems in which there is usually some numerical

tive human judgments. One way to overcome many of these information available, although incomplete and uncertain. A key

shortcomings is to use fuzzy models or fuzzy inference systems feature of the FIS is that it can readily integrate expert knowledge

共FIS兲 that can handle the uncertainties arising from insufficient in the form of linguistic information and uncertain numerical data

knowledge, partial truth, and vagueness 共Zadeh 1973兲. These in the form of input-output records into a model and then use it

models combine the transparent linguistic representation of expert for approximate reasoning. According to Zadeh 共1973兲, the FIS

knowledge with the ability to learn from datasets. Various fuzzy contains three features:

modeling techniques have been presented in literature 共e.g., • Linguistic variables instead of, or in addition to numerical

Sugeno and Yasukawa 1993; Klir and Yuan 1995; and Emami variables;

et al. 1998兲. Jang 共1993兲 proposed an adaptive network-based • Relations between the variables in terms of IF-THEN rules;

fuzzy inference system 共ANFIS兲 to construct a FIS in which and

membership functions are adapted using a BPNN in combination • An inference mechanism that uses approximate reasoning al-

with the least-squares optimization. gorithms to formulate complex relationships.

ANFIS has recently been used in civil and environmental en- These features can be explained using the notion of fuzzy sets. A

gineering applications. Akbuluta et al. 共2004兲 used ANFIS for fuzzy set is a collection of ordered pairs that describe the rela-

data generation of shear modulus and damping ratio in reinforced tionship between an uncertain quantity and a membership func-

sands. Chau et al. 共2005兲 used ANFIS and ANN for comparison tion 共x兲, where 0 艋 共x兲 艋 1. A fuzzy number is a normal and

of flood forecasting models and reported that ANFIS obtained convex fuzzy set in a continuous universe of discourse in which

optimal results. Chang and Chang 共2006兲 utilized it to build a the variable is defined. Fig. 2 shows the commonly used fuzzy

prediction model for reservoir management. Vernieuwe et al. numbers including triangular, trapezoidal, and Gaussian shape

共2005兲 applied it to the modeling of rainfall–discharge dynamics. fuzzy numbers. Finally, a linguistic variable can be regarded as a

Nayak et al. 共2004兲 applied it to model hydrologic time series, variable whose value is a fuzzy number, but fuzzy numbers can

and reported that ANFIS was superior to ANN and other statisti- also represent numerical variables without being firmly connected

cal methods. to linguistic terms. An excellent introduction to the fuzzy set

In this study, ANFIS is introduced as a tool to develop a fuzzy theory and fuzzy logic can be found in 共Klir and Yuan 1995; Lee

model that can estimate compressive strength of concrete given 1990a,b兲. In this section, the components of the FIS and the meth-

its mix proportioning. Previously reported data 共Kim et al. 2004, ods for constructing a FIS are explained.

2005兲 are used to train and validate the fuzzy model. The esti-

mated strengths are compared with the reported concrete

Fuzzy Inference System

strengths. The results highlight the utility of ANFIS in the con-

struction industry. The outline of the paper is as follows. First, the The information of the FIS is encapsulated in two modules: A

concept of fuzzy based methods, including FISs and fuzzy mod- fuzzy knowledge base and an inference mechanism. The former is

JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / JULY 2007 / 551

J. Mater. Civ. Eng. 2007.19:550-560.

Downloaded from ascelibrary.org by University of Notre Dame on 08/24/14. Copyright ASCE. For personal use only; all rights reserved.

Fig. 3. Fuzzy reasoning models

a model developed based on expert knowledge and/or input- It has been demonstrated 共Sugeno and Tanaka 1991兲 that the

output data. The inference mechanism then uses the knowledge TSK models can accurately represent complex behavior with a

base to estimate the output of the system for given inputs. A few rules. Although the TSK fuzzy models are computationally

modularized design of the FIS enables it to maintain a generic less involved than the Mamdani type fuzzy models, the difficulty

processing structure that is capable of dealing with various in defining a numerical function for the output propositions has

systems in different application domains 共e.g., physical, medical, often made them less attractive in fuzzy applications. This prob-

financial兲 as long as a relevant knowledge base is defined. Also, lem is resolved when the model is constructed automatically

the FIS can be readily updated by modifying the knowledge base based on input-output data acquired from the systems. Another

using new information as it becomes available. problem with the TSK models is that it is difficult to assign an

appropriate linguistic term to the consequence propositions of the

TSK models, but this will not be a problem if a qualitative model

Knowledge Base

of the system is not required.

The knowledge base defines the relationships between the input The rule base of a complex system usually requires a large

and output parameters of a system. The most commonly used number of rules to describe the behavior of a system for all

representation of the input-output relationships is Mamdani type possible values of the input variables. This is referred to as the

fuzzy models 共after Mamdani, 1977兲. In this type of fuzzy “completeness” of a fuzzy model. The aggregation of the rules

models, linguistic propositions are used both in antecedent and described in Eq. 共1兲 forms a rule base that is valid over the entire

consequent parts of the IF-THEN rules. application domain. The aggregation is obtained using the union

Another type of representing the input-output relationships is of the rules or subsystems as

Takagi-Sugeno-Kang 共TSK兲 共Takagi and Sugeno 1985兲 fuzzy

models in which the antecedent part of the rules is composed of n

linguistic propositions, but the consequent parts is defined by R = 艛 Ri = R1 ALSO R2 ALSO . . . ALSO Rn 共2兲

i=1

either a constant number 共zeroth order兲 or linear equations 共first

order兲. A first-order TSK model of a multi-input-single-output

system may be represented by a set of linear subsystems 共rules兲 Inference Mechanism

each of which defined by a linear consequent statement

The inference mechanism of Mamdani type and TSK fuzzy mod-

Ri:IF x1 is Ai1 AND . . . xm is Aim els are slightly different. Mamdani’s inference mechanism 关Fig.

3共a兲兴 consists of three connectives: The aggregation of anteced-

THEN y i = bi0 + bi1x1 + ¯ + bimxm, i = 1, . . . ,n 共1兲

ents in each rule 共AND connectives兲, implication 共i.e., IF-THEN

where Ri represents the ith rule, n⫽total number of rules, x j connectives兲, and aggregation of the rules 共ALSO connectives兲.

共j = 1 , . . . , m兲⫽input variables, y i⫽output variable, Aij⫽input The operators performing the connectives distinguish the type of

fuzzy set defined in the input space U j, and bij⫽consequent pa- fuzzy inferencing. The AND and ALSO connectives are chosen

rameters. Thus, every rule is a local fuzzy relationship that maps from a family of t-norm and t-conorm operators, respectively.

a part of the multidimensional input space U into a certain part of Comprehensive discussions on t-norm 共e.g., minimum and prod-

the output space V. uct operators兲 and t-conorm 共e.g., maximum and sum operators兲

552 / JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / JULY 2007

J. Mater. Civ. Eng. 2007.19:550-560.

can be found in 共Lee 1990a,b兲. The implication 共IF-THEN con- Structure Identification

nective兲 also uses t-norm operators, but not necessarily identical

The input variables are selected from a pool of input candidates

to the ones used for the AND connectives.

that most likely affect the output. Typically, there is no systematic

The inference mechanism of TSK models 关Fig. 3共b兲兴 is more

way to specify the input candidates, and hence, selection is pri-

straightforward than the more common Mamdani’s type, because marily carried out based on experience or common sense. Subse-

the outputs of individual subsystems are crisp numbers. An alge- quently, given a finite number of input candidates and the training

braic product operator is usually selected to perform the t-norm to data, the input variables can be selected using the combinatorial

simplify the computations further. The result of implication of algorithm described in 共Takaei and Sugeno 1985兲. In the latter,

each rule is a weight factor that indicates the rule degree of firing first, a combination of input variables is selected from of a num-

共dof兲, wi. The aggregation of the rules is simply adding the ber of input candidates. Next, the optimum premise and conse-

weighted average of the output of the individual rules. Thus, the quent parameters are identified according to the input-output data

crisp output y * of a TSK model is given by and a performance index 共e.g., mean square of differences

between the model output and output data兲 is calculated. The

Downloaded from ascelibrary.org by University of Notre Dame on 08/24/14. Copyright ASCE. For personal use only; all rights reserved.

n optimal combination of input variables is the one that yields the

wi

*

y = 兺 n yi 共3兲 minimum performance index.

The selection of the input variables is generally a complicated

兺

i=1

wk problem requiring iterative algorithms, if a priori knowledge of

k=1 the system is not available. At this point, a general understanding

of the system performance or a sensitivity analysis of the input

Fuzzy Modeling candidates prior to modeling can help in reducing the number of

There are two basic approaches for developing a FIS: Direct ap- input candidates.

proach and system identification 共Yager and Filev 1994b兲. In the The most important step of structure identification is the rule

direct approach, the information extracted from the expert knowl- generation. Clustering of the input-output data is an intuitive

edge is used to: approach to rule generation. The idea of clustering is to produce a

concise representation of a system’s behavior by dividing the

• Specify the input, state, and output variables;

output data into a certain number of fuzzy partitions. The fuzzy

• Determine the partitions of input and output variables in their

C-Means 共FCM兲 clustering algorithm 共Bezdek 1981, Bezdek et al.

universes of discourse, and optionally label the partitions with

1987兲 has been widely studied and applied in many applications.

appropriate linguistic terms;

The convergence of the FCM optimization similar to most

• Define a set of IF-THEN statements 共rules兲 that represent the

optimization problems depends on the choice of initial values 共i.e.,

relationships between the system variables;

the number of clusters c and initial cluster centers i兲. Yager and

• Select an appropriate reasoning method; and

Filev 共1994a兲 proposed a simple and effective clustering

• Evaluate the model adequacy.

algorithm, called the mountain method, for estimating the number

Direct approach is essentially simple and intuitive, but it has in-

and initial location of cluster centers. In this method, a grid is

herent limitations. The main limitation is due to the fact that

generated for data space of each input and output variable, and

quantitative observations provide an overview of the performance

then a potential value for each grid point based on the distances to

of the system, but do not explicitly determine the structure or

the actual data points is calculated. The grid points with high

parameters of the model. Also, it is often the case that an expert

potential values correspond to the cluster centers. The problem

cannot tell linguistically what kind of outcome he expects or what

with this clustering method is that the computational load

kind of action he takes in a particular situation. As a result, the

increases exponentially with the number of input variables. Chiu

adequacy of the direct approach is restricted to the boundaries of

共1994兲 proposed a modified form of the mountain method, called

the expert knowledge. In other words, if the expert knowledge

subtractive clustering, which significantly decreases the

about the system is incomplete and subjective, then so will be the computational load, especially for systems with a large number of

model.

input variables. In this method, the potential value P1i is calculated

Another approach for developing a FIS is system identifica-

with respect to the actual data points, not some inscribed grid

tion. In this approach, the FIS is developed based on the points. The potential of a data point xi is given by

input-output data 共training data兲 obtained from the actual system.

System identification is predominantly useful when a predeter- n

4储xi − x j储2

mined model structure based on characteristics of variables is not

available. Therefore, system identification can increase the objec-

P1i = 兺

j=1

e− r2a , i = 1, . . . ,n 共4兲

tivity of fuzzy modeling by introducing new knowledge to the

where ra⫽positive constant. The first cluster center is at 1 that

model 共Zadeh 1991兲. System identification is divided into two

has the highest potential value 0 = max共P1i 兲, i = 1 , . . . n.

parts: Structure identification and parameter identification

Subsequently, the potential values of the remaining data points are

共Sugeno and Yasukawa 1993兲. Similar to the direct approach, the

updated with respect to the first cluster by

objective of structure identification is to determine the input and

output variables, partitions of the input and output spaces 共i.e., 4储xi − k−1储2

fuzzy sets兲, relationships between the input and output variables Pki = Pk−1

i − k−1e− r2b , k = 2, . . . ,c i = 1, . . . ,n − 1

共IF-THEN rules兲, and finally the number of rules. Parameter iden-

共5兲

tification involves adjusting the parameters of the model obtained

in the first part so that a performance index such as the root mean where rb⫽positive constant; and c⫽total number of clusters. The

square of the output errors is minimized. The parameters of a procedure is repeated until all cluster centers are obtained. The

TSK type fuzzy model define the input fuzzy sets Aij and the parameters ra and rb are used to adjust the distance between the

output coefficients bij of Eq. 共1兲. clusters. Typically, the clusters stand in an appropriate distance

JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / JULY 2007 / 553

J. Mater. Civ. Eng. 2007.19:550-560.

when rb = 1.5ra. In this paper, subtractive clustering is used to

partition the input space and find the initial structure of the FIS.

The number of rules is an important parameter of the FIS.

Aij = exp − 再 共x − cij兲 2

2aij

冎 共7兲

Clearly, the appropriate number of rules depends on the where aij and cij⫽antecedent parameters of the FIS.

complexity of the system. According to Sugeno and Yasukawa 2. Layer 2: Every node i in this layer is a fixed node, labeled ⌸,

共1993兲, the number of fuzzy rules corresponds to the order of a which multiplies the incoming signals and sends the product

conventional model where an optimal model minimizes both the out

order and the output error. A statistical analysis for evaluating the m

optimal order of a model is discussed by Akaike 共1974兲. A large

number of rules, similar to a high order of a model, will bias the

O2,i = wi = 兿

j=1

A 共x j兲

ij

共8兲

model towards specific data that can be imprecise or even

erroneous. On the other hand, less number of rules will likely where wi⫽degree of firing strength 共dof兲 of rule i. Any

increase the output error, which is essentially equivalent to t-norm operator that performs AND connective can be used

Downloaded from ascelibrary.org by University of Notre Dame on 08/24/14. Copyright ASCE. For personal use only; all rights reserved.

disregarding the effect of some of the data points containing as the node function in this layer.

valuable information. Thus, the optimal number of rules n can be 3. Layer 3: Every node in this layer is a fixed node labeled N.

obtained from a tradeoff between the number of rules and the The ith node calculates the ration of the ith rule’s firing

output error. The number of rules will be automatically strength to the sum of all rules’ firing strength

determined through clustering the input and output spaces. Each

wi

cluster center is used as the basis of a rule that describes the O3,i = w̄i = n 共9兲

system behavior. Thus, the neighborhood radii ra and rb can be

selected such that an optimal number of rules is achieved. 兺

k=1

wk

where w̄i is called the normalized dof of each rule.

Parameter Identification 4. Layer 4: Every node i in this layer is an adaptive node with

Parameter identification concerns the adjustment of the anteced- a node function

ent and consequent membership functions. In general, parameter

O4,i = w̄iy i = w̄i共bi0 + bi1x1 + . . . + bimxm兲 共10兲

identification is more straightforward than structure identification,

especially when an initial structure of the model is determined where w̄i⫽output of layer 3; and bij, j = 1 , . . . , m⫽consequent

based on expert knowledge or through clustering. In this paper, parameters of the FIS.

parameter identification is carried out using ANFIS 共Jang 1993兲, 5. Layer 5: The single node in this layer is a fixed node labeled

which is also called Adaptive Neuro-fuzzy Inference System. The 兺 that composes the overall output as the summation of all

ANFIS algorithm basically provides a learning technique for ex- incoming signals, i.e.

tracting information from an input-output dataset viz., training n

data, and setting up the antecedent and consequent parameters of

a fuzzy inference system, accordingly. n 兺 wiy i

兺

i=1

The ANFIS is essentially an adaptive multilayer feedforward O5,1 = w̄iy i = n 共11兲

兺

network whose mathematical functionality is equivalent to a FIS. i=1

The network is composed of a number of nodes connected wi

i=1

through directed links. Each node is a processing unit that per-

forms a node function on its incoming signal and yields the node The above 5-layer network is functionally equivalent to a

output. The links only specify the direction of signal flow from TSK type fuzzy inference system.

one node to another. If a node function depends on certain param- The parameter identification of the TSK models involves the

eter values 共i.e., node’s parameter set is nonempty兲, the node is an determination of antecedent parameters aij and cij and consequent

adaptive node. If a node function is fixed 共i.e., node’s parameter parameters bij using a given input-output dataset. A basic ap-

set is empty兲 then it is a fixed node. The output of the nodes, as proach for identifying the parameters of an adaptive network is

well as the overall behavior of the adaptive network, can be modi- based on the gradient method 共Werbos 1974兲. The learning rule

fied by changing the node function parameters. Thus, these pa- concerns how to recursively obtain a gradient vector in which

rameters can be updated according to the training data to achieve each element is defined as the derivative of an error measure with

a desired input-output mapping. respect to a parameter. In the gradient method, the learning rule is

The ANFIS network consists of the following five layers: a chain rule, generally referred to as “back propagation” 共Rumel-

1. Layer 1: Every node i in this layer is an adaptive node with hart et al. 1986兲, because the gradient vector is calculated in the

a node output O1,i given by direction opposite to the flow of the output of each node.

Although the gradient method seems to be a straightforward

approach for the determination of the parameters of an adaptive

O1,i = Aij共x j兲, i = 1, . . . ,n j = 1, . . . ,r 共6兲 network, this method is generally slow and likely to become un-

stable or trapped in local minima. The ANFIS constructs a FIS

using a hybrid of the least-squares estimate 共LSE兲 and gradient

where x j⫽input to the node; Aij⫽fuzzy set associated with descent proposed by Jang 共1993兲 共see also Jang and Sun 1995兲.

the node; m⫽number of inputs; and n⫽number of rules. The Specifically, the learning procedure uses the LSE in a forward

use of Gaussian-shaped fuzzy sets is usually preferable from pass and the gradient descent in a backward pass. In the forward

a computational point of view. A Gaussian fuzzy set with a pass, the network is simulated till layer 4, and the consequent

maximum membership equal to 1 and minimum membership parameters are identified by the LSE under the condition that the

equal to 0 is given by antecedent parameters are fixed. In the backward pass, the error

554 / JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / JULY 2007

J. Mater. Civ. Eng. 2007.19:550-560.

ANFIS Model Development for Concrete Strength

Estimation

The efficiency of the proposed ANFIS modeling technique is il-

lustrated using the mix proportioning and material characteriza-

tion data reported in Kim et al. 共2004兲 and Kim et al. 共2005兲. A

three step procedure on the implementation of ANFIS to estimate

the concrete strength using the mix design is illustrated in this

section. Fig. 4 shows the flowchart of the proposed modeling

approach.

Step 1: Preparation of Training Data

The concrete mix constituents used in the model development are

Downloaded from ascelibrary.org by University of Notre Dame on 08/24/14. Copyright ASCE. For personal use only; all rights reserved.

similar to those used in Kim et al. 共2004兲 and Kim et al. 共2005兲.

The reported data were gathered from actual mix proportions of

two companies, Company A and Company B. The overall basic

material properties between the two companies are similar, with

the exception of sand used. Company B uses only natural sand,

whereas, Company A mixes both natural and crushed sand.

Sample input data of the specified concrete mix proportions of

Company A and B are presented in Table 1, respectively. Further,

the main difference between the reported Kim et al. 共2004兲 and

Kim et al. 共2005兲 data is the units assigned to the mix proportions.

Kim et al. 共2004兲 use kN / m3 for water, cement, fine aggregate,

and coarse aggregate contents, whereas, Kim et al. 共2005兲 use

kg/ m3 for those proportions. Consequently, to combine the two

datasets, the kN / m3 units 共shown in Table 1兲 are converted into

kg/ m3.

Fig. 4. Flowchart of ANFIS model development for concrete The Company A and B data were combined for model training

strength modeling under the assumption that the data are commensurate. Hence, the

final training data for Company A and B consist of 45 data points

each. Further, a combined model of Company A and B, hence-

forth, described as Company A-B is generated using a total of 90

rates propagate backward and the antecedent parameters are up- training data points. It is noted that Company A and B have dif-

dated by the gradient descent. The learning process is continued ferent fine aggregate constituents. Thus, for combined Company

based on a learning rule, usually represented by the discrepancy A-B data, the natural and crushed sand of Company A are com-

between the desired output and the network output under the bined and represented with a single fine aggregate 共FA兲 label. For

same input conditions. This discrepancy is called the error mea- brevity, data are not repeated here; curious readers are referred to

sure, which is usually defined as the sum of the squared differ- Kim et al. 共2004兲 and Kim et al. 共2005兲.

ences between the desired and network outputs. Kim et al. 共2004兲 and Kim et al. 共2005兲 have considered nine

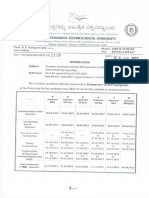

Table 1. Sample Input Data, Specified Concrete Mix Proportions of Company A and Company B for Traininga

Fine Unit Unit fine aggregate content Unit coarse

Specified Water-cement aggregate Unit water cement 共kN/ m3兲 aggregate

strength Slump ratio percentage content content content Admixture

共MPa兲 共cm兲 共w/c兲 共%兲 共kN/ m3兲 共kN/ m3兲 Natural sand 共s1兲 Crushed sand 共s2兲 共kN/ m3兲 共%兲

Company A

15.68 10 64.2 46.6 1.75 2.73 3.28 4.93 9.67 0.84

15.68 15 64.2 47.6 1.86 2.90 3.27 4.92 9.26 0.89

— — — — — — — — — —

39.20 15 32.1 41.2 1.76 5.50 2.53 3.79 9.26 1.68

39.20 18 32.1 41.8 1.82 5.67 2.51 3.77 8.99 1.74

Company B

15.68 10 63.1 50.9 1.68 2.66 9.23 — 9.08 1.36

15.68 15 63.2 50.4 1.76 2.79 8.98 — 9.01 1.43

— — — — — — — — — —

39.20 15 33.2 44.4 1.71 5.14 7.11 — 9.08 2.62

39.20 18 33.2 44.1 1.75 5.28 6.96 — 9.00 2.70

a

From Kim et al. 2004.

JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / JULY 2007 / 555

J. Mater. Civ. Eng. 2007.19:550-560.

Table 2. Datasets of Specified Concrete Mix Proportions

Absolute value modeling Relative value modeling

Specified concrete strength 共MPa兲 Specified concrete strength 共MPa兲

Slump 共cm兲 Slump 共cm兲

Unit water content 共kg/ m3兲 Water-cement ratio 共w / c兲

Unit cement content 共kg/ m3兲 FA percentage 共%兲

Unit FA content 共kg/ m3兲 CA percentage 共%兲

Natural sand 共s1兲, crushed sand 共s2兲 Admixture 共%兲

Unit CA content 共kg/ m3兲

Admixture 共%兲

Downloaded from ascelibrary.org by University of Notre Dame on 08/24/14. Copyright ASCE. For personal use only; all rights reserved.

different concrete mix proportioning parameters to model the 28

day compressive strength. The efficiency of a given model can be

demonstrated using minimal input parameters to capture the

desired model output. Hence, in this paper, initial screening is

carried out to eliminate any redundant input parameters. For Fig. 5. ANFIS equivalent of TSK model for concrete strength

example, the simultaneous use of water-cement ratio and the modeling

corresponding water and cement contents as input parameters is

redundant. Hence, the input parameters are divided into two

groups, absolute variables and relative variables 共Table 2兲. The

absolute value modeling includes absolute values, input param- Slump共x兲 = e− 2

冉

1 共x − 4.5386兲

14.9938

2

冊

eters entail, where possible, parameters without any relative ra-

The ANFIS equivalent of the TSK model is illustrated in Fig. 5.

tios, e.g., using only unit water content and unit cement content,

As discussed in the previous section, the ANFIS is represented in

without the w/c ratio, specified concrete strength, slump, etc. The

five layers. Layer 1 corresponds to the membership functions

input of the relative value modeling includes relative ratios where

共Table 3兲. Layer 2, is a product layer, which illustrate the firing

possible 共e.g., w/c ratio, FA percentage, etc. . . .兲.

strength of a rule. Hence, the ith rule firing strength 共wi兲 of input

Step 2: Structure and Parameter Identification parameters associated with Rule i is Eq. 共8兲

ANFIS is used for structure and parameter identification as out- wi = Slump共Slump兲 ⫻ w/c共w/c兲 ⫻ FA共FA兲 ⫻ CA共CA兲

lined in the previous section. The models are generated using

datasets of Company A, Company B, and the combination of ⫻ Amix共Amix兲

Company A and B that are referred to as Model A, Model B, and Layer three entails normalization of the ith rule strength to the

Model A-B, respectively. Moreover, each of the three models is sum of all rules firing strength Eq. 共9兲

implemented for absolute variables and relative variables, which

are referred to as absolute model and relative model, respectively.

wi

In this way, a total of six models are generated. Initial sensitivity w̄i =

analysis is carried out to observe if there is any significant differ- w1 + w3 + w3 + w4

ence between the actual concrete strength and those predicted Hence, w̄i is called normalized firing strengths. Layer four com-

using the six models. The analysis showed that the results are putes the corresponding output Oi strength estimation of Rule i

only slightly different. Nevertheless, for a pragmatic model appli- Eq. 共10兲

cation, where a more generic model with the minimum number of

inputs is typically more desirable, Model A-B is preferable. The Oi = w̄iy i = w̄i共b1 ⫻ slump + b2 ⫻ w/c + b3 ⫻ FA + b4 ⫻ CA + b5

ensuing discussion is only for the relative Model A-B, but the

derived conclusion is equally applicable to the other five models. ⫻ Amix + b0兲

The FIS generated for the five relative input parameters 共Table The parameters, 兵b1, b2, b3, and b4其 are referred as consequent

2: Slump, w / c ratio, FA, CA, Amix兲 has four rules. Each input parameters 共Table 4兲. For example, the model output from Rule 1

parameter is modeled using a Gaussian type membership function can be shown as

Eq. 共7兲. Result of coefficients of the Gaussian type membership

function, for slump 共Slump兲, w / c ratio 共w/c兲, FA 共FA兲, CA

O1 = w̄1共− 0.0471 ⫻ slump − 0.4684 ⫻ w/c + 0.4255 ⫻ FA %

共CA兲, and Amix 共Amix兲 are summarized in Table 3. For ex-

ample, from Table 3, the Slump associated with Rule 1 is + 0.000988 ⫻ CA − 8.866 ⫻ Amix + 34.46兲

Table 3. Membership Function of the Model A-B Input Parameters

Rules Slump, Slump w / c ratio, w/c FA, FA CA, CA Amix, Amix

ci1 ai1 ci2 ai2 ci3 ai3 ci4 ai4 ci5 ai5

R1 4.5386 14.9938 14.9342 53.3991 4.1284 45.4977 14.4901 56.0001 0.5983 1.0611

R2 4.5242 15.0009 14.9346 35.7003 4.1316 41.9012 14.4901 59.6099 0.5704 1.5168

R3 4.5236 15.0006 14.9342 45.2000 4.1297 46.7999 14.4902 16.7901 0.5888 1.9525

R4 4.5217 12.0046 14.9333 66.3006 4.128 51.4011 14.4901 49.4499 0.5793 1.3134

556 / JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / JULY 2007

J. Mater. Civ. Eng. 2007.19:550-560.

Table 4. Datasets of Specified Concrete Mix Proportions Finally, the estimated concrete strength, f ⬘c , is obtained by sum-

Rules b1 b2 b3 b4 b5 b0 ming the model output of the four rules Eq. 共11兲

R1 −0.0471 −0.4684 0.4255 0.000988 −8.866 34.46

兺 i wi f i

兺i w̄i f i =

R2 −0.4072 0.2037 1.329 −0.9398 18.57 −59.22

f ⬘c =

R3

R4

−0.06809

−0.4016

−1.013

−0.9981

1.298

1.512

1.09

−0.6199

3.304

−0.6334

−51.54

48.12

兺 i wi

Step 3: ANFIS Model Validation

Model validation must be carried out using the input-output data

that are not used for training to evaluate the efficiency the FIS in

predicting concrete strength. The reported 共Kim et al. 2004 and

Downloaded from ascelibrary.org by University of Notre Dame on 08/24/14. Copyright ASCE. For personal use only; all rights reserved.

Fig. 6. Comparison of target and predicted concrete strength for a combined and relative model

JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / JULY 2007 / 557

J. Mater. Civ. Eng. 2007.19:550-560.

Kim et al. 2005兲 testing data points are combined in the model

validation, which resulted in a total of 24 data points for each of

Model A and B, and 48 data points for Model A-B. The FIS

model predicted and actual concrete strength are used for model

validation. The results are plotted in Figs. 6共a–e兲. Figs. 6共a–e兲

show result of the absolute model validation of Models A, B, and

A-B, respectively. Similarly, Figs. 6共b–d and f兲 show result of the

relative model validation of Models A, B, and A-B, respectively.

A linear regression fit is performed between the actual and pre-

dicted concrete strength. The corresponding absolute and relative

model coefficient of determination r2 values are as follows:

Model A 共0.999, 0.984兲, Model B 共0.970, 0.995兲, and Model A-B

共0.999, 0.998兲.

Downloaded from ascelibrary.org by University of Notre Dame on 08/24/14. Copyright ASCE. For personal use only; all rights reserved.

Discussion

Fig. 7. Sensitivity analysis of concrete strength input parameters

Concrete mix proportioning is a highly nonlinear process that is

using a tornado graphs

also subject to experimental error 共Kim et al. 2004兲. Reliable

prediction of concrete strength necessitates the development of

models which are tolerant of various manifestations of that stringent quality control of the in situ w / c ratio should be

uncertainty. Identification of dominant parameters can help to implemented.

implement stringent monitoring and quality control during mix Further, two parameters at a time simulation is carried out for

proportioning 共Jain et al. 2005兲. A sensitivity analysis is the three most dominant variables; w / c ratio, CA, and FA. Fig.

commonly carried out using random sampling 共Monte Carlo-type 8共a兲 shows the simulation between the w / c ratio and CA. At a

simulations兲 where the probability distributions for input data can higher CA content, e.g., 60%, there is a linear decrease in con-

either be assumed or derived from observations. Thereafter, the crete strength with an increase in the w / c ratio. At a lower CA

rank correlation method 共Cullen and Frey 1999兲 is applied to the content, e.g., 10%, the variation of the w / c ratio from 40% to

results of the Monte Carlo simulations to identify input data/ roughly 65% show negligible variation. However, at CA= 10%,

parameters that dominate the output. The rank correlation method significant decrease in concrete strength is observed with an in-

crease in the w / c ratio from 65% to 80%. At a lower w / c ratio,

involves the determination of coefficient of determinations, which

e.g., ⬍50%, an increase in CA content 共from 10% to 30%兲 is

measure the strength of the linear relationship between two

followed by a decrease in concrete strength. However, with fur-

variables. The procedure utilized for the sensitivity analysis is as

ther increase in the CA content 共from 30% to 60%兲, the concrete

reported in Tesfamariam et al. 共2006兲 and the basic steps are

strength increases. This relation is in agreement with a reported

outlined here. For ns number of realization,

共Neville 1997兲 relationship, and Neville underlined that the rea-

1. For i = 1 to ns,

son for this effect is not clear. At a higher w / c ratio, an increase

• Generate a uniformly distributed random numbers for the

in the CA content 共beyond 35%兲 reaches minima and the variation

five input parameters 共ranging between the min and max

is not significant.

values兲, x j;

Fig. 8共b兲 shows the relationship between FA and w / c ratio. In

• Compute the corresponding membership function Eqs. 共6兲

general, an increase in FA and a decrease in the w / c ratio are

and 共7兲, Aij共x j兲;

followed by a linear increase in concrete strength. Fig. 8共c兲 shows

• Compute the dof Eq. 共8兲 and normalized dof Eq. 共9兲; and

the variation of CA and FA in the estimated concrete strength. At

• Compute the output of each layer Eq. 共10兲 and normalized

any level of the FA content, increase in CA is followed by a

output Eq. 共11兲.

decrease in concrete strength; however, after 35% CA content, it

2. Next i

reaches minima. Similarly, and increase in FA is followed by an

• For the n input-output results, rank order the results and increase in concrete in strength, however, after 48% FA, it reaches

perform rank correlation; and a maxima.

• Normalize the rank correlation results and show the result The accuracy of the ANFIS model generated from the input

on a tornado graph. parameters may be compromised outside the range of the training

Sensitivity analysis of the FIS model is carried out for 3,000 datasets. The input parameters for the proposed ANFIS model

realizations from the relative Model A-B, and the results of the discussed in this paper are bounded within the following ranges:

rank correlation are normalized to the sum of one and are plotted Slump, mm 关5, 18兴; unit water content 关160, 185兴; unit cement

in a tornado graph 共Fig. 7兲. Fig. 7 shows that an increase in CA content, kg/ m3 关228, 524兴; unit FA content, kg/ m3 共663, 1004兲;

共16% contribution兲 and w / c ratio 共72% contribution兲 decreases unit CA content, kg/ m3 关882, 1060兴; admixture, % 关0.7, 2.6兴; and

the concrete strength. Clearly, the contribution of Slump is not specified strength, MPa 关10.8, 39.2兴. Extrapolating the model out-

considerable. On other hand, an increase in FA 共11% contribution兲 side these limits should be carried out with caution.

and Amix 共1% contribution兲, albeit to a smaller degree, is fol-

lowed by an increase in the concrete strength. It is interesting to

note that the impact of CA, w / c ratio, Amix, and FA is in agree- Conclusions

ment with the results reported in Neville 共1997兲. Overall the w / c

ratio is the most dominant parameter towards the variability of Concrete mix proportioning is a nonlinear process, for which de-

the concrete strength. This reinforces our intuitive understanding veloping a comprehensive and reliable analytical model is rather

558 / JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / JULY 2007

J. Mater. Civ. Eng. 2007.19:550-560.

presents ANFIS modeling for concrete strength estimation from

concrete mix proportioning. The open architecture of the ANFIS

model is appealing as it captures the designer’s intuitive experi-

ence as well as the numerical information included in the datasets.

The ANFIS modeling also allows postmodeling adjustment and

fine tuning based on the new datasets as they become available.

The ANFIS modeling has a significant potential in the concrete

industry. Sensitivity analysis is carried out to identify critical pa-

rameters that impact the concrete strength. Results of this analysis

can be used to develop in situ construction quality. The ANFIS

model is developed for absolute input parameters where neces-

sary 共e.g., unit water content 共kg/ m3兲, unit FA content 共kg/ m3兲,

etc. . . .兲. However, to minimize the number of input parameters,

Downloaded from ascelibrary.org by University of Notre Dame on 08/24/14. Copyright ASCE. For personal use only; all rights reserved.

relative input parameters 共e.g., w / c ratio 共%兲, FA percentage 共%兲,

etc. . . .兲 are taken into account where possible. The proposed

model is tested and validated with actual reported data in the

literature. The coefficients of determination r2 of the correspond-

ing absolute and relative models are as follows: Model A 共0.999,

0.984兲, Model B 共0.970, 0.995兲, and Model A-B 共0.999, 0.998兲.

The proposed ANFIS modeling method is a step forward to-

ward the development of a comprehensive model for the concrete

industry. In any future development, the concrete strength model-

ing should incorporate external factors that impact the concrete

strength, such as construction quality, environmental condition,

etc. Further, this modeling approach can be used at different

stages of the concrete industry. These stages include, but not lim-

ited to, mix design proportioning, simulation of concrete strength

using mix design proportioning, estimation of in situ concrete

strength given the history of construction quality, and in situ con-

struction quality monitoring using the a measured slump and air

content. Finally, the use of soft computing techniques such as

ANFIS modeling allows the concrete industry to avoid the risk of

faulty or deficient concrete that often entails durability and safety

problems.

Notation

The following symbols are used in this paper:

Aij ⫽ input fuzzy set;

aij, cij ⫽ parameters of Gaussian-shaped function;

bij ⫽ consequent parameters;

c ⫽ subtractive cluster, total number of clusters;

f ⬘c ⫽ minimum 28 days specified strength;

i , j ⫽ counters;

n ⫽ total number of rules;

O1,i ⫽ node output of the ANFIS network;

Fig. 8. 共a兲 Impact of variation in water cement ratio and coarse P1i ⫽ subtractive cluster, potential value;

aggregate on the estimated concrete strength: slump 共10 mm兲, Amix Ri ⫽ ith rule;

共1.5%兲, and FA 共50%兲; 共b兲 impact of variation fine aggregate and ra, rb ⫽ subtractive cluster, adjustment parameters;

water cement ratio on the estimated concrete strength: slump U j ⫽ input space;

共10 mm兲, CA 共40%兲, and admixture 共1.5%兲; 共c兲 impact of variation in V ⫽ output universe of discourse;

coarse aggregate and fine aggregate on the estimated concrete i ⫽ subtractive cluster, cluster centers;

strength: slump 共10 mm兲, w / c ratio 共60%兲, and admixture 共1.5%兲 wi ⫽ degree of firing strength;

w̄i ⫽ normalized dof of each rule;

x j ⫽ input variables 共j = 1 , . . . , m兲;

challenging, if not impossible. Typically, concrete manufacturing y i ⫽ output variable;

companies have extensive datasets of past mix proportions, which y * ⫽ defuzzified crisp value;

can be used for modeling and validation. Hence, the concrete ⫽ error measure;

industry can benefit from their historical datasets in conjunctions 共x兲 ⫽ membership function;

with soft computing techniques to automate mix proportioning 0 ⫽ highest potential value; and

and predict the strength of the final product, reliably. This study ⌺ ⫽ summation of all incoming signals.

JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / JULY 2007 / 559

J. Mater. Civ. Eng. 2007.19:550-560.

References ler. Part II.” IEEE Trans. Syst. Man Cybern., 20共2兲, 419–435.

Lee, S. C. 共2003兲. “Prediction of concrete strength using artificial neural

ACI 211.1-91. 共2001兲. “Standard practice for selecting proportions for network.” Eng. Struct., 25, 849–857.

normal, heavyweight and mass concrete.” ACI Committee Rep. 211, Mamdani, E. H. 共1977兲. “Application of fuzzy logic to approximate rea-

American Concrete Institute, Detroit. soning using linguistic synthesis.” IEEE Trans. Comput., 26共12兲,

Akaike, H. 共1974兲. “New look at the statistical model identification.” 1182–1191.

IEEE Trans. Autom. Control, 19, 716–723. Nayak, P. C., Sudheer, K. P., Rangan, D. M., and Ramasastri, K. S.

Akbuluta, S., Hasiloglub, A. S., and Pamukcuc, S. 共2004兲. “Data genera- 共2004兲. “A neuro-fuzzy computing technique for modeling hydrologi-

tion for shear modulus and damping ratio in reinforced sands using cal time series.” J. Hydrol., 291, 52–66.

adaptive neuro-fuzzy inference system.” Soil Dyn. Earthquake Eng., Neville, A. M. 共1997兲. Properties of concrete, 4th Ed., Wiley, New York.

24, 805–814. Ni, H. G., and Wang, J. Z. 共2000兲. “Prediction of compressive strength

Bezdek, J. C. 共1981兲. Pattern recognition with fuzzy objective function of concrete by artificial neural networks.” Cem. Concr. Res., 30,

algorithms, Plenum, New York. 1245–1250.

Bezdek, J. C., Hathaway, R., Sabin, M., and Tucker, W. 共1987兲. “Con- Oh, J. W., Lee, I. W., Kim, J. T., and Lee, G. W. 共1999兲. “Application of

Downloaded from ascelibrary.org by University of Notre Dame on 08/24/14. Copyright ASCE. For personal use only; all rights reserved.

vergence theory for fuzzy c-means: Counterexamples and repairs.” neural networks for proportioning of concrete mixes.” ACI Mater. J.,

The analysis of fuzzy information, Bezdek, J., ed., CRC, 3, Chap. 8. 96共1兲, 61–67.

Chang, F.-J., and Chang, Y.-T. 共2006兲. “Adaptive neuro-fuzzy inference Rumelhart, D. E., Hinton, G. E., and Williams, R. J. 共1986兲. “Learning

system for prediction of water level in reservoir. Advances in Water internal representations by error propagation.” Parallel distributed

Resources.” Adv. Water Resour., 29共1兲, 1–10. processing: Explorations in the microstructure of cognition, D. E.

Chau, K. W., Wu, C. L., and Li, Y. S. 共2005兲. “Comparison of several Rumelhart and J. L. McClelland, eds., MIT Press, Cambridge, Mass.,

flood forecasting models in Yangtze River.” J. Hydrol. Eng., 10共6兲, 1, 318–362.

485–491. Sugeno, M., and Yasukawa, T. 共1993兲. “A fuzzy-logic-based approach to

Chiang, C-H., and Yang, C.-C. 共2005兲. “Artificial neural networks in qualitative modeling.” IEEE Trans. Fuzzy Syst., 1共1兲, 7–31.

prediction of concrete strength reduction due to high temperature.” Sugeno, T., and Tanaka, K. 共1991兲. “Successive identification of systems

ACI Mater. J., 102共2兲, 93–102. and its application to modeling and control.” Fuzzy Sets Syst., 42共3兲,

Chiu, S. L. 共1994兲. “Fuzzy model identification based on cluster estima- 315–334.

tion.” J. Intell. Fuzzy Syst., 2, 267–278. Takagi, T., and Sugeno, M. 共1985兲. “Fuzzy identification of systems and

Cullen, A. C., and Frey, H. C. 共1999兲. Probabilistic techniques in expo- its applications to modeling and control.” IEEE Trans. Syst. Man Cy-

sure assessment: A handbook for dealing with variability and uncer- bern., 15共1兲, 116–131.

tainty in models and inputs, Plenum, New York, 352. Tesfamariam, S., Rajani, B., and Sadiq, R. 共2006兲. “Consideration of

Emami, M. R., Turksen, I. B., and Goldenberg, A. A. 共1998兲. “Develop- uncertainties to estimate structural capacity of ageing cast iron water

ment of a systematic methodology of fuzzy logic modeling.” IEEE mains—A possibilistic approach.” Can. J. Civ. Eng., 33共8兲, 1050–

Trans. Fuzzy Syst., 6共3兲, 346–361. 1064.

Hong-Guang, N., and Ji-Zong, W. 共2000兲. “Prediction of compressive Vernieuwe, H., et al. 共2005兲. “Comparison of data-driven Takagi—

strength of concrete by neural networks.” Cem. Concr. Res., 30, Sugeno models of rainfall—Discharge dynamics.” J. Hydrol., 302,

1245–1250. 173–186.

Jain, A., Misra, S., and Jha, S. K. 共2005兲. “Discussion of ‘Application of Werbos, P. 共1974兲. “Beyond regression: New tools for prediction and

neural networks for estimation of concrete strength.’ ” J. Mater. Civ. analysis in the behavioral sciences.” Ph.D. dissertation, Harvard

Eng., 17共6兲, 736–738. Univ., Cambridge, Mass.

Jang, J. S. R. 共1993兲. “ANFIS: Adaptive-network-based fuzzy inference Yager, R. R., and Filev, D. P. 共1994a兲. “Generation of fuzzy rules by

system.” IEEE Trans. Syst. Man Cybern., 23共3兲, 665–685.

mountain clustering.” J. Intell. Fuzzy Syst., 2, 209–219.

Jang, J. S. R., and Sun, C. T. 共1995兲. “Neuro-fuzzy modeling and con-

Yager, R. R., and Filev, D. P. 共1994b兲. Essentials of fuzzy modeling and

trol.” Proc. IEEE, 83共3兲, 378–406.

Kim, D. K., Lee, J. J., Lee, J. H., and Chang, S. K. 共2005兲. “Application control, Wiley, New York.

of probabilistic neural networks for prediction of concrete strength.” Yeh, I.-C. 共1998兲. “Modeling of strength of high-performance concrete

J. Mater. Civ. Eng., 17共3兲, 353–362. using artificial neural networks.” Cem. Concr. Res., 28共12兲, 1797–

Kim, J. I., Kim, D. K., Feng, M. Q., and Yazdani, F. 共2004兲. “Application 1808.

of neural networks for estimation of concrete strength.” J. Mater. Civ. Zadeh, L. A. 共1965兲. “Fuzzy sets.” Information Control., 8, 338–353.

Eng., 16共3兲, 257–264. Zadeh, L. A. 共1973兲. “Outline of a new approach to the analysis of com-

Klir, G. J., and Yuan, B. 共1995兲. Fuzzy sets and fuzzy logic—Theory and plex systems and decision processes.” IEEE Trans. Syst. Man Cy-

bern., 3, 28–44.

applications, Prentice-Hall, Englewood Cliffs, N.J.

Lai, S., and Serra, M. 共1997兲. “Concrete strength prediction by means of Zadeh, L. A. 共1991兲. “From circuit theory to system theory.” Facets of

neural network.” Constr. Build. Mater., 11共2兲, 93–98. systems science, G. J. Klir, ed., Plenum, New York.

Lee, C. C. 共1990a兲. “Fuzzy logic in control systems: Fuzzy logic control- Zadeh, L. A. 共1997兲. “The role of fuzzy logic and soft computing in the

ler. Part I.” IEEE Trans. Syst. Man Cybern., 20共2兲, 404–418. conception, design and deployment of intelligent systems.” Software

Lee, C. C. 共1990b兲. “Fuzzy logic in control systems: Fuzzy logic control- agents and soft computing, Springer, New York.

560 / JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / JULY 2007

J. Mater. Civ. Eng. 2007.19:550-560.

You might also like

- Damage Mechanics Modeling of Nonlinear Seismic Behavior Concrete StructuresDocument10 pagesDamage Mechanics Modeling of Nonlinear Seismic Behavior Concrete StructuresDaniele Dominic ColluraNo ratings yet

- Hydrolysis of Nucleic AcidsDocument7 pagesHydrolysis of Nucleic Acidskeepersake81% (16)

- Bai 1994Document17 pagesBai 1994manish469patidarNo ratings yet

- Concrete Mix Design Using Neural NetworkDocument5 pagesConcrete Mix Design Using Neural NetworkPennarasi G (RC2113001011001)No ratings yet

- (Asce) ST 1943-541X 0002979Document13 pages(Asce) ST 1943-541X 0002979rithy khouyNo ratings yet

- Structures: Hossein Mahmoudi, Maryam Bitaraf, Mojtaba Salkhordeh, Siavash SoroushianDocument18 pagesStructures: Hossein Mahmoudi, Maryam Bitaraf, Mojtaba Salkhordeh, Siavash SoroushianLt HasanNo ratings yet

- 2021 Estimating The Flexural Strength of Concrete Using Compressive StrengthDocument6 pages2021 Estimating The Flexural Strength of Concrete Using Compressive Strengthfarid boursasNo ratings yet

- Rational Approach To Prediction of Shear Capacity of RC Beam-Column ElementsDocument13 pagesRational Approach To Prediction of Shear Capacity of RC Beam-Column ElementsRayan MahgoubNo ratings yet

- ACT M1 Ktunotes - inDocument9 pagesACT M1 Ktunotes - inMohammed ImranNo ratings yet

- (Asce) 0733-9399 (2004) 130 6Document11 pages(Asce) 0733-9399 (2004) 130 6abhinav thakurNo ratings yet

- 10 1061@asce0733-93991997123@7660Document9 pages10 1061@asce0733-93991997123@7660dsvdfbgNo ratings yet

- Application of Neural Networks For Estimation of Concrete StrengthDocument10 pagesApplication of Neural Networks For Estimation of Concrete StrengthAravind H B Engineering CivilNo ratings yet

- Nemati Et Al 2007 Bayesian Statistical Framework To Construct Probabilistic Models For The Elastic Modulus of ConcreteDocument8 pagesNemati Et Al 2007 Bayesian Statistical Framework To Construct Probabilistic Models For The Elastic Modulus of Concrete云帆 张No ratings yet

- Regularization Neural Network For Construction Cost Estimation by Hoijat Adeli and Mingyang WuDocument7 pagesRegularization Neural Network For Construction Cost Estimation by Hoijat Adeli and Mingyang WuKabir YaqubiNo ratings yet

- Adeli1998 PDFDocument7 pagesAdeli1998 PDFbernard nezarlonNo ratings yet

- Construction and Building Materials: Itzel Nunez, Afshin Marani, Majdi Flah, Moncef L. NehdiDocument17 pagesConstruction and Building Materials: Itzel Nunez, Afshin Marani, Majdi Flah, Moncef L. NehdingothientuNo ratings yet

- DSC Model For Soil and Interface Including Liquefaction and Prediction of Centrifuge TestDocument9 pagesDSC Model For Soil and Interface Including Liquefaction and Prediction of Centrifuge TestMahmoud. HlelaiNo ratings yet

- (Asce) 0733-9445 (2001) 127 7Document11 pages(Asce) 0733-9445 (2001) 127 7abadittadesseNo ratings yet

- Guzmán-Torres 2021 IOP Conf. Ser. - Mater. Sci. Eng. 1150 012019Document6 pagesGuzmán-Torres 2021 IOP Conf. Ser. - Mater. Sci. Eng. 1150 012019farid boursasNo ratings yet

- Designing Concrete Mixtures Designing Concrete Mixtures: CIVL 1112 ACI Mix Design /10Document10 pagesDesigning Concrete Mixtures Designing Concrete Mixtures: CIVL 1112 ACI Mix Design /10Muhammad Ave SenaNo ratings yet

- 2014 Ferroscan Probabilistic NDT Data Fusion of FerroscDocument5 pages2014 Ferroscan Probabilistic NDT Data Fusion of Ferroscalcides seguraNo ratings yet

- Damage Mechanics Modeling of Nonlinear Seismic Behavior of Concrete StructuresDocument10 pagesDamage Mechanics Modeling of Nonlinear Seismic Behavior of Concrete StructuresDiego Leonel Suárez VásquezNo ratings yet

- Optimization and Sensitivity of Retaining Structures: by A KM Sarlba L and Fuat ErbaturDocument8 pagesOptimization and Sensitivity of Retaining Structures: by A KM Sarlba L and Fuat ErbaturIngénieurCivilNo ratings yet

- Buildings: Experimental Tests On A Dowel-Type Timber Connection and Validation of Numerical ModelsDocument14 pagesBuildings: Experimental Tests On A Dowel-Type Timber Connection and Validation of Numerical ModelsFritz NatividadNo ratings yet

- Neural Network Estimating Compaction Quality of Hot Asphalt MixesDocument11 pagesNeural Network Estimating Compaction Quality of Hot Asphalt MixesFikry Ahmad Al-imamNo ratings yet

- DSC Model For Soil and Interface Including Liquefaction and Prediction of Centrifuge TestDocument9 pagesDSC Model For Soil and Interface Including Liquefaction and Prediction of Centrifuge Testroshan.karkiNo ratings yet

- Club 5Document12 pagesClub 5Daniel ErazoNo ratings yet

- CIE Lab of ConcreteDocument14 pagesCIE Lab of ConcreteMadhavi Latha KasulanatiNo ratings yet

- Yu Et Al 2021Document14 pagesYu Et Al 2021Murillo HenriqueNo ratings yet

- 1 s2.0 S0263224121007429 MainDocument15 pages1 s2.0 S0263224121007429 MainSiva GuruNo ratings yet

- Reduction of Uncertainty in The Assessment of Concrete Strength in Existing StructuresDocument1 pageReduction of Uncertainty in The Assessment of Concrete Strength in Existing StructuresArturo GonzalezNo ratings yet

- Predicting SCC Performance Using ANN98-m43Document8 pagesPredicting SCC Performance Using ANN98-m43Ilhame HarNo ratings yet

- Correia Esquivel Zornberg 2018Document8 pagesCorreia Esquivel Zornberg 2018mercedesNo ratings yet

- 1 s2.0 S095006182200561X Main PDFDocument11 pages1 s2.0 S095006182200561X Main PDFDaniela Gonzalez BetancurNo ratings yet

- 21-0027 Mante SO22Document15 pages21-0027 Mante SO22AgileNo ratings yet

- Engineering Structures: V. Sarhosis, Y. ShengDocument11 pagesEngineering Structures: V. Sarhosis, Y. ShengPedro SilvaNo ratings yet

- Strength Prediction Model For Concrete: AUGUST 2013Document7 pagesStrength Prediction Model For Concrete: AUGUST 2013MustafaMahdiNo ratings yet

- Evaluation of Comp Stength 4 of 4Document1 pageEvaluation of Comp Stength 4 of 4rameshkaaNo ratings yet

- (Asce) 0733 9445 (1992) 118:7 (1751)Document19 pages(Asce) 0733 9445 (1992) 118:7 (1751)ashap1905_90005917No ratings yet

- Homogenizationof Masonry Using Numerical SimulationsDocument12 pagesHomogenizationof Masonry Using Numerical SimulationsvadaleNo ratings yet

- Ahmad, Bhupinder - 2018 - An Experimental Study On Shear Capacity of Interfaces in Recycled Aggregate ConcreteDocument16 pagesAhmad, Bhupinder - 2018 - An Experimental Study On Shear Capacity of Interfaces in Recycled Aggregate ConcreteTANVEER HABIBNo ratings yet

- A Computational Modelling Approach For LDocument20 pagesA Computational Modelling Approach For Lnawel mezighecheNo ratings yet

- Ezzeldin 2017Document11 pagesEzzeldin 2017Benjamin RuzNo ratings yet

- ElasticModulusofConcrete CECRDocument8 pagesElasticModulusofConcrete CECRzeb.bhuttoNo ratings yet

- Indoor Stadium, GOA: Flat TrussDocument1 pageIndoor Stadium, GOA: Flat TrussUrvashi SindhiNo ratings yet

- Determination of Actual Design Moment in Ultradeep Reinforced Concrete RaftsDocument3 pagesDetermination of Actual Design Moment in Ultradeep Reinforced Concrete RaftsklllNo ratings yet

- Homogenization Strategy For Brick Masonry Walls Under iPLoDocument12 pagesHomogenization Strategy For Brick Masonry Walls Under iPLoRaul Robledo AlvaradoNo ratings yet

- s43503 024 00024 8Document24 pagess43503 024 00024 8DeeptiNo ratings yet

- Design Optimization of Shear Wall High-Rise Building StructuresDocument11 pagesDesign Optimization of Shear Wall High-Rise Building StructuresSachintha WijekoonNo ratings yet

- Prozzi Madanat 2003 Incremental Nonlinear Model For Predicting Pavement ServiceabilityDocument7 pagesProzzi Madanat 2003 Incremental Nonlinear Model For Predicting Pavement ServiceabilityMearg NgusseNo ratings yet

- Concrete Advice 68Document9 pagesConcrete Advice 68YF NNo ratings yet

- Effect of Geocell Confinement On Strength and Deformation Behavior of GravelDocument13 pagesEffect of Geocell Confinement On Strength and Deformation Behavior of GravelAnirudh SabooNo ratings yet

- Cecchi 2002Document10 pagesCecchi 2002geniecivil2218No ratings yet

- (Lim Et Al., 2016) Finite-Element Modeling of Actively Confined Normal-Strength and High-Strength Concrete Under CompressionDocument12 pages(Lim Et Al., 2016) Finite-Element Modeling of Actively Confined Normal-Strength and High-Strength Concrete Under CompressionJose ManuelNo ratings yet

- Applsci 13 08971Document29 pagesApplsci 13 08971shastry_vishNo ratings yet

- By Hamid R. Lotfi and P. Benson Shing, 2 Members, ASCE AbstractDocument18 pagesBy Hamid R. Lotfi and P. Benson Shing, 2 Members, ASCE AbstractafuhcivNo ratings yet

- RCC MixtureDocument8 pagesRCC MixtureAhmed AllamNo ratings yet

- Digital Image Correlation Technique For Measurement of Surface Strains in Reinforced Asphalt Concrete Beams Under Fatigue LoadingDocument10 pagesDigital Image Correlation Technique For Measurement of Surface Strains in Reinforced Asphalt Concrete Beams Under Fatigue LoadingMahmoud EissaNo ratings yet

- Curosuetal2021materials 14 03631Document25 pagesCurosuetal2021materials 14 03631Mirza BasitNo ratings yet

- Numerical Modelling of Masonry StructuresDocument12 pagesNumerical Modelling of Masonry StructuresMichael PisfilNo ratings yet

- Bicok107Document2 pagesBicok107CIVIL ENGINEERINGNo ratings yet

- India Rural Water Supply and Sanitation Project For Low Income States ProjectDocument72 pagesIndia Rural Water Supply and Sanitation Project For Low Income States ProjectCIVIL ENGINEERINGNo ratings yet

- 2 CivsyllDocument79 pages2 CivsyllCIVIL ENGINEERINGNo ratings yet

- LR CD Cell 2012Document249 pagesLR CD Cell 2012CIVIL ENGINEERINGNo ratings yet

- Entrepreneurship Essentials - Unit 7 - Week 4Document5 pagesEntrepreneurship Essentials - Unit 7 - Week 4CIVIL ENGINEERINGNo ratings yet

- B.tech Civil Engg. CBC 2018 SchemeDocument118 pagesB.tech Civil Engg. CBC 2018 SchemeCIVIL ENGINEERINGNo ratings yet

- Entrepreneurship Essentials - Unit 4 - Week 1Document5 pagesEntrepreneurship Essentials - Unit 4 - Week 1CIVIL ENGINEERINGNo ratings yet

- MBA III Sem Internship VivaDocument1 pageMBA III Sem Internship VivaCIVIL ENGINEERINGNo ratings yet

- Bearing Capacity in Terms of SPT N Value and SettlementDocument1 pageBearing Capacity in Terms of SPT N Value and SettlementCIVIL ENGINEERINGNo ratings yet

- Cricket Pitchesin TrinidadDocument14 pagesCricket Pitchesin TrinidadCIVIL ENGINEERINGNo ratings yet

- DualityDocument20 pagesDualityCIVIL ENGINEERINGNo ratings yet

- Conference Training On Total 23april2023 BrouDocument2 pagesConference Training On Total 23april2023 BrouCIVIL ENGINEERINGNo ratings yet

- UHPFRCDocument2 pagesUHPFRCCIVIL ENGINEERINGNo ratings yet

- Materials 14 01661 v2Document34 pagesMaterials 14 01661 v2CIVIL ENGINEERINGNo ratings yet

- Effectsof Water Contentand Compactionon Ball Movementon Major Cricket Pitch Soilsin TrinidadDocument8 pagesEffectsof Water Contentand Compactionon Ball Movementon Major Cricket Pitch Soilsin TrinidadCIVIL ENGINEERINGNo ratings yet

- Affiliated - College - Manual - 20-07-2023 (As On 20.10.2023)Document92 pagesAffiliated - College - Manual - 20-07-2023 (As On 20.10.2023)CIVIL ENGINEERINGNo ratings yet

- GRIHA Rating - Green Rating For Integrated Habitat AssesmentDocument5 pagesGRIHA Rating - Green Rating For Integrated Habitat AssesmentCIVIL ENGINEERINGNo ratings yet

- RJ061Document16 pagesRJ061CIVIL ENGINEERINGNo ratings yet

- J Conbuildmat 2019 117109Document12 pagesJ Conbuildmat 2019 117109CIVIL ENGINEERINGNo ratings yet

- NBA Accreditation and Teaching and Learning in Engineering (NATE) - Unit 3 - Week 1 - NBA, SAR and OBE (Module 1 - NBA and OBE Framework)Document4 pagesNBA Accreditation and Teaching and Learning in Engineering (NATE) - Unit 3 - Week 1 - NBA, SAR and OBE (Module 1 - NBA and OBE Framework)CIVIL ENGINEERING100% (1)

- European Journal of Environmental and Civil EngineeringDocument14 pagesEuropean Journal of Environmental and Civil EngineeringCIVIL ENGINEERINGNo ratings yet

- Ac Ii PG 2022 23 1129aDocument2 pagesAc Ii PG 2022 23 1129aCIVIL ENGINEERINGNo ratings yet

- ಸುತ್ತೋಲೆ ಜಲಶಕ್ತಿ ಅಭಿಯಾನDocument1 pageಸುತ್ತೋಲೆ ಜಲಶಕ್ತಿ ಅಭಿಯಾನCIVIL ENGINEERINGNo ratings yet

- Modern Construction Materials: Prof. Ravindra Gettu Type of Course: Course Duration: Exam Date: 2Document1 pageModern Construction Materials: Prof. Ravindra Gettu Type of Course: Course Duration: Exam Date: 2CIVIL ENGINEERINGNo ratings yet

- UniversityDocument10 pagesUniversityCIVIL ENGINEERINGNo ratings yet

- Nihms 647352Document6 pagesNihms 647352CIVIL ENGINEERINGNo ratings yet

- Quantities of Sodium Hydroxide Solids AnDocument6 pagesQuantities of Sodium Hydroxide Solids AnCIVIL ENGINEERINGNo ratings yet

- Institutional Ethics Committee (Iec) Maharaja Sriram Chandra Bhanja Deo University Ethical Review Procedures: As Per The Icmr Guidelines)Document35 pagesInstitutional Ethics Committee (Iec) Maharaja Sriram Chandra Bhanja Deo University Ethical Review Procedures: As Per The Icmr Guidelines)CIVIL ENGINEERINGNo ratings yet

- Scan 4 Dec 2020Document3 pagesScan 4 Dec 2020CIVIL ENGINEERINGNo ratings yet

- Underground Watertank RFT DetailsDocument1 pageUnderground Watertank RFT DetailsCIVIL ENGINEERINGNo ratings yet

- Suhas S R: Email-ID: Mobile: 9535610175 / 7019470710Document2 pagesSuhas S R: Email-ID: Mobile: 9535610175 / 7019470710Sachin S KukkalliNo ratings yet

- Person To PersonDocument126 pagesPerson To PersonYalmi AdiNo ratings yet

- DX-790-960-65-16.5i-M Model: A79451600v02: Antenna SpecificationsDocument2 pagesDX-790-960-65-16.5i-M Model: A79451600v02: Antenna SpecificationsakiselNo ratings yet

- Shareholder Value Analysis FrameworkDocument9 pagesShareholder Value Analysis Frameworkashish.the7353No ratings yet

- ADM Marketing Module 4 Lesson 4 Promotional ToolsDocument20 pagesADM Marketing Module 4 Lesson 4 Promotional ToolsMariel Santos75% (8)

- Admission LetterDocument7 pagesAdmission Letterduke cyberNo ratings yet

- Aquamaster 4 Few4 and Fet4: Electromagnetic FlowmeterDocument48 pagesAquamaster 4 Few4 and Fet4: Electromagnetic FlowmeterAmol BorikarNo ratings yet

- Jamboree GRE StudyPlan PDFDocument3 pagesJamboree GRE StudyPlan PDFMd Minhaj Ahmed AhmedNo ratings yet

- Presentation - Pragati MaidanDocument22 pagesPresentation - Pragati MaidanMohamed Anas100% (4)

- Reducing Major Defects in Radiators Manufacturing: Kumar P., Sonawane B.S., Sontakke R.R., Surves.B., Wasnik A.RDocument5 pagesReducing Major Defects in Radiators Manufacturing: Kumar P., Sonawane B.S., Sontakke R.R., Surves.B., Wasnik A.RKrushnaNo ratings yet

- Piping Stress AnalysisDocument10 pagesPiping Stress AnalysisM Alim Ur Rahman100% (1)

- (Shuangzhu Jia Et Al 2020) Study On The Preparing and Mechanism of Chitosan-Based Nanomesoporous Carbons by Hydrothermal MethodDocument21 pages(Shuangzhu Jia Et Al 2020) Study On The Preparing and Mechanism of Chitosan-Based Nanomesoporous Carbons by Hydrothermal MethodSilvia Devi Eka PutriNo ratings yet

- File Handling in JavaDocument8 pagesFile Handling in JavaDipendra KmNo ratings yet

- Beginner's Guide To SoloDocument12 pagesBeginner's Guide To SoloTiurNo ratings yet

- The Little Book of Breaks 1840241519 PDFDocument61 pagesThe Little Book of Breaks 1840241519 PDFksrbhaskarNo ratings yet

- 'Beware of Being Burgoyned.': Marching Toward Monmouth, Delaware River To Freehold, 18 To 27 June 1778Document35 pages'Beware of Being Burgoyned.': Marching Toward Monmouth, Delaware River To Freehold, 18 To 27 June 1778John U. Rees100% (1)

- AfPS&CS Ch-01Document10 pagesAfPS&CS Ch-01Amelwork AlchoNo ratings yet

- Experiencing Postsocialist CapitalismDocument251 pagesExperiencing Postsocialist CapitalismjelisNo ratings yet

- Deodorization - W. de Greyt and M. KellensDocument43 pagesDeodorization - W. de Greyt and M. KellensGabriel VoglarNo ratings yet

- Oracle Read STATSPACK OutputDocument43 pagesOracle Read STATSPACK OutputRajNo ratings yet

- Machine Tool TestingDocument4 pagesMachine Tool Testingnm2007k100% (1)

- Montessori ObservationsDocument7 pagesMontessori Observationsapi-439426688No ratings yet

- 38 Parasrampuria Synthetics LTD 20 Sot 248Document5 pages38 Parasrampuria Synthetics LTD 20 Sot 248Chanakya ReddyNo ratings yet

- 5054 s16 Ms 41 PDFDocument3 pages5054 s16 Ms 41 PDFKritish RamnauthNo ratings yet

- SD Hackman Leading TeamsDocument13 pagesSD Hackman Leading TeamsIliana SanmartinNo ratings yet

- Hospice SynopsisDocument6 pagesHospice SynopsisPhalguna NaiduNo ratings yet

- MIL SyllabusDocument15 pagesMIL SyllabusChristopher PilotinNo ratings yet

- Vol-37 Let's Eat! MagazineDocument80 pagesVol-37 Let's Eat! MagazineLetseatmagNo ratings yet

- English Upsr: English Paper 2 - Section B 2 (B) - How To Write Your Reasons - SamplesDocument6 pagesEnglish Upsr: English Paper 2 - Section B 2 (B) - How To Write Your Reasons - SamplesAhmad Firdaus IdrisNo ratings yet