Professional Documents

Culture Documents

Design and Calculations of 10 Ton LPG Tank

Design and Calculations of 10 Ton LPG Tank

Uploaded by

RPOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Calculations of 10 Ton LPG Tank

Design and Calculations of 10 Ton LPG Tank

Uploaded by

RPCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/322603436

DESIGN CALCULATIONS OF LPG TANK (10 TON)

Cover Page · January 2018

CITATIONS READS

0 10,699

1 author:

Alaa Abdulhasan Atiyah

University of Technology, Iraq

83 PUBLICATIONS 199 CITATIONS

SEE PROFILE

All content following this page was uploaded by Alaa Abdulhasan Atiyah on 19 January 2018.

The user has requested enhancement of the downloaded file.

) طه01( الحسابات التصميميه لخسان غاز مسال سعة

DESIGN CALCULATIONS OF LPG TANK (10 TON)

وزارة الصناعه والمعادن/لحساب شركة الفارش العامه

By

Prof. Dr. Eng. Alaa Abdulhasan Atiyah

___________________________________________________________

1.1 Design Criteria:

The code design criteria consist of basic rules specifying the design method, design load, allowable

stress, acceptable material, and fabrication – inspection certification requirements for LPG vessel

construction. The design method known as “Design by Rule” uses design pressure, allowable stress,

and a design formula compatible with the geometry of the part to calculate the minimum required

thickness of the LPG vessel items. This procedure minimizes the amount of analysis required to ensure

that the vessel will not rupture or undergo an excessive distortion. The quantities or dimensions that are

to be determined for designing are listed below

a. Thickness of shell (according to UG -27(c)).

b. Thickness of 2:1 semi ellipsoidal head (according to UG-32(d)).

c. Openings in the pressure vessel as per requirement (according to UG-36 (b) (1) (2)).

d. Selection of flanges (according to UG-44 & UG-11 (a) (2)).

e. Thickness of skirt or design of supports.(according to UG-54 & appendix G).

1.2 Design Constraints:

General Assumptions:

1. Design by rule, ASME Code Section VIII-1, 210.

2. Cylindrical horizontal orientated.

3. Only subjected to static internal load.

4. Corrosion Allowances is zero.

5. Weldments efficiency is considered 1%.

6. No Attachments / special components on the pressure vessel.

7. One type of head (semi ellipsoidal).

Design Constraints:

1. Liquid LPG capacity: 10 ton

2. Content Fluid Specific Gravity: LPG/0.65

3.

Design Pressure: 18.8 Kg/cm2

4. Design temperature: -20 - 700 C

5. Corrosion Allowance: 1.5 mm

6. Radiography: (Shell – Shell)full, (Shell-Heads)full , Heads-Seamless

7.

Hydro test Pressure (Horizontal Position): 27.75 Kg/cm2

Materials:

Shell: A-516 Gr. 70

Heads: A-516 Gr. 70 Normalized

Compensation Plate: A-516 Gr. 70

Pipe, Plate, Ladder, Clips: A-36

Supports:

External Branches: Pipe A-106 Gr.B, Flange A-105

Internal Branches: Pipe A-106 Gr.B, Flange A-105

Man way: Pipe A-106 Gr.B, Flange A-105

External Bolting/Nut: A-193 B7, A-194-2H

Coupling: A-105

Gaskets (Spiral Wound) S.S ASB Filled

Finish:

Cleaning: Sand Blast from Inside & Outside.

Painting Primer: (Double Layer) White Finish: (See Note 3)

Vessel Geometric Capacity: 21.01 m3

W.T. of Vessel Fabrication (Empty): 8500 Kg

W.T. of Vessel Full of water: 31000 Kg

W.T. of Vessel Operating: 21700 Kg

View publication stats

You might also like

- Cnooc Attachment 2F - Hse Assessment QuestionnaireDocument8 pagesCnooc Attachment 2F - Hse Assessment QuestionnaireAhmed Alkashf100% (1)

- Guiding Principle: Working Over, On or Near WaterDocument12 pagesGuiding Principle: Working Over, On or Near WaterMogodan GabrielNo ratings yet

- M2007-005 TranskorMTM TBv2011 012412Document2 pagesM2007-005 TranskorMTM TBv2011 012412daniel_silabanNo ratings yet

- Vega AVUM Gas TankDocument14 pagesVega AVUM Gas TankrenatobellarosaNo ratings yet

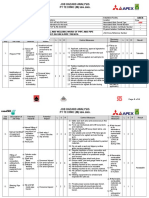

- JSA Fitting and Welding Work For Pipe Trench InstalationDocument6 pagesJSA Fitting and Welding Work For Pipe Trench InstalationVishnu VijayanNo ratings yet

- Jacking Procedurefor Construction of Tanks OLDDocument10 pagesJacking Procedurefor Construction of Tanks OLDVikram RangasamyNo ratings yet

- SOP FOR Pigging OperationDocument4 pagesSOP FOR Pigging OperationpankajNo ratings yet

- Esmat CVDocument8 pagesEsmat CVعصمت ضيف اللهNo ratings yet

- CVMCDocument4 pagesCVMCAzhar HussainNo ratings yet

- 5313 RTI Membrane (Toy) Mar09Document26 pages5313 RTI Membrane (Toy) Mar09argirotopNo ratings yet

- Earth Moving EquipmentsDocument2 pagesEarth Moving EquipmentsSHARAFUDHEEN TKNo ratings yet

- Hydrotest JHADocument29 pagesHydrotest JHABenjamin EmmanuelNo ratings yet

- MC L 01A Pre Hydrotest LinewalkDocument1 pageMC L 01A Pre Hydrotest LinewalkMemyhu MahmudahNo ratings yet

- Klamflexproduct BrochureDocument24 pagesKlamflexproduct BrochureblindjaxxNo ratings yet

- Pds Project SetupDocument3 pagesPds Project SetupSRIKANTHNo ratings yet

- Chapter 5 - Conclusion & RecommendationDocument4 pagesChapter 5 - Conclusion & RecommendationMohamad Shukri0% (1)

- Shop Inspection Requirements and Inspection and Testing Sequence For Tank ComponentsDocument4 pagesShop Inspection Requirements and Inspection and Testing Sequence For Tank ComponentsdurraaiNo ratings yet

- Polyken 2000 High TempDocument2 pagesPolyken 2000 High TempKyaw Kyaw AungNo ratings yet

- HAZID HAZOP Project Brief PDFDocument15 pagesHAZID HAZOP Project Brief PDFAndi Ade Putra SiregarNo ratings yet

- Pipe Inspection Robot PDFDocument7 pagesPipe Inspection Robot PDFKarthi KeyanNo ratings yet

- Technical Proposal Descaling Removal Pulai - A (2013 ASD)Document22 pagesTechnical Proposal Descaling Removal Pulai - A (2013 ASD)hash117No ratings yet

- Process Safety: Are There Proven Tools For ATEX Risk Assessment?Document1 pageProcess Safety: Are There Proven Tools For ATEX Risk Assessment?SARFRAZ ALINo ratings yet

- Total Pms Scope of Work: Days Start Date End DateDocument6 pagesTotal Pms Scope of Work: Days Start Date End DateElhamy M. SobhyNo ratings yet

- QATAR Pin Braze pdfr1Document14 pagesQATAR Pin Braze pdfr1Karunanithi NagarajanNo ratings yet

- Work Permits: Hse Directive 1Document36 pagesWork Permits: Hse Directive 1safetyjulNo ratings yet

- Polyken Utility Tape 900 910 908 911 920Document2 pagesPolyken Utility Tape 900 910 908 911 920Tracy EvansNo ratings yet

- Risk Assessment-Hazards For Deep Water Port LNG Receiving TerminalsDocument17 pagesRisk Assessment-Hazards For Deep Water Port LNG Receiving TerminalsmacrobcsNo ratings yet

- Fire Protection Pipes Method Statement PDFDocument16 pagesFire Protection Pipes Method Statement PDFفاعل خيرNo ratings yet

- Safaniya Field: Location: Persian Gulf Owner: Saudi Aramco Recoverable ReservesDocument9 pagesSafaniya Field: Location: Persian Gulf Owner: Saudi Aramco Recoverable ReservesBrayan MuñozNo ratings yet

- Inspection Test Record (Itr) - A Jacket Pre-Loadout ST08-A Inspection / TestDocument1 pageInspection Test Record (Itr) - A Jacket Pre-Loadout ST08-A Inspection / TestMomo ItachiNo ratings yet

- PDO Approved Inspection BodiesDocument15 pagesPDO Approved Inspection BodiesMohammed Rizwan AhmedNo ratings yet

- PROTEGO ® Technology Volume 1Document50 pagesPROTEGO ® Technology Volume 1Nemezis1987No ratings yet

- Lifting Plan No:-Project IWWTP at Banyan Project: Mobile CraneDocument7 pagesLifting Plan No:-Project IWWTP at Banyan Project: Mobile CraneHtin Lin Aung100% (1)

- Robots in Shipbuilding Industry (1160) PDFDocument9 pagesRobots in Shipbuilding Industry (1160) PDFWahyu WahyurachmatdhaniNo ratings yet

- Spherical Pressure VesselDocument4 pagesSpherical Pressure VesselYetkin Erdoğan0% (1)

- PROJECT STANDARDS AND SPECIFICATIONS Fla PDFDocument12 pagesPROJECT STANDARDS AND SPECIFICATIONS Fla PDFAsif Haq100% (1)

- Idbu-Ed-Fspds-000014 Rev C (Human Factor)Document113 pagesIdbu-Ed-Fspds-000014 Rev C (Human Factor)aan2014211No ratings yet

- Gunnebo Masterlink PDFDocument3 pagesGunnebo Masterlink PDFJason RobertsNo ratings yet

- All To Know About IFR & EFRDocument30 pagesAll To Know About IFR & EFRyazNo ratings yet

- TanneryDocument64 pagesTanneryDivya NaradasuNo ratings yet

- Pipe Cold Bending (HBG)Document15 pagesPipe Cold Bending (HBG)Haries Bugarin GarciaNo ratings yet

- SOP-Attachment 3d - CNL JV - SWP 404 - Confined Space Entry - Dec10Document33 pagesSOP-Attachment 3d - CNL JV - SWP 404 - Confined Space Entry - Dec10tomychalilNo ratings yet

- Earth Moving Equipment ChekclistDocument2 pagesEarth Moving Equipment ChekclistBakri Bin SapilahNo ratings yet

- Tai PresentationDocument43 pagesTai PresentationusamafalakNo ratings yet

- Da and Dhda Datasheet Master - XLSM - Hpu-Dhda118-4.1 Rev1Document3 pagesDa and Dhda Datasheet Master - XLSM - Hpu-Dhda118-4.1 Rev1jujuroyaleNo ratings yet

- Cold Bending FdatDocument1 pageCold Bending FdatAnonymous AdofXEYAgE100% (1)

- SAES-L-470 PDF Download - Trenchless Pipelines Construction - PDFYARDocument7 pagesSAES-L-470 PDF Download - Trenchless Pipelines Construction - PDFYARZahidRafiqueNo ratings yet

- 14 Procedure For Shop and Field PaintingDocument24 pages14 Procedure For Shop and Field PaintingdnbinhNo ratings yet

- Anchor FlangeDocument1 pageAnchor FlangeHector MejiaNo ratings yet

- TT11 PRC 037 Rev.0 Pipeline Hydrotest ProcedureDocument14 pagesTT11 PRC 037 Rev.0 Pipeline Hydrotest ProcedureParthiban NCNo ratings yet

- Pipe SwabsDocument2 pagesPipe SwabsadammzjinNo ratings yet

- 10 DryingDocument31 pages10 DryingHridyaAshokanNo ratings yet

- Cold Cutting PipeDocument1 pageCold Cutting PipeTharach JanesuapasaereeNo ratings yet

- World LNG Plants & Terminals PDFDocument3 pagesWorld LNG Plants & Terminals PDFlulut falaNo ratings yet

- Safety Moment - PDF - Conserving Water at WorkplaceDocument1 pageSafety Moment - PDF - Conserving Water at WorkplaceShareen Prem DSouzaNo ratings yet

- Pressure Vessel Hydrotest Procedure - Google SearchDocument3 pagesPressure Vessel Hydrotest Procedure - Google SearchAsad KhanNo ratings yet

- Choi 2020Document10 pagesChoi 2020obaidullah.dsuNo ratings yet

- Natural Gas Storage TankDocument10 pagesNatural Gas Storage TankSurya Budi WidagdoNo ratings yet

- Sonatrach Casing DesignDocument8 pagesSonatrach Casing DesignJosue FishNo ratings yet

- Design of Pressure Vessel 1Document55 pagesDesign of Pressure Vessel 1Ezio3511No ratings yet

- 0846-XFRMR Test CertificateDocument4 pages0846-XFRMR Test CertificateRPNo ratings yet

- Set Point and Alarm DetailsDocument21 pagesSet Point and Alarm DetailsRPNo ratings yet

- PSIM-24885-01, Rev.1Document17 pagesPSIM-24885-01, Rev.1RPNo ratings yet

- Mechanical Data Sheet For Scrubber Exhaust Stack: 91856-MEC-DS-301-ST-02 C 27-Dec-2016 3 of 3 Doc. No. REV Date Page NoDocument1 pageMechanical Data Sheet For Scrubber Exhaust Stack: 91856-MEC-DS-301-ST-02 C 27-Dec-2016 3 of 3 Doc. No. REV Date Page NoRPNo ratings yet

- Signal and CancerDocument10 pagesSignal and CancerRPNo ratings yet

- Wika DG10E CatalogDocument4 pagesWika DG10E CatalogTitanplyNo ratings yet

- Sydney Girls 2019 Chemistry Prelim Yearly & SolutionsDocument24 pagesSydney Girls 2019 Chemistry Prelim Yearly & SolutionsmabbuttbNo ratings yet

- Reservoir Simulation Report UKCSDocument190 pagesReservoir Simulation Report UKCSValar MorghulisNo ratings yet

- Research Projects JiitDocument14 pagesResearch Projects JiitSAMAIRA SINGHNo ratings yet

- Course - Human Resource Management Assignment - SELE...Document4 pagesCourse - Human Resource Management Assignment - SELE...MUSHINo ratings yet

- Introduction To VibrationsDocument36 pagesIntroduction To VibrationsMajid SattarNo ratings yet

- 8.1 Purpose of The Unit: 8 Design of Distillation ColumnDocument16 pages8.1 Purpose of The Unit: 8 Design of Distillation Columnsami ullahNo ratings yet

- Soal UNBK Bahasa Inggris SMPDocument13 pagesSoal UNBK Bahasa Inggris SMPfendiwaloyosugiartoNo ratings yet

- Compressed Air System Design, Operating and MaintenanceDocument29 pagesCompressed Air System Design, Operating and Maintenanceibrahim1961No ratings yet

- Spindle Motor Troubleshooting GuideDocument7 pagesSpindle Motor Troubleshooting GuideIsrael Martinez AlonsoNo ratings yet

- Special Lomi RecipeDocument8 pagesSpecial Lomi RecipeCabalo DominicNo ratings yet

- IDSE Unit 2 E9Document12 pagesIDSE Unit 2 E9Kannan JaganNo ratings yet

- Design and Fabrication of Pesticide Solar SprayerDocument6 pagesDesign and Fabrication of Pesticide Solar SprayerK IsmailNo ratings yet

- Vitamin-A Prophylaxis Programme 0rDocument38 pagesVitamin-A Prophylaxis Programme 0rShubhendu ChattopadhyayNo ratings yet

- Sme Package Summary of Benefits (2305843009215646953)Document7 pagesSme Package Summary of Benefits (2305843009215646953)RIVERA - SARVIDA CONSTRUCTION INC.No ratings yet

- Biology Higher Level Paper 1: 8810-6001 17 Pages © International Baccalaureate Organization 2010Document17 pagesBiology Higher Level Paper 1: 8810-6001 17 Pages © International Baccalaureate Organization 2010Victor Junhe SONG [11S1]No ratings yet

- PDS - Clean - Guard - 71F01 - EN - White PDFDocument3 pagesPDS - Clean - Guard - 71F01 - EN - White PDFAbdelfatah Newishy100% (1)

- Devyani International Limited: Issue HighlightsDocument11 pagesDevyani International Limited: Issue Highlightschinna raoNo ratings yet

- Problem Solving Barriers and Its ApproachesDocument22 pagesProblem Solving Barriers and Its Approachesvasu mittalNo ratings yet

- Chem 161.1 Exer 1 KimDocument8 pagesChem 161.1 Exer 1 KimBanana QNo ratings yet

- Marathonnorco Aerospace, Inc.: Operating and Maintenance Manual For Nickel-Cadmium Aircraft BatteriesDocument59 pagesMarathonnorco Aerospace, Inc.: Operating and Maintenance Manual For Nickel-Cadmium Aircraft Batteriestmuthukumar100% (1)

- Autotrophic Nutrition Heterotrophic NutritionDocument1 pageAutotrophic Nutrition Heterotrophic NutritionAditya KediaNo ratings yet

- Amway 12 FullDocument4 pagesAmway 12 Fullapi-3705095100% (2)

- Victory Driller SpecificationDocument1 pageVictory Driller SpecificationGriffithNo ratings yet

- 6 Types of Cell Culture-2024Document49 pages6 Types of Cell Culture-2024hamza najmNo ratings yet

- L6S Final Examination Students)Document12 pagesL6S Final Examination Students)Fazliawati MahayuddinNo ratings yet

- Model ESFR-17 16.8 K-Factor Pendent Sprinkler Early Suppression, Fast Response General DescriptionDocument4 pagesModel ESFR-17 16.8 K-Factor Pendent Sprinkler Early Suppression, Fast Response General DescriptionJUANA MONSERRATE PARRALES PILAYNo ratings yet

- Swimming Pool Form GuidelinesDocument4 pagesSwimming Pool Form GuidelinesBNo ratings yet

- Animals Vocabulary Esl Multiple Choice Tests For KidsDocument9 pagesAnimals Vocabulary Esl Multiple Choice Tests For Kidsanon_858380046No ratings yet