Professional Documents

Culture Documents

Murphy Dump Valve

Murphy Dump Valve

Uploaded by

daniel.landeroOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Murphy Dump Valve

Murphy Dump Valve

Uploaded by

daniel.landeroCopyright:

Available Formats

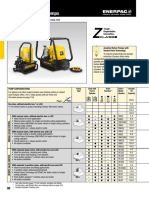

00-02-0483

Installation and Operation Manual for Revised 03-06

Section 15

DVU Series Dump Valves

Models: DVU150, DVU175, DVU2105, DVU2115 and DVU2120

Please read the following information before installing. A visual inspection of this product for damage during shipping is recommended

before mounting. It is your responsibility to have a qualified person install this unit and make sure it conforms to local codes.

GENERAL INFORMATION

Fig. 2 Dimensions (all models)

WARNING Pressure

Inlet Port

A

Manual Valve

Operator

1/8 in.-27 NPT

BEFORE BEGINNING INSTALLATION OF THIS MURPHY PRODUCT

✔ Disconnect all electrical power to the machine.

✔ Make sure the machine cannot operate during installation. Vent

B

✔ Follow all safety warnings of the machine manufacturer. Weep Hole Valve Open/Closed

Union

✔ Read and follow all installation instructions. Indicator Button

Description

The DVU Series models are pneumatically controlled dump valves. F Drain

The valves open and close automatically by pneumatic control from a Connection C

Murphy L1200NDVOR or similar level controller and dump valve opera-

E D

tor. Diaphragm actuated, the DVU series dump valves operate at 30–70 psi

(207–483 kPa) [2.07–4.83 bar] and up to 2000 psi (13.8 MPa) [138 bar] Plug Seal G for

(dimension shown

reference only)

vessel pressure (depending on the model).

A key benefit of this design is a hex union that provides the ability

to replace the seat without removing the valve from piping.

Model A B C D E F G

DVU2120 7.50 (191) 8.0 (203) 2.75 (70) 1.0 (25) 2-11.5 NPT 1-11.5 NPT 1.03

DVU2115 7.50 (191) 8.0 (203) 2.75 (70) 1.0 (25) 2-11.5 NPT 1-11.5 NPT 1.03

DVU2105 7.50 (191) 8.0 (203) 2.75 (70) 1.0 (25) 2-11.5 NPT 1-11.5 NPT 1.03

Fig. 1 Control Pressure vs. Working Pressure DVU175 7.50 (191) 6.75 (171) 2.06 (52) 1.0 (25) 1-11.5 NPT 3/4”-14 NPT 1.03

DVU150 7.50 (191) 6.75 (171) 2.06 (52) 1.0 (25) 1-11.5 NPT 1/2”-14 NPT 1.03

Minimum Actuation Pressure NOTE: Dimensions are in inches and (millimeters)

70

DVU2115 DVU2120

Control Pressure (PSIG)

60

50 Specifications

40

DVU2105 DVU150/175 Operating Temperature: -30 to 250°F (-34.4 to +121°C)

30 Valve Operating Pressure: Refer to chart, Fig 1.

20

Maximum Process Pressure:

10 DVU2120: 2000 psi (13.8 MPa) [138 bar].

0 500 1000 1500 2000 DVU2115: 1500 psi (10.3 MPa) [103 bar].

Vessel Pressure (PSIG) DVU2105: 500 psi (3.44 MPa) [34 bar].

DVU150 and DVU175: 1800 psi (12.4 MPa) [124 bar].

Flow Characteristics: See chart, page 4 (DVU150/175 models only).

Body Material: Electroless Nickel Plated 12L14 Carbon Steel

Model Inlet Outlet Trim Size

Internal Wetted Parts: Plug Seal: 90 Durometer Urethane.

DVU2120 2 NPT 1 NPT 0.436 in. (11 mm) Other: 303 stainless steel; Electroless Nickel Plated 12L14 Carbon Steel

DVU2115 2 NPT 1 NPT 0.576 in. (15 mm) Shipping Weights: DVU150 and DVU175: 9 lbs. (4 kg.).

DVU2105 2 NPT 1 NPT 0.859 in. (22 mm) Shipping Weights: DVU2105, DVU2115 and DVU2120: 14 lbs. (6.4 kg.).

DVU175 1 NPT 3/4 NPT 0.359 in. (9 mm) Shipping Dimensions: 7-1/2 x 7-1/2 x 10-3/4 in. (191 x 191 x 274 mm.).

DVU150 1 NPT 1/2 NPT 0.359 in. (9 mm)

Installation 00-02-0483 page 1 of 4

TYPICAL INSTALLATION ON GAS COMPRESSORS

Fig. 3 The Murphy Gas Compressor Scrubber Level System (SLS)

Scrubber/Separators

The system provides for liq-

uid control in gas scrubber High Level Shutdown Switch

Basic Operation applications, by dumping liq- Stainless steel float actuated level switches to alarm

As condensate rises in the scrubber, the float uids to drain and protecting and/or shutdown the equipment.

on the L1200NDVOR rises and trips its pneu- compressors with a high liq- L1200: 2” NPT pipe connection; Rated 2000 psi

matic valve. The valve opens allowing pres- uid level switch. Wetted metal (13.7MPa) [137bar]; Class I, Division 1. SPDT

snap-switch standard. DPDT Optional.

sure to enter the dump valve pilot chamber. parts are made to survive

All Stainless Steel available.

Once the pressure enters the pilot chamber it constant use in corrosive

environments.

forces the diaphragm and valve stem forward

See Bulletin: SLS-04005B for

thus opening the valve seat (valve open/closed more details.

indicator button pops out) and releasing con-

Filter/Regulator &

densate through the valve stem and out the Control

MURPHYGAGE®

drain. As the condensate level drops, the Panel

L1200NDVOR pneumatic valve closes to shut

“Instrument

off the pressure to the dump valve causing it to Quality Air/Gas

close. Supply”

If for any reason the condensate continues to

rise beyond normal dump levels, model L1200

operates the alarm and/or shuts down the

Pneumatic Level Control

equipment. Float actuated level snap-acting switch

The L1200NDVOR Filter/Regulator and the controls pneumatic pressure to open

and close dump valve.

Pneumatic Dump

MURPHYGAGE® help keep the control pres- Valves See DVU-01069B

sure clean and dry. They also allow the opera- L1200NDVOR: Dump Valve Operator,

for more details.

pressure regulator, and pressure indi-

tor to adjust pressure to recommended levels. Two piece union design with manual valve operator

cating MURPHYGAGE.® allows soft plug and hard seat to be replaced with-

NOTE: Always use clean, dry, out disassembling outlet piping or scrubber pipe

instrument quality gas. connection. Diaphragm actuated valves operate on

30-70 psi (207-483 kPa; 2-5 bar).

DUMP VALVE INSTALLATION

DVU Series Installation

Upper Assembly

(removable)

CAUTION: ALWAYS USE “NON-SPARKING TOOLS”

Pneumatic

WHEN GAS IS KNOWN TO BE PRESENT. Input Signal

Valve

Union

The following describes the “Direct Mounting” method to the Fig. 4

tank wall. Typical

1. Install the valve so the drain connection is on the bottom. Use Dump Valve Maintenance

Bolt

pipe thread sealant on all the connections. Installation

2. Be sure the unit is screwed tight and does not leak. Valve Indicator

3. Install the piping for the pneumatic input signal into the

Vessel Wall

1/8 NPT threaded connection of the pressure inlet port (on Weep Hole

top of the diaphragm housing of the DVU).

6. Install a union between the DVU drain connection and the Drain

condensate out line. Use pipe thread sealant on all the con- Connection

nections.

Union

Condensate Out

2-Way (Manual Drain)

Shutoff Valve

Installation 00-02-0483 page 2 of 4

REPAIR PROCEDURE

CAUTION: THE INSTALLATION AND REPAIR PROCEDURES SHOULD 6. Using a back-up wrench on the plug, remove the stem nut on the shaft

ONLY BE PERFORMED BY TRAINED, QUALIFIED, AND EXPERIENCED under the plug. Once the stem nut is broken loose, the 9/16” head main-

PERSONNEL. THE TRAINING, QUALIFICATION AND EXPERIENCE

tenance bolt and top assembly will keep the stem from turning. The plug

turns freely on the stem once loose. The plug and seat can now be

REQUIRED IS FOR WORK AROUND PRESSURE VESSELS, NATURAL GAS, POSSI- removed. All soft seals should be replaced. Refer to kit part numbers

BLY SOUR GAS, OR ANY SUBSTANCE TO BE FOUND IN THE VESSEL. EXTREME under service parts on page 4.

CARE MUST BE TAKEN TO INSURE ANY RESIDUAL OR FULL PRESSURE IS

RELIEVED FROM ALL PARTS OF THE SYSTEM TO BE SERVICED. Replacing the Diaphragm

6A. If the diaphragm is to be replaced, all preceding steps have to be

Suggested Tools (Sizes listed are wrench openings. done. Additionally, do the following:

Adjustable crescent wrenches, socket and/or end wrench, pipe wrenches, 6B. Loosen the 9/16” head maintenance bolt, allowing the diaphragm

flat edge screwdriver with 1/4” blade width, can also be used .) spring to relax, and the stem to retract. Make alignment marks on

Model Valve Body Union Nut Plug Seal Hex Stem Nut the top and bottom halves of the diaphragm assembly for align-

DVU2120 3” 3” 7/8” 1/2” ment during re-assembly.

DVU2115 3” 3” 1” 1/2” 6C. Remove the 8, 7/16" bolts/nuts holding the diaphragm housing

DVU2105 3” 3” 1-1/4” 1/2” together.

DVU150/DVU175 2-1/4” 2-1/4” 3/4” 3/8” 6D. Using a straight edge screwdriver, gently separate the 2 halves of

the diaphragm housing, and remove the top, or outside portion.

Replacing the Plug and Seat 6E. Lift the diaphragm and support plates far enough for the 1-1/8" hex

1. Close the pressure block valves (suction & discharge valves) on the inlet or 1” round nut on the bottom of the diaphragm assembly to be

and outlet of the skid. Lock them closed if possible. accessible to a wrench and not have the spring interfere. If it is

2. Open the blowdown valve to remove pressure from the unit. Lock the desired to replace the packing, pull the stem all the way out. The

blowdown valve open if possible. packing can be easily removed using a small screwdriver to pry the

3. After taking all possible precautions to insure there is no pressure in the packing out. The new packing can be simply pressed in, making

vessel. (If the condensate line is pressurized, it must also be blocked and sure the orientation of the packing installed is the same as the ori-

locked.) Open the manual drain valve so it bleeds into the vessel so it entation of the packing removed. The packing is wider toward the

can also be bled down. Disconnect the pneumatic input signal connection plug end. You will have to use the seat to hold the packing in place

after insuring it also has been de-pressurized. when re-inserting the stem.

4. Using a back-up wrench on the valve body, with a quick "breaking" 6F. With the 1-1/8" hex or 1” round nut held by a wrench, use a

action loosen the union nut on the valve. There is a "weep" hole in the wrench to loosen and remove the 1/2" nut on top of the diaphragm.

nut. If at any time while loosening and taking off the nut pressure is The diaphragm can now be removed and replaced.

escaping through the "weep" hole, immediately stop loosening the nut. 6G. With the new diaphragm in place and the 1/2" nut tightened, place

Retighten the nut and check the preceding procedures to ensure the pres- the assembly, diaphragm down on a clean, smooth sturdy surface.

sure is bled off the vessel. Never remove the assembly if pressure is 6H. Have the seat, plug, washers and stem nut handy (if any of these

coming through the weep hole. See Figure 4 on page 2.

parts are to be replaced, use the old parts for this procedure). Press

5. With the upper assembly removed from the vessel the plug and/or seat can

down evenly and smoothly on the bottom of the diaphragm assem-

be replaced. Loosen the 9/16” jam nut on the maintenance bolt on top of

bly to cause stem to come up. Place the seat and plug in place.

the diaphragm cover. Spin the nut up against the head of the bolt. Tighten

the bolt to extend the shaft and plug. DO NOT OVERTIGHTEN. Then push the bottom of the diaphragm assembly down far enough

to install the washers and stem nut on the stem. Tighten the stem

nut enough to hold against the diaphragm spring.

Fig. 5 Stem O-Ring Seals 6J. Align the diaphragm holes to the bolt holes (bottom half of the

Plug Seat Stem Packing Against Outlet housing). Install the upper diaphragm housing using the alignment

Washer(s)* marks from step 6B. Install the 8, 7/16" bolts and nuts. Tighten the

bolts evenly going from one bolt then 180° around to the next bolt,

then either 120°or 240° around to the next bolt and so forth until

all 8 bolts are evenly tight.

Stem O-Ring 6K. Using the 9/16” head maintenance bolt, tighten, pushing the stem

Nut Crush Washer Seal Seat butts into here out until the 9/16"bolt stops – DO NOT OVERTIGHTEN.

*Number of washers varies depending on the model from 1 to 3. 6L. Remove the stem nut holding the plug. (If old parts were used, pre-

pare to install the new parts now.)

Seal Washer Maintenance 7. Install the seat and plug. Place the O-ring on the stem, followed by the

Fig. 6 Bolt Diaphragm

Pressure Inlet washer and stem nut.

Housing 8. Tighten the stem nut. Loosen the 9/16” head maintenance bolt by at least one

Diaphragm 1/2" Nut

turn past the point where it is no longer in contact with the stem. Tighten the

9/16" jam nut holding the 9/16” head maintenance bolt.

9. Replace the crush washer and the O-ring hidden by the union nut.

NOTE: If pressure or fluid comes out the weep hole of the union nut,

either the O-ring under the union nut is leaking, or the packing could be

Backup leaking through the internal weep hole above that O-ring.

1-1/8" or Diaphragm 10. The assembly is ready to be re-installed. Check for relative position of

Plate Spring

1" round nut Stem Assembly the pneumatic input signal connections before tightening the union nut.

Installation 00-02-0483 page 3 of 4

PRESSURE VS. FLOW CHART

Fig. 7 Pressure vs. Flow for DVU150 and DVU175 models only

250

250

200

200

150

150

Pressure (psid)

100

100

50

50

0

0 5 10 15 20 25 30 35 40 45

Flow (gpm)

SERVICE PARTS

Part No. Description Typical Diaphragm Repair Kit includes:

DVU2120 Diaphragm; Diaphragm Washer (upper), Diaphragm Nut, Diaphragm Plate

55-00-0237 Seal Kit (includes plug) (1 or 2 pcs.), Packing, “O” Ring, Stem, Seal Washer for Maintenance Bolt.

55-00-0236 Diaphragm Kit

The DVU Series Valve is included in the

DVU2115 following Scrubber Levels Systems.

55-00-0241 Seal Kit (includes plug)

55-00-0240 Diaphragm Kit (Includes L1200, L1200NDVOR, and DVU valve)

SLS2120: Includes DVU2120 valve

DVU2105

55-00-0245 Seal Kit (includes plug) SLS2115: Includes DVU2115 valve

55-00-0244 Diaphragm Kit SLS2105: Includes DVU2105 valve

DVU175 SLS175: Includes DVU175 valve

55-00-0230 Seal Kit (includes plug)

55-00-0231 Diaphragm Kit SLS150: Includes DVU150 valve

DVU150 -LR: Less Regulator option

55-00-0230 Seal Kit (includes plug) Warranty

55-00-0231 Diaphragm Kit A limited warranty on materials and workmanship is given with this FW

Typical Seal Kit includes: Nut, Washer (1 to 3), “O” Ring, Plug and Murphy product. A copy of the warranty may be viewed or printed by going

Seal, Seat, Crush Washer. to www.fwmurphy.com/support/warranty.htm

MURPHY, the Murphy logo are registered and/or common law trademarks of Murphy Industries, Inc. This document,

including textual matter and illustrations, is copyright protected by Murphy Industries, Inc., with all rights reserved.

www.fwmurphy.com (c) 2006 Murphy Industries, Inc. Other third party product or trade names referenced herein are the property of

918.317.4100 Email: sales@fwmurphy.com their respective owners and are used for identification purposes only.

Installation 00-02-0483 page 4 of 4

You might also like

- ELME Manual For 817, 1-2676Document89 pagesELME Manual For 817, 1-2676mario80% (10)

- SERVICE TOOL CATALOG Carrier TransicoldDocument98 pagesSERVICE TOOL CATALOG Carrier Transicoldgamagg100% (3)

- V61167 Commercial VA20 35 VG20 35 DCVDocument31 pagesV61167 Commercial VA20 35 VG20 35 DCVPaulPaucarCampos100% (1)

- Service Guide For Maintenance of Hoerbiger Valves: Compression Technology GroupDocument8 pagesService Guide For Maintenance of Hoerbiger Valves: Compression Technology Groupmahmod alrousan100% (2)

- Report Project EsteemDocument5 pagesReport Project EsteemHani Barjok100% (1)

- ExamDocument2 pagesExamSiva SreeramdasNo ratings yet

- HAWE - MVGDocument15 pagesHAWE - MVGSsaannddyy SandyNo ratings yet

- LS200, LS200N and LS200NDVOR Series Liquid Level Switches: Installation and Operations ManualDocument20 pagesLS200, LS200N and LS200NDVOR Series Liquid Level Switches: Installation and Operations ManualAdolfo EyzaguirreNo ratings yet

- D1WWEF01EDocument88 pagesD1WWEF01ELeonardo FigueroaNo ratings yet

- BVA P Series Manual P240LDocument8 pagesBVA P Series Manual P240LTitanplyNo ratings yet

- Warning: L1200 Superseded by LS200. For L1100 & DVU, See New InfoDocument6 pagesWarning: L1200 Superseded by LS200. For L1100 & DVU, See New InfoRiky AyalaNo ratings yet

- A Polyhydron Group Company: Pressure Compensated Flow Control Valve Model: 2PF 10Document3 pagesA Polyhydron Group Company: Pressure Compensated Flow Control Valve Model: 2PF 10Rakesh SharmaNo ratings yet

- Re29255 2009-07Document4 pagesRe29255 2009-07Mustapha AlaouiNo ratings yet

- Series BBV-2 5-Valve Block and Bleed Manifold: Specifications - Installation and Operating InstructionsDocument4 pagesSeries BBV-2 5-Valve Block and Bleed Manifold: Specifications - Installation and Operating InstructionsGuillermo de la Fuente SantiagoNo ratings yet

- A3-Sicherheit 00 ENDocument4 pagesA3-Sicherheit 00 ENbiuroNo ratings yet

- Series T Pressure Microregulators: Ports G1/8 and G1/4Document2 pagesSeries T Pressure Microregulators: Ports G1/8 and G1/4EduardoNo ratings yet

- Instruction and Mantenance ManualDocument142 pagesInstruction and Mantenance ManualJUN ZHOUNo ratings yet

- Murphy.70 Press - SendDocument1 pageMurphy.70 Press - SendAndres CelyNo ratings yet

- TSC 400 Man 0575 G 16884Document4 pagesTSC 400 Man 0575 G 16884Carolina Vanessa Miranda FritzNo ratings yet

- Gilmore Relief Valve CatalogDocument16 pagesGilmore Relief Valve CatalogALBINO97No ratings yet

- Manuals - G200 Series Back Check Valves Instruction Manual, Fisher-ENDocument4 pagesManuals - G200 Series Back Check Valves Instruction Manual, Fisher-ENrey sarNo ratings yet

- M Series Manual Handwheel Gear Actuators For Type A11, A31A and A41 Butterfly ValvesDocument8 pagesM Series Manual Handwheel Gear Actuators For Type A11, A31A and A41 Butterfly ValvesGUNAWAN SAMIARTONo ratings yet

- Advanced Electrode Steam Humidifier: Tools NeededDocument28 pagesAdvanced Electrode Steam Humidifier: Tools NeededlaboratorioNo ratings yet

- Operator'S Manual Exxxxx-Xxx-X: E Series ValvesDocument24 pagesOperator'S Manual Exxxxx-Xxx-X: E Series ValvesMauricio GarciaNo ratings yet

- B737-200 Flight ControlDocument4 pagesB737-200 Flight ControlLa Team masqueNo ratings yet

- Mitsubishi MS-A09-12WA - Service - OB448C - 10-08Document36 pagesMitsubishi MS-A09-12WA - Service - OB448C - 10-08Michel GauvinNo ratings yet

- Vpi SeriesDocument27 pagesVpi Serieshumayra.tasneem1No ratings yet

- Wet Blasting MachineDocument18 pagesWet Blasting MachineRenaud TamoNo ratings yet

- MSH-A 18-30WV - Part - Catalog - (OB321)Document32 pagesMSH-A 18-30WV - Part - Catalog - (OB321)trezor lamNo ratings yet

- Manual Advance Gauges eDocument2 pagesManual Advance Gauges ebob marleyNo ratings yet

- Oversized 3/5/reverse & Underdrive Pressure Control Valve KitDocument2 pagesOversized 3/5/reverse & Underdrive Pressure Control Valve KithidraulicNo ratings yet

- نموذج محابس مياه شربDocument2 pagesنموذج محابس مياه شربBassam AlmadhjiNo ratings yet

- Technical Data DUO-ED HDocument18 pagesTechnical Data DUO-ED HMario SliškoNo ratings yet

- Instruction Manual For Control ValvesDocument13 pagesInstruction Manual For Control ValvesBruno RachidNo ratings yet

- Vib. Sol. SMCDocument2 pagesVib. Sol. SMCarjunoselaoNo ratings yet

- Service Manual: MS-A18WV - MS-A24WV - MS-A30WVDocument32 pagesService Manual: MS-A18WV - MS-A24WV - MS-A30WVCesc BonetNo ratings yet

- LEWA Ecodos - 6S2 - BA - 553267 - 30 - 40 - ENDocument124 pagesLEWA Ecodos - 6S2 - BA - 553267 - 30 - 40 - ENnowtronicservicosNo ratings yet

- Electric Valve Actuators VA 7450 SeriesDocument7 pagesElectric Valve Actuators VA 7450 SeriescesarintiNo ratings yet

- 14 Commissioning ProcedureDocument2 pages14 Commissioning ProcedureIonut StavaracheNo ratings yet

- ZE-Series Electric Pumps EN-GBDocument6 pagesZE-Series Electric Pumps EN-GBjølle jølleNo ratings yet

- Control Valve V80Document20 pagesControl Valve V80vency100% (1)

- Valve Type 3010 2CH A3Document2 pagesValve Type 3010 2CH A3univers durNo ratings yet

- Small Enclosure Cylinder and Valve Assemblies: Part Number Cylinder VolumeDocument6 pagesSmall Enclosure Cylinder and Valve Assemblies: Part Number Cylinder VolumeMar SolNo ratings yet

- IcadDocument4 pagesIcadRikiNo ratings yet

- Valvula Belimo F780hdu - GMX24-MFT-X1Document5 pagesValvula Belimo F780hdu - GMX24-MFT-X1Lionel ZacharonokNo ratings yet

- Pneumatische Wegeventile Serie VA13 Und VA15 - Katalog PDE2617TCDEDocument16 pagesPneumatische Wegeventile Serie VA13 Und VA15 - Katalog PDE2617TCDEMatija BušićNo ratings yet

- ABSC-200 Blast Machine - 200 LTRDocument18 pagesABSC-200 Blast Machine - 200 LTRTamerGalhoumNo ratings yet

- Yuken Relief ValveDocument38 pagesYuken Relief ValveCarlos ParedesNo ratings yet

- 273 15 15 Ton Strap Bender ManualDocument4 pages273 15 15 Ton Strap Bender ManualinsaanNo ratings yet

- 70-024-B Semi-Automatic Car Tire Changer User and Maintenance ManualDocument26 pages70-024-B Semi-Automatic Car Tire Changer User and Maintenance ManualRocky SarafNo ratings yet

- Aiwa TV 1402 Manual de Usuario 5 6Document2 pagesAiwa TV 1402 Manual de Usuario 5 6Mr. Gonza M.No ratings yet

- Product Data Sheet Damcos BRC 250 en 60334Document4 pagesProduct Data Sheet Damcos BRC 250 en 60334Конструкторский отдел РосНефтеГазИнструментNo ratings yet

- Manual: Safety Warning 【Please read carefully.】Document2 pagesManual: Safety Warning 【Please read carefully.】Rakoy GamerNo ratings yet

- Fisher 9000 Valtek MK1 Refit Manual 1997Document2 pagesFisher 9000 Valtek MK1 Refit Manual 1997SMcNo ratings yet

- New 003 2012 HyDocument2 pagesNew 003 2012 HyРома БлошенкоNo ratings yet

- SENTRON LV10-PH08 Complete English 10-2015 201603161111100751Document62 pagesSENTRON LV10-PH08 Complete English 10-2015 201603161111100751Benbrahim AbdelkaderNo ratings yet

- Im Avl Smy11enDocument1 pageIm Avl Smy11enNassar Al-shabiNo ratings yet

- Accumulator Block - Hydac - SAFDocument26 pagesAccumulator Block - Hydac - SAFBenAbrahamSamuelNo ratings yet

- Dump Valves DVU Series: FeaturesDocument2 pagesDump Valves DVU Series: FeaturesalopezvillavicencioNo ratings yet

- Tiempo de Impresión VT3500Document5 pagesTiempo de Impresión VT3500AgostinhoNo ratings yet

- E Series Proportional Pressure Controls: Pilot Relief / Relief / Reducing and RelievingDocument30 pagesE Series Proportional Pressure Controls: Pilot Relief / Relief / Reducing and RelievinghaggNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Loop-Ip6702A Tdmoethernet: DescriptionDocument8 pagesLoop-Ip6702A Tdmoethernet: DescriptionEduardoRiosRaaNo ratings yet

- TriosDocument22 pagesTriosAdrian FortescuNo ratings yet

- Caav Question Bank - Atr 72Document65 pagesCaav Question Bank - Atr 72Hlaing Myint100% (1)

- Nvidia Virtual GPU PackagingDocument22 pagesNvidia Virtual GPU PackagingGary Ryan DonovanNo ratings yet

- TeklaS-Midas v20 ManualDocument10 pagesTeklaS-Midas v20 ManualNikola RajićNo ratings yet

- UNIT 4 1 Pointers Stuctures Unions PDFDocument28 pagesUNIT 4 1 Pointers Stuctures Unions PDFNelanti Santhosh KumarNo ratings yet

- ONT G-25E Hardware Installation Manual: CIG CIGDocument20 pagesONT G-25E Hardware Installation Manual: CIG CIGAdnan YounisNo ratings yet

- Assignment 1 Photomontge JD2015Document2 pagesAssignment 1 Photomontge JD2015Mad ShahNo ratings yet

- C-Series C142 Machine Controller Eurocard DIN Packaged SystemsDocument2 pagesC-Series C142 Machine Controller Eurocard DIN Packaged SystemsawemetalNo ratings yet

- A Low-Cost and Scaled Automation System For Education in Industrial AutomationDocument6 pagesA Low-Cost and Scaled Automation System For Education in Industrial AutomationLuis Pujay MateoNo ratings yet

- Cisco Diplom PDFDocument7 pagesCisco Diplom PDFAnonymous Pdrb2Us8No ratings yet

- Ordenes - CDP 2021Document75 pagesOrdenes - CDP 2021Alfredo JimenezNo ratings yet

- 2014-08-28 ECS Java Memory ManagementDocument53 pages2014-08-28 ECS Java Memory ManagementHarunNo ratings yet

- Ekin Freezone Presentation 2023 1Document42 pagesEkin Freezone Presentation 2023 1Metin Taha YilmazNo ratings yet

- Chapter - I: 1.1 Organization ProfileDocument60 pagesChapter - I: 1.1 Organization Profilepreeth_tNo ratings yet

- P743 OrderForm - v23 - 032018Document14 pagesP743 OrderForm - v23 - 032018SentaNo ratings yet

- Electrical InformationDocument66 pagesElectrical InformationAjay SastryNo ratings yet

- PSU6n, PSU14n Buyers GuideDocument8 pagesPSU6n, PSU14n Buyers GuidekkrishnamoorthyNo ratings yet

- AndroidDocument15 pagesAndroidNitesh KhatriNo ratings yet

- Canh Bao DPC Is ProhibitedDocument3 pagesCanh Bao DPC Is ProhibitedhangkekeNo ratings yet

- ET7104-Design of Embedded SystemsDocument5 pagesET7104-Design of Embedded SystemsAnonymous zQOH5ikNo ratings yet

- Service Manual - Info Center - EnglDocument519 pagesService Manual - Info Center - EnglDiep NguyentuanNo ratings yet

- Fpga Implementation of Usb 2.0 Receiver ProtocolDocument5 pagesFpga Implementation of Usb 2.0 Receiver ProtocolAldo RodNo ratings yet

- Linsn Sending Card TS802 Cascade Control Large LED DisplayDocument9 pagesLinsn Sending Card TS802 Cascade Control Large LED DisplaymaxhernanNo ratings yet

- Repeater Compass System With Serial Interface RS 422: Operator, Technical and Service ManualDocument62 pagesRepeater Compass System With Serial Interface RS 422: Operator, Technical and Service ManualDimon SergeevichNo ratings yet

- Introduction of XC2000 FamilyDocument26 pagesIntroduction of XC2000 FamilyJosé AdelinoNo ratings yet

- LCD Led TV Course Schedule-12 DaysDocument4 pagesLCD Led TV Course Schedule-12 DaysMayur100% (1)

- 8834.system Software 1Document77 pages8834.system Software 1Sheenu BaidwanNo ratings yet