Professional Documents

Culture Documents

弹簧作业指导书-Testing Procedure

弹簧作业指导书-Testing Procedure

Uploaded by

M. Andri Ludfi Fanani0 ratings0% found this document useful (0 votes)

22 views7 pagestesting procedure

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenttesting procedure

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

22 views7 pages弹簧作业指导书-Testing Procedure

弹簧作业指导书-Testing Procedure

Uploaded by

M. Andri Ludfi Fananitesting procedure

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 7

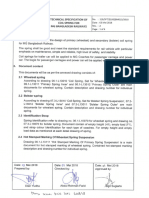

Tecrail= AA ilies AIR a)

EGWIGiae JIANGSU Tedrail Industrial.,Co.LTD

SS: AMA HITRL-0O1-2018

Doe. No: QC/TRL-001-2018

He WS Ve Mh AS

Spring inspection work instructions

LF: RBA R/TRL-001-2018

Document Number: QC/TRL-001-2018

DATA: 2.0

Revision: 2.0

ZR AH: 2018-444 308

Date: April 30, 2018

Tecrail HACE MIE BIRD A)

EGG Gig JIANGSU Tedrail Industrial.,Co.LTD

CA: HACER R/TRL-001-2018

Doe: No: QC/TRL-00L2018

RAE

am | gone | arco | weno | ieee

Version | Revision | Compilerand | Reviewer and | Af gral

ween | Revisio ‘ompiler and | Reviewer a poroverand | ns

revision | page number date date date

een Cit

Tie:

2.0 x

Revision PO | ph [Zhu

reaahl !

27

Tecrail= ACE A IE BARA Bl

Sve JIANGSU Tedrail Industrial.,Co.LTD

TRS:

Doe. N

1. Af

Purpose

yi HEFL BRE iB LY A S98 5 EAE STO AE 7S Ae RAE

PTT SOO RAE.

In order to further improve the normative operation of the incoming inspection, in order to avoid

different judgment standards arising from personal experience and thinking, a unified inspection

standard is formulated

2. fi

Range

ACES SHALE AA) ORE.

This work instruction is applicable to the inspection procedures of our company's springs.

3, RAS

Responsibilities and authorities

3.1 BIO A TTT A PBA HS EAT A RU ALE

The inspector is responsible for determining the quality of the springs produced by the

production department.

3.2 HLA RA DTN SALEM TROT, AAO ASHE PRE PBT HO

ates

The inspector shall be responsible for the inspection and determination plan, be

responsible for the implementation of the inspection process, and supervise the inspection

standards implemented by the production department.

3.3 HORA SARE OT a EOE

The product that the inspector cannot determine is finalized by the quality manager.

37

me KARA Ba AR ZA

JIANGSU Tedrail Industrial.,Co.LTD

ARS: WH

Tetrall

FTRL-001-2018,

/TRL-0O1-2018

SOIT, WHER AE Pa TALE, JEL 7 4 [A]

AE.

Inspectors must fil out the inspection report form in real time to ensure that the traceability

3.4 A

SCRE RGR T bse

Sei eM

of the product has been determined and as an effective basis for quality improvement or rework

processing,

4, BRAR

Inspectors

Hs ED Sea HO PR MAE SG PAS MUA EAT RR

The quality department arranges the inspection and supervision by professional technicians

who are familiar with the spring acceptance inspection standards and methods.

5. HHI

Validation tools

TRA AL. HR ER, RON, ARE

Temperature control water tank, vernier caliper, pressure testing machine, detour inspection

ruler, etc.

Tetras

SKA EA lia RA

JIANGSU Tedrail Industrial.,Co.LTD

6. HR RHE

Inspection standards

See

Fle ate AEE

Judgment standard Judgment conclusion

Bae PEGE SE ES AR OR th

Material inspection _| Suppliers provide product material

inspection report

RLS EE BHI HS

SpA Surface isino rust Passffail

Visual inspection RMI EE PITA

Surface is / no burr Passifail

FUR ALIS TE BUI CHIR EHS

Surface is / no crack Passifail

Sa IEP Poh

End face is / no flush Pass/fail

IRAE PE AS iE ER BHD

Rope Original length is / no meets Passffail

Dimensional inspection drawing requirements

ARBRE SRL ARER STA

Effective number of tums is / no Passifail

meets drawing requirements

PIR FELTAIB. SUS PR AEG Go EE iI ae

Gap between the ends, thickness Pass/fail

of the end accord with drawing

7 AE AL EER et eh

Hardness of product meets Passffail

drawing requirements

5

SUPP: HENS IA/TRL-001-2013

1, BATES

Inspection method and process

6.1 HGH RE AAEHEIEL UR, bse NOT ATAAE 98°C. FPUAET Ha BSE LAL:

Turn on the temperature control water tank and set the temperature required for

inspection to 98 °C until the temperature rises to the set value.

6.2 HPRIR OGRA, FF 24 AMIN, OLR UAT BEE. ANE TATE

DAE, BBR OD AGE oR A Hah:

Put the spring into the boiling water. After 24 hours, observe whether the paint on

the surface of the spring is detached. If it does not falll off, the next step can be tested. If it

falls off, it can be judged as a non-conforming product;

6.3 ARR E RRMA HIE, SCN ER OY air FP

FREAPAARERT AEA Rs

Use the vernier caliper to measure the length of the spring after free extension. If

the length meets the requirements of the drawing, the next step can be tested. If the length

does not meet the requirements of the drawing, it can be judged as a non-conforming

product.

6.4 RA aROMLYSR LE: FT FPR, HTTP FERS FRG SE

PIE ASA: RARER TE, HOES. FAME

BERET, CRAWTEM NMEA. PURER RT MRER, IRE

Operation of the pressure testing machine: Turn on the power, press the “up” and

“down” keys to adjust the appropriate height of the upper and lower molds into the test

spring: press the cancel button to enter the parameter input: input the stroke according to

the drawing requirements, press the enter key to return to the test interface. The

displacement to be tested reaches the set value, and the pressure value corresponding to

the current stroke is recorded. Print test data after the test is over and save the record.

6.5 SOLA: ATARI ARTERY. EMIS, RMITEAE:

Appearance inspection: Observe the spring surface for cracks, burrs, etc.,

67

SH: ALAS R/TRL-001-2013,

affecting its performance

7. ER RAE

Inspection results and treatment methods

7.1 i LW STE, HSH, RAR RST

Bi, HBR T AO AAR

Through the above test methods and processes, the spring is gradually

determined, the qualified products, the non-conforming products and the total number of

the totals are calculated, and the data is carefully filled into the inspection report.

7.2 EH SAAS, FEE EH SANE aR:

Classify qualified products and non-conforming products, and mark the qualified

products and non-conforming products;

73 GRRERERMS, MOAR RAE IER

Report the inspection results to the leader, and make the qualified goods storage

and non-conforming product processing records.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Certificate 2019.08.13Document10 pagesCertificate 2019.08.13M. Andri Ludfi FananiNo ratings yet

- RM4TR32 DATASHEET SG en-GBDocument9 pagesRM4TR32 DATASHEET SG en-GBM. Andri Ludfi FananiNo ratings yet

- TeSys LRD - LR3D086Document3 pagesTeSys LRD - LR3D086M. Andri Ludfi FananiNo ratings yet

- 0899 - 119-SPT-E1002BM013-18 - CoilSpring - A - 20180516085320.601 - XDocument21 pages0899 - 119-SPT-E1002BM013-18 - CoilSpring - A - 20180516085320.601 - XM. Andri Ludfi FananiNo ratings yet

- Ut 0001Document10 pagesUt 0001M. Andri Ludfi FananiNo ratings yet

- 28. Effectiveness of Shot Peening 喷丸强度Document1 page28. Effectiveness of Shot Peening 喷丸强度M. Andri Ludfi FananiNo ratings yet

- Industry 4.0 Technology ImplementationDocument6 pagesIndustry 4.0 Technology ImplementationM. Andri Ludfi FananiNo ratings yet

- Approval Subtitusi MCCB 600A 4P REKADocument3 pagesApproval Subtitusi MCCB 600A 4P REKAM. Andri Ludfi FananiNo ratings yet

- Lesson IvDocument9 pagesLesson IvM. Andri Ludfi FananiNo ratings yet

- Booklet - Workshop Reading ProTEFLDocument10 pagesBooklet - Workshop Reading ProTEFLM. Andri Ludfi FananiNo ratings yet

- TM4 CO150 - Dana TM4 1Document2 pagesTM4 CO150 - Dana TM4 1M. Andri Ludfi FananiNo ratings yet

- 1 s2.0 S1474667015383245 MainDocument6 pages1 s2.0 S1474667015383245 MainM. Andri Ludfi FananiNo ratings yet

- Tyfon MKT 75-660Document2 pagesTyfon MKT 75-660M. Andri Ludfi FananiNo ratings yet

- Data Sheet2004-1301 21.05.2021Document20 pagesData Sheet2004-1301 21.05.2021M. Andri Ludfi FananiNo ratings yet

- Skywell - The Readiness of Skywell EBus Sept 8 2020Document14 pagesSkywell - The Readiness of Skywell EBus Sept 8 2020M. Andri Ludfi FananiNo ratings yet

- LX4FH110: Product Data SheetDocument2 pagesLX4FH110: Product Data SheetM. Andri Ludfi FananiNo ratings yet

- APTA-PR-CS-S-016-99 - Rev2 - Standard For Passenger SeatsDocument52 pagesAPTA-PR-CS-S-016-99 - Rev2 - Standard For Passenger SeatsM. Andri Ludfi FananiNo ratings yet

- Job Vacancy LRT JakartaDocument2 pagesJob Vacancy LRT JakartaM. Andri Ludfi FananiNo ratings yet

- Nova Electric CGL SeriesDocument18 pagesNova Electric CGL SeriesM. Andri Ludfi FananiNo ratings yet

- Siemens MotorDocument18 pagesSiemens MotorM. Andri Ludfi FananiNo ratings yet

- 5436 ZP 2240 Power Amplifier SpecificationDocument1 page5436 ZP 2240 Power Amplifier SpecificationM. Andri Ludfi Fanani100% (1)

- 2018 Lfse en RevDocument2 pages2018 Lfse en RevM. Andri Ludfi FananiNo ratings yet

- Penerbit, 009Document8 pagesPenerbit, 009M. Andri Ludfi FananiNo ratings yet

- Selecontrol® Mas: Tcp/Ip and UdpDocument26 pagesSelecontrol® Mas: Tcp/Ip and UdpM. Andri Ludfi FananiNo ratings yet

- Iris Guideline 4 - Rams-Lcc 4994enDocument11 pagesIris Guideline 4 - Rams-Lcc 4994enM. Andri Ludfi Fanani100% (2)

- 5586 ZM 380c As Chime Microphone Specification PDFDocument1 page5586 ZM 380c As Chime Microphone Specification PDFM. Andri Ludfi FananiNo ratings yet

- Krauss & Naimer KN100GBDocument60 pagesKrauss & Naimer KN100GBM. Andri Ludfi FananiNo ratings yet

- Weidmuller PROmax Datasheet PDFDocument2 pagesWeidmuller PROmax Datasheet PDFM. Andri Ludfi FananiNo ratings yet

- AA1-230 Shunt Trip: General InformationDocument3 pagesAA1-230 Shunt Trip: General InformationM. Andri Ludfi FananiNo ratings yet

- MPT 3000R - User Manual PDFDocument91 pagesMPT 3000R - User Manual PDFM. Andri Ludfi FananiNo ratings yet