Professional Documents

Culture Documents

Cilindro Con Amortiguador

Cilindro Con Amortiguador

Uploaded by

Jesús AhuatziCopyright:

Available Formats

You might also like

- Volvo Ec290 LC Ec290lc Excavator Service Repair ManualDocument10 pagesVolvo Ec290 LC Ec290lc Excavator Service Repair ManualAngie Ross100% (8)

- Mtu 4000 Water Pump DismantleDocument93 pagesMtu 4000 Water Pump Dismantlesxturbo100% (1)

- Aldi in Australia Case Study AnalysisDocument22 pagesAldi in Australia Case Study AnalysisBIbee NIpanNo ratings yet

- STP 1212Document22 pagesSTP 1212waleedyehiaNo ratings yet

- Kia Sorento Engine (XM) InfoDocument61 pagesKia Sorento Engine (XM) Inforeluma0% (1)

- Diagrama de ArmadoDocument12 pagesDiagrama de ArmadoFernando ÁlvarezNo ratings yet

- SteerDocument40 pagesSteerssinokrotNo ratings yet

- Brake & Fan Load Sensing Pump CTRL ValveDocument6 pagesBrake & Fan Load Sensing Pump CTRL ValveMohamed OmarNo ratings yet

- Service Library Culata Wrangler 3.6Document7 pagesService Library Culata Wrangler 3.6Andres RodriguezNo ratings yet

- Group 9 Front AxleDocument71 pagesGroup 9 Front AxleTaha RdmanNo ratings yet

- Equipment Description: Original InstructionsDocument12 pagesEquipment Description: Original InstructionsEduardoNo ratings yet

- Komatsu PC27R-8 WEBM000201Document79 pagesKomatsu PC27R-8 WEBM000201Даниил Поговоров100% (1)

- Group 4 Auxiliary Pump: 1. FunctionDocument6 pagesGroup 4 Auxiliary Pump: 1. FunctionTaha RdmanNo ratings yet

- Gruppe 150 enDocument28 pagesGruppe 150 enMarco MaximilianoNo ratings yet

- ActuatorsDocument4 pagesActuatorsAlin ChehadeNo ratings yet

- Chapter 14 - Valve Mechanism and CamshaftDocument12 pagesChapter 14 - Valve Mechanism and CamshaftsezarNo ratings yet

- Operation Manual: XQ140/12Y Hydraulic Power TongDocument44 pagesOperation Manual: XQ140/12Y Hydraulic Power TongAgustin Roncallo100% (2)

- Montacarga Eléctrico 25bt HyundaiDocument24 pagesMontacarga Eléctrico 25bt HyundaimichaelshelterNo ratings yet

- Man 12 20220510 93762a5Document30 pagesMan 12 20220510 93762a5riurikNo ratings yet

- 7. اذرعت التحكم (العصيان)Document14 pages7. اذرعت التحكم (العصيان)المهندسوليدالطويلNo ratings yet

- MODEL XQ140/20 Hydraulic Power Tong: Parts and Operation ManualDocument57 pagesMODEL XQ140/20 Hydraulic Power Tong: Parts and Operation ManualCarlos Antonio Fontalvo Carrascal100% (1)

- Cone Crusher Intro - Entry2Document178 pagesCone Crusher Intro - Entry2axel.correaNo ratings yet

- 2-6 RCV PedalDocument6 pages2-6 RCV PedalErnesto EndaraNo ratings yet

- STP 1010Document26 pagesSTP 1010waleedyehiaNo ratings yet

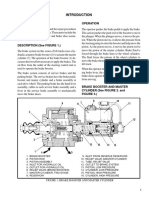

- Frenos de Servicio Cat 950H K5KDocument19 pagesFrenos de Servicio Cat 950H K5KhectorNo ratings yet

- ED - pc2.5 & PC2.6 2 - Injection.E 00Document23 pagesED - pc2.5 & PC2.6 2 - Injection.E 00Wagner GuimarãesNo ratings yet

- 320dl Swivel SystemDocument2 pages320dl Swivel SystemDaniel Rhasty-ghee AhmanorNo ratings yet

- Hid 4.2x14.5m Cement Mill InstructionDocument21 pagesHid 4.2x14.5m Cement Mill InstructionabdulfetahNo ratings yet

- Chapter 3 ClutchDocument25 pagesChapter 3 ClutchHải Long VănNo ratings yet

- Coiled Tubing Dual Action Hydraulic JarDocument13 pagesCoiled Tubing Dual Action Hydraulic JarAhmedNo ratings yet

- Hydraulic Components Structure and The OperationDocument54 pagesHydraulic Components Structure and The OperationAung KhaingNo ratings yet

- AE12 - ClutchDocument20 pagesAE12 - ClutchMohit AiryNo ratings yet

- Fan Motor, Description: Service InformationDocument8 pagesFan Motor, Description: Service InformationIfani Syaiful HudaNo ratings yet

- Chapter 11 - Crankshaft, Connecting Rod, PistonDocument46 pagesChapter 11 - Crankshaft, Connecting Rod, PistonsezarNo ratings yet

- PC450 (LC, HD) - 8 UEN02233-00 Hydraulic SystemDocument144 pagesPC450 (LC, HD) - 8 UEN02233-00 Hydraulic SystemdatphuongNo ratings yet

- 2-3 Swing DeviceDocument21 pages2-3 Swing Devicejesus silva100% (2)

- 2 - 4 CX50DX50 TrainingDocument43 pages2 - 4 CX50DX50 TrainingSina ShirdelNo ratings yet

- Reductor Llantas Ro-56Document39 pagesReductor Llantas Ro-56DavidNo ratings yet

- John Deere 27Czts Compact Excavator Service Repair Manual (TM2053)Document17 pagesJohn Deere 27Czts Compact Excavator Service Repair Manual (TM2053)laopaodunNo ratings yet

- SM Volvo l70d Wheel Loader Service Repair ManualDocument21 pagesSM Volvo l70d Wheel Loader Service Repair Manualpokeefe.pok0% (1)

- Group 10 Rear AxleDocument42 pagesGroup 10 Rear AxleTaha RdmanNo ratings yet

- Karcher Pressure Washer Basic Troubleshooting Training 2005Document47 pagesKarcher Pressure Washer Basic Troubleshooting Training 2005t_zonne8557100% (1)

- Hydraulic Pump/Regulator: Section E - HydraulicsDocument1 pageHydraulic Pump/Regulator: Section E - Hydraulicsvut73 aNo ratings yet

- Jac HFC4GB1Document70 pagesJac HFC4GB1Jeifred Espitia AraujoNo ratings yet

- Location of ComponentsDocument103 pagesLocation of ComponentsAstrit Strati100% (1)

- Modulação Da ValvulaDocument5 pagesModulação Da Valvulavaldelei limaNo ratings yet

- Accent Compession Pressure InspectionDocument12 pagesAccent Compession Pressure Inspectionflash_24014910No ratings yet

- Disassembly Cylinder Head 920 Wheel LoaderDocument7 pagesDisassembly Cylinder Head 920 Wheel LoaderAmir Bambang YudhoyonoNo ratings yet

- The Brake SystemDocument15 pagesThe Brake SystemweldsaidiNo ratings yet

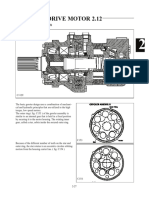

- Manual Service Danfoss Motor OMTDocument26 pagesManual Service Danfoss Motor OMTsergio blandon l100% (3)

- Me Piston Replacement ProcedureDocument6 pagesMe Piston Replacement ProcedureGaurav MaithilNo ratings yet

- Group 6 RCV PedalDocument6 pagesGroup 6 RCV Pedaldeniden2013No ratings yet

- Group 9 Front AxleDocument56 pagesGroup 9 Front AxlePhú Đinh QuốcNo ratings yet

- Sherwood 29000 - Tech GuideDocument8 pagesSherwood 29000 - Tech GuidePaško KelavaNo ratings yet

- Group 7 RCV Lever: 1. Removal and InstallDocument15 pagesGroup 7 RCV Lever: 1. Removal and InstallRafał DworakNo ratings yet

- Semihermetic Scroll CompressorsDocument34 pagesSemihermetic Scroll CompressorsAdrian AzcuagaNo ratings yet

- 1992/04/01 Systems Operation (SENR2625-01)Document63 pages1992/04/01 Systems Operation (SENR2625-01)Milorad ZelenovicNo ratings yet

- Electrovalvula 928GDocument7 pagesElectrovalvula 928Garnoldmec100% (1)

- Dissassembly and Assembly Hydo Pump 120GDocument14 pagesDissassembly and Assembly Hydo Pump 120GSteven Y.MNo ratings yet

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsFrom EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsNo ratings yet

- Running Times 2014-01-02.bakDocument72 pagesRunning Times 2014-01-02.bakJsueNo ratings yet

- Example of RPHDocument2 pagesExample of RPHTamil ArasiNo ratings yet

- Tingkat Kepatuhan Minum Obat Pada Penderita Penyakit Hipertensi Di Puskesmas Kedaung Wetan Kota Tangerang Bulan Juni - Juli Tahun 2021Document6 pagesTingkat Kepatuhan Minum Obat Pada Penderita Penyakit Hipertensi Di Puskesmas Kedaung Wetan Kota Tangerang Bulan Juni - Juli Tahun 2021Ninin KepoNo ratings yet

- Grounds For ObjectionsDocument4 pagesGrounds For ObjectionsKath100% (2)

- You Have To Choose The Best Answer To Each Questions From The Alternatives GivenDocument5 pagesYou Have To Choose The Best Answer To Each Questions From The Alternatives Givenaida FitriahNo ratings yet

- 28224lab 3Document6 pages28224lab 3aman singhNo ratings yet

- Social Safety NetDocument7 pagesSocial Safety NetrahatNo ratings yet

- Republic vs. Castelvi, 58 SCRA 336 (1974)Document4 pagesRepublic vs. Castelvi, 58 SCRA 336 (1974)Gabriel HernandezNo ratings yet

- Choreography Proposal: Dance Ensemble 2023: Choreographer'S InformationDocument6 pagesChoreography Proposal: Dance Ensemble 2023: Choreographer'S InformationTrey ErnyNo ratings yet

- Digest Sun Bros.Document29 pagesDigest Sun Bros.Marc VirtucioNo ratings yet

- Parking Standards: Parking Stall Dimensions (See Separate Handout For R-1 Single Family)Document1 pageParking Standards: Parking Stall Dimensions (See Separate Handout For R-1 Single Family)Ali HusseinNo ratings yet

- Youth Arts Jersey - MembershipDocument2 pagesYouth Arts Jersey - MembershipSteve HaighNo ratings yet

- Tubacex India CatalogueDocument12 pagesTubacex India CatalogueHimanshu UniyalNo ratings yet

- TsimeClaroline ManualDocument25 pagesTsimeClaroline ManualMwana WaChumaNo ratings yet

- Penggunaan Metode Waterfall Untuk Pengembangan Sistem Monitoring Dan Evaluasi Pembangunan PedesaanDocument26 pagesPenggunaan Metode Waterfall Untuk Pengembangan Sistem Monitoring Dan Evaluasi Pembangunan PedesaanII8I40O24 Oktaviana Rinda SariNo ratings yet

- Helical Pile Behaviour Analysis in Different Soils: January 2009Document11 pagesHelical Pile Behaviour Analysis in Different Soils: January 2009mohamed magdyNo ratings yet

- Lesson 7Document20 pagesLesson 7rj libayNo ratings yet

- Exercice 3Document2 pagesExercice 3Quang Anh LêNo ratings yet

- Flusser - Crisis of LinearityDocument12 pagesFlusser - Crisis of LinearitynatelbNo ratings yet

- Manual de Manutenção DCF 80Document366 pagesManual de Manutenção DCF 80João Paulo MerloNo ratings yet

- Early ImpressionsDocument32 pagesEarly ImpressionsElvis FuentesNo ratings yet

- Learn GermnaDocument36 pagesLearn Germnarahulchow2No ratings yet

- Quaid e AzamDocument7 pagesQuaid e AzamFM statusNo ratings yet

- Guide To HandstandDocument23 pagesGuide To HandstandLegendarystength100% (7)

- Grupe III 2016 20171Document10 pagesGrupe III 2016 20171No RulesNo ratings yet

- Twelve Angry Men Act 1 Summary Ans Analysis HandoutsDocument5 pagesTwelve Angry Men Act 1 Summary Ans Analysis Handoutsstale cakeNo ratings yet

- SFMDocument132 pagesSFMKomal BagrodiaNo ratings yet

- Populorum ProgressioDocument4 pagesPopulorum ProgressioSugar JumuadNo ratings yet

- The Period of Suppressed NationalismDocument9 pagesThe Period of Suppressed Nationalismkbj_batch0980% (5)

Cilindro Con Amortiguador

Cilindro Con Amortiguador

Uploaded by

Jesús AhuatziOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cilindro Con Amortiguador

Cilindro Con Amortiguador

Uploaded by

Jesús AhuatziCopyright:

Available Formats

152295

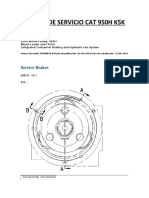

Breaking cylinder

1 2 3 4 5 6

13 12 11 10 9 8 7

Construction The cylinder consists of: piston (1), piston seal and piston guide (2), piston

rod (3), piston rod bearing (4), piston rod seal (5), scrape

ring (6), cylinder cap (7), connections (8, 13), cylinder

barrel (9), piston rod area (10), piston area (11), cylinder

base (12)

Function The piston area (11) is put under pressure via connection (13). A force is produced

from the pressure and the piston surface which leads to movement of the piston. At

the same time oil is released from the piston rod area which drains off at the

connection (8). To retract the piston again, pressure is admitted to the piston rod

area (10) at connection (8). The oil discharged then drains off at connection (13).

The piston seal (2) seals both chambers against each other and the piston guide

supports the piston. The piston rod seal (5) seals the outward piston rod area (10).

The scrape ring (6) protects the piston rod seal (5) from soiling. The piston rod

bearing (4) guides and supports the piston rod.

Load cylinder If the cylinder is used as a load cylinder for the linear unit (Order No. 167089), two

cylinders will be placed in opposing positions.

© Festo Didactic 06/2015 Subject to change 1/2

152295

Breaking cylinder

Different options are available to load working cylinders:

1. The oil displaced in the load cylinder is restricted (passive load)

2. The oil displaced in the load cylinder is directed to the tank via a pressure relief

valve (passive load)

3. A chamber is connected to a hydraulic accumulator (increasing passive load)

4. A chamber of the load cylinder is pressurised (active load)

p 1.1 p 1.2 p 2.1 p 2.2

Further circuitry options:

1. The two full piston surfaces or the two annular surfaces serve as working

cylinders (tandem cylinder).

2. The "load cylinder" is connected in addition to support the working cylinder,

whereby the full piston surface of the working cylinder operates jointly with the

annular surface of the load cylinders at pressures p1.1 and p2.1 respectively,

against the annular surface of the working cylinder and the full piston surface of

the load cylinder.

Note Assembly of cylinder on linear unit (Order No. 167089):

The cylinder housing is screwed to the yoke of the linear unit via the front sur-

face.

The piston rod is screwed into the slide and locked with a nut.

Technical data Hydraulic

Medium Mineral oil, recommended viscosity 22 cSt (mm²/s)

Piston diameter 16 mm

Piston rod diameter 10 mm, mit M 8

Stroke 200 mm

Operating pressure p 6 MPa (60 bar)

Max. permissible high pressure pmax 12 MPa (120 bar)

Connections For two coupling socket

2/2 Subject to change © Festo Didactic 06/2015

You might also like

- Volvo Ec290 LC Ec290lc Excavator Service Repair ManualDocument10 pagesVolvo Ec290 LC Ec290lc Excavator Service Repair ManualAngie Ross100% (8)

- Mtu 4000 Water Pump DismantleDocument93 pagesMtu 4000 Water Pump Dismantlesxturbo100% (1)

- Aldi in Australia Case Study AnalysisDocument22 pagesAldi in Australia Case Study AnalysisBIbee NIpanNo ratings yet

- STP 1212Document22 pagesSTP 1212waleedyehiaNo ratings yet

- Kia Sorento Engine (XM) InfoDocument61 pagesKia Sorento Engine (XM) Inforeluma0% (1)

- Diagrama de ArmadoDocument12 pagesDiagrama de ArmadoFernando ÁlvarezNo ratings yet

- SteerDocument40 pagesSteerssinokrotNo ratings yet

- Brake & Fan Load Sensing Pump CTRL ValveDocument6 pagesBrake & Fan Load Sensing Pump CTRL ValveMohamed OmarNo ratings yet

- Service Library Culata Wrangler 3.6Document7 pagesService Library Culata Wrangler 3.6Andres RodriguezNo ratings yet

- Group 9 Front AxleDocument71 pagesGroup 9 Front AxleTaha RdmanNo ratings yet

- Equipment Description: Original InstructionsDocument12 pagesEquipment Description: Original InstructionsEduardoNo ratings yet

- Komatsu PC27R-8 WEBM000201Document79 pagesKomatsu PC27R-8 WEBM000201Даниил Поговоров100% (1)

- Group 4 Auxiliary Pump: 1. FunctionDocument6 pagesGroup 4 Auxiliary Pump: 1. FunctionTaha RdmanNo ratings yet

- Gruppe 150 enDocument28 pagesGruppe 150 enMarco MaximilianoNo ratings yet

- ActuatorsDocument4 pagesActuatorsAlin ChehadeNo ratings yet

- Chapter 14 - Valve Mechanism and CamshaftDocument12 pagesChapter 14 - Valve Mechanism and CamshaftsezarNo ratings yet

- Operation Manual: XQ140/12Y Hydraulic Power TongDocument44 pagesOperation Manual: XQ140/12Y Hydraulic Power TongAgustin Roncallo100% (2)

- Montacarga Eléctrico 25bt HyundaiDocument24 pagesMontacarga Eléctrico 25bt HyundaimichaelshelterNo ratings yet

- Man 12 20220510 93762a5Document30 pagesMan 12 20220510 93762a5riurikNo ratings yet

- 7. اذرعت التحكم (العصيان)Document14 pages7. اذرعت التحكم (العصيان)المهندسوليدالطويلNo ratings yet

- MODEL XQ140/20 Hydraulic Power Tong: Parts and Operation ManualDocument57 pagesMODEL XQ140/20 Hydraulic Power Tong: Parts and Operation ManualCarlos Antonio Fontalvo Carrascal100% (1)

- Cone Crusher Intro - Entry2Document178 pagesCone Crusher Intro - Entry2axel.correaNo ratings yet

- 2-6 RCV PedalDocument6 pages2-6 RCV PedalErnesto EndaraNo ratings yet

- STP 1010Document26 pagesSTP 1010waleedyehiaNo ratings yet

- Frenos de Servicio Cat 950H K5KDocument19 pagesFrenos de Servicio Cat 950H K5KhectorNo ratings yet

- ED - pc2.5 & PC2.6 2 - Injection.E 00Document23 pagesED - pc2.5 & PC2.6 2 - Injection.E 00Wagner GuimarãesNo ratings yet

- 320dl Swivel SystemDocument2 pages320dl Swivel SystemDaniel Rhasty-ghee AhmanorNo ratings yet

- Hid 4.2x14.5m Cement Mill InstructionDocument21 pagesHid 4.2x14.5m Cement Mill InstructionabdulfetahNo ratings yet

- Chapter 3 ClutchDocument25 pagesChapter 3 ClutchHải Long VănNo ratings yet

- Coiled Tubing Dual Action Hydraulic JarDocument13 pagesCoiled Tubing Dual Action Hydraulic JarAhmedNo ratings yet

- Hydraulic Components Structure and The OperationDocument54 pagesHydraulic Components Structure and The OperationAung KhaingNo ratings yet

- AE12 - ClutchDocument20 pagesAE12 - ClutchMohit AiryNo ratings yet

- Fan Motor, Description: Service InformationDocument8 pagesFan Motor, Description: Service InformationIfani Syaiful HudaNo ratings yet

- Chapter 11 - Crankshaft, Connecting Rod, PistonDocument46 pagesChapter 11 - Crankshaft, Connecting Rod, PistonsezarNo ratings yet

- PC450 (LC, HD) - 8 UEN02233-00 Hydraulic SystemDocument144 pagesPC450 (LC, HD) - 8 UEN02233-00 Hydraulic SystemdatphuongNo ratings yet

- 2-3 Swing DeviceDocument21 pages2-3 Swing Devicejesus silva100% (2)

- 2 - 4 CX50DX50 TrainingDocument43 pages2 - 4 CX50DX50 TrainingSina ShirdelNo ratings yet

- Reductor Llantas Ro-56Document39 pagesReductor Llantas Ro-56DavidNo ratings yet

- John Deere 27Czts Compact Excavator Service Repair Manual (TM2053)Document17 pagesJohn Deere 27Czts Compact Excavator Service Repair Manual (TM2053)laopaodunNo ratings yet

- SM Volvo l70d Wheel Loader Service Repair ManualDocument21 pagesSM Volvo l70d Wheel Loader Service Repair Manualpokeefe.pok0% (1)

- Group 10 Rear AxleDocument42 pagesGroup 10 Rear AxleTaha RdmanNo ratings yet

- Karcher Pressure Washer Basic Troubleshooting Training 2005Document47 pagesKarcher Pressure Washer Basic Troubleshooting Training 2005t_zonne8557100% (1)

- Hydraulic Pump/Regulator: Section E - HydraulicsDocument1 pageHydraulic Pump/Regulator: Section E - Hydraulicsvut73 aNo ratings yet

- Jac HFC4GB1Document70 pagesJac HFC4GB1Jeifred Espitia AraujoNo ratings yet

- Location of ComponentsDocument103 pagesLocation of ComponentsAstrit Strati100% (1)

- Modulação Da ValvulaDocument5 pagesModulação Da Valvulavaldelei limaNo ratings yet

- Accent Compession Pressure InspectionDocument12 pagesAccent Compession Pressure Inspectionflash_24014910No ratings yet

- Disassembly Cylinder Head 920 Wheel LoaderDocument7 pagesDisassembly Cylinder Head 920 Wheel LoaderAmir Bambang YudhoyonoNo ratings yet

- The Brake SystemDocument15 pagesThe Brake SystemweldsaidiNo ratings yet

- Manual Service Danfoss Motor OMTDocument26 pagesManual Service Danfoss Motor OMTsergio blandon l100% (3)

- Me Piston Replacement ProcedureDocument6 pagesMe Piston Replacement ProcedureGaurav MaithilNo ratings yet

- Group 6 RCV PedalDocument6 pagesGroup 6 RCV Pedaldeniden2013No ratings yet

- Group 9 Front AxleDocument56 pagesGroup 9 Front AxlePhú Đinh QuốcNo ratings yet

- Sherwood 29000 - Tech GuideDocument8 pagesSherwood 29000 - Tech GuidePaško KelavaNo ratings yet

- Group 7 RCV Lever: 1. Removal and InstallDocument15 pagesGroup 7 RCV Lever: 1. Removal and InstallRafał DworakNo ratings yet

- Semihermetic Scroll CompressorsDocument34 pagesSemihermetic Scroll CompressorsAdrian AzcuagaNo ratings yet

- 1992/04/01 Systems Operation (SENR2625-01)Document63 pages1992/04/01 Systems Operation (SENR2625-01)Milorad ZelenovicNo ratings yet

- Electrovalvula 928GDocument7 pagesElectrovalvula 928Garnoldmec100% (1)

- Dissassembly and Assembly Hydo Pump 120GDocument14 pagesDissassembly and Assembly Hydo Pump 120GSteven Y.MNo ratings yet

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsFrom EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsNo ratings yet

- Running Times 2014-01-02.bakDocument72 pagesRunning Times 2014-01-02.bakJsueNo ratings yet

- Example of RPHDocument2 pagesExample of RPHTamil ArasiNo ratings yet

- Tingkat Kepatuhan Minum Obat Pada Penderita Penyakit Hipertensi Di Puskesmas Kedaung Wetan Kota Tangerang Bulan Juni - Juli Tahun 2021Document6 pagesTingkat Kepatuhan Minum Obat Pada Penderita Penyakit Hipertensi Di Puskesmas Kedaung Wetan Kota Tangerang Bulan Juni - Juli Tahun 2021Ninin KepoNo ratings yet

- Grounds For ObjectionsDocument4 pagesGrounds For ObjectionsKath100% (2)

- You Have To Choose The Best Answer To Each Questions From The Alternatives GivenDocument5 pagesYou Have To Choose The Best Answer To Each Questions From The Alternatives Givenaida FitriahNo ratings yet

- 28224lab 3Document6 pages28224lab 3aman singhNo ratings yet

- Social Safety NetDocument7 pagesSocial Safety NetrahatNo ratings yet

- Republic vs. Castelvi, 58 SCRA 336 (1974)Document4 pagesRepublic vs. Castelvi, 58 SCRA 336 (1974)Gabriel HernandezNo ratings yet

- Choreography Proposal: Dance Ensemble 2023: Choreographer'S InformationDocument6 pagesChoreography Proposal: Dance Ensemble 2023: Choreographer'S InformationTrey ErnyNo ratings yet

- Digest Sun Bros.Document29 pagesDigest Sun Bros.Marc VirtucioNo ratings yet

- Parking Standards: Parking Stall Dimensions (See Separate Handout For R-1 Single Family)Document1 pageParking Standards: Parking Stall Dimensions (See Separate Handout For R-1 Single Family)Ali HusseinNo ratings yet

- Youth Arts Jersey - MembershipDocument2 pagesYouth Arts Jersey - MembershipSteve HaighNo ratings yet

- Tubacex India CatalogueDocument12 pagesTubacex India CatalogueHimanshu UniyalNo ratings yet

- TsimeClaroline ManualDocument25 pagesTsimeClaroline ManualMwana WaChumaNo ratings yet

- Penggunaan Metode Waterfall Untuk Pengembangan Sistem Monitoring Dan Evaluasi Pembangunan PedesaanDocument26 pagesPenggunaan Metode Waterfall Untuk Pengembangan Sistem Monitoring Dan Evaluasi Pembangunan PedesaanII8I40O24 Oktaviana Rinda SariNo ratings yet

- Helical Pile Behaviour Analysis in Different Soils: January 2009Document11 pagesHelical Pile Behaviour Analysis in Different Soils: January 2009mohamed magdyNo ratings yet

- Lesson 7Document20 pagesLesson 7rj libayNo ratings yet

- Exercice 3Document2 pagesExercice 3Quang Anh LêNo ratings yet

- Flusser - Crisis of LinearityDocument12 pagesFlusser - Crisis of LinearitynatelbNo ratings yet

- Manual de Manutenção DCF 80Document366 pagesManual de Manutenção DCF 80João Paulo MerloNo ratings yet

- Early ImpressionsDocument32 pagesEarly ImpressionsElvis FuentesNo ratings yet

- Learn GermnaDocument36 pagesLearn Germnarahulchow2No ratings yet

- Quaid e AzamDocument7 pagesQuaid e AzamFM statusNo ratings yet

- Guide To HandstandDocument23 pagesGuide To HandstandLegendarystength100% (7)

- Grupe III 2016 20171Document10 pagesGrupe III 2016 20171No RulesNo ratings yet

- Twelve Angry Men Act 1 Summary Ans Analysis HandoutsDocument5 pagesTwelve Angry Men Act 1 Summary Ans Analysis Handoutsstale cakeNo ratings yet

- SFMDocument132 pagesSFMKomal BagrodiaNo ratings yet

- Populorum ProgressioDocument4 pagesPopulorum ProgressioSugar JumuadNo ratings yet

- The Period of Suppressed NationalismDocument9 pagesThe Period of Suppressed Nationalismkbj_batch0980% (5)