Professional Documents

Culture Documents

James 4

James 4

Uploaded by

Ahmed KhedrCopyright:

Available Formats

You might also like

- Chapter 01 - Principles of Reinforced Concrete PDFDocument9 pagesChapter 01 - Principles of Reinforced Concrete PDFVatsala PareekNo ratings yet

- Sample Assignment of Prestressed Concrete DesignDocument21 pagesSample Assignment of Prestressed Concrete DesignjrmmansayonNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- RC-I Chapter 1 PDFDocument14 pagesRC-I Chapter 1 PDFWendimu TolessaNo ratings yet

- Chapter 1 IntroductionDocument10 pagesChapter 1 Introductionzeru3261172No ratings yet

- Chapter 1 RCDocument12 pagesChapter 1 RCalaa altaee100% (1)

- Chapter 1. Introducton To Reinforced ConcreteDocument35 pagesChapter 1. Introducton To Reinforced Concretesahle mamoNo ratings yet

- 2 PDFDocument41 pages2 PDF123No ratings yet

- Chapter One IntrodutionDocument30 pagesChapter One Introdution123No ratings yet

- Introduction To Structural DesignDocument4 pagesIntroduction To Structural DesignaefNo ratings yet

- RCC Design ManualDocument318 pagesRCC Design ManualSankalp Lama50% (2)

- Fama Homework01Document2 pagesFama Homework01Bojo FamaNo ratings yet

- Pre-Tensioning and Post-Tensioning in Prestressed Concrete DesignDocument17 pagesPre-Tensioning and Post-Tensioning in Prestressed Concrete DesignEarl UbiñaNo ratings yet

- Arc 022 Building Technology 1: Department of ArchitectureDocument19 pagesArc 022 Building Technology 1: Department of ArchitectureLenard UsonNo ratings yet

- CHAPTER 1: Introduction: 1.1 General ReviewDocument9 pagesCHAPTER 1: Introduction: 1.1 General ReviewKubaNo ratings yet

- RC 1 Chapter OneDocument34 pagesRC 1 Chapter OneFekadu DebelaNo ratings yet

- Prestressed ConcreteDocument14 pagesPrestressed ConcreteMilenaNo ratings yet

- Lecture 1 (Introduction)Document7 pagesLecture 1 (Introduction)hssan AliNo ratings yet

- Structural DesignDocument71 pagesStructural DesignJam CamuNo ratings yet

- Pertemuan 1Document14 pagesPertemuan 1Clara Oktaviana SitinjakNo ratings yet

- Construction Methods and Structures As Expression of Architectural DesignDocument19 pagesConstruction Methods and Structures As Expression of Architectural DesignRen MariNo ratings yet

- ARAS Chapter 1Document10 pagesARAS Chapter 1patatas e.No ratings yet

- Chapter 1Document61 pagesChapter 1ቀዳሚሃ ለጥበብ ፈሪሃ እግዚያብሔርNo ratings yet

- 14 Reinforced EarthDocument28 pages14 Reinforced Earthhapce100% (1)

- General About ConcreteDocument10 pagesGeneral About Concretekeshav1980No ratings yet

- Unit-I (Introduction & Methods of Prestressing)Document10 pagesUnit-I (Introduction & Methods of Prestressing)Sasi HoneyNo ratings yet

- Orca Share Media1674568894076 7023651010702707637Document11 pagesOrca Share Media1674568894076 7023651010702707637Fernando MatienzoNo ratings yet

- Reinforced Concrete: AI-Gadhib/CE 315/CE 323Document22 pagesReinforced Concrete: AI-Gadhib/CE 315/CE 323Thalia Arias GuevaraNo ratings yet

- Plain & Reinforced Concrete-1: Lecture # 1Document19 pagesPlain & Reinforced Concrete-1: Lecture # 1Manoj BalakrishnanNo ratings yet

- Theory of Pre-Stress Concrete: Comparative Analysis of Pre Tension and Post Tension SlabDocument39 pagesTheory of Pre-Stress Concrete: Comparative Analysis of Pre Tension and Post Tension SlabJp NaydaaNo ratings yet

- CE 327 RConcrete Module 1Document7 pagesCE 327 RConcrete Module 1Niel John BaquilarNo ratings yet

- DR KP-JayaDocument7 pagesDR KP-JayaRiyaz SiddiqueNo ratings yet

- Dcs 1Document130 pagesDcs 1Mukesh Kumar SamotaNo ratings yet

- Assign 1 & 2Document26 pagesAssign 1 & 2Rozhelle PedernalNo ratings yet

- RCC Unit-1 PDFDocument40 pagesRCC Unit-1 PDFSandeep Gowda100% (1)

- Reinforced Concrete Part 1Document33 pagesReinforced Concrete Part 1Danica Mae AmicayNo ratings yet

- RCD PLATE1 IntoductionDocument6 pagesRCD PLATE1 IntoductionEugene TongolNo ratings yet

- Chapter 1 - Introduction To Reinforced Concrete DesignDocument19 pagesChapter 1 - Introduction To Reinforced Concrete DesignJosiah Flores100% (1)

- By: Nirmla G.F. Lecturer Civil BKN Govt. Polytechnic NarnaulDocument53 pagesBy: Nirmla G.F. Lecturer Civil BKN Govt. Polytechnic NarnaulAshish JoshiNo ratings yet

- Structural DesignDocument119 pagesStructural DesignKannan KandappanNo ratings yet

- Lesson 13Document73 pagesLesson 13Darlene SarnoNo ratings yet

- Pre-Stressed Concrete Electric PolesDocument25 pagesPre-Stressed Concrete Electric PolesRahul Ramesh100% (3)

- Prestressing MethodDocument18 pagesPrestressing MethodMeghanaagarwal9No ratings yet

- Reinforced Concrete I: Lecture-1Document54 pagesReinforced Concrete I: Lecture-1Temesgen BihonegnNo ratings yet

- Prestressed Concrete: 2Nd Semester 2020-2021Document7 pagesPrestressed Concrete: 2Nd Semester 2020-2021Nino MontaNo ratings yet

- Acm UNIT 1Document19 pagesAcm UNIT 1Samreen KhanNo ratings yet

- PRC 001Document93 pagesPRC 001youremyboss0623No ratings yet

- Reinforced Concrete: TOLENTINO, Paul Diony S. CE133P/E01 Homework No. 1Document6 pagesReinforced Concrete: TOLENTINO, Paul Diony S. CE133P/E01 Homework No. 1Paul Diony TolentinoNo ratings yet

- Reinforced Concrete StructuresDocument7 pagesReinforced Concrete Structuressiraj soNo ratings yet

- Simpson - 04 - Design and Construction of Water Retaining StructuresDocument13 pagesSimpson - 04 - Design and Construction of Water Retaining StructuresJacky TamNo ratings yet

- Research On BeamsDocument4 pagesResearch On BeamsNicole SesaldoNo ratings yet

- Reinforcement C-WPS OfficeDocument7 pagesReinforcement C-WPS OfficeNoah Oluwatoyin AderiyikeNo ratings yet

- Tos Vii Unit 01 & 02dfhtgfijkDocument20 pagesTos Vii Unit 01 & 02dfhtgfijkKanak YadavNo ratings yet

- Prestressed Concrete 2Document18 pagesPrestressed Concrete 2Faizan rasoolNo ratings yet

- CE8501 Notes PDFDocument53 pagesCE8501 Notes PDFprem rajanNo ratings yet

- Instructor GuideDocument5 pagesInstructor GuidePipoy ReglosNo ratings yet

- 1 Prestressed ConcreteDocument8 pages1 Prestressed ConcreteWiy Guom0% (1)

- Concrete Basics PDFDocument30 pagesConcrete Basics PDFDarshan Rokztar100% (1)

- 1-Principles and Practice of Ground Improvement-Wiley (2015) - 26Document1 page1-Principles and Practice of Ground Improvement-Wiley (2015) - 26Ahmed KhedrNo ratings yet

- 1-Principles and Practice of Ground Improvement-Wiley (2015) - 20Document1 page1-Principles and Practice of Ground Improvement-Wiley (2015) - 20Ahmed KhedrNo ratings yet

- 1-Principles and Practice of Ground Improvement-Wiley (2015) - 25Document1 page1-Principles and Practice of Ground Improvement-Wiley (2015) - 25Ahmed KhedrNo ratings yet

- 1-Principles and Practice of Ground Improvement-Wiley (2015) - 23Document1 page1-Principles and Practice of Ground Improvement-Wiley (2015) - 23Ahmed KhedrNo ratings yet

- 1-Principles and Practice of Ground Improvement-Wiley (2015) - 5Document1 page1-Principles and Practice of Ground Improvement-Wiley (2015) - 5Ahmed KhedrNo ratings yet

- Prestressed Concrete Analysis and Design Fundamentals PDFDrive Com 3Document1 pagePrestressed Concrete Analysis and Design Fundamentals PDFDrive Com 3Ahmed KhedrNo ratings yet

- 1-Principles and Practice of Ground Improvement-Wiley (2015) - 2Document1 page1-Principles and Practice of Ground Improvement-Wiley (2015) - 2Ahmed KhedrNo ratings yet

- Prestressed Concrete Analysis and Design Fundamentals PDFDrive Com 1Document1 pagePrestressed Concrete Analysis and Design Fundamentals PDFDrive Com 1Ahmed KhedrNo ratings yet

- Ertqa 1Document1 pageErtqa 1Ahmed KhedrNo ratings yet

- Mid Term Examination of Academic Year 2021/ 2022Document2 pagesMid Term Examination of Academic Year 2021/ 2022Ahmed KhedrNo ratings yet

- Switchboard Schedule FF and SF r2 19.10.232Document1 pageSwitchboard Schedule FF and SF r2 19.10.232amitjangirhnhNo ratings yet

- List of Miscellenious DrawingDocument1 pageList of Miscellenious DrawingRamBhuvan SonkarNo ratings yet

- Maxroof Corporation PVT - LTD.: RMTR Nos Nos Nos RMTR Nos Nos Nos RMTR Nos Nos Nos RMTR Nos Nos Nos RMTR Nos Nos NosDocument5 pagesMaxroof Corporation PVT - LTD.: RMTR Nos Nos Nos RMTR Nos Nos Nos RMTR Nos Nos Nos RMTR Nos Nos Nos RMTR Nos Nos Nosspsingh_jmdNo ratings yet

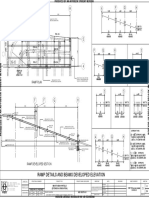

- H E F G F: Ramp Details and Beams Developed ElevationDocument1 pageH E F G F: Ramp Details and Beams Developed ElevationJhecy RodriguezNo ratings yet

- Models BV10 & BV11 On/Off Solenoid Operated Valves: DescriptionDocument4 pagesModels BV10 & BV11 On/Off Solenoid Operated Valves: DescriptionadrianioantomaNo ratings yet

- Demag All Terrain Cranes Spec Ff4c8dDocument13 pagesDemag All Terrain Cranes Spec Ff4c8dFarag ElgarhyNo ratings yet

- Timber and Metal Formworks and Scaffolds Materials Price List - PHILCON PRICESDocument4 pagesTimber and Metal Formworks and Scaffolds Materials Price List - PHILCON PRICESjohn reyesNo ratings yet

- Technical Schedule A To D & H Pkg-2Document101 pagesTechnical Schedule A To D & H Pkg-2vinodNo ratings yet

- ICC ES Report ESR 1961: The Dow Chemical CompanyDocument3 pagesICC ES Report ESR 1961: The Dow Chemical CompanymurdicksNo ratings yet

- Alg 11. WorkDocument3 pagesAlg 11. WorkTrisha AbalosNo ratings yet

- Flexible Waterproofing - Sikaplan - 508 PDFDocument11 pagesFlexible Waterproofing - Sikaplan - 508 PDFالاوربيه للبلاستكNo ratings yet

- Voltaic X Kovaaks Benchmarks & Leaderboard - Season 4Document5 pagesVoltaic X Kovaaks Benchmarks & Leaderboard - Season 4AriakNo ratings yet

- WHP01-PMC1-ASYYY-23-182002-0001 - Rev01 Inspection & Test Plan For Piping FabriDocument24 pagesWHP01-PMC1-ASYYY-23-182002-0001 - Rev01 Inspection & Test Plan For Piping FabriTĩnh Hồ TrungNo ratings yet

- 7.TDI FCR Data 7.0 23 PPF NL80 BTC Rev.7Document1 page7.TDI FCR Data 7.0 23 PPF NL80 BTC Rev.7javier monteroNo ratings yet

- Development Control RegulationsDocument2 pagesDevelopment Control RegulationsAyshwarya SureshNo ratings yet

- Department of Archaeology Item Rates: Ministry of Culture, Tourism & Civil AviationDocument7 pagesDepartment of Archaeology Item Rates: Ministry of Culture, Tourism & Civil AviationKrijan Mali100% (1)

- Shona Balaji SANTHARAM - Chartered EngineerDocument4 pagesShona Balaji SANTHARAM - Chartered EngineerHeera RamjiNo ratings yet

- Topic 16 Expression of PossessionDocument12 pagesTopic 16 Expression of PossessionMiriam Reinoso SánchezNo ratings yet

- Cat Hammers C842898Document8 pagesCat Hammers C842898maggioraNo ratings yet

- Annex2 - 11999 210705 KS LCCADocument6 pagesAnnex2 - 11999 210705 KS LCCAkrishanthi senarathNo ratings yet

- Sec07 - RacewaysDocument10 pagesSec07 - RacewaysYusufNo ratings yet

- Nycwy: Low Voltage Power Cable (0.6/1 KV)Document2 pagesNycwy: Low Voltage Power Cable (0.6/1 KV)Сергей КозловNo ratings yet

- Architectural Record - 03 - 2023Document148 pagesArchitectural Record - 03 - 2023Roumen DonevNo ratings yet

- (MRDTM 418) : Quantitative Extraction of Asphalt From Asphalt Paving MixDocument7 pages(MRDTM 418) : Quantitative Extraction of Asphalt From Asphalt Paving MixBelal AlmokdadNo ratings yet

- E100 - Electrical PlansDocument1 pageE100 - Electrical PlansDagmawi GashawNo ratings yet

- BOQ - Method of Measurement and BOQ PDFDocument176 pagesBOQ - Method of Measurement and BOQ PDFyousef100% (1)

- Quality Assurance Plan For Civil4mDocument3 pagesQuality Assurance Plan For Civil4mMohammed Abdul BaseerNo ratings yet

- 005 - OBA-QAC-MST-DIS-REV - R00 - Dismantling WorksDocument11 pages005 - OBA-QAC-MST-DIS-REV - R00 - Dismantling WorksDritan PeshtaniNo ratings yet

- 1-Pile FoundationsDocument32 pages1-Pile FoundationshannaNo ratings yet

- Bill of Materials FormatDocument3 pagesBill of Materials FormatAilyn RamosNo ratings yet

James 4

James 4

Uploaded by

Ahmed KhedrOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

James 4

James 4

Uploaded by

Ahmed KhedrCopyright:

Available Formats

1

Introduction

1-1 REINFORCED CONCRETE STRUCTURES

Concrete and reinforced concrete are used as building construction materials in every

country. In many, including the United States and Canada, reinforced concrete is a domi-

nant structural material in engineered construction. The universal nature of reinforced

concrete construction stems from the wide availability of reinforcing bars and of the con-

stituents of concrete (gravel or crushed rock, sand, water, and cement), from the relatively

simple skills required in concrete construction, and from the economy of reinforced con-

crete compared with other forms of construction. Plain concrete and reinforced concrete

are used in buildings of all sorts (Fig. 1-1), underground structures, water tanks, wind tur-

bine foundations (Fig. 1-2) and towers, offshore oil exploration and production structures,

dams, bridges (Fig. 1-3), and even ships.

1-2 MECHANICS OF REINFORCED CONCRETE

Concrete is strong in compression, but weak in tension. As a result, cracks develop whenever

loads, restrained shrinkage, or temperature changes give rise to tensile stresses in excess

of the tensile strength of the concrete. In the plain concrete beam shown in Fig. 1-4b, the

moments about point O due to applied loads are resisted by an internal tension–compression

couple involving tension in the concrete. An unreinforced beam fails very suddenly and

completely when the first crack forms. In a reinforced concrete beam (Fig. 1-4c), reinforcing

bars are embedded in the concrete in such a way that the tension forces needed for moment

equilibrium after the concrete cracks can be developed in the bars.

Alternatively, the reinforcement could be placed in a longitudinal duct near the bot-

tom of the beam, as shown in Fig. 1-5, and stretched or prestressed, reacting on the con-

crete in the beam. This would put the reinforcement into tension and the concrete into

compression. This compression would delay cracking of the beam. Such a member is said

to be a prestressed concrete beam. The reinforcement in such a beam is referred to as pres-

tressing tendons and must be fabricated from high-strength steel.

The construction of a reinforced concrete member involves building a form or mould

in the shape of the member being built. The form must be strong enough to support the

weight and hydrostatic pressure of the wet concrete, plus any forces applied to it by workers,

You might also like

- Chapter 01 - Principles of Reinforced Concrete PDFDocument9 pagesChapter 01 - Principles of Reinforced Concrete PDFVatsala PareekNo ratings yet

- Sample Assignment of Prestressed Concrete DesignDocument21 pagesSample Assignment of Prestressed Concrete DesignjrmmansayonNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- RC-I Chapter 1 PDFDocument14 pagesRC-I Chapter 1 PDFWendimu TolessaNo ratings yet

- Chapter 1 IntroductionDocument10 pagesChapter 1 Introductionzeru3261172No ratings yet

- Chapter 1 RCDocument12 pagesChapter 1 RCalaa altaee100% (1)

- Chapter 1. Introducton To Reinforced ConcreteDocument35 pagesChapter 1. Introducton To Reinforced Concretesahle mamoNo ratings yet

- 2 PDFDocument41 pages2 PDF123No ratings yet

- Chapter One IntrodutionDocument30 pagesChapter One Introdution123No ratings yet

- Introduction To Structural DesignDocument4 pagesIntroduction To Structural DesignaefNo ratings yet

- RCC Design ManualDocument318 pagesRCC Design ManualSankalp Lama50% (2)

- Fama Homework01Document2 pagesFama Homework01Bojo FamaNo ratings yet

- Pre-Tensioning and Post-Tensioning in Prestressed Concrete DesignDocument17 pagesPre-Tensioning and Post-Tensioning in Prestressed Concrete DesignEarl UbiñaNo ratings yet

- Arc 022 Building Technology 1: Department of ArchitectureDocument19 pagesArc 022 Building Technology 1: Department of ArchitectureLenard UsonNo ratings yet

- CHAPTER 1: Introduction: 1.1 General ReviewDocument9 pagesCHAPTER 1: Introduction: 1.1 General ReviewKubaNo ratings yet

- RC 1 Chapter OneDocument34 pagesRC 1 Chapter OneFekadu DebelaNo ratings yet

- Prestressed ConcreteDocument14 pagesPrestressed ConcreteMilenaNo ratings yet

- Lecture 1 (Introduction)Document7 pagesLecture 1 (Introduction)hssan AliNo ratings yet

- Structural DesignDocument71 pagesStructural DesignJam CamuNo ratings yet

- Pertemuan 1Document14 pagesPertemuan 1Clara Oktaviana SitinjakNo ratings yet

- Construction Methods and Structures As Expression of Architectural DesignDocument19 pagesConstruction Methods and Structures As Expression of Architectural DesignRen MariNo ratings yet

- ARAS Chapter 1Document10 pagesARAS Chapter 1patatas e.No ratings yet

- Chapter 1Document61 pagesChapter 1ቀዳሚሃ ለጥበብ ፈሪሃ እግዚያብሔርNo ratings yet

- 14 Reinforced EarthDocument28 pages14 Reinforced Earthhapce100% (1)

- General About ConcreteDocument10 pagesGeneral About Concretekeshav1980No ratings yet

- Unit-I (Introduction & Methods of Prestressing)Document10 pagesUnit-I (Introduction & Methods of Prestressing)Sasi HoneyNo ratings yet

- Orca Share Media1674568894076 7023651010702707637Document11 pagesOrca Share Media1674568894076 7023651010702707637Fernando MatienzoNo ratings yet

- Reinforced Concrete: AI-Gadhib/CE 315/CE 323Document22 pagesReinforced Concrete: AI-Gadhib/CE 315/CE 323Thalia Arias GuevaraNo ratings yet

- Plain & Reinforced Concrete-1: Lecture # 1Document19 pagesPlain & Reinforced Concrete-1: Lecture # 1Manoj BalakrishnanNo ratings yet

- Theory of Pre-Stress Concrete: Comparative Analysis of Pre Tension and Post Tension SlabDocument39 pagesTheory of Pre-Stress Concrete: Comparative Analysis of Pre Tension and Post Tension SlabJp NaydaaNo ratings yet

- CE 327 RConcrete Module 1Document7 pagesCE 327 RConcrete Module 1Niel John BaquilarNo ratings yet

- DR KP-JayaDocument7 pagesDR KP-JayaRiyaz SiddiqueNo ratings yet

- Dcs 1Document130 pagesDcs 1Mukesh Kumar SamotaNo ratings yet

- Assign 1 & 2Document26 pagesAssign 1 & 2Rozhelle PedernalNo ratings yet

- RCC Unit-1 PDFDocument40 pagesRCC Unit-1 PDFSandeep Gowda100% (1)

- Reinforced Concrete Part 1Document33 pagesReinforced Concrete Part 1Danica Mae AmicayNo ratings yet

- RCD PLATE1 IntoductionDocument6 pagesRCD PLATE1 IntoductionEugene TongolNo ratings yet

- Chapter 1 - Introduction To Reinforced Concrete DesignDocument19 pagesChapter 1 - Introduction To Reinforced Concrete DesignJosiah Flores100% (1)

- By: Nirmla G.F. Lecturer Civil BKN Govt. Polytechnic NarnaulDocument53 pagesBy: Nirmla G.F. Lecturer Civil BKN Govt. Polytechnic NarnaulAshish JoshiNo ratings yet

- Structural DesignDocument119 pagesStructural DesignKannan KandappanNo ratings yet

- Lesson 13Document73 pagesLesson 13Darlene SarnoNo ratings yet

- Pre-Stressed Concrete Electric PolesDocument25 pagesPre-Stressed Concrete Electric PolesRahul Ramesh100% (3)

- Prestressing MethodDocument18 pagesPrestressing MethodMeghanaagarwal9No ratings yet

- Reinforced Concrete I: Lecture-1Document54 pagesReinforced Concrete I: Lecture-1Temesgen BihonegnNo ratings yet

- Prestressed Concrete: 2Nd Semester 2020-2021Document7 pagesPrestressed Concrete: 2Nd Semester 2020-2021Nino MontaNo ratings yet

- Acm UNIT 1Document19 pagesAcm UNIT 1Samreen KhanNo ratings yet

- PRC 001Document93 pagesPRC 001youremyboss0623No ratings yet

- Reinforced Concrete: TOLENTINO, Paul Diony S. CE133P/E01 Homework No. 1Document6 pagesReinforced Concrete: TOLENTINO, Paul Diony S. CE133P/E01 Homework No. 1Paul Diony TolentinoNo ratings yet

- Reinforced Concrete StructuresDocument7 pagesReinforced Concrete Structuressiraj soNo ratings yet

- Simpson - 04 - Design and Construction of Water Retaining StructuresDocument13 pagesSimpson - 04 - Design and Construction of Water Retaining StructuresJacky TamNo ratings yet

- Research On BeamsDocument4 pagesResearch On BeamsNicole SesaldoNo ratings yet

- Reinforcement C-WPS OfficeDocument7 pagesReinforcement C-WPS OfficeNoah Oluwatoyin AderiyikeNo ratings yet

- Tos Vii Unit 01 & 02dfhtgfijkDocument20 pagesTos Vii Unit 01 & 02dfhtgfijkKanak YadavNo ratings yet

- Prestressed Concrete 2Document18 pagesPrestressed Concrete 2Faizan rasoolNo ratings yet

- CE8501 Notes PDFDocument53 pagesCE8501 Notes PDFprem rajanNo ratings yet

- Instructor GuideDocument5 pagesInstructor GuidePipoy ReglosNo ratings yet

- 1 Prestressed ConcreteDocument8 pages1 Prestressed ConcreteWiy Guom0% (1)

- Concrete Basics PDFDocument30 pagesConcrete Basics PDFDarshan Rokztar100% (1)

- 1-Principles and Practice of Ground Improvement-Wiley (2015) - 26Document1 page1-Principles and Practice of Ground Improvement-Wiley (2015) - 26Ahmed KhedrNo ratings yet

- 1-Principles and Practice of Ground Improvement-Wiley (2015) - 20Document1 page1-Principles and Practice of Ground Improvement-Wiley (2015) - 20Ahmed KhedrNo ratings yet

- 1-Principles and Practice of Ground Improvement-Wiley (2015) - 25Document1 page1-Principles and Practice of Ground Improvement-Wiley (2015) - 25Ahmed KhedrNo ratings yet

- 1-Principles and Practice of Ground Improvement-Wiley (2015) - 23Document1 page1-Principles and Practice of Ground Improvement-Wiley (2015) - 23Ahmed KhedrNo ratings yet

- 1-Principles and Practice of Ground Improvement-Wiley (2015) - 5Document1 page1-Principles and Practice of Ground Improvement-Wiley (2015) - 5Ahmed KhedrNo ratings yet

- Prestressed Concrete Analysis and Design Fundamentals PDFDrive Com 3Document1 pagePrestressed Concrete Analysis and Design Fundamentals PDFDrive Com 3Ahmed KhedrNo ratings yet

- 1-Principles and Practice of Ground Improvement-Wiley (2015) - 2Document1 page1-Principles and Practice of Ground Improvement-Wiley (2015) - 2Ahmed KhedrNo ratings yet

- Prestressed Concrete Analysis and Design Fundamentals PDFDrive Com 1Document1 pagePrestressed Concrete Analysis and Design Fundamentals PDFDrive Com 1Ahmed KhedrNo ratings yet

- Ertqa 1Document1 pageErtqa 1Ahmed KhedrNo ratings yet

- Mid Term Examination of Academic Year 2021/ 2022Document2 pagesMid Term Examination of Academic Year 2021/ 2022Ahmed KhedrNo ratings yet

- Switchboard Schedule FF and SF r2 19.10.232Document1 pageSwitchboard Schedule FF and SF r2 19.10.232amitjangirhnhNo ratings yet

- List of Miscellenious DrawingDocument1 pageList of Miscellenious DrawingRamBhuvan SonkarNo ratings yet

- Maxroof Corporation PVT - LTD.: RMTR Nos Nos Nos RMTR Nos Nos Nos RMTR Nos Nos Nos RMTR Nos Nos Nos RMTR Nos Nos NosDocument5 pagesMaxroof Corporation PVT - LTD.: RMTR Nos Nos Nos RMTR Nos Nos Nos RMTR Nos Nos Nos RMTR Nos Nos Nos RMTR Nos Nos Nosspsingh_jmdNo ratings yet

- H E F G F: Ramp Details and Beams Developed ElevationDocument1 pageH E F G F: Ramp Details and Beams Developed ElevationJhecy RodriguezNo ratings yet

- Models BV10 & BV11 On/Off Solenoid Operated Valves: DescriptionDocument4 pagesModels BV10 & BV11 On/Off Solenoid Operated Valves: DescriptionadrianioantomaNo ratings yet

- Demag All Terrain Cranes Spec Ff4c8dDocument13 pagesDemag All Terrain Cranes Spec Ff4c8dFarag ElgarhyNo ratings yet

- Timber and Metal Formworks and Scaffolds Materials Price List - PHILCON PRICESDocument4 pagesTimber and Metal Formworks and Scaffolds Materials Price List - PHILCON PRICESjohn reyesNo ratings yet

- Technical Schedule A To D & H Pkg-2Document101 pagesTechnical Schedule A To D & H Pkg-2vinodNo ratings yet

- ICC ES Report ESR 1961: The Dow Chemical CompanyDocument3 pagesICC ES Report ESR 1961: The Dow Chemical CompanymurdicksNo ratings yet

- Alg 11. WorkDocument3 pagesAlg 11. WorkTrisha AbalosNo ratings yet

- Flexible Waterproofing - Sikaplan - 508 PDFDocument11 pagesFlexible Waterproofing - Sikaplan - 508 PDFالاوربيه للبلاستكNo ratings yet

- Voltaic X Kovaaks Benchmarks & Leaderboard - Season 4Document5 pagesVoltaic X Kovaaks Benchmarks & Leaderboard - Season 4AriakNo ratings yet

- WHP01-PMC1-ASYYY-23-182002-0001 - Rev01 Inspection & Test Plan For Piping FabriDocument24 pagesWHP01-PMC1-ASYYY-23-182002-0001 - Rev01 Inspection & Test Plan For Piping FabriTĩnh Hồ TrungNo ratings yet

- 7.TDI FCR Data 7.0 23 PPF NL80 BTC Rev.7Document1 page7.TDI FCR Data 7.0 23 PPF NL80 BTC Rev.7javier monteroNo ratings yet

- Development Control RegulationsDocument2 pagesDevelopment Control RegulationsAyshwarya SureshNo ratings yet

- Department of Archaeology Item Rates: Ministry of Culture, Tourism & Civil AviationDocument7 pagesDepartment of Archaeology Item Rates: Ministry of Culture, Tourism & Civil AviationKrijan Mali100% (1)

- Shona Balaji SANTHARAM - Chartered EngineerDocument4 pagesShona Balaji SANTHARAM - Chartered EngineerHeera RamjiNo ratings yet

- Topic 16 Expression of PossessionDocument12 pagesTopic 16 Expression of PossessionMiriam Reinoso SánchezNo ratings yet

- Cat Hammers C842898Document8 pagesCat Hammers C842898maggioraNo ratings yet

- Annex2 - 11999 210705 KS LCCADocument6 pagesAnnex2 - 11999 210705 KS LCCAkrishanthi senarathNo ratings yet

- Sec07 - RacewaysDocument10 pagesSec07 - RacewaysYusufNo ratings yet

- Nycwy: Low Voltage Power Cable (0.6/1 KV)Document2 pagesNycwy: Low Voltage Power Cable (0.6/1 KV)Сергей КозловNo ratings yet

- Architectural Record - 03 - 2023Document148 pagesArchitectural Record - 03 - 2023Roumen DonevNo ratings yet

- (MRDTM 418) : Quantitative Extraction of Asphalt From Asphalt Paving MixDocument7 pages(MRDTM 418) : Quantitative Extraction of Asphalt From Asphalt Paving MixBelal AlmokdadNo ratings yet

- E100 - Electrical PlansDocument1 pageE100 - Electrical PlansDagmawi GashawNo ratings yet

- BOQ - Method of Measurement and BOQ PDFDocument176 pagesBOQ - Method of Measurement and BOQ PDFyousef100% (1)

- Quality Assurance Plan For Civil4mDocument3 pagesQuality Assurance Plan For Civil4mMohammed Abdul BaseerNo ratings yet

- 005 - OBA-QAC-MST-DIS-REV - R00 - Dismantling WorksDocument11 pages005 - OBA-QAC-MST-DIS-REV - R00 - Dismantling WorksDritan PeshtaniNo ratings yet

- 1-Pile FoundationsDocument32 pages1-Pile FoundationshannaNo ratings yet

- Bill of Materials FormatDocument3 pagesBill of Materials FormatAilyn RamosNo ratings yet