Professional Documents

Culture Documents

Development of Highly Efficient Construction Technologies For Super Long Span Bridge

Development of Highly Efficient Construction Technologies For Super Long Span Bridge

Uploaded by

bhavesh.patil20Copyright:

Available Formats

You might also like

- Cpci Design Manual 5 - Secured - 10-20-2017Document732 pagesCpci Design Manual 5 - Secured - 10-20-2017atiqur_rehman07100% (5)

- Analysis and Design of Flyover: Kavitha.N, Jaya Kumari.r, Jeeva.K, Bavithra.K, Kokila.KDocument5 pagesAnalysis and Design of Flyover: Kavitha.N, Jaya Kumari.r, Jeeva.K, Bavithra.K, Kokila.KjophinNo ratings yet

- CHAPTER IDocument4 pagesCHAPTER Imaddih gayeNo ratings yet

- DsgnConstr CableSuppBridgesDocument20 pagesDsgnConstr CableSuppBridgescaptain_tamNo ratings yet

- 41 Ijmtst0703117Document8 pages41 Ijmtst0703117Myo Htet AungNo ratings yet

- T02 01 Feng - Gao - Zheng - GNP2020Document11 pagesT02 01 Feng - Gao - Zheng - GNP2020Kenan KajosevicNo ratings yet

- StructuralAnalysis Sutong BridgeDocument10 pagesStructuralAnalysis Sutong BridgenvngonNo ratings yet

- 2000 Present Situation and Development of BridgesDocument16 pages2000 Present Situation and Development of BridgesStevan Zimbi IvkovicNo ratings yet

- 1717 Two International Finance Centre PDFDocument9 pages1717 Two International Finance Centre PDFBatoul ObeidNo ratings yet

- Design and Construction of Simple Beam Bridges For High-Speed Rails in China: Standardization and IndustrializationDocument9 pagesDesign and Construction of Simple Beam Bridges For High-Speed Rails in China: Standardization and IndustrializationAashish kumarNo ratings yet

- Bridge and Flyover Construction: A ReviewDocument4 pagesBridge and Flyover Construction: A ReviewBhat TalhaNo ratings yet

- Time and Cost Comparision of PSC and RCCDocument4 pagesTime and Cost Comparision of PSC and RCCmahakNo ratings yet

- Iricen Journal Sept. 2008Document52 pagesIricen Journal Sept. 2008js kalyana ramaNo ratings yet

- A Review Paper On "Comparative Analysis & Design of RCC & PSC Girder & Feasibility"Document4 pagesA Review Paper On "Comparative Analysis & Design of RCC & PSC Girder & Feasibility"Abhishek nirmaleNo ratings yet

- Cost AnalysisDocument13 pagesCost AnalysisReaditReaditNo ratings yet

- Introduction: Recent Structures in India: B. C. RoyDocument6 pagesIntroduction: Recent Structures in India: B. C. RoyKishan KumarNo ratings yet

- Optimal Submarine Cable Path Planning and Trunk-and-Branch Tree Network Topology DesignDocument11 pagesOptimal Submarine Cable Path Planning and Trunk-and-Branch Tree Network Topology DesignFERNANDO HUGO HUAMAN ARANCIBIANo ratings yet

- Analysis and Design of Box Underpass Bridge Using SoftwareDocument4 pagesAnalysis and Design of Box Underpass Bridge Using SoftwareEditor IJTSRDNo ratings yet

- Life Cycle Costing System Rail Transit Construction ProjectsDocument11 pagesLife Cycle Costing System Rail Transit Construction ProjectsjayaramanrathnamNo ratings yet

- Bridge Erection Techniques and Construction EquipmDocument2 pagesBridge Erection Techniques and Construction EquipmAbderrahmane SaidNo ratings yet

- Modular For High Rise in KoreaDocument10 pagesModular For High Rise in KoreaYunita MentariNo ratings yet

- Steel Bridge Design Brief 2012-2013Document22 pagesSteel Bridge Design Brief 2012-2013cr231181No ratings yet

- Crossrail Sprayed Concrete LiningsDocument20 pagesCrossrail Sprayed Concrete LiningsDEBASIS BARMANNo ratings yet

- Detailed Design of The Padma Multipurpose Bridge, Bangladesh - AnDocument14 pagesDetailed Design of The Padma Multipurpose Bridge, Bangladesh - AnMehtab Hussain SyedNo ratings yet

- 03 11 2015Document12 pages03 11 2015Yuvaraj DhandapaniNo ratings yet

- FOUNDATION DESIGN & CONSTRUCTION IN HONG KONG - PRESENT & BEYOND, Daman Lee HK-Taiwan 2005Document28 pagesFOUNDATION DESIGN & CONSTRUCTION IN HONG KONG - PRESENT & BEYOND, Daman Lee HK-Taiwan 2005M Mushanif MuktiNo ratings yet

- Padma Bridge DesignDocument14 pagesPadma Bridge DesignAbdul Majid KhanNo ratings yet

- Research On Key Construction Technology of UrbanDocument6 pagesResearch On Key Construction Technology of UrbanSOFIA NABILAH MOHAMAD ZAHIDNo ratings yet

- Stonecutters Bridge 1Document9 pagesStonecutters Bridge 1raisa ehsanNo ratings yet

- Optimisation and Analysis of CostDocument4 pagesOptimisation and Analysis of CostJustin JohnsonNo ratings yet

- Submarine Cable Path Planning Based On Weight Selection of Design ConsiderationsDocument14 pagesSubmarine Cable Path Planning Based On Weight Selection of Design ConsiderationsFilho EngenheiroNo ratings yet

- Analysis and Design of Reinforced Concrete Solid Slab BridgeDocument6 pagesAnalysis and Design of Reinforced Concrete Solid Slab BridgeEditor IJTSRDNo ratings yet

- Steel Concrete Composite Structures IntroductionDocument2 pagesSteel Concrete Composite Structures IntroductionUsha EngineeringNo ratings yet

- Design of The Dubai Metro Light Rail Viaducts SubstructureDocument12 pagesDesign of The Dubai Metro Light Rail Viaducts SubstructureUvie M. Ptwolan100% (2)

- Irjet V8i12174Document4 pagesIrjet V8i12174baskar_saNo ratings yet

- Recent Trends in Design and Construction of Yovers: January 2015Document5 pagesRecent Trends in Design and Construction of Yovers: January 2015sai vemunuriNo ratings yet

- Fact Sheet: Basis of DesignDocument4 pagesFact Sheet: Basis of DesignHiddenDNo ratings yet

- Recent Trends in Design and Construction of Flyovers: January 2015Document5 pagesRecent Trends in Design and Construction of Flyovers: January 2015Neil Myco Duterte Sarsalejo100% (1)

- Chhatrapati Shivaji International Airport Integrated Terminal BuildingDocument6 pagesChhatrapati Shivaji International Airport Integrated Terminal BuildingRiddhi PatelNo ratings yet

- Study and Analysis of Cable Stayed Bridges Using STAAD Pro: Nayan K. Janbandhu, Sandeep GaikwadDocument5 pagesStudy and Analysis of Cable Stayed Bridges Using STAAD Pro: Nayan K. Janbandhu, Sandeep GaikwadMananNo ratings yet

- Tandon Consultants InfoDocument41 pagesTandon Consultants Infomitnath100% (1)

- Fender Segmentation in Unmanned Aerial Vehi 2022 International Journal of NaDocument9 pagesFender Segmentation in Unmanned Aerial Vehi 2022 International Journal of NaNguyen Phuc LinhNo ratings yet

- Fuad Fahmi Jurnal IjeatDocument7 pagesFuad Fahmi Jurnal Ijeatbuku lamaNo ratings yet

- Investigation Regarding Bridge Expansion Joints Deterioration in Pakistan and Its Remedial MeasuresDocument6 pagesInvestigation Regarding Bridge Expansion Joints Deterioration in Pakistan and Its Remedial MeasuresAslam KyonNo ratings yet

- Present Status and Technology of Shield Tunneling Method in JapanDocument15 pagesPresent Status and Technology of Shield Tunneling Method in JapanKhuê - 64XE1 Nguyễn TuấnNo ratings yet

- 18 Technical and Economic Analysis of The Life CycleDocument14 pages18 Technical and Economic Analysis of The Life CycleStephen Musenga ChiwamaNo ratings yet

- Full ProjectDocument10 pagesFull ProjectIsmail HussainNo ratings yet

- Suspension BridgeDocument56 pagesSuspension Bridgeritesh chauhanNo ratings yet

- A Review On Design and Analysis of Foot Over Bridge Using Plated Fabricated Steel MemberDocument5 pagesA Review On Design and Analysis of Foot Over Bridge Using Plated Fabricated Steel MemberIJRASETPublicationsNo ratings yet

- The Selection of The International Port Design StaDocument12 pagesThe Selection of The International Port Design StaT. LimNo ratings yet

- Expression of InterestDocument33 pagesExpression of InterestYaredo MessiNo ratings yet

- Construction of Underground Metro Stations and Associated TunnellingDocument7 pagesConstruction of Underground Metro Stations and Associated TunnellingDarshan Lingaraj100% (1)

- The New Engineering Contract - A Promising Start BriefingDocument2 pagesThe New Engineering Contract - A Promising Start BriefingchouszeszeNo ratings yet

- ESTIMATE W SinghbhumDocument315 pagesESTIMATE W Singhbhummarsplanning108No ratings yet

- Pre-Feasibility Desk Study Lamu Port Offshore Energy Industrial ParkDocument11 pagesPre-Feasibility Desk Study Lamu Port Offshore Energy Industrial ParkEric Mwangi NjorogeNo ratings yet

- Optimum Pavement Design For Colombo SoutDocument13 pagesOptimum Pavement Design For Colombo SoutnanesculNo ratings yet

- A Proposed Three-Storey Parking Building For Capiz State University StakeholdersDocument19 pagesA Proposed Three-Storey Parking Building For Capiz State University StakeholdersIrish Calma100% (1)

- Analysis of Cable-Stayed Suspension Hybrid Bridge: (Document Title)Document17 pagesAnalysis of Cable-Stayed Suspension Hybrid Bridge: (Document Title)Nandpal PrashantNo ratings yet

- CONQUASDocument50 pagesCONQUASFrankie Chan100% (3)

- Sachpazis Cantilever Steel Sheetpile Retaining Wall Analysis Design Free Earth Support To Eurocode 7Document14 pagesSachpazis Cantilever Steel Sheetpile Retaining Wall Analysis Design Free Earth Support To Eurocode 7rowatersNo ratings yet

- Folded Plate StructureDocument18 pagesFolded Plate StructureTejaswini50% (2)

- Water Tanks StructuralDesignsDocument55 pagesWater Tanks StructuralDesignsuma venkata ramanaNo ratings yet

- 56 - Venkat - MoRTH 5th Revision Essential Tables For Highway Field Engineers PrintDocument34 pages56 - Venkat - MoRTH 5th Revision Essential Tables For Highway Field Engineers PrintV Venkata Narayana100% (4)

- Building Guide - Pole Barn 2011Document6 pagesBuilding Guide - Pole Barn 2011Jorge SouzaNo ratings yet

- Concrete PropertiesDocument32 pagesConcrete PropertiesEldho CaNo ratings yet

- (13-27) Construction of Extradosed Bridge in The Government PDFDocument8 pages(13-27) Construction of Extradosed Bridge in The Government PDFOanh PhanNo ratings yet

- JumpformDocument19 pagesJumpformAhmad Mukhroji WiratamaNo ratings yet

- Technical Note TN 105 Asphalt Surfacing of Concrete Bridge DecksDocument3 pagesTechnical Note TN 105 Asphalt Surfacing of Concrete Bridge DecksSpiros LicoudisNo ratings yet

- Durability of ConcreteDocument33 pagesDurability of Concreteabdulwahab11No ratings yet

- Civil Engg Site Data CompendiumDocument212 pagesCivil Engg Site Data CompendiumIlancheral NedumaranNo ratings yet

- Concrete Patch HDocument2 pagesConcrete Patch HJohn vincent SalazarNo ratings yet

- A8-2 - Wall TypesDocument1 pageA8-2 - Wall TypesvaleriaNo ratings yet

- Schiedel Chimney SystemsDocument15 pagesSchiedel Chimney SystemsAli ÖzgençNo ratings yet

- New Series 6000Document78 pagesNew Series 6000Kintu MunabangogoNo ratings yet

- T10 Columns PDFDocument2 pagesT10 Columns PDFRutuj ShahNo ratings yet

- Apron Concrete Cracks RepairDocument3 pagesApron Concrete Cracks RepairEric Isidore AgossouNo ratings yet

- Hazrina - ICASET Paper - AIPDocument8 pagesHazrina - ICASET Paper - AIPEhsan WasimNo ratings yet

- Steel Design: Project Job Number EngineerDocument1 pageSteel Design: Project Job Number EngineeronuroztkNo ratings yet

- Sor CivilDocument33 pagesSor CivilYugal Pandey Sonu100% (1)

- Shed Ga FoundationDocument5 pagesShed Ga FoundationDarshit VyasNo ratings yet

- Pre-Engineered Building Design and Its Design ChartsDocument9 pagesPre-Engineered Building Design and Its Design ChartsPavan RajNo ratings yet

- Water Proofing Damp ProofingDocument17 pagesWater Proofing Damp ProofingSalama ShurrabNo ratings yet

- Unit 3: Arches, Lintels and BalconyDocument12 pagesUnit 3: Arches, Lintels and BalconyManjunath Tontanal100% (1)

- Behaviour and Strength of Fully Encased Composite Columns PDFDocument198 pagesBehaviour and Strength of Fully Encased Composite Columns PDFdxzaberNo ratings yet

- Design of ScaffoldingDocument9 pagesDesign of ScaffoldingdfdgggNo ratings yet

- Pow-Entrance Gate and Fencing 1Document12 pagesPow-Entrance Gate and Fencing 1Earl Justin EnriqueNo ratings yet

Development of Highly Efficient Construction Technologies For Super Long Span Bridge

Development of Highly Efficient Construction Technologies For Super Long Span Bridge

Uploaded by

bhavesh.patil20Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Development of Highly Efficient Construction Technologies For Super Long Span Bridge

Development of Highly Efficient Construction Technologies For Super Long Span Bridge

Uploaded by

bhavesh.patil20Copyright:

Available Formats

Engineering, 2013, 5, 629-636

http://dx.doi.org/10.4236/eng.2013.58075 Published Online August 2013 (http://www.scirp.org/journal/eng)

Development of Highly Efficient Construction

Technologies for Super Long Span Bridge

Hee Seok Kim, Young Jin Kim, Won Jong Chin, Hyejin Yoon

Structural Engineering Research Division, Korea Institute of Construction Technology, Goyang-Si, South Korea

Email: lagoon@kict.re.kr

Received June 2, 2013; revised July 2, 2013; accepted July 9, 2013

Copyright © 2013 Hee Seok Kim et al. This is an open access article distributed under the Creative Commons Attribution License,

which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

ABSTRACT

This paper presents highly efficient cable erection equipments and methods related to the construction of super-long-

span bridges, construction technology of high towers and, technology for offshore foundations currently developed

through a R&D on accelerated and cost-saving construction technology for long-span cable bridges to secure our inter-

national competitiveness. In the field of cable erection technology, AS and PPWS equipments for highly efficient erec-

tion of cable longer than 2000 m, world-class clamping bolt tensioning equipment and shape control system for super-

long cable are under development. The technologies developed in the domain of construction of towers are tapered slip

form system for the construction of 400 m high tower, shape and erection precision control of elevated tower and, light-

weight and modular formwork for slip form system. In the domain of foundation construction, remote controlled survey

equipment and analysis system for water-depth of 100 m and depth of 50 m, prediction and evaluation technology of

optimal load carrying capacity and settlement complying with international standard and, highly efficient hybrid foun-

dation construction technology suitable for ground acceleration of 0.5 g and deep soft soil are currently developed.

Keywords: AS Equipment; PPWS Equipment; Slip Form System; Large Scale Foundation

1. Introduction with the necessity to develop technologies with the scale

and organization of a national project have been empha-

The globe has become borderless with the emergence of

sized. In response to such needs, the “Super-Long-Span

interregional, cross-border and intercontinental projects

like the Asian Highway. In the worldwide trend for tech- Bridge Project” was selected as one of the 10 flagship

nological independence, the market for long-span cable- R&BD projects (VC-10) of the Ministry of Land, Trans-

supported bridge requiring high-level of expertise offers portation and Maritime Affairs of Korea. Experts in re-

promising prospects. Until 1990s, the long-span cable- levant fields are today conducting research in the form of

supported bridge market was concentrated in advanced a consortium.

countries like Europe, USA and Japan but, at the en- The “Super-Long-Span Bridge R&D Center” launched

trance of the Post BRICs era, new and active market has to secure self-reliant and independent core technologies

opened in China, Southeast Asia and South America. Ac- for long-span cable-supported bridge is performing re-

cordingly, securing technology and cost-competitiveness search through 4 core projects during a period of 8 years

will widen our opportunities in penetrating this new (2008-2015). Core Project 1 focuses on the development

overseas market. of engineering technologies, Core Project 2 on the de-

The cable-supported bridge stock in Korea is com- velopment of strategic materials and corresponding ap-

posed by 12 bridges. This stock will enlarge in the near plication technologies, Core Project 3 on the develop-

future with 20 bridges under construction or planning. ment of construction technology, and Core Project 4 on

Our domestic market is thus extremely demanding but the support of the test bed. Among them, Core Project 3

the independence of our technology remains still partial. led by the Korea Institute of Construction Technology

Accordingly, the necessity to secure quickly world- targets highly-efficient and cost-saving construction me-

leading technology level through the rapid acquisition of thods and equipments to provide footholds for our ad-

construction technology and dedicated R&D together vance into foreign market.

Copyright © 2013 SciRes. ENG

630 H. S. KIM ET AL.

2. Long-Span Bridge Market and Prospect summing up the bridges currently under construction

in Korea and Overseas with those under planning represents a market of about 9

trillion KRW. Especially, Korea will occupy approxi-

The template is used to format your paper and style the

mately 20% of the worldwide long-span bridge market in

text. All margins, column widths, line spaces, and text

2000s, which will rank at the second place after China

fonts are prescribed; please do not alter them. You may

note peculiarities. For example, the head margin in this [1].

template measures proportionately more than is custom-

ary. This measurement and others are deliberate, using 3. Development of Highly Efficient

specifications that anticipate your paper as one part of the Construction Technology for Super Long

entire journals, and not as an independent document. Span Bridge

Please do not revise any of the current designations. The cost competitiveness of long-span bridges can be se-

A review of the construction trend of long-span bridges cured in terms of direct cost saving and reduction of in-

overseas reveals a construction boom in the late 1990s direct social costs by shortening the construction period

followed by slight reduction until 2010. This trend is ex- and thus moving up the entrance in service of the bridge.

pected to regain activity after 2011. The total market The shortening of the construction period can be achi-

volume of long-span bridges overseas tended to decrease eved not only by means of optimized process manage-

after 1990s but represents now 10 - 30 trillion KRW as of ment but also by improving the erection method in cor-

year 2010. Forecast of the long-span bridges planned relation with the construction equipment. To that goal,

after 2011 previews 150 trillion KRW (Figure 1). The

this research is subdivided into three domains that are

areas sharing the largest market are Extreme Asia (China,

cable erection, tower erection and construction of foun-

Japan) and Europe. USA and Southeast Asia also consti-

dation to acquire accelerated and cost saving construction

tute a steady market.

technology for long-span cable-supported bridge (Figure

The long-span bridge market in Korea represented

3). The program dedicated to cable erection undertakes

merely a volume of 800 billion KRW in 1990s but grew

up to 4.5 trillion KRW in 2000s to reach 6.7 trillion the development of AS (air spinning) and PPWS (prefab-

KRW considering only the results available currently in- ricated parallel wire strand) equipments for highly effi-

cluding Yi Sun-Shin Bridge with central span of 1545 m cient erection of cable longer than 2000 m, world-class

actually under construction (Figure 2). Accordingly, clamping bolt tensioning equipment and shape control

system for super-long cable in order to develop highly

1600

efficient cable erection equipment and method for super-

1400 long-span bridges. In the domain of tower erection, ta-

1200 pered slipform system for the construction of 400 m high

(1,000 billion KRW)

Construction Cost

1000 tower, shape and erection precision control of elevated

800

tower and, lightweight and modular formwork for slip-

600

form system are developed to secure accelerated con-

struction for elevated towers. In the domain of founda-

400

tion construction, remote controlled survey equipment

200

and analysis system for water-depth of 100 m and depth

0

1981~1990 1991~2000 2001~2010 2011~

of 50 m, prediction and evaluation technology of optimal

load carrying capacity and settlement complying with

Figure 1. Volume change of long-span bridge market in for- international standard and, highly efficient hybrid foun-

eign countries [1].

dation construction technology suitable for ground ac-

80 40 celeration of 0.5 g and deep soft soil are currently devel-

66.9 oped to realize cost saving construction technology for

Number of Construction Field

60 30 large scale foundations.

(1,000 billion KRW)

Construction Cost

44.5

40 20

3.1. Development of Highly Efficient Cable

Erection Equipment and Method

20 10 The method for the efficient construction of super long

8.1 span suspension bridge can be classified into AS and

1.1

0 0

PPWS methods according to the method chosen for the

1981~1990 1991~2000 2001~2010 2011~ erection of the main cables. Need is also for a system

Figure 2. Evolution of long-span bridge market volume in enabling sag measurement, tension control and manage-

Korea [1]. ment of construction error to control the shape of the

Copyright © 2013 SciRes. ENG

H. S. KIM ET AL. 631

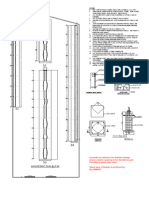

Figure 3. TRM of core project 3.

main cables during construction. tion of the main cable are conducted automatically by

(1) Development of AS erection equipment and me- measuring and controlling the shape by strand unit [2].

thod The AS erection equipment includes the catwalk sys-

The AS method processes as follows: a steel wire with tem corresponding to an aerial workshop, the reel fabri-

diameter of about 5 mm coiled around a reel is looped on cation equipment for the continuous operation of the

to the spinning wheel on site; the strand is formed by hauled wire, the hauling system for hauling the wire and

repeatedly traveling the spinning wheel between the an- introducing constant tension in the wire, the spinning

chorages located at both ends of the bridge; once the de- system and cable shaping system [3,4].

sired amount of strands has been spun, the strands are (2) Development of PPWS erection equipment and

packed together to complete the main cable (Figure 4). method

The spun wire is tensioned with a tension force smaller The PPWS erection method proceeds as follows: the

than that in free-hang state. Throughout the motion of the strands prefabricated in factory by packing the wires dis-

spinning wheel, the wire is automatically loaded in the posed in parallel are transported after having been coiled

cable formers disposed at regular intervals along the around a reel and, the strands are hauled one by one on

catwalk. After the formation of the strand according to site (Figure 5). The PPWS erection equipment includes

the repeated traveling of the wheel, the tasks for the erec- the catwalk system corresponding to an aerial workshop,

Copyright © 2013 SciRes. ENG

632 H. S. KIM ET AL.

Figure 4. Erection equipment for AS cable.

Figure 5. Erection equipment for PPWS cable.

hauling system for hauling the strands, unreeler, carrier rial can be supplied, the erection engineering and equip-

and cable shaping system. Compared to the traditional ment are relying completely on foreign support. Accord-

AS method, the PPWS is less sensitive to the effect of ingly, acquiring domestic and independent engineering

wind during the erection, requires shortened construction technology for PPWS cable erection will minimize the

period and simpler equipment. However, since the mar- drain of erection costs and equipment into foreign coun-

ket producing PPWS cable is concentrated in China and tries and promote our opportunity and position when

Japan, supplying materials is difficult and, even if mate- participating to foreign suspension bridge projects.

Copyright © 2013 SciRes. ENG

H. S. KIM ET AL. 633

(3) Development of cable shape control system in sus- trol of the tower and, the design and fabrication of light-

pension bridge weight form system.

The cable shape control system in suspension bridge is (1) Development of design and fabrication technolo-

necessary to achieve the target cable profile established gies for tapered slipform

during design at completion of the suspension bridge. The towers of long-span bridges generally present ta-

The shape control of the cable is defined as the series of pered section in which the section changes gradually

processes involving the precise measurement of the er- from the top of the foundation to the top of the tower.

rors caused by the effects of temperature, wind speed and When the section of the tower varies with respect to the

hauling system during erection, the construction errors height, the slipform system should be designed to be

introduced by the worker and, the shape control to realize adaptable. The tapered slipform system is composed by a

the target shape for the erected cables. Since the span of concrete silo for the placing of concrete, a top-deck, a

suspension bridge reaches hundreds of meters to several lattice truss, the yoke, the ascending device, the working-

kilometers, the latest measurement devices like conven- deck, the hanging-deck and the form panel. Research to

tional laser displacement sensor or sensors using GPS optimize and improve the structure of each of these com-

together with integrated system enabling to consider er- ponents has been conducted [6,7].

rors introduced by the refraction of light due to differ- (2) Design of slipform control system

ence in the air density and curvature of the earth are re- In order to ascend the slipform system without eccen-

quired for the precise measurement of the shape [5]. tricity, the capacity of the hydraulic pump must be de-

termined to transmit simultaneously the hydraulic pres-

3.2. Development of Accelerated Erection sure to several jacks. In addition, the hydraulic manifold

Technology for Elevated Tower and hydraulic hose should also be constituted and oper-

The major movable form systems for the erection of the ated suitably. However, the current method in which the

concrete towers of super-long-span bridges are the ACS hydraulic jack is operated by visual verification presents

(Auto Climbing form System) and the slipform system, limitation for precise control. Accordingly, an automated

which differ by their operational methods. The slipform hydraulic system enabling to ascend or descend precisely

method, also called sliding method, erects the structure the jack should be developed. Moreover, when the ele-

vertically or horizontally without construction joint and vated tower is erected using slipform system, errors in

with a uniform shape. For elevated towers, this method the verticality occur because of deformation of the form

proceeds by ascending vertically the yoke leg and form due to eccentric loading of the hoop reinforcement wait-

panel using a vertical jack supported embedded inside ing for assembling at the top of the slipform or deforma-

the concrete body of the tower. During the ascension, tion of the form due to partial ascension of the form.

concrete is placed continuously. A total of 5 processes Therefore, an integrated shape control system for ele-

(assembling of form, assembling of rebar, concrete plac- vated towers must be developed. This system should in-

ing, curing, removal of form) are conducted repeatedly clude positioning and shape control for the construction

and simultaneously, which make this method signifi- quality improvement of slipform system, sensors for the

cantly shorter than other methods even in view of the efficiency of error calibration, analysis and processing of

period needed for installation and dismantlement (Figure the measurement of each sensor, and control of tapered

6). The core technologies of the slipform method are the slipform for the minimization of errors in the verticality

design and fabrication of a slipform system adaptable to and position (Figure 7).

tapered section, the automatic ascension of the slipform, (3) Design and fabrication technology of lightweight

the precise measurement of the position, the shape con- form system

The conventional slipform systems mostly composed

by steel and wood present difficulties in their assembling,

installation and quality control regard to the construction

characteristics of super-long-span bridges in offshore

areas. In the case of the application of lightweight form

system with significantly reduced weight and offering

easy moldability, the device itself can be maintained in

satisfactory state and the management of the erection

equipment can be more effective. Accordingly, research

is dedicated to the minimization of the weight of the slip-

form by using lightweight material and the modulariza-

tion of the components so as to adapt efficiently with

Figure 6. Tower erection using slipform. irregular section and shorten effectively the time needed

Copyright © 2013 SciRes. ENG

634 H. S. KIM ET AL.

Figure 7. Smart control of slip-form system.

for the fabrication and assembling of the form (Figure by soft soil, deep water and rapid current drift. This im-

8). plies that tremendous costs will be required for the con-

struction of the offshore foundations. Therefore, research

3.3. Development of Cost-Saving Large Scale is led to develop cost-saving hybrid foundations enabling

Foundations to overcome unfavorable soil conditions of the towers.

(1) Development of submarine soil survey equipment

The towers of super-long-span bridges are mostly located

and analysis system

offshore. In order to guarantee the stability of such struc-

Most of the submarine soil surveys performed to date

tures, priority should be given to securing technologies

for the design and erection of the foundation structure of

for the survey, design and construction under deep water

sea-crossing bridges in Korea applied common inshore

and soft soil conditions. Large scale offshore foundations

are generally designed using conservative soil parameters boring equipment and in-situ equipment using low water-

due to the difficulty in surveying the offshore soil. Ac- depth barge at depth around 20 m. However, the tower

cordingly, improving the reliability and economic effi- foundations of super-long-span bridges are likely to be

ciency of offshore foundations by computing the design erected at depth deeper than 20 m, which means that the

soil parameters based on precise soil survey results is conventional barge will lose efficiency. Accordingly,

required. In addition, the precise forecast of the bearing economically efficient and effective submarine soil sur-

capacity and settlement of offshore foundations is pri- vey equipment should be developed to achieve efficient

mordial for the improvement of the economic efficiency. design and construction of large scale offshore founda-

Since the evaluation of the bearing capacity by in-situ tions. The developed system is a floating type unmanned

loading test is extremely costly, need is to develop an automated boring equipment enabling to derive more

economically efficient test method enabling the evalua- than 3 design parameters per depth down to a depth of 50

tion of the bearing capacity. Moreover, the recent occur- m or water-depth of 100 m (Figure 9).

rence of large scale earthquakes in China and Japan to- (2) Development of forecast and evaluation techniques

gether with the increase of seismic events in the marine of the bearing capacity of large offshore foundations

areas around Korea also emphasizes the necessity to de- Predicting exactly the bearing capacity and settlement

velop strong seismic offshore foundations. A large por- is primordial to secure economic efficiency of large scale

tion of the long-span bridges planned in the western and offshore foundations. Since the soil characteristics in

southern coasts of Korea will be erected in areas featured Korea and overseas are extremely different, the computa-

Copyright © 2013 SciRes. ENG

H. S. KIM ET AL. 635

Figure 8. Optimizing & minimizing the slip-form system.

shore foundations. In addition, the increase of strait-

crossing large scale marine bridge projects requires the

installation of tower foundations in deep depths. Such

situation implies the need for diverse methods enabling

to construct economically the foundations of large scale

bridges. Accordingly, seismic isolation system resisting

to ground acceleration of 0.5 g, foundations using walled

steel pipe piles applicable to soft soils at depth of 100 m

and highly efficient hybrid foundation applicable to wa-

ter depth exceeding 50 m are developed to prepare for

deep depths, soft soils and earthquakes.

Figure 9. Conceptual drawing of floating detection equip-

ment for submarine soil survey. 4. Conclusions

This paper presented the development of construction

tion of the bearing capacity fitted to the domestic char-

technologies for long-span cable-supported bridges ena-

acteristics is necessary together with the development of

bling accelerated construction and coast saving in order

LRFD design technology. Besides, need is for research

to secure our international competitiveness. The follow-

on the settlement analysis considering the pile-founda- ing effects are expected through the achievement of these

tion plate-pile interaction of the tower foundation in objectives.

which piles are disposed in group. Moreover, need is also 1) There is only 2 to 3 highly efficient cable erection

to develop bi-directional high-pressure loading test de- equipment worldwide, which implies a complete depen-

vice to secure the exactness and economic efficiency of dence on foreign technology in this field. Achieving our

the loading test performed to verify the load bearing ca- objectives will provide substitute to foreign import and

pacity of the large scale foundations constructed off- allow us to secure a leading or competitive position when

shore. participating in foreign projects through self-relying tech-

(3) Development of highly efficient hybrid foundation nology.

technology 2) In the field of tower erection, the localization of

The continuous lengthening of the span of cable-sup- automated slipform system will solve the delicate tech-

ported bridges results in the increase of the scale of off- nical problem of erecting towers higher than 400 m and

Copyright © 2013 SciRes. ENG

636 H. S. KIM ET AL.

promote economically efficient erection of concrete tower. for Super-Long-Span Bridge R&BD Project,” 2008.

Significant reduction of the construction cost will also be [2] H. S. Choi and J. H. Kim, “Construction Method of Main

realized through accelerated and effective construction Cable for Suspension Bridges,” Magazine and Journal of

owing to rapid decision-making of the calibration of con- Korean Society of Steel Construction, Vol. 20, No. 2,

2008, pp. 79-86.

struction errors, eased quality control of the structure and

precise construction management technology. [3] M. J. Ryall, G. A. R. Parke and J. E. Harding, “The Man-

3) In the field of foundation erection, the results of ual of Bridge Engineering,” Thomas Telford Ltd., 2000.

R&D will secure technological level superior or equiva- [4] Y. Yasutsugu and F. Rouvillain, “Cable Construction of

lent to that of advanced countries, achieve efficient de- the Great Belt East Bridge,” Foundation of Bridge, Vol.

97, No. 5, 1997, pp. 15-22.

sign of foundation structures as well as cost-saving con-

struction technology and will be applicable to the erec- [5] J. H. Moon and S. P. Chang, “Shape Adjustment of the

Main-Cable of Suspension Bridges,” Magazine and Jour-

tion of the foundations of large scale sea-crossing bridges

nal of Korean Society of Steel Construction, Vol. 20, No.

and special structures. 2, 2008, pp. 47-53.

[6] Jinsung Construction Co. Ltd., “Erection and Quality

5. Acknowledgements Control Using Slip-Form System,” 2009.

This work was supported by the “Development of accel- [7] D. Thomas, “Slipform Works for Pylons—Machang

erated construction technologies for high pylons” project Bridge,” GBG.

of the Super Long Span Bridge R&D Program. The au-

thors express their gratitude for the support.

REFERENCES

[1] Korea Institute of Construction & Transportation Tech-

nology Evaluation and Planning, “Detailed Planning Study

Copyright © 2013 SciRes. ENG

You might also like

- Cpci Design Manual 5 - Secured - 10-20-2017Document732 pagesCpci Design Manual 5 - Secured - 10-20-2017atiqur_rehman07100% (5)

- Analysis and Design of Flyover: Kavitha.N, Jaya Kumari.r, Jeeva.K, Bavithra.K, Kokila.KDocument5 pagesAnalysis and Design of Flyover: Kavitha.N, Jaya Kumari.r, Jeeva.K, Bavithra.K, Kokila.KjophinNo ratings yet

- CHAPTER IDocument4 pagesCHAPTER Imaddih gayeNo ratings yet

- DsgnConstr CableSuppBridgesDocument20 pagesDsgnConstr CableSuppBridgescaptain_tamNo ratings yet

- 41 Ijmtst0703117Document8 pages41 Ijmtst0703117Myo Htet AungNo ratings yet

- T02 01 Feng - Gao - Zheng - GNP2020Document11 pagesT02 01 Feng - Gao - Zheng - GNP2020Kenan KajosevicNo ratings yet

- StructuralAnalysis Sutong BridgeDocument10 pagesStructuralAnalysis Sutong BridgenvngonNo ratings yet

- 2000 Present Situation and Development of BridgesDocument16 pages2000 Present Situation and Development of BridgesStevan Zimbi IvkovicNo ratings yet

- 1717 Two International Finance Centre PDFDocument9 pages1717 Two International Finance Centre PDFBatoul ObeidNo ratings yet

- Design and Construction of Simple Beam Bridges For High-Speed Rails in China: Standardization and IndustrializationDocument9 pagesDesign and Construction of Simple Beam Bridges For High-Speed Rails in China: Standardization and IndustrializationAashish kumarNo ratings yet

- Bridge and Flyover Construction: A ReviewDocument4 pagesBridge and Flyover Construction: A ReviewBhat TalhaNo ratings yet

- Time and Cost Comparision of PSC and RCCDocument4 pagesTime and Cost Comparision of PSC and RCCmahakNo ratings yet

- Iricen Journal Sept. 2008Document52 pagesIricen Journal Sept. 2008js kalyana ramaNo ratings yet

- A Review Paper On "Comparative Analysis & Design of RCC & PSC Girder & Feasibility"Document4 pagesA Review Paper On "Comparative Analysis & Design of RCC & PSC Girder & Feasibility"Abhishek nirmaleNo ratings yet

- Cost AnalysisDocument13 pagesCost AnalysisReaditReaditNo ratings yet

- Introduction: Recent Structures in India: B. C. RoyDocument6 pagesIntroduction: Recent Structures in India: B. C. RoyKishan KumarNo ratings yet

- Optimal Submarine Cable Path Planning and Trunk-and-Branch Tree Network Topology DesignDocument11 pagesOptimal Submarine Cable Path Planning and Trunk-and-Branch Tree Network Topology DesignFERNANDO HUGO HUAMAN ARANCIBIANo ratings yet

- Analysis and Design of Box Underpass Bridge Using SoftwareDocument4 pagesAnalysis and Design of Box Underpass Bridge Using SoftwareEditor IJTSRDNo ratings yet

- Life Cycle Costing System Rail Transit Construction ProjectsDocument11 pagesLife Cycle Costing System Rail Transit Construction ProjectsjayaramanrathnamNo ratings yet

- Bridge Erection Techniques and Construction EquipmDocument2 pagesBridge Erection Techniques and Construction EquipmAbderrahmane SaidNo ratings yet

- Modular For High Rise in KoreaDocument10 pagesModular For High Rise in KoreaYunita MentariNo ratings yet

- Steel Bridge Design Brief 2012-2013Document22 pagesSteel Bridge Design Brief 2012-2013cr231181No ratings yet

- Crossrail Sprayed Concrete LiningsDocument20 pagesCrossrail Sprayed Concrete LiningsDEBASIS BARMANNo ratings yet

- Detailed Design of The Padma Multipurpose Bridge, Bangladesh - AnDocument14 pagesDetailed Design of The Padma Multipurpose Bridge, Bangladesh - AnMehtab Hussain SyedNo ratings yet

- 03 11 2015Document12 pages03 11 2015Yuvaraj DhandapaniNo ratings yet

- FOUNDATION DESIGN & CONSTRUCTION IN HONG KONG - PRESENT & BEYOND, Daman Lee HK-Taiwan 2005Document28 pagesFOUNDATION DESIGN & CONSTRUCTION IN HONG KONG - PRESENT & BEYOND, Daman Lee HK-Taiwan 2005M Mushanif MuktiNo ratings yet

- Padma Bridge DesignDocument14 pagesPadma Bridge DesignAbdul Majid KhanNo ratings yet

- Research On Key Construction Technology of UrbanDocument6 pagesResearch On Key Construction Technology of UrbanSOFIA NABILAH MOHAMAD ZAHIDNo ratings yet

- Stonecutters Bridge 1Document9 pagesStonecutters Bridge 1raisa ehsanNo ratings yet

- Optimisation and Analysis of CostDocument4 pagesOptimisation and Analysis of CostJustin JohnsonNo ratings yet

- Submarine Cable Path Planning Based On Weight Selection of Design ConsiderationsDocument14 pagesSubmarine Cable Path Planning Based On Weight Selection of Design ConsiderationsFilho EngenheiroNo ratings yet

- Analysis and Design of Reinforced Concrete Solid Slab BridgeDocument6 pagesAnalysis and Design of Reinforced Concrete Solid Slab BridgeEditor IJTSRDNo ratings yet

- Steel Concrete Composite Structures IntroductionDocument2 pagesSteel Concrete Composite Structures IntroductionUsha EngineeringNo ratings yet

- Design of The Dubai Metro Light Rail Viaducts SubstructureDocument12 pagesDesign of The Dubai Metro Light Rail Viaducts SubstructureUvie M. Ptwolan100% (2)

- Irjet V8i12174Document4 pagesIrjet V8i12174baskar_saNo ratings yet

- Recent Trends in Design and Construction of Yovers: January 2015Document5 pagesRecent Trends in Design and Construction of Yovers: January 2015sai vemunuriNo ratings yet

- Fact Sheet: Basis of DesignDocument4 pagesFact Sheet: Basis of DesignHiddenDNo ratings yet

- Recent Trends in Design and Construction of Flyovers: January 2015Document5 pagesRecent Trends in Design and Construction of Flyovers: January 2015Neil Myco Duterte Sarsalejo100% (1)

- Chhatrapati Shivaji International Airport Integrated Terminal BuildingDocument6 pagesChhatrapati Shivaji International Airport Integrated Terminal BuildingRiddhi PatelNo ratings yet

- Study and Analysis of Cable Stayed Bridges Using STAAD Pro: Nayan K. Janbandhu, Sandeep GaikwadDocument5 pagesStudy and Analysis of Cable Stayed Bridges Using STAAD Pro: Nayan K. Janbandhu, Sandeep GaikwadMananNo ratings yet

- Tandon Consultants InfoDocument41 pagesTandon Consultants Infomitnath100% (1)

- Fender Segmentation in Unmanned Aerial Vehi 2022 International Journal of NaDocument9 pagesFender Segmentation in Unmanned Aerial Vehi 2022 International Journal of NaNguyen Phuc LinhNo ratings yet

- Fuad Fahmi Jurnal IjeatDocument7 pagesFuad Fahmi Jurnal Ijeatbuku lamaNo ratings yet

- Investigation Regarding Bridge Expansion Joints Deterioration in Pakistan and Its Remedial MeasuresDocument6 pagesInvestigation Regarding Bridge Expansion Joints Deterioration in Pakistan and Its Remedial MeasuresAslam KyonNo ratings yet

- Present Status and Technology of Shield Tunneling Method in JapanDocument15 pagesPresent Status and Technology of Shield Tunneling Method in JapanKhuê - 64XE1 Nguyễn TuấnNo ratings yet

- 18 Technical and Economic Analysis of The Life CycleDocument14 pages18 Technical and Economic Analysis of The Life CycleStephen Musenga ChiwamaNo ratings yet

- Full ProjectDocument10 pagesFull ProjectIsmail HussainNo ratings yet

- Suspension BridgeDocument56 pagesSuspension Bridgeritesh chauhanNo ratings yet

- A Review On Design and Analysis of Foot Over Bridge Using Plated Fabricated Steel MemberDocument5 pagesA Review On Design and Analysis of Foot Over Bridge Using Plated Fabricated Steel MemberIJRASETPublicationsNo ratings yet

- The Selection of The International Port Design StaDocument12 pagesThe Selection of The International Port Design StaT. LimNo ratings yet

- Expression of InterestDocument33 pagesExpression of InterestYaredo MessiNo ratings yet

- Construction of Underground Metro Stations and Associated TunnellingDocument7 pagesConstruction of Underground Metro Stations and Associated TunnellingDarshan Lingaraj100% (1)

- The New Engineering Contract - A Promising Start BriefingDocument2 pagesThe New Engineering Contract - A Promising Start BriefingchouszeszeNo ratings yet

- ESTIMATE W SinghbhumDocument315 pagesESTIMATE W Singhbhummarsplanning108No ratings yet

- Pre-Feasibility Desk Study Lamu Port Offshore Energy Industrial ParkDocument11 pagesPre-Feasibility Desk Study Lamu Port Offshore Energy Industrial ParkEric Mwangi NjorogeNo ratings yet

- Optimum Pavement Design For Colombo SoutDocument13 pagesOptimum Pavement Design For Colombo SoutnanesculNo ratings yet

- A Proposed Three-Storey Parking Building For Capiz State University StakeholdersDocument19 pagesA Proposed Three-Storey Parking Building For Capiz State University StakeholdersIrish Calma100% (1)

- Analysis of Cable-Stayed Suspension Hybrid Bridge: (Document Title)Document17 pagesAnalysis of Cable-Stayed Suspension Hybrid Bridge: (Document Title)Nandpal PrashantNo ratings yet

- CONQUASDocument50 pagesCONQUASFrankie Chan100% (3)

- Sachpazis Cantilever Steel Sheetpile Retaining Wall Analysis Design Free Earth Support To Eurocode 7Document14 pagesSachpazis Cantilever Steel Sheetpile Retaining Wall Analysis Design Free Earth Support To Eurocode 7rowatersNo ratings yet

- Folded Plate StructureDocument18 pagesFolded Plate StructureTejaswini50% (2)

- Water Tanks StructuralDesignsDocument55 pagesWater Tanks StructuralDesignsuma venkata ramanaNo ratings yet

- 56 - Venkat - MoRTH 5th Revision Essential Tables For Highway Field Engineers PrintDocument34 pages56 - Venkat - MoRTH 5th Revision Essential Tables For Highway Field Engineers PrintV Venkata Narayana100% (4)

- Building Guide - Pole Barn 2011Document6 pagesBuilding Guide - Pole Barn 2011Jorge SouzaNo ratings yet

- Concrete PropertiesDocument32 pagesConcrete PropertiesEldho CaNo ratings yet

- (13-27) Construction of Extradosed Bridge in The Government PDFDocument8 pages(13-27) Construction of Extradosed Bridge in The Government PDFOanh PhanNo ratings yet

- JumpformDocument19 pagesJumpformAhmad Mukhroji WiratamaNo ratings yet

- Technical Note TN 105 Asphalt Surfacing of Concrete Bridge DecksDocument3 pagesTechnical Note TN 105 Asphalt Surfacing of Concrete Bridge DecksSpiros LicoudisNo ratings yet

- Durability of ConcreteDocument33 pagesDurability of Concreteabdulwahab11No ratings yet

- Civil Engg Site Data CompendiumDocument212 pagesCivil Engg Site Data CompendiumIlancheral NedumaranNo ratings yet

- Concrete Patch HDocument2 pagesConcrete Patch HJohn vincent SalazarNo ratings yet

- A8-2 - Wall TypesDocument1 pageA8-2 - Wall TypesvaleriaNo ratings yet

- Schiedel Chimney SystemsDocument15 pagesSchiedel Chimney SystemsAli ÖzgençNo ratings yet

- New Series 6000Document78 pagesNew Series 6000Kintu MunabangogoNo ratings yet

- T10 Columns PDFDocument2 pagesT10 Columns PDFRutuj ShahNo ratings yet

- Apron Concrete Cracks RepairDocument3 pagesApron Concrete Cracks RepairEric Isidore AgossouNo ratings yet

- Hazrina - ICASET Paper - AIPDocument8 pagesHazrina - ICASET Paper - AIPEhsan WasimNo ratings yet

- Steel Design: Project Job Number EngineerDocument1 pageSteel Design: Project Job Number EngineeronuroztkNo ratings yet

- Sor CivilDocument33 pagesSor CivilYugal Pandey Sonu100% (1)

- Shed Ga FoundationDocument5 pagesShed Ga FoundationDarshit VyasNo ratings yet

- Pre-Engineered Building Design and Its Design ChartsDocument9 pagesPre-Engineered Building Design and Its Design ChartsPavan RajNo ratings yet

- Water Proofing Damp ProofingDocument17 pagesWater Proofing Damp ProofingSalama ShurrabNo ratings yet

- Unit 3: Arches, Lintels and BalconyDocument12 pagesUnit 3: Arches, Lintels and BalconyManjunath Tontanal100% (1)

- Behaviour and Strength of Fully Encased Composite Columns PDFDocument198 pagesBehaviour and Strength of Fully Encased Composite Columns PDFdxzaberNo ratings yet

- Design of ScaffoldingDocument9 pagesDesign of ScaffoldingdfdgggNo ratings yet

- Pow-Entrance Gate and Fencing 1Document12 pagesPow-Entrance Gate and Fencing 1Earl Justin EnriqueNo ratings yet