Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

5 viewsService Loop Incl Manifold(s) in Derrick

Service Loop Incl Manifold(s) in Derrick

Uploaded by

mhmdtrainingService loop

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Check List For Pre Commissioning of MV SwitchgearDocument2 pagesCheck List For Pre Commissioning of MV Switchgeararuna100% (10)

- Wahl Deluxe Rechargeable Trimmer Model 9865 1401 Groomer Ear Nose Eyebrow Users Guide Owners ManualDocument9 pagesWahl Deluxe Rechargeable Trimmer Model 9865 1401 Groomer Ear Nose Eyebrow Users Guide Owners ManualGreg Johnson100% (1)

- Project Report On MS Pipe and TubeDocument9 pagesProject Report On MS Pipe and TubeEIRI Board of Consultants and PublishersNo ratings yet

- 1 UL SEVO Flex Manual PDFDocument64 pages1 UL SEVO Flex Manual PDFHarshith KunjathurNo ratings yet

- Maneuvering Diagram With ExplanationDocument8 pagesManeuvering Diagram With ExplanationArun S100% (2)

- Conmaco 385 Winch ManualDocument44 pagesConmaco 385 Winch ManualdarioNo ratings yet

- Opencv 4.X Cheat Sheet (Python Version) : FilteringDocument2 pagesOpencv 4.X Cheat Sheet (Python Version) : FilteringMinh NguyễnNo ratings yet

- Swivel & Main ShaftDocument2 pagesSwivel & Main ShaftmhmdtrainingNo ratings yet

- Travelling Block AdaptorDocument1 pageTravelling Block AdaptormhmdtrainingNo ratings yet

- Climaveneta BRATDocument38 pagesClimaveneta BRATm.machelskiNo ratings yet

- Pre-Commissioning Check List Form Switchgear-General: October 2019Document3 pagesPre-Commissioning Check List Form Switchgear-General: October 2019xchannel28No ratings yet

- PrecommissioningSwitchgear GeneralDocument3 pagesPrecommissioningSwitchgear GeneralPeter IyereNo ratings yet

- MP Misc 255 April 10 Emd CommissioningDocument6 pagesMP Misc 255 April 10 Emd CommissioningmailbkraoNo ratings yet

- Blasting PaintingDocument3 pagesBlasting PaintingAthirah AkhmaNo ratings yet

- Eot Ibl Crane Yearly ChecksheetDocument3 pagesEot Ibl Crane Yearly ChecksheetAmit ThakurNo ratings yet

- Climaveneta i-KIR2-Technical-Installation-ManualDocument68 pagesClimaveneta i-KIR2-Technical-Installation-ManualbojanNo ratings yet

- Abbott i1000SR - PM ChecklistDocument7 pagesAbbott i1000SR - PM Checklistاكرم امينNo ratings yet

- Eot Crane Monthly ChecksheetDocument4 pagesEot Crane Monthly ChecksheetAmit ThakurNo ratings yet

- Substation Equipment MaintenanceDocument15 pagesSubstation Equipment MaintenanceDr. R. SharmaNo ratings yet

- Chapter 5: Checking and Maintaining Ultrasound EquipmentDocument8 pagesChapter 5: Checking and Maintaining Ultrasound EquipmentUmar DhaniNo ratings yet

- Checklist 16 Blasting and Painting Including Use of EtcDocument3 pagesChecklist 16 Blasting and Painting Including Use of EtcFatin ZulkifliNo ratings yet

- 15b17b Umeng0400 PDFDocument20 pages15b17b Umeng0400 PDFkishore_bulli6666No ratings yet

- FM-OHS-1700-30 Pre Use Daily Weekly G20 Crane InspectionDocument2 pagesFM-OHS-1700-30 Pre Use Daily Weekly G20 Crane InspectiondavidburkepsNo ratings yet

- Samsung TV Service Manual PDFDocument98 pagesSamsung TV Service Manual PDFali83No ratings yet

- Method Statement For MV Power Cables & Accessories InstallationDocument2 pagesMethod Statement For MV Power Cables & Accessories InstallationAdil Hasanov100% (1)

- CRS SEC - 10632 - Warranty Inspection Procedure For TransformersDocument2 pagesCRS SEC - 10632 - Warranty Inspection Procedure For TransformersKhaja SayeedNo ratings yet

- Check List For: Installation of Fahu: Project Name & LogosDocument2 pagesCheck List For: Installation of Fahu: Project Name & LogosSamer AliNo ratings yet

- Safety & Special Instructions:: Preventive Maintenance Checklist E09H - Automatic Transfer SwitchDocument2 pagesSafety & Special Instructions:: Preventive Maintenance Checklist E09H - Automatic Transfer SwitchEdward SchenkNo ratings yet

- CRS SEC - 10657 - Warranty Inspection Procedures For Vacuum SkidsDocument3 pagesCRS SEC - 10657 - Warranty Inspection Procedures For Vacuum SkidsKhaja SayeedNo ratings yet

- Samsung p2050 p2250 p2350 SM PDFDocument47 pagesSamsung p2050 p2250 p2350 SM PDFCaim MarmolNo ratings yet

- PrecommissioningSwitchgear GeneralDocument3 pagesPrecommissioningSwitchgear GeneralSatish ReddyNo ratings yet

- Clamp On HIOKI 3286B981 - 13Document84 pagesClamp On HIOKI 3286B981 - 13andhangsNo ratings yet

- Dewatering Pump ChecklistDocument1 pageDewatering Pump ChecklistMD Abdullah100% (1)

- High Voltage Switchgear: Technical Data Schedule (TDS) - Guidance Note E06 ElectricalDocument3 pagesHigh Voltage Switchgear: Technical Data Schedule (TDS) - Guidance Note E06 Electrical20082012No ratings yet

- 5-Year Maintenance On Hydra RackerDocument2 pages5-Year Maintenance On Hydra Rackermohamed hamedNo ratings yet

- Globe Valve Inspection and Functionality Test Check Sheet - SafetyCultureDocument36 pagesGlobe Valve Inspection and Functionality Test Check Sheet - SafetyCulturenavidNo ratings yet

- Samsung 2033hd Chassis Ls20cfvkfen SM PDFDocument70 pagesSamsung 2033hd Chassis Ls20cfvkfen SM PDFGoce TrajanovNo ratings yet

- Vdocuments - MX Moduspec-ChecklistDocument64 pagesVdocuments - MX Moduspec-Checklistmostafa bahnasNo ratings yet

- 1w Mech Mob Crane-Hyd Insp. Maint. 15tonDocument18 pages1w Mech Mob Crane-Hyd Insp. Maint. 15tonebonilla88No ratings yet

- Accurate: User and Maintenance ManualDocument28 pagesAccurate: User and Maintenance ManualRobin DittoNo ratings yet

- BC348QDocument47 pagesBC348QFRANK NIELE DE OLIVEIRANo ratings yet

- 2620 Series (HK1012) ArconicDocument22 pages2620 Series (HK1012) ArconicRalph OrinaNo ratings yet

- Checklist For T&C of Chemical Fire Suppression SystemDocument2 pagesChecklist For T&C of Chemical Fire Suppression Systembeho2000No ratings yet

- Check List For Sub Main Distribution Board InstallationDocument2 pagesCheck List For Sub Main Distribution Board InstallationNaing Win TunNo ratings yet

- Ventsand DrainsDocument1 pageVentsand DrainsGabriel MistreanuNo ratings yet

- AHU FAHU - AnnuallyDocument3 pagesAHU FAHU - AnnuallyDreamliner100% (1)

- Construction Check Sheet E-008A: Electrical LV Starters, Fuse Switch / Isolators & FeederDocument2 pagesConstruction Check Sheet E-008A: Electrical LV Starters, Fuse Switch / Isolators & FeederhrimklimNo ratings yet

- Service: ManualDocument94 pagesService: ManualBruno Carmona BorregoNo ratings yet

- MPM 311 02 07Document3 pagesMPM 311 02 07Mousa PetrolNo ratings yet

- Fire Hose ReelDocument11 pagesFire Hose ReelMinhaj ENo ratings yet

- Maintenance Work Instruction: Page. 1 of 2Document2 pagesMaintenance Work Instruction: Page. 1 of 2hobam3297No ratings yet

- 5 - DHHS Adjusting Instructions PDFDocument39 pages5 - DHHS Adjusting Instructions PDFToddNo ratings yet

- SPET001HO3 - Hydraulic EquipmentDocument52 pagesSPET001HO3 - Hydraulic EquipmentAndy DowdNo ratings yet

- 02 API 570 Points To RecallDocument6 pages02 API 570 Points To RecallMohammedBujairNo ratings yet

- WI-NG-6460-002-063 Work Instruction For Trip-Circuit Supervision Rev00Document7 pagesWI-NG-6460-002-063 Work Instruction For Trip-Circuit Supervision Rev00Mohamed NasrNo ratings yet

- Auto Buff PM Check ListDocument1 pageAuto Buff PM Check ListPiyush VyasNo ratings yet

- Equipment Checklist PDFDocument34 pagesEquipment Checklist PDFHector IbarraNo ratings yet

- SMP-E-010 - Power TransformersDocument2 pagesSMP-E-010 - Power TransformersNaeem HussainNo ratings yet

- 18 Document of Part Wise Inspection ProcessDocument111 pages18 Document of Part Wise Inspection ProcessQAD LotusNo ratings yet

- Maintenance Work Instruction: Instrument To Be Tagged With Dated Test LabelDocument2 pagesMaintenance Work Instruction: Instrument To Be Tagged With Dated Test Labelhobam3297No ratings yet

- Auxiliary Contactors Test FormatDocument1 pageAuxiliary Contactors Test FormatHumayun Ahsan100% (1)

- 2020-12-04 Pre-Delivery - Frequent - AMI BL and Trailer Mounted BLDocument1 page2020-12-04 Pre-Delivery - Frequent - AMI BL and Trailer Mounted BLhossam marzoukNo ratings yet

- Gradual and Certain Deterioration Aircaft MaintenanceDocument6 pagesGradual and Certain Deterioration Aircaft Maintenancevinh vinhNo ratings yet

- Photovoltaic Pre Commissioning ChecklistDocument25 pagesPhotovoltaic Pre Commissioning ChecklistEka Yuniansah WidiastutyNo ratings yet

- Travelling Block AdaptorDocument1 pageTravelling Block AdaptormhmdtrainingNo ratings yet

- R Bj601 Um 5137235 - 01 - MDDM 1250 Ac 2m Pipehandler Prox Bracket Steel AssemblyDocument1 pageR Bj601 Um 5137235 - 01 - MDDM 1250 Ac 2m Pipehandler Prox Bracket Steel AssemblymhmdtrainingNo ratings yet

- 170484-R-bc661-Um-5217964 - 05 - Utility Arm - Slewing Bracket Full - AssemblyDocument1 page170484-R-bc661-Um-5217964 - 05 - Utility Arm - Slewing Bracket Full - AssemblymhmdtrainingNo ratings yet

- 2000H Service Wheel Loader 993KDocument4 pages2000H Service Wheel Loader 993KmhmdtrainingNo ratings yet

- R Bc571 Um 5225972 - 02 - Hydraulic Roughneck Speed Reducer AssemblyDocument1 pageR Bc571 Um 5225972 - 02 - Hydraulic Roughneck Speed Reducer AssemblymhmdtrainingNo ratings yet

- 170484-R-bc662-Um-5217964 - 05 - Utility Arm - Slewing Bracket Full - AssemblyDocument1 page170484-R-bc662-Um-5217964 - 05 - Utility Arm - Slewing Bracket Full - AssemblymhmdtrainingNo ratings yet

- Ahmed Khairy SSOW ID 022196Document1 pageAhmed Khairy SSOW ID 022196mhmdtrainingNo ratings yet

- 170484-R-bb401-Um-5212226 - 01 - Riser Gantry Crane - Camera Beam Assy - AssemblyDocument1 page170484-R-bb401-Um-5212226 - 01 - Riser Gantry Crane - Camera Beam Assy - AssemblymhmdtrainingNo ratings yet

- 170484-R-bb401-Um-5210952 - 02 - Riser Gantry Crane - Valve Bracket - AssemblyDocument1 page170484-R-bb401-Um-5210952 - 02 - Riser Gantry Crane - Valve Bracket - AssemblymhmdtrainingNo ratings yet

- FusesDocument1 pageFusesmhmdtrainingNo ratings yet

- 170484-Z-Bc012-Um-1941416 - 01 - Bridge Crane 2 - Cvu, Trolley Trav &slew - Hydraulic Flow Diagrma, SDocument1 page170484-Z-Bc012-Um-1941416 - 01 - Bridge Crane 2 - Cvu, Trolley Trav &slew - Hydraulic Flow Diagrma, SmhmdtrainingNo ratings yet

- Chapter 3:modal AnalysisDocument35 pagesChapter 3:modal AnalysisSahithyananda ShashidharNo ratings yet

- Aluminium Alloy - Wikipedia, The Free EncyclopediaDocument13 pagesAluminium Alloy - Wikipedia, The Free EncyclopediajishnuNo ratings yet

- CPI - Lesson 3Document16 pagesCPI - Lesson 3Kim Tracey LadagaNo ratings yet

- ALGEBRA (Practice Sheet) PDFDocument132 pagesALGEBRA (Practice Sheet) PDFManavSaksariaNo ratings yet

- Effect of Financial Reporting Quality On Corporate Performance Evidence From Listed Banks in NigeriaDocument8 pagesEffect of Financial Reporting Quality On Corporate Performance Evidence From Listed Banks in NigeriaEditor IJTSRDNo ratings yet

- Dbms Model Question PapersDocument5 pagesDbms Model Question PapersJaswanth PadigalaNo ratings yet

- Laboratory Activity - 6 - Ultraviolet ExaminationDocument4 pagesLaboratory Activity - 6 - Ultraviolet ExaminationCristina BalanquitNo ratings yet

- Lecture+10 TestingDocument7 pagesLecture+10 TestingSelvaNo ratings yet

- Automatic Transfer Switch ATS104DMSDocument2 pagesAutomatic Transfer Switch ATS104DMSJabir QuadriNo ratings yet

- CSE460: VLSI Design: Lecture 5: Finite State Machines (Part 1)Document13 pagesCSE460: VLSI Design: Lecture 5: Finite State Machines (Part 1)Shovon BhowmickNo ratings yet

- Power Electronics Drives U1Document67 pagesPower Electronics Drives U1Ruvenderan SuburamaniamNo ratings yet

- Commands in AVR-assembler LanguageDocument1 pageCommands in AVR-assembler LanguageFrutzNo ratings yet

- DSC Gs3060 RadioDocument24 pagesDSC Gs3060 RadioJuan Paulo Espinoza M.No ratings yet

- Dokumen - Tips - Dynamic Systems Mechanical SystemsDocument64 pagesDokumen - Tips - Dynamic Systems Mechanical SystemsAnas AlsayarNo ratings yet

- Arduino Based Pressure Sensor Integration in The Measurement of Flow FieldDocument12 pagesArduino Based Pressure Sensor Integration in The Measurement of Flow FieldIJRASETPublicationsNo ratings yet

- M4 - Differentiation of Transcendental FunctionsDocument21 pagesM4 - Differentiation of Transcendental FunctionsARJUN ABUBAKARNo ratings yet

- AaadadwDocument5 pagesAaadadwSudhir GargNo ratings yet

- CE304 Design of Concrete Structures - II PDFDocument2 pagesCE304 Design of Concrete Structures - II PDFVineeth BavaNo ratings yet

- WW3 - Long QuizDocument3 pagesWW3 - Long QuizOLIVEROS DESIREE L.No ratings yet

- Welder Guide Book No. 2Document17 pagesWelder Guide Book No. 2MarcioNo ratings yet

- 078bct031 DL Assignment 3 Bikash NiraulaDocument6 pages078bct031 DL Assignment 3 Bikash NirauladHIRAJ thPNo ratings yet

- Ajol File Journals - 589 - Articles - 218546 - Submission - Proof - 218546 6927 536990 1 10 20211210Document6 pagesAjol File Journals - 589 - Articles - 218546 - Submission - Proof - 218546 6927 536990 1 10 20211210Vinyze MarapaoNo ratings yet

- English 7 Directions: Read The Questions Carefully and Select The Correct AnswerDocument8 pagesEnglish 7 Directions: Read The Questions Carefully and Select The Correct AnswerDafchen Nio MahasolNo ratings yet

- Gec108 LQ2Document10 pagesGec108 LQ2Suzy LeeNo ratings yet

- SurveyingDocument1 pageSurveyingrommel baldagoNo ratings yet

Service Loop Incl Manifold(s) in Derrick

Service Loop Incl Manifold(s) in Derrick

Uploaded by

mhmdtraining0 ratings0% found this document useful (0 votes)

5 views2 pagesService loop

Original Title

Service Loop incl Manifold(s) in derrick

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentService loop

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

5 views2 pagesService Loop Incl Manifold(s) in Derrick

Service Loop Incl Manifold(s) in Derrick

Uploaded by

mhmdtrainingService loop

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

EXIT

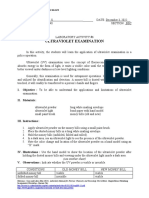

Aker MH AS

MAINTENANCE AND INSPECTION SHEET

Rig: Owner/User: Carried out by: Date: Page:

Conditions: V = OK O = Further action required NA = Not Applicable

Component:

Figure/Drawing references:

Service Loop incl. Manifold(s) in derrick 1797335

Frequency:

No. Job description: Days: Month: Years:

NP

1 7 1 3 6 1 5

General, visual inspection of the equipment.

Ref. general description of Category I inspection.

1 I I

Note! Check that all applicable Safety alerts, HSE (Safety) bulletins

and Product bulletins are reviewed and implemented.

General, visual inspection of the equipment.

2 II II

Ref. general description of Category II inspection.

Disassembly inspection.

3 IV

Ref. general description of Category IV inspection.

Electrical cables (Instrument, aux power and power).

Inspect all electrical loop cables from manifolds/end of protection

4 hose to junction boxes/termination points for wear mechanical II II

damage and sufficient slack between manifold and termination

points.

Protection hoses for el-cables (loop hoses).

Inspect all protection hoses for wear and mechanical damage.

5 II II

Check termination to manifolds. Check fixing bolts including locking

device on support clamps.

Hydraulic/Air loop hoses.

Check hoses for wear and damage. Check hose connections for

6 II II

leaks etc. Check fixing bolts including locking device on hose

flanges.

Junction boxes in derrick.

7 Inspect all junction boxes for outer damage. II II

Inspect cable glands, fixing bolts and junction box brackets.

Junction boxes in derrick.

Open all junction boxes and inspect for humidity, loose parts or

8 II II

loose cable terminations.

Replace condensation inhibitors as required.

Manifolds.

Check manifolds for cracks, damage and any sign of overloading.

9 II II

Check clamps for loop hoses. Check fixing bolts including locking

device for manifolds and clamps.

Safety shrouds (if installed).

10 Check safety shrouds on loop cables including shackles, wires and II II

chains, adjust if necessary. Check locking device on shackles.

Power cables.

Check that the cables have not worked down in the protection

11 II II

hose. Check that the cables are not rubbing against the coupling

sleeve.

Quick connectors (if installed).

Check for damage on the connector housing and cable gland.

Check that the coupling is fully connected.

12 II II

Manifold components.

Check hydraulic valves, transmitters, hydraulic hoses, pipes and

13 fittings mounted on manifold in derrick and manifold frame for block

dolly (if installed). Check for leaks and damaged components.

Check retaining bolts including locking device on all components.

More pages - Use arrow keys to navigate

EXIT

Aker MH AS

MAINTENANCE AND INSPECTION SHEET

Rig: Owner/User: Carried out by: Date: Page:

Conditions: V = OK O = Further action required NA = Not Applicable

Component:

Figure/Drawing references:

Service Loop incl. Manifold(s) in derrick 1797335

Frequency:

No. Job description: Days: Month: Years:

NP

1 7 1 3 6 1 5

Remarks/Further actions required:

You might also like

- Check List For Pre Commissioning of MV SwitchgearDocument2 pagesCheck List For Pre Commissioning of MV Switchgeararuna100% (10)

- Wahl Deluxe Rechargeable Trimmer Model 9865 1401 Groomer Ear Nose Eyebrow Users Guide Owners ManualDocument9 pagesWahl Deluxe Rechargeable Trimmer Model 9865 1401 Groomer Ear Nose Eyebrow Users Guide Owners ManualGreg Johnson100% (1)

- Project Report On MS Pipe and TubeDocument9 pagesProject Report On MS Pipe and TubeEIRI Board of Consultants and PublishersNo ratings yet

- 1 UL SEVO Flex Manual PDFDocument64 pages1 UL SEVO Flex Manual PDFHarshith KunjathurNo ratings yet

- Maneuvering Diagram With ExplanationDocument8 pagesManeuvering Diagram With ExplanationArun S100% (2)

- Conmaco 385 Winch ManualDocument44 pagesConmaco 385 Winch ManualdarioNo ratings yet

- Opencv 4.X Cheat Sheet (Python Version) : FilteringDocument2 pagesOpencv 4.X Cheat Sheet (Python Version) : FilteringMinh NguyễnNo ratings yet

- Swivel & Main ShaftDocument2 pagesSwivel & Main ShaftmhmdtrainingNo ratings yet

- Travelling Block AdaptorDocument1 pageTravelling Block AdaptormhmdtrainingNo ratings yet

- Climaveneta BRATDocument38 pagesClimaveneta BRATm.machelskiNo ratings yet

- Pre-Commissioning Check List Form Switchgear-General: October 2019Document3 pagesPre-Commissioning Check List Form Switchgear-General: October 2019xchannel28No ratings yet

- PrecommissioningSwitchgear GeneralDocument3 pagesPrecommissioningSwitchgear GeneralPeter IyereNo ratings yet

- MP Misc 255 April 10 Emd CommissioningDocument6 pagesMP Misc 255 April 10 Emd CommissioningmailbkraoNo ratings yet

- Blasting PaintingDocument3 pagesBlasting PaintingAthirah AkhmaNo ratings yet

- Eot Ibl Crane Yearly ChecksheetDocument3 pagesEot Ibl Crane Yearly ChecksheetAmit ThakurNo ratings yet

- Climaveneta i-KIR2-Technical-Installation-ManualDocument68 pagesClimaveneta i-KIR2-Technical-Installation-ManualbojanNo ratings yet

- Abbott i1000SR - PM ChecklistDocument7 pagesAbbott i1000SR - PM Checklistاكرم امينNo ratings yet

- Eot Crane Monthly ChecksheetDocument4 pagesEot Crane Monthly ChecksheetAmit ThakurNo ratings yet

- Substation Equipment MaintenanceDocument15 pagesSubstation Equipment MaintenanceDr. R. SharmaNo ratings yet

- Chapter 5: Checking and Maintaining Ultrasound EquipmentDocument8 pagesChapter 5: Checking and Maintaining Ultrasound EquipmentUmar DhaniNo ratings yet

- Checklist 16 Blasting and Painting Including Use of EtcDocument3 pagesChecklist 16 Blasting and Painting Including Use of EtcFatin ZulkifliNo ratings yet

- 15b17b Umeng0400 PDFDocument20 pages15b17b Umeng0400 PDFkishore_bulli6666No ratings yet

- FM-OHS-1700-30 Pre Use Daily Weekly G20 Crane InspectionDocument2 pagesFM-OHS-1700-30 Pre Use Daily Weekly G20 Crane InspectiondavidburkepsNo ratings yet

- Samsung TV Service Manual PDFDocument98 pagesSamsung TV Service Manual PDFali83No ratings yet

- Method Statement For MV Power Cables & Accessories InstallationDocument2 pagesMethod Statement For MV Power Cables & Accessories InstallationAdil Hasanov100% (1)

- CRS SEC - 10632 - Warranty Inspection Procedure For TransformersDocument2 pagesCRS SEC - 10632 - Warranty Inspection Procedure For TransformersKhaja SayeedNo ratings yet

- Check List For: Installation of Fahu: Project Name & LogosDocument2 pagesCheck List For: Installation of Fahu: Project Name & LogosSamer AliNo ratings yet

- Safety & Special Instructions:: Preventive Maintenance Checklist E09H - Automatic Transfer SwitchDocument2 pagesSafety & Special Instructions:: Preventive Maintenance Checklist E09H - Automatic Transfer SwitchEdward SchenkNo ratings yet

- CRS SEC - 10657 - Warranty Inspection Procedures For Vacuum SkidsDocument3 pagesCRS SEC - 10657 - Warranty Inspection Procedures For Vacuum SkidsKhaja SayeedNo ratings yet

- Samsung p2050 p2250 p2350 SM PDFDocument47 pagesSamsung p2050 p2250 p2350 SM PDFCaim MarmolNo ratings yet

- PrecommissioningSwitchgear GeneralDocument3 pagesPrecommissioningSwitchgear GeneralSatish ReddyNo ratings yet

- Clamp On HIOKI 3286B981 - 13Document84 pagesClamp On HIOKI 3286B981 - 13andhangsNo ratings yet

- Dewatering Pump ChecklistDocument1 pageDewatering Pump ChecklistMD Abdullah100% (1)

- High Voltage Switchgear: Technical Data Schedule (TDS) - Guidance Note E06 ElectricalDocument3 pagesHigh Voltage Switchgear: Technical Data Schedule (TDS) - Guidance Note E06 Electrical20082012No ratings yet

- 5-Year Maintenance On Hydra RackerDocument2 pages5-Year Maintenance On Hydra Rackermohamed hamedNo ratings yet

- Globe Valve Inspection and Functionality Test Check Sheet - SafetyCultureDocument36 pagesGlobe Valve Inspection and Functionality Test Check Sheet - SafetyCulturenavidNo ratings yet

- Samsung 2033hd Chassis Ls20cfvkfen SM PDFDocument70 pagesSamsung 2033hd Chassis Ls20cfvkfen SM PDFGoce TrajanovNo ratings yet

- Vdocuments - MX Moduspec-ChecklistDocument64 pagesVdocuments - MX Moduspec-Checklistmostafa bahnasNo ratings yet

- 1w Mech Mob Crane-Hyd Insp. Maint. 15tonDocument18 pages1w Mech Mob Crane-Hyd Insp. Maint. 15tonebonilla88No ratings yet

- Accurate: User and Maintenance ManualDocument28 pagesAccurate: User and Maintenance ManualRobin DittoNo ratings yet

- BC348QDocument47 pagesBC348QFRANK NIELE DE OLIVEIRANo ratings yet

- 2620 Series (HK1012) ArconicDocument22 pages2620 Series (HK1012) ArconicRalph OrinaNo ratings yet

- Checklist For T&C of Chemical Fire Suppression SystemDocument2 pagesChecklist For T&C of Chemical Fire Suppression Systembeho2000No ratings yet

- Check List For Sub Main Distribution Board InstallationDocument2 pagesCheck List For Sub Main Distribution Board InstallationNaing Win TunNo ratings yet

- Ventsand DrainsDocument1 pageVentsand DrainsGabriel MistreanuNo ratings yet

- AHU FAHU - AnnuallyDocument3 pagesAHU FAHU - AnnuallyDreamliner100% (1)

- Construction Check Sheet E-008A: Electrical LV Starters, Fuse Switch / Isolators & FeederDocument2 pagesConstruction Check Sheet E-008A: Electrical LV Starters, Fuse Switch / Isolators & FeederhrimklimNo ratings yet

- Service: ManualDocument94 pagesService: ManualBruno Carmona BorregoNo ratings yet

- MPM 311 02 07Document3 pagesMPM 311 02 07Mousa PetrolNo ratings yet

- Fire Hose ReelDocument11 pagesFire Hose ReelMinhaj ENo ratings yet

- Maintenance Work Instruction: Page. 1 of 2Document2 pagesMaintenance Work Instruction: Page. 1 of 2hobam3297No ratings yet

- 5 - DHHS Adjusting Instructions PDFDocument39 pages5 - DHHS Adjusting Instructions PDFToddNo ratings yet

- SPET001HO3 - Hydraulic EquipmentDocument52 pagesSPET001HO3 - Hydraulic EquipmentAndy DowdNo ratings yet

- 02 API 570 Points To RecallDocument6 pages02 API 570 Points To RecallMohammedBujairNo ratings yet

- WI-NG-6460-002-063 Work Instruction For Trip-Circuit Supervision Rev00Document7 pagesWI-NG-6460-002-063 Work Instruction For Trip-Circuit Supervision Rev00Mohamed NasrNo ratings yet

- Auto Buff PM Check ListDocument1 pageAuto Buff PM Check ListPiyush VyasNo ratings yet

- Equipment Checklist PDFDocument34 pagesEquipment Checklist PDFHector IbarraNo ratings yet

- SMP-E-010 - Power TransformersDocument2 pagesSMP-E-010 - Power TransformersNaeem HussainNo ratings yet

- 18 Document of Part Wise Inspection ProcessDocument111 pages18 Document of Part Wise Inspection ProcessQAD LotusNo ratings yet

- Maintenance Work Instruction: Instrument To Be Tagged With Dated Test LabelDocument2 pagesMaintenance Work Instruction: Instrument To Be Tagged With Dated Test Labelhobam3297No ratings yet

- Auxiliary Contactors Test FormatDocument1 pageAuxiliary Contactors Test FormatHumayun Ahsan100% (1)

- 2020-12-04 Pre-Delivery - Frequent - AMI BL and Trailer Mounted BLDocument1 page2020-12-04 Pre-Delivery - Frequent - AMI BL and Trailer Mounted BLhossam marzoukNo ratings yet

- Gradual and Certain Deterioration Aircaft MaintenanceDocument6 pagesGradual and Certain Deterioration Aircaft Maintenancevinh vinhNo ratings yet

- Photovoltaic Pre Commissioning ChecklistDocument25 pagesPhotovoltaic Pre Commissioning ChecklistEka Yuniansah WidiastutyNo ratings yet

- Travelling Block AdaptorDocument1 pageTravelling Block AdaptormhmdtrainingNo ratings yet

- R Bj601 Um 5137235 - 01 - MDDM 1250 Ac 2m Pipehandler Prox Bracket Steel AssemblyDocument1 pageR Bj601 Um 5137235 - 01 - MDDM 1250 Ac 2m Pipehandler Prox Bracket Steel AssemblymhmdtrainingNo ratings yet

- 170484-R-bc661-Um-5217964 - 05 - Utility Arm - Slewing Bracket Full - AssemblyDocument1 page170484-R-bc661-Um-5217964 - 05 - Utility Arm - Slewing Bracket Full - AssemblymhmdtrainingNo ratings yet

- 2000H Service Wheel Loader 993KDocument4 pages2000H Service Wheel Loader 993KmhmdtrainingNo ratings yet

- R Bc571 Um 5225972 - 02 - Hydraulic Roughneck Speed Reducer AssemblyDocument1 pageR Bc571 Um 5225972 - 02 - Hydraulic Roughneck Speed Reducer AssemblymhmdtrainingNo ratings yet

- 170484-R-bc662-Um-5217964 - 05 - Utility Arm - Slewing Bracket Full - AssemblyDocument1 page170484-R-bc662-Um-5217964 - 05 - Utility Arm - Slewing Bracket Full - AssemblymhmdtrainingNo ratings yet

- Ahmed Khairy SSOW ID 022196Document1 pageAhmed Khairy SSOW ID 022196mhmdtrainingNo ratings yet

- 170484-R-bb401-Um-5212226 - 01 - Riser Gantry Crane - Camera Beam Assy - AssemblyDocument1 page170484-R-bb401-Um-5212226 - 01 - Riser Gantry Crane - Camera Beam Assy - AssemblymhmdtrainingNo ratings yet

- 170484-R-bb401-Um-5210952 - 02 - Riser Gantry Crane - Valve Bracket - AssemblyDocument1 page170484-R-bb401-Um-5210952 - 02 - Riser Gantry Crane - Valve Bracket - AssemblymhmdtrainingNo ratings yet

- FusesDocument1 pageFusesmhmdtrainingNo ratings yet

- 170484-Z-Bc012-Um-1941416 - 01 - Bridge Crane 2 - Cvu, Trolley Trav &slew - Hydraulic Flow Diagrma, SDocument1 page170484-Z-Bc012-Um-1941416 - 01 - Bridge Crane 2 - Cvu, Trolley Trav &slew - Hydraulic Flow Diagrma, SmhmdtrainingNo ratings yet

- Chapter 3:modal AnalysisDocument35 pagesChapter 3:modal AnalysisSahithyananda ShashidharNo ratings yet

- Aluminium Alloy - Wikipedia, The Free EncyclopediaDocument13 pagesAluminium Alloy - Wikipedia, The Free EncyclopediajishnuNo ratings yet

- CPI - Lesson 3Document16 pagesCPI - Lesson 3Kim Tracey LadagaNo ratings yet

- ALGEBRA (Practice Sheet) PDFDocument132 pagesALGEBRA (Practice Sheet) PDFManavSaksariaNo ratings yet

- Effect of Financial Reporting Quality On Corporate Performance Evidence From Listed Banks in NigeriaDocument8 pagesEffect of Financial Reporting Quality On Corporate Performance Evidence From Listed Banks in NigeriaEditor IJTSRDNo ratings yet

- Dbms Model Question PapersDocument5 pagesDbms Model Question PapersJaswanth PadigalaNo ratings yet

- Laboratory Activity - 6 - Ultraviolet ExaminationDocument4 pagesLaboratory Activity - 6 - Ultraviolet ExaminationCristina BalanquitNo ratings yet

- Lecture+10 TestingDocument7 pagesLecture+10 TestingSelvaNo ratings yet

- Automatic Transfer Switch ATS104DMSDocument2 pagesAutomatic Transfer Switch ATS104DMSJabir QuadriNo ratings yet

- CSE460: VLSI Design: Lecture 5: Finite State Machines (Part 1)Document13 pagesCSE460: VLSI Design: Lecture 5: Finite State Machines (Part 1)Shovon BhowmickNo ratings yet

- Power Electronics Drives U1Document67 pagesPower Electronics Drives U1Ruvenderan SuburamaniamNo ratings yet

- Commands in AVR-assembler LanguageDocument1 pageCommands in AVR-assembler LanguageFrutzNo ratings yet

- DSC Gs3060 RadioDocument24 pagesDSC Gs3060 RadioJuan Paulo Espinoza M.No ratings yet

- Dokumen - Tips - Dynamic Systems Mechanical SystemsDocument64 pagesDokumen - Tips - Dynamic Systems Mechanical SystemsAnas AlsayarNo ratings yet

- Arduino Based Pressure Sensor Integration in The Measurement of Flow FieldDocument12 pagesArduino Based Pressure Sensor Integration in The Measurement of Flow FieldIJRASETPublicationsNo ratings yet

- M4 - Differentiation of Transcendental FunctionsDocument21 pagesM4 - Differentiation of Transcendental FunctionsARJUN ABUBAKARNo ratings yet

- AaadadwDocument5 pagesAaadadwSudhir GargNo ratings yet

- CE304 Design of Concrete Structures - II PDFDocument2 pagesCE304 Design of Concrete Structures - II PDFVineeth BavaNo ratings yet

- WW3 - Long QuizDocument3 pagesWW3 - Long QuizOLIVEROS DESIREE L.No ratings yet

- Welder Guide Book No. 2Document17 pagesWelder Guide Book No. 2MarcioNo ratings yet

- 078bct031 DL Assignment 3 Bikash NiraulaDocument6 pages078bct031 DL Assignment 3 Bikash NirauladHIRAJ thPNo ratings yet

- Ajol File Journals - 589 - Articles - 218546 - Submission - Proof - 218546 6927 536990 1 10 20211210Document6 pagesAjol File Journals - 589 - Articles - 218546 - Submission - Proof - 218546 6927 536990 1 10 20211210Vinyze MarapaoNo ratings yet

- English 7 Directions: Read The Questions Carefully and Select The Correct AnswerDocument8 pagesEnglish 7 Directions: Read The Questions Carefully and Select The Correct AnswerDafchen Nio MahasolNo ratings yet

- Gec108 LQ2Document10 pagesGec108 LQ2Suzy LeeNo ratings yet

- SurveyingDocument1 pageSurveyingrommel baldagoNo ratings yet