Professional Documents

Culture Documents

Travelling Block Adaptor

Travelling Block Adaptor

Uploaded by

mhmdtraining0 ratings0% found this document useful (0 votes)

16 views1 pageTravel

Original Title

Travelling block adaptor

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTravel

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

16 views1 pageTravelling Block Adaptor

Travelling Block Adaptor

Uploaded by

mhmdtrainingTravel

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

EXIT

Aker MH AS

MAINTENANCE AND INSPECTION SHEET

Rig: Owner/User: Carried out by: Date: Page:

Conditions: V = OK O = Further action required NA = Not Applicable

Component:

Figure/Drawing references:

Travelling block adaptor 1797334, 1797358

Frequency:

No. Job description: Days: Month: Years:

NP

1 7 1 3 6 1 5

General, visual inspection of the equipment.

Ref. general description of Category I inspection.

1 I I

Note! Check that all applicable Safety alerts, HSE (Safety) bulletins

and Product bulletins are reviewed and implemented.

General, visual inspection of the equipment.

2 II II

Ref. general description of Category II inspection.

Disassembly inspection.

3 IV

Ref. general description of Category IV inspection.

Visual inspection.

4 Visually check the complete adapter for cracks, deformation, corro- II II

sion and any sign of overloading.

Bondura Bolts®.

Inspect all bolts for indication of wear, damage and any sign of

overloading. Check that locking plates, taper sleeves and screws

5 are in place. Inspect the locking wire on all bolts. Check that the II II

bolt has not shifted to one side. Check for indications of loose

cones. Retighten cones if necessary.

Ref. Bondura bolt description in the General part of the document.

Bondura Bolts®.

6 Retighten cones. II

Ref. Bondura bolt description in the General part of the document.

Visual inspection including NDE of critical areas.

Place the MDDM on drill floor and remove the travelling block with

travelling block adaptor from the load frame.

Perform a thorough visual check for cracks, excessive wear, defor-

mation, corrosion and overloading on travelling block adaptor and

bondura bolts. Perform NDE inspection on the visible parts of the

bondura bolts and on the outer surface of the adaptor lugs without

7 removing the Bondura bolts®. III III

If any faults are found on the adaptor or on the upper part of the

load frame, then a more thorough NDE inspection of the travelling

block adaptor and bondura bolts are necessary. Disassemble the

bondura bolts and perform NDE according to attached figures.

Further checks are also necessary if the taper sleeves on the bon-

dura bolts are very slack or shows sign of wear and deformation.

Remarks/Further actions required:

You might also like

- Hiab Crane Preuse Inspection ChecklistDocument2 pagesHiab Crane Preuse Inspection ChecklistBeyar. Sh100% (2)

- Jishu Hozen by Sudhansu Bhushan Mohapatra TPM Consultant - IIPM E-Mail: Sbm@iipm - Ac.inDocument64 pagesJishu Hozen by Sudhansu Bhushan Mohapatra TPM Consultant - IIPM E-Mail: Sbm@iipm - Ac.insudhansu_cvrce100% (9)

- Conmaco 385 Winch ManualDocument44 pagesConmaco 385 Winch ManualdarioNo ratings yet

- SOP Overhead Crane-Rev.1Document5 pagesSOP Overhead Crane-Rev.1RonniNo ratings yet

- Daihatsu Type K3 Engine Service Manual No.9737 No.9332 No. 9237 General Information PDFDocument9 pagesDaihatsu Type K3 Engine Service Manual No.9737 No.9332 No. 9237 General Information PDFMozes Simataa100% (1)

- Images - A ReaderDocument169 pagesImages - A Readeralicethecamel100% (4)

- Swivel & Main ShaftDocument2 pagesSwivel & Main ShaftmhmdtrainingNo ratings yet

- Service Loop Incl Manifold(s) in DerrickDocument2 pagesService Loop Incl Manifold(s) in DerrickmhmdtrainingNo ratings yet

- PRO12 2P621CT - Rev 7 - 09 19Document24 pagesPRO12 2P621CT - Rev 7 - 09 19Edwin Montenegro MurilloNo ratings yet

- Verif EPI Poulies Procedure ENDocument3 pagesVerif EPI Poulies Procedure ENaliya azharNo ratings yet

- Inspection Procedure: Grillon LanyardDocument5 pagesInspection Procedure: Grillon LanyardUlviyye ElesgerovaNo ratings yet

- Verif EPI GRIGRI Procedure enDocument3 pagesVerif EPI GRIGRI Procedure eninternetNo ratings yet

- Inspection: AIR Winch Ingersoll RandDocument19 pagesInspection: AIR Winch Ingersoll RandAbdou BoucheritNo ratings yet

- Cur Soar Condicion A Do AutoDocument37 pagesCur Soar Condicion A Do AutoFabio Adriana FláviaNo ratings yet

- FM-OHS-1700-30 Pre Use Daily Weekly G20 Crane InspectionDocument2 pagesFM-OHS-1700-30 Pre Use Daily Weekly G20 Crane InspectiondavidburkepsNo ratings yet

- Intermediate Inspection Criteria, Well Control Equipment: Equipment Group: Shooting NippleDocument2 pagesIntermediate Inspection Criteria, Well Control Equipment: Equipment Group: Shooting NippleKaleem UllahNo ratings yet

- Chapter 5: Checking and Maintaining Ultrasound EquipmentDocument8 pagesChapter 5: Checking and Maintaining Ultrasound EquipmentUmar DhaniNo ratings yet

- Eot Ibl Crane Yearly ChecksheetDocument3 pagesEot Ibl Crane Yearly ChecksheetAmit ThakurNo ratings yet

- GM 002 AccessoriesDocument45 pagesGM 002 AccessoriesJohn DareNo ratings yet

- Canrig TDS NDT Manual PDFDocument35 pagesCanrig TDS NDT Manual PDFThomson JosephNo ratings yet

- Intermediate Well Control Equipment Inspection Criteria: Equipment Group: Choke Line Coflexip Type HoseDocument2 pagesIntermediate Well Control Equipment Inspection Criteria: Equipment Group: Choke Line Coflexip Type HoseKaleem UllahNo ratings yet

- MPM 311 02 07Document3 pagesMPM 311 02 07Mousa PetrolNo ratings yet

- SOP Mobile Crane-Rev.1Document7 pagesSOP Mobile Crane-Rev.1RonniNo ratings yet

- 801 I.1.3 Man Rider Winch Product Maintenance InformationDocument14 pages801 I.1.3 Man Rider Winch Product Maintenance InformationPedro SanchezNo ratings yet

- JSA - Replace Grinding Wheel From Bench GrinderDocument2 pagesJSA - Replace Grinding Wheel From Bench GrinderAshok Suresh100% (1)

- CltiDocument53 pagesCltiGURMUKH SINGH100% (1)

- V30ZMUDocument26 pagesV30ZMUmanuelsaenzNo ratings yet

- Verif Epi Protraxion Procedure enDocument4 pagesVerif Epi Protraxion Procedure eninternetNo ratings yet

- Verif EPI IDS IDL RIG Procedure enDocument5 pagesVerif EPI IDS IDL RIG Procedure enAldisley OliveiraNo ratings yet

- Vdocuments - MX Moduspec-ChecklistDocument64 pagesVdocuments - MX Moduspec-Checklistmostafa bahnasNo ratings yet

- ISP M2000 Head ManualDocument27 pagesISP M2000 Head ManualArezkiNo ratings yet

- Eot Crane Monthly ChecksheetDocument4 pagesEot Crane Monthly ChecksheetAmit ThakurNo ratings yet

- PrecommissioningSwitchgear GeneralDocument3 pagesPrecommissioningSwitchgear GeneralSatish ReddyNo ratings yet

- Instructions Hydraulic Table PressDocument26 pagesInstructions Hydraulic Table PressHanna HorváthNo ratings yet

- Pre-Commissioning Check List Form Switchgear-General: October 2019Document3 pagesPre-Commissioning Check List Form Switchgear-General: October 2019xchannel28No ratings yet

- PMS Tail Cone SectionDocument1 pagePMS Tail Cone SectionManuel CoronelNo ratings yet

- PrecommissioningSwitchgear GeneralDocument3 pagesPrecommissioningSwitchgear GeneralPeter IyereNo ratings yet

- List of InspectionDocument17 pagesList of InspectionNQTNo ratings yet

- 02 Iris1Document24 pages02 Iris1AndiosoNo ratings yet

- Sony kdl-50w805b Chassis rb2g Ver.1.0 Segm - He RMDocument29 pagesSony kdl-50w805b Chassis rb2g Ver.1.0 Segm - He RMMarceloNo ratings yet

- Loader Safety ChecklistDocument3 pagesLoader Safety Checklistabdullah ashrafNo ratings yet

- TDS Manual-TescoDocument33 pagesTDS Manual-TescoQAMAR ALI KHAN100% (1)

- H Tong Maintenance ManualDocument8 pagesH Tong Maintenance ManualBahman MatouriNo ratings yet

- Globe Valve Inspection and Functionality Test Check Sheet - SafetyCultureDocument36 pagesGlobe Valve Inspection and Functionality Test Check Sheet - SafetyCulturenavidNo ratings yet

- 104-EMP-01 Rev 0 - Drilling Hook Level III Inspection-USA OnlyDocument10 pages104-EMP-01 Rev 0 - Drilling Hook Level III Inspection-USA OnlyJuan LorenzoNo ratings yet

- Domelux Series Manual de ServicioDocument43 pagesDomelux Series Manual de ServicioJohan LunaNo ratings yet

- Flygt 2640 PDFDocument28 pagesFlygt 2640 PDFAlberto Roca M100% (1)

- Incoming Nozzle F5 2nd GheshmDocument18 pagesIncoming Nozzle F5 2nd GheshmAli Ramezani KhoozestaniNo ratings yet

- MPM 441 02 06Document5 pagesMPM 441 02 06Mousa PetrolNo ratings yet

- Weekly Maintenance On Hydra RackerDocument4 pagesWeekly Maintenance On Hydra Rackermohamed hamedNo ratings yet

- Climaveneta BRATDocument38 pagesClimaveneta BRATm.machelskiNo ratings yet

- Pms Tail Rotor Pylon SectionDocument2 pagesPms Tail Rotor Pylon SectionManuel CoronelNo ratings yet

- Boom Lift - Man Lift Inspection ChecklistsDocument3 pagesBoom Lift - Man Lift Inspection ChecklistsAgung Tri SugihartoNo ratings yet

- 38 311105Document40 pages38 311105Ciocanea DenisNo ratings yet

- Manrider Manual MODEL # FA150KGIMR12AIH-CEDocument16 pagesManrider Manual MODEL # FA150KGIMR12AIH-CESamuel Perez0% (1)

- Auto Buff PM Check ListDocument1 pageAuto Buff PM Check ListPiyush VyasNo ratings yet

- 70-024-B Semi-Automatic Car Tire Changer User and Maintenance ManualDocument26 pages70-024-B Semi-Automatic Car Tire Changer User and Maintenance ManualRocky SarafNo ratings yet

- Inspection Procedure: Zig ZagDocument3 pagesInspection Procedure: Zig ZagAli Ben AmorNo ratings yet

- Dinamic 081 100Document20 pagesDinamic 081 100Aroldo PacitoNo ratings yet

- Matrice 300 RTK: Maintenance ManualDocument19 pagesMatrice 300 RTK: Maintenance ManualOscar ChávezNo ratings yet

- R Bj601 Um 5137235 - 01 - MDDM 1250 Ac 2m Pipehandler Prox Bracket Steel AssemblyDocument1 pageR Bj601 Um 5137235 - 01 - MDDM 1250 Ac 2m Pipehandler Prox Bracket Steel AssemblymhmdtrainingNo ratings yet

- 2000H Service Wheel Loader 993KDocument4 pages2000H Service Wheel Loader 993KmhmdtrainingNo ratings yet

- 170484-R-bc661-Um-5217964 - 05 - Utility Arm - Slewing Bracket Full - AssemblyDocument1 page170484-R-bc661-Um-5217964 - 05 - Utility Arm - Slewing Bracket Full - AssemblymhmdtrainingNo ratings yet

- Ahmed Khairy SSOW ID 022196Document1 pageAhmed Khairy SSOW ID 022196mhmdtrainingNo ratings yet

- R Bc571 Um 5225972 - 02 - Hydraulic Roughneck Speed Reducer AssemblyDocument1 pageR Bc571 Um 5225972 - 02 - Hydraulic Roughneck Speed Reducer AssemblymhmdtrainingNo ratings yet

- 170484-R-bb401-Um-5212226 - 01 - Riser Gantry Crane - Camera Beam Assy - AssemblyDocument1 page170484-R-bb401-Um-5212226 - 01 - Riser Gantry Crane - Camera Beam Assy - AssemblymhmdtrainingNo ratings yet

- 170484-R-bc662-Um-5217964 - 05 - Utility Arm - Slewing Bracket Full - AssemblyDocument1 page170484-R-bc662-Um-5217964 - 05 - Utility Arm - Slewing Bracket Full - AssemblymhmdtrainingNo ratings yet

- FusesDocument1 pageFusesmhmdtrainingNo ratings yet

- 170484-R-bb401-Um-5210952 - 02 - Riser Gantry Crane - Valve Bracket - AssemblyDocument1 page170484-R-bb401-Um-5210952 - 02 - Riser Gantry Crane - Valve Bracket - AssemblymhmdtrainingNo ratings yet

- 170484-Z-Bc012-Um-1941416 - 01 - Bridge Crane 2 - Cvu, Trolley Trav &slew - Hydraulic Flow Diagrma, SDocument1 page170484-Z-Bc012-Um-1941416 - 01 - Bridge Crane 2 - Cvu, Trolley Trav &slew - Hydraulic Flow Diagrma, SmhmdtrainingNo ratings yet

- UNIT-11-JUST-SUPPOSEDocument13 pagesUNIT-11-JUST-SUPPOSECesar RodriguezNo ratings yet

- Cell Phone Dete-WPS OfficeDocument9 pagesCell Phone Dete-WPS OfficekrishnaNo ratings yet

- An Inalienable Possession ConstructionDocument5 pagesAn Inalienable Possession ConstructionSam SNo ratings yet

- BD F118S en WW - LDocument12 pagesBD F118S en WW - LyusufNo ratings yet

- Instructions For Accessing MathXL 30 Day TrialDocument3 pagesInstructions For Accessing MathXL 30 Day TrialAdie94No ratings yet

- 253-Article Text-1257-1-10-20210925Document10 pages253-Article Text-1257-1-10-20210925Farhan SyamsuNo ratings yet

- Towards A Social Theory of Rhythm - Nelson PDFDocument10 pagesTowards A Social Theory of Rhythm - Nelson PDFugubroNo ratings yet

- Chapter 7Document6 pagesChapter 7Glace AbellanaNo ratings yet

- Octal Numbering System AssignmentDocument3 pagesOctal Numbering System Assignmentusmanf87No ratings yet

- Astm D2414-21Document9 pagesAstm D2414-21Rajdeep MalNo ratings yet

- Consumer Behavior and Pricing Strategy: Mcgraw-Hill/IrwinDocument32 pagesConsumer Behavior and Pricing Strategy: Mcgraw-Hill/IrwinNg. Minh ThảoNo ratings yet

- Problem Book in RelativityDocument25 pagesProblem Book in Relativitylinamohdzhor481520% (5)

- Parents Feedback 11 ADocument10 pagesParents Feedback 11 Adeepika yashaswiNo ratings yet

- DEH Governor - Mitsubishi Heavy Industries, LTD PDFDocument2 pagesDEH Governor - Mitsubishi Heavy Industries, LTD PDFhamidkatebi100% (1)

- WF Chapt1Document12 pagesWF Chapt1Shinmei KyoshiNo ratings yet

- Achievement Report PDFDocument4 pagesAchievement Report PDFAnonymous IpBC61ZNo ratings yet

- Petroleum Geomechanics Assignment 3Document6 pagesPetroleum Geomechanics Assignment 3Binish KhanNo ratings yet

- Bus Body Construction and RegulationsDocument6 pagesBus Body Construction and RegulationsAghil Buddy100% (1)

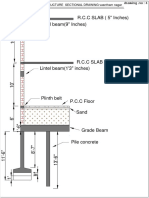

- R.C.C SLAB (5" Inches) Lintel Beam (9" Inches) : Structure Sectional Drawing Vasntham NagarDocument1 pageR.C.C SLAB (5" Inches) Lintel Beam (9" Inches) : Structure Sectional Drawing Vasntham NagarsanthoshNo ratings yet

- Treatment of Real Printing Wastewater Using Electrocoagulation Process With Titanium and Zinc ElectrodesDocument9 pagesTreatment of Real Printing Wastewater Using Electrocoagulation Process With Titanium and Zinc ElectrodesCUEVA VASQUEZ BRYAN ALBERTONo ratings yet

- E38 DSC System PDFDocument32 pagesE38 DSC System PDFjoker63000No ratings yet

- Peter GärdenforsDocument9 pagesPeter GärdenforsusamaknightNo ratings yet

- Political FactorsDocument4 pagesPolitical FactorsThùyy DunggNo ratings yet

- Chapter1 - Preferences of Second Hand ClothingDocument5 pagesChapter1 - Preferences of Second Hand ClothingMehludNo ratings yet

- 31fuel Injection Valve MaintenanceDocument4 pages31fuel Injection Valve Maintenancenauta007No ratings yet

- Proposal MathDocument18 pagesProposal MathKarrel Joy Dela CruzNo ratings yet

- Technical Specification 150917Document517 pagesTechnical Specification 150917Amit Kumar MishraNo ratings yet

- Nov 2001 p1Document15 pagesNov 2001 p1Wojtek BłażejNo ratings yet

- Technical and Operating Documentation: Smoke and Heat Exhaust Control Unit MCR 9705Document24 pagesTechnical and Operating Documentation: Smoke and Heat Exhaust Control Unit MCR 9705Constantin GubavuNo ratings yet