Professional Documents

Culture Documents

Underground Piping

Underground Piping

Uploaded by

Muhammad Bilal SajidCopyright:

Available Formats

You might also like

- Jsa For Pipe Laying Water and Sewer-1Document8 pagesJsa For Pipe Laying Water and Sewer-1Mikael Naqib83% (6)

- DPWH PDM PiceDocument55 pagesDPWH PDM Picemmabee100% (4)

- Method Statement For Trial Pit ExcavationDocument4 pagesMethod Statement For Trial Pit ExcavationCwazy MarooyNo ratings yet

- The Impact of Forward and Backward Integration On Microsoft S Performance and Sustainability in AmericaDocument32 pagesThe Impact of Forward and Backward Integration On Microsoft S Performance and Sustainability in Americakariuki josephNo ratings yet

- Method Statement - Site ClearanceDocument6 pagesMethod Statement - Site Clearanceqoci5ko100% (1)

- Job Safety Analysis Lifting and RiggingDocument17 pagesJob Safety Analysis Lifting and RiggingSam Seed100% (1)

- StatementOfAccount 150954646 Oct24 183900Document2 pagesStatementOfAccount 150954646 Oct24 183900keerthiram1991No ratings yet

- Examination 680Document22 pagesExamination 680Maha Al AmadNo ratings yet

- Water ProofingDocument2 pagesWater ProofingMuhammad Bilal SajidNo ratings yet

- Work Method Statement: BNPP-HSE-JHA-2014-210 6Document8 pagesWork Method Statement: BNPP-HSE-JHA-2014-210 6Karthik babuNo ratings yet

- JSA For Crane Columan Foundation - AB.1Document9 pagesJSA For Crane Columan Foundation - AB.1hse2No ratings yet

- Fence Installation - Method StatementDocument5 pagesFence Installation - Method StatementvelisantshuntsheNo ratings yet

- Excavation Safety - Hazards and Precautions - Safety NotesDocument5 pagesExcavation Safety - Hazards and Precautions - Safety Notesaneethavils100% (1)

- Jsa PCC & RCCDocument2 pagesJsa PCC & RCCNilesh koliNo ratings yet

- IPM - MOS - Roofing Program-Rev3.0 (15.06.2022)Document8 pagesIPM - MOS - Roofing Program-Rev3.0 (15.06.2022)mohdnurasyraafNo ratings yet

- Risk Assessment: Concrete Work (PCC/RCC)Document2 pagesRisk Assessment: Concrete Work (PCC/RCC)hemant yadavNo ratings yet

- Job Hazard Analysis (Earth Mounted Tank)Document8 pagesJob Hazard Analysis (Earth Mounted Tank)jay RNo ratings yet

- Geotextile Installation Procedure - SPEDIDocument1 pageGeotextile Installation Procedure - SPEDIRyan DizonNo ratings yet

- Job Hazard Analysis: Amichand Technological Pvt. LTDDocument6 pagesJob Hazard Analysis: Amichand Technological Pvt. LTDSandeep KumarNo ratings yet

- Method Statements For Construction of Masonry Lined Drains Rev 0Document13 pagesMethod Statements For Construction of Masonry Lined Drains Rev 0McDonald WesleyNo ratings yet

- Method Statement - FOC - FYSH - 031010Document2 pagesMethod Statement - FOC - FYSH - 031010DilxazNo ratings yet

- Site Security Barricading Procedure-SPEDIDocument2 pagesSite Security Barricading Procedure-SPEDIRyan DizonNo ratings yet

- JSA FOR WELDING, GRINDING, GAS CUTTINGDocument2 pagesJSA FOR WELDING, GRINDING, GAS CUTTINGm.rehanhseNo ratings yet

- Risk Assessment What Work Excavation Work With Help of JCB Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDDocument2 pagesRisk Assessment What Work Excavation Work With Help of JCB Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDhemant yadav33% (3)

- 02 Job Hazard Analysis For Deep Excavation & TrenchingDocument3 pages02 Job Hazard Analysis For Deep Excavation & TrenchingAmanNo ratings yet

- METH-00002-A - Method Statement - Supply & Return DuctworkDocument5 pagesMETH-00002-A - Method Statement - Supply & Return Ductworkmohd arshadNo ratings yet

- Jsa For Welding, Grinding, Gas CuttingDocument2 pagesJsa For Welding, Grinding, Gas Cuttingwahyu nugroho67% (3)

- Part 4 ExcavationDocument6 pagesPart 4 ExcavationHana Seiadi100% (1)

- Jsa For PCCDocument6 pagesJsa For PCCCICON EngineersNo ratings yet

- Relocation of Device On Concrete SlabDocument1 pageRelocation of Device On Concrete SlabBento BoxNo ratings yet

- JOB HAZARD ANALYSIS Deep Excavation-2Document9 pagesJOB HAZARD ANALYSIS Deep Excavation-2jay RNo ratings yet

- 1-JHA - ExcavationDocument2 pages1-JHA - ExcavationAnna Marie Filipinas RajilNo ratings yet

- Revised - MosDocument15 pagesRevised - MosNadeesha BandaraNo ratings yet

- Del 861117751920793Document9 pagesDel 861117751920793Varahi VigneshNo ratings yet

- 2-JHA - FormworksDocument3 pages2-JHA - FormworksAnna Marie Filipinas RajilNo ratings yet

- Activity Hazard Analysis: Well DiggingDocument1 pageActivity Hazard Analysis: Well DiggingarjunkoiralaNo ratings yet

- Method of Statement For Filling Grout Into Sonic PipeDocument5 pagesMethod of Statement For Filling Grout Into Sonic PipeNara Kong100% (3)

- Method Statment Cable Tray & TrunkingDocument4 pagesMethod Statment Cable Tray & Trunkingmahroof mkuttyNo ratings yet

- New Austrian Tunneling MethodDocument31 pagesNew Austrian Tunneling MethodJudy Ann CacutNo ratings yet

- Work Method Statement - Soil ProtectionDocument2 pagesWork Method Statement - Soil ProtectionAugust Caezar LagatNo ratings yet

- New Austrian Tunneling MethodDocument31 pagesNew Austrian Tunneling MethodJudy Ann CacutNo ratings yet

- Hip - Qatif Aramco - FinalDocument10 pagesHip - Qatif Aramco - FinalDarius DsouzaNo ratings yet

- Tuaman Engineering Limited: Job Safety Analysis (Jsa)Document6 pagesTuaman Engineering Limited: Job Safety Analysis (Jsa)abhijit janaNo ratings yet

- RADocument2 pagesRAalisheeraz0302No ratings yet

- FOC InstallationProceduresDocument10 pagesFOC InstallationProceduresjahanzaibNo ratings yet

- 472415886 Jsa for Pipe Laying Water and Sewer 1Document1 page472415886 Jsa for Pipe Laying Water and Sewer 1nagavijayababu108No ratings yet

- 002 Under Ground CableDocument8 pages002 Under Ground CableMohamed KasemNo ratings yet

- E1B118065 - KOMALA PUTRI-dikonversiDocument26 pagesE1B118065 - KOMALA PUTRI-dikonversiKomala Putri00No ratings yet

- Standard Operating Procedure - Fibre Optic InstallationDocument17 pagesStandard Operating Procedure - Fibre Optic InstallationKaavi MaharajNo ratings yet

- WMS Installing Precast Concrete Ring Using Sinking MethodDocument4 pagesWMS Installing Precast Concrete Ring Using Sinking Methodasr.engineering2023No ratings yet

- 5 Fall Protection & Prevention Methodology For DE Shuttering WorkDocument3 pages5 Fall Protection & Prevention Methodology For DE Shuttering WorkKiran ChenchalaNo ratings yet

- Critical Steps Hazard(s) Controls/Recommended Action: Concrete Cutting & Breaking Core Cutting On Existing Man HoleDocument5 pagesCritical Steps Hazard(s) Controls/Recommended Action: Concrete Cutting & Breaking Core Cutting On Existing Man HoleSrikanth GandepalliNo ratings yet

- Unit2 ConsDocument22 pagesUnit2 ConsAmay HarshitNo ratings yet

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisDeshbandhu Aman PandeyNo ratings yet

- 14 - JSA For Replacement of Tube Bundles of (100-EA4-C3, C8) & 284-E52 & 810E7 With New OneDocument1 page14 - JSA For Replacement of Tube Bundles of (100-EA4-C3, C8) & 284-E52 & 810E7 With New OneSHAH NAWAZ SAEEDNo ratings yet

- Concrete Pouring of SHEARWALL and Columns First LiftDocument5 pagesConcrete Pouring of SHEARWALL and Columns First LiftJhundel Factor Pajarillaga100% (2)

- 14 - JSA For Replacement of Tube Bundles of (100-EA4-C3, C8) & 284-E52 & 810E7 With New OneDocument1 page14 - JSA For Replacement of Tube Bundles of (100-EA4-C3, C8) & 284-E52 & 810E7 With New OneSHAH NAWAZ SAEED100% (1)

- Job Safety Analysis Sheet:: GOR TestDocument1 pageJob Safety Analysis Sheet:: GOR Testhp9mzbjzsfNo ratings yet

- Kano Racks Methd StatementDocument8 pagesKano Racks Methd StatementOdejobi OloladeNo ratings yet

- Trimurti Fabricators PVT LTD.: Monsoon Protection PlanDocument4 pagesTrimurti Fabricators PVT LTD.: Monsoon Protection Planalla malikNo ratings yet

- Excavation Shoring and Protection ProcedureDocument7 pagesExcavation Shoring and Protection ProcedureREBAA HatemNo ratings yet

- Job Hazard Analysis ON Erection of High Mast Lighting SystemDocument5 pagesJob Hazard Analysis ON Erection of High Mast Lighting SystemKiran Bhatt100% (4)

- SOP 002 - Excavation Work and Underground ServicesDocument2 pagesSOP 002 - Excavation Work and Underground ServicesBrandon OelofseNo ratings yet

- Bombers' Training, and Application of Same in Trench WarfareFrom EverandBombers' Training, and Application of Same in Trench WarfareNo ratings yet

- Duplicate Result Card Application FormDocument4 pagesDuplicate Result Card Application FormShoaib akhterNo ratings yet

- A Project Report ON: Customers Perception Towards Lays in IndiaDocument5 pagesA Project Report ON: Customers Perception Towards Lays in Indiamahathi patelNo ratings yet

- PSA 580 Focus NotesDocument1 pagePSA 580 Focus Noteskristel-marie-pitogo-4419No ratings yet

- Government Procurement Law McqsDocument9 pagesGovernment Procurement Law Mcqsagaceram9090No ratings yet

- Executives PDFDocument49 pagesExecutives PDFdharmender singhNo ratings yet

- A1+ UNIT 6 Culture PDFDocument2 pagesA1+ UNIT 6 Culture PDFNardiaNo ratings yet

- Hyped Mangoes Portfolio - Manila Malls-JcoDocument46 pagesHyped Mangoes Portfolio - Manila Malls-JcoMaria AlvarezNo ratings yet

- Parcel Compare InvoiceDocument1 pageParcel Compare InvoiceGadde Niharika ChowdaryNo ratings yet

- Project Finance Application FormDocument16 pagesProject Finance Application FormAlidu Abdul-MajeedNo ratings yet

- Midterms Exam Tech BsitDocument8 pagesMidterms Exam Tech BsitAC GanadoNo ratings yet

- A Report On Organization StudyDocument63 pagesA Report On Organization StudyGowtham KSNo ratings yet

- Influencer MarketingDocument54 pagesInfluencer Marketingtdkhoa92No ratings yet

- Upsc - Mains Exam - 2019 Economics (Optional) Paper IDocument5 pagesUpsc - Mains Exam - 2019 Economics (Optional) Paper Iamol maliNo ratings yet

- Form 27Document1 pageForm 27JORDANNo ratings yet

- Do-It-Yourself (DIY)Document8 pagesDo-It-Yourself (DIY)Anas WaseemNo ratings yet

- DEED OF ABSOLUTE SALE - Headstrong Realty Corporation - June 14, 2020Document9 pagesDEED OF ABSOLUTE SALE - Headstrong Realty Corporation - June 14, 2020Humberto Jr LimNo ratings yet

- Statutory Bank Branch Audit Technical and Practical AspectsDocument101 pagesStatutory Bank Branch Audit Technical and Practical AspectsAayush BansalNo ratings yet

- LAS ABM - FABM12 Ia B 4 Week 1Document7 pagesLAS ABM - FABM12 Ia B 4 Week 1ROMMEL RABONo ratings yet

- Aquib Sadman Bari Lumid Thesis - LupDocument58 pagesAquib Sadman Bari Lumid Thesis - LupAl-amin princeNo ratings yet

- 9 MPSDocument49 pages9 MPSIrmanda SyahraniNo ratings yet

- Print - Udyam Registration CertificateDocument2 pagesPrint - Udyam Registration CertificateanandranisatiNo ratings yet

- Hse Cost BudgetDocument53 pagesHse Cost BudgetGamma Rais RizaniNo ratings yet

- A Study On Customer Perception Towards Advaith Hyundai, BangaloreDocument99 pagesA Study On Customer Perception Towards Advaith Hyundai, Bangaloresridhar mNo ratings yet

- JRC 92241Document110 pagesJRC 92241felipedulinskiNo ratings yet

- Florente Jr. vs. FlorenteDocument3 pagesFlorente Jr. vs. FlorentetulipcatcherNo ratings yet

- State Bank of India Vrs Case Study: By: Saurabh AmbaselkarDocument17 pagesState Bank of India Vrs Case Study: By: Saurabh AmbaselkarSaurabh Ambaselkar0% (1)

Underground Piping

Underground Piping

Uploaded by

Muhammad Bilal SajidOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Underground Piping

Underground Piping

Uploaded by

Muhammad Bilal SajidCopyright:

Available Formats

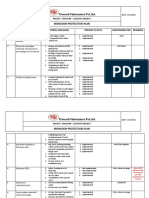

METHOD STATEMENT

CONTRACTOR T&T BROTHERS

PROJECT TITLE Kak Bridge F/S

PROJECT START DATE 01/09/2023

Work Scope Underground Piping

Tools, Equipment, and Machineries 1. Leveling Instruments

2. Brush for Bitumen Application.

Materials 1. Bitumen

2. Cement

3. Aggregate

4. Sand

Personal Protective Equipment (PPE) 1. Hard hat

2. Reflective Vest

3. Cut Resistant Gloves

4. Cotton Gloves

5. Dust Mask

6. Goggles

7. Safety Harness

Safety Equipment 1. Hard Barricading

2. Flag for Traffic Control

3. Safety Cones

4. First Aid Kit

5. Fire Blanket

6. Fire Extinguisher

7. Safety Signage

Procedures

1 Quality Inspection Plan (QIP) specific to project requirements shall be made and inspection

activities shall be recorded on the given Format

2 Layout marking for excavation using the latest construction drawings

3 Excavation must proceed with the help of the Excavation method statement.

4 The piping material shall be shifted from the warehouse or from lay down area by using a

suitable crane and nylon slings for lifting purposes. Proper care should be taken for shifting

of pipes depending upon the nature of the material, e.g. cement lined piping needs more

care in handling as compared to drainpipes.

5 The pipes shall be lowered into the trench directly on sandbags (or firm bearing surface as

per project specification) except portions where field joints shall be done. After welding and

testing activity, the bearing shall be extended under leftover positions.

General Safety Instruction

METHOD STATEMENT

1. Appropriate personal protective gear shall be used for manual brush cleaning or handling primer

as per manufacturer instructions.

2. Handling, cutting & and joining operation of piping shall be done as per safety standards keeping

in view that personal and environmental hazards are to be avoided.

3. Handling, heating, and application of primer and/or coal tar shall be done as per manufacturer

specifications.

4. Before lowering or inspecting in site ensure appropriate route/access to the excavation area.

Unwanted burials of materials/equipment or injury to any person are to be avoided during

backfilling.

5. Excavations & Openings

6. • Prior to any excavation, a survey shall be carried out of the area to establish the presence of

any underground utilities and identify any overhead lines and other obstructions.

7. Where “live” services are present, hand excavation shall be carried out, after getting a work

safety permit from Shell/Meinhardt.

8. Only rigid & and fixed barriers will be provided for edge protection on excavations & and floor

openings.

9. The trenches that go across roads shall be done in such a manner that ensures and maintains

access.

10. Personnel will be kept clear of machinery whilst it is in operation at a minimum distance of 5

meters.

11. Trucks used for the removal of soil shall be controlled and sited by a bank man.

12. Excavated soil shall be stacked at a minimum distance of one meter from the edge of the

excavation.

13. All shoring shall be constructed of materials capable of withstanding collapse and shall be

adequately braced.

14. The excavation shall be provided with built staircases or a ladder at 8-meter intervals as a means

of escape.

15. The walkways of a minimum 600mm width shall be placed across trenches where access is

required.

16. Uncovered services and utilities will be adequately supported.

17. Minimize the soil erosion.

18. All hole ditches and sumps should be backfilled to prevent the subsurface water from

contamination.

19. Periodically water sprinkling to prevent dust arias.

20. Minimize the disturbances to the natural drainage system.

21. Preserve your natural environment.

Prepared by Syed Fakhar Abbas

Muhammad Bilal Sajid

Approved by Naeem Anjum

You might also like

- Jsa For Pipe Laying Water and Sewer-1Document8 pagesJsa For Pipe Laying Water and Sewer-1Mikael Naqib83% (6)

- DPWH PDM PiceDocument55 pagesDPWH PDM Picemmabee100% (4)

- Method Statement For Trial Pit ExcavationDocument4 pagesMethod Statement For Trial Pit ExcavationCwazy MarooyNo ratings yet

- The Impact of Forward and Backward Integration On Microsoft S Performance and Sustainability in AmericaDocument32 pagesThe Impact of Forward and Backward Integration On Microsoft S Performance and Sustainability in Americakariuki josephNo ratings yet

- Method Statement - Site ClearanceDocument6 pagesMethod Statement - Site Clearanceqoci5ko100% (1)

- Job Safety Analysis Lifting and RiggingDocument17 pagesJob Safety Analysis Lifting and RiggingSam Seed100% (1)

- StatementOfAccount 150954646 Oct24 183900Document2 pagesStatementOfAccount 150954646 Oct24 183900keerthiram1991No ratings yet

- Examination 680Document22 pagesExamination 680Maha Al AmadNo ratings yet

- Water ProofingDocument2 pagesWater ProofingMuhammad Bilal SajidNo ratings yet

- Work Method Statement: BNPP-HSE-JHA-2014-210 6Document8 pagesWork Method Statement: BNPP-HSE-JHA-2014-210 6Karthik babuNo ratings yet

- JSA For Crane Columan Foundation - AB.1Document9 pagesJSA For Crane Columan Foundation - AB.1hse2No ratings yet

- Fence Installation - Method StatementDocument5 pagesFence Installation - Method StatementvelisantshuntsheNo ratings yet

- Excavation Safety - Hazards and Precautions - Safety NotesDocument5 pagesExcavation Safety - Hazards and Precautions - Safety Notesaneethavils100% (1)

- Jsa PCC & RCCDocument2 pagesJsa PCC & RCCNilesh koliNo ratings yet

- IPM - MOS - Roofing Program-Rev3.0 (15.06.2022)Document8 pagesIPM - MOS - Roofing Program-Rev3.0 (15.06.2022)mohdnurasyraafNo ratings yet

- Risk Assessment: Concrete Work (PCC/RCC)Document2 pagesRisk Assessment: Concrete Work (PCC/RCC)hemant yadavNo ratings yet

- Job Hazard Analysis (Earth Mounted Tank)Document8 pagesJob Hazard Analysis (Earth Mounted Tank)jay RNo ratings yet

- Geotextile Installation Procedure - SPEDIDocument1 pageGeotextile Installation Procedure - SPEDIRyan DizonNo ratings yet

- Job Hazard Analysis: Amichand Technological Pvt. LTDDocument6 pagesJob Hazard Analysis: Amichand Technological Pvt. LTDSandeep KumarNo ratings yet

- Method Statements For Construction of Masonry Lined Drains Rev 0Document13 pagesMethod Statements For Construction of Masonry Lined Drains Rev 0McDonald WesleyNo ratings yet

- Method Statement - FOC - FYSH - 031010Document2 pagesMethod Statement - FOC - FYSH - 031010DilxazNo ratings yet

- Site Security Barricading Procedure-SPEDIDocument2 pagesSite Security Barricading Procedure-SPEDIRyan DizonNo ratings yet

- JSA FOR WELDING, GRINDING, GAS CUTTINGDocument2 pagesJSA FOR WELDING, GRINDING, GAS CUTTINGm.rehanhseNo ratings yet

- Risk Assessment What Work Excavation Work With Help of JCB Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDDocument2 pagesRisk Assessment What Work Excavation Work With Help of JCB Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDhemant yadav33% (3)

- 02 Job Hazard Analysis For Deep Excavation & TrenchingDocument3 pages02 Job Hazard Analysis For Deep Excavation & TrenchingAmanNo ratings yet

- METH-00002-A - Method Statement - Supply & Return DuctworkDocument5 pagesMETH-00002-A - Method Statement - Supply & Return Ductworkmohd arshadNo ratings yet

- Jsa For Welding, Grinding, Gas CuttingDocument2 pagesJsa For Welding, Grinding, Gas Cuttingwahyu nugroho67% (3)

- Part 4 ExcavationDocument6 pagesPart 4 ExcavationHana Seiadi100% (1)

- Jsa For PCCDocument6 pagesJsa For PCCCICON EngineersNo ratings yet

- Relocation of Device On Concrete SlabDocument1 pageRelocation of Device On Concrete SlabBento BoxNo ratings yet

- JOB HAZARD ANALYSIS Deep Excavation-2Document9 pagesJOB HAZARD ANALYSIS Deep Excavation-2jay RNo ratings yet

- 1-JHA - ExcavationDocument2 pages1-JHA - ExcavationAnna Marie Filipinas RajilNo ratings yet

- Revised - MosDocument15 pagesRevised - MosNadeesha BandaraNo ratings yet

- Del 861117751920793Document9 pagesDel 861117751920793Varahi VigneshNo ratings yet

- 2-JHA - FormworksDocument3 pages2-JHA - FormworksAnna Marie Filipinas RajilNo ratings yet

- Activity Hazard Analysis: Well DiggingDocument1 pageActivity Hazard Analysis: Well DiggingarjunkoiralaNo ratings yet

- Method of Statement For Filling Grout Into Sonic PipeDocument5 pagesMethod of Statement For Filling Grout Into Sonic PipeNara Kong100% (3)

- Method Statment Cable Tray & TrunkingDocument4 pagesMethod Statment Cable Tray & Trunkingmahroof mkuttyNo ratings yet

- New Austrian Tunneling MethodDocument31 pagesNew Austrian Tunneling MethodJudy Ann CacutNo ratings yet

- Work Method Statement - Soil ProtectionDocument2 pagesWork Method Statement - Soil ProtectionAugust Caezar LagatNo ratings yet

- New Austrian Tunneling MethodDocument31 pagesNew Austrian Tunneling MethodJudy Ann CacutNo ratings yet

- Hip - Qatif Aramco - FinalDocument10 pagesHip - Qatif Aramco - FinalDarius DsouzaNo ratings yet

- Tuaman Engineering Limited: Job Safety Analysis (Jsa)Document6 pagesTuaman Engineering Limited: Job Safety Analysis (Jsa)abhijit janaNo ratings yet

- RADocument2 pagesRAalisheeraz0302No ratings yet

- FOC InstallationProceduresDocument10 pagesFOC InstallationProceduresjahanzaibNo ratings yet

- 472415886 Jsa for Pipe Laying Water and Sewer 1Document1 page472415886 Jsa for Pipe Laying Water and Sewer 1nagavijayababu108No ratings yet

- 002 Under Ground CableDocument8 pages002 Under Ground CableMohamed KasemNo ratings yet

- E1B118065 - KOMALA PUTRI-dikonversiDocument26 pagesE1B118065 - KOMALA PUTRI-dikonversiKomala Putri00No ratings yet

- Standard Operating Procedure - Fibre Optic InstallationDocument17 pagesStandard Operating Procedure - Fibre Optic InstallationKaavi MaharajNo ratings yet

- WMS Installing Precast Concrete Ring Using Sinking MethodDocument4 pagesWMS Installing Precast Concrete Ring Using Sinking Methodasr.engineering2023No ratings yet

- 5 Fall Protection & Prevention Methodology For DE Shuttering WorkDocument3 pages5 Fall Protection & Prevention Methodology For DE Shuttering WorkKiran ChenchalaNo ratings yet

- Critical Steps Hazard(s) Controls/Recommended Action: Concrete Cutting & Breaking Core Cutting On Existing Man HoleDocument5 pagesCritical Steps Hazard(s) Controls/Recommended Action: Concrete Cutting & Breaking Core Cutting On Existing Man HoleSrikanth GandepalliNo ratings yet

- Unit2 ConsDocument22 pagesUnit2 ConsAmay HarshitNo ratings yet

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisDeshbandhu Aman PandeyNo ratings yet

- 14 - JSA For Replacement of Tube Bundles of (100-EA4-C3, C8) & 284-E52 & 810E7 With New OneDocument1 page14 - JSA For Replacement of Tube Bundles of (100-EA4-C3, C8) & 284-E52 & 810E7 With New OneSHAH NAWAZ SAEEDNo ratings yet

- Concrete Pouring of SHEARWALL and Columns First LiftDocument5 pagesConcrete Pouring of SHEARWALL and Columns First LiftJhundel Factor Pajarillaga100% (2)

- 14 - JSA For Replacement of Tube Bundles of (100-EA4-C3, C8) & 284-E52 & 810E7 With New OneDocument1 page14 - JSA For Replacement of Tube Bundles of (100-EA4-C3, C8) & 284-E52 & 810E7 With New OneSHAH NAWAZ SAEED100% (1)

- Job Safety Analysis Sheet:: GOR TestDocument1 pageJob Safety Analysis Sheet:: GOR Testhp9mzbjzsfNo ratings yet

- Kano Racks Methd StatementDocument8 pagesKano Racks Methd StatementOdejobi OloladeNo ratings yet

- Trimurti Fabricators PVT LTD.: Monsoon Protection PlanDocument4 pagesTrimurti Fabricators PVT LTD.: Monsoon Protection Planalla malikNo ratings yet

- Excavation Shoring and Protection ProcedureDocument7 pagesExcavation Shoring and Protection ProcedureREBAA HatemNo ratings yet

- Job Hazard Analysis ON Erection of High Mast Lighting SystemDocument5 pagesJob Hazard Analysis ON Erection of High Mast Lighting SystemKiran Bhatt100% (4)

- SOP 002 - Excavation Work and Underground ServicesDocument2 pagesSOP 002 - Excavation Work and Underground ServicesBrandon OelofseNo ratings yet

- Bombers' Training, and Application of Same in Trench WarfareFrom EverandBombers' Training, and Application of Same in Trench WarfareNo ratings yet

- Duplicate Result Card Application FormDocument4 pagesDuplicate Result Card Application FormShoaib akhterNo ratings yet

- A Project Report ON: Customers Perception Towards Lays in IndiaDocument5 pagesA Project Report ON: Customers Perception Towards Lays in Indiamahathi patelNo ratings yet

- PSA 580 Focus NotesDocument1 pagePSA 580 Focus Noteskristel-marie-pitogo-4419No ratings yet

- Government Procurement Law McqsDocument9 pagesGovernment Procurement Law Mcqsagaceram9090No ratings yet

- Executives PDFDocument49 pagesExecutives PDFdharmender singhNo ratings yet

- A1+ UNIT 6 Culture PDFDocument2 pagesA1+ UNIT 6 Culture PDFNardiaNo ratings yet

- Hyped Mangoes Portfolio - Manila Malls-JcoDocument46 pagesHyped Mangoes Portfolio - Manila Malls-JcoMaria AlvarezNo ratings yet

- Parcel Compare InvoiceDocument1 pageParcel Compare InvoiceGadde Niharika ChowdaryNo ratings yet

- Project Finance Application FormDocument16 pagesProject Finance Application FormAlidu Abdul-MajeedNo ratings yet

- Midterms Exam Tech BsitDocument8 pagesMidterms Exam Tech BsitAC GanadoNo ratings yet

- A Report On Organization StudyDocument63 pagesA Report On Organization StudyGowtham KSNo ratings yet

- Influencer MarketingDocument54 pagesInfluencer Marketingtdkhoa92No ratings yet

- Upsc - Mains Exam - 2019 Economics (Optional) Paper IDocument5 pagesUpsc - Mains Exam - 2019 Economics (Optional) Paper Iamol maliNo ratings yet

- Form 27Document1 pageForm 27JORDANNo ratings yet

- Do-It-Yourself (DIY)Document8 pagesDo-It-Yourself (DIY)Anas WaseemNo ratings yet

- DEED OF ABSOLUTE SALE - Headstrong Realty Corporation - June 14, 2020Document9 pagesDEED OF ABSOLUTE SALE - Headstrong Realty Corporation - June 14, 2020Humberto Jr LimNo ratings yet

- Statutory Bank Branch Audit Technical and Practical AspectsDocument101 pagesStatutory Bank Branch Audit Technical and Practical AspectsAayush BansalNo ratings yet

- LAS ABM - FABM12 Ia B 4 Week 1Document7 pagesLAS ABM - FABM12 Ia B 4 Week 1ROMMEL RABONo ratings yet

- Aquib Sadman Bari Lumid Thesis - LupDocument58 pagesAquib Sadman Bari Lumid Thesis - LupAl-amin princeNo ratings yet

- 9 MPSDocument49 pages9 MPSIrmanda SyahraniNo ratings yet

- Print - Udyam Registration CertificateDocument2 pagesPrint - Udyam Registration CertificateanandranisatiNo ratings yet

- Hse Cost BudgetDocument53 pagesHse Cost BudgetGamma Rais RizaniNo ratings yet

- A Study On Customer Perception Towards Advaith Hyundai, BangaloreDocument99 pagesA Study On Customer Perception Towards Advaith Hyundai, Bangaloresridhar mNo ratings yet

- JRC 92241Document110 pagesJRC 92241felipedulinskiNo ratings yet

- Florente Jr. vs. FlorenteDocument3 pagesFlorente Jr. vs. FlorentetulipcatcherNo ratings yet

- State Bank of India Vrs Case Study: By: Saurabh AmbaselkarDocument17 pagesState Bank of India Vrs Case Study: By: Saurabh AmbaselkarSaurabh Ambaselkar0% (1)