Professional Documents

Culture Documents

Problems Eoq

Problems Eoq

Uploaded by

Hoàng Ngọc Lan0 ratings0% found this document useful (0 votes)

4 views2 pages1. The automobile manufacturer should order 289 pairs of bumpers each time (the EOQ) to minimize total annual costs of $10,392. This will result in 208 orders per year. Ordering 600 pairs each time would cost $13,300 annually, saving $2,908 by ordering the EOQ.

2. The bumper manufacturer's EOQ is 1,633 pairs, minimizing total annual costs of $18,371. Producing 3,000 pairs each run would cost $21,875 annually, saving $3,504 by producing the EOQ each time.

Original Description:

Original Title

problems_eoq

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. The automobile manufacturer should order 289 pairs of bumpers each time (the EOQ) to minimize total annual costs of $10,392. This will result in 208 orders per year. Ordering 600 pairs each time would cost $13,300 annually, saving $2,908 by ordering the EOQ.

2. The bumper manufacturer's EOQ is 1,633 pairs, minimizing total annual costs of $18,371. Producing 3,000 pairs each run would cost $21,875 annually, saving $3,504 by producing the EOQ each time.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

4 views2 pagesProblems Eoq

Problems Eoq

Uploaded by

Hoàng Ngọc Lan1. The automobile manufacturer should order 289 pairs of bumpers each time (the EOQ) to minimize total annual costs of $10,392. This will result in 208 orders per year. Ordering 600 pairs each time would cost $13,300 annually, saving $2,908 by ordering the EOQ.

2. The bumper manufacturer's EOQ is 1,633 pairs, minimizing total annual costs of $18,371. Producing 3,000 pairs each run would cost $21,875 annually, saving $3,504 by producing the EOQ each time.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

Problems

1. An automobile manufacturer uses about 60,000 pairs of bumpers (front

bumper and rear bumper) per year, which it orders from a supplier. The bumpers

are used at a reasonably steady rate during the 240 working days per year. It

costs $3.00 to keep one pair of bumpers in inventory for one month, and it costs

$25.00 to place an order. A pair of bumpers costs $150.00.

a. Write the annual carrying cost function.

b. Write the annual ordering cost function.

c. Write the annual total cost function.

d. What is the EOQ?

e. What is the significance of the EOQ?

f. What is the total annual expense of ordering the EOQ every time?

g. How many orders will be placed per year?

h. What is the total annual expense of ordering 600 pairs of bumpers

every time? How much is saved per year by ordering the EOQ?

2. The Acme Bumper Co. manufactures bumpers for automobiles for one of the

big three auto companies. About 60,000 pairs of bumpers (front bumper and

rear bumper) are ordered by the auto company per year, at a price of $150.00

per pair. Pairs of bumpers are produced at a rate of about 400 per working day,

and the company operates 240 days per year. The company manufactures other

products, and it must set up the manufacturing system for a production order for

pairs of bumpers, which costs $250.00. It costs $2.50 to store one pair of

bumpers for one month.

Write the annual carrying cost function.

a. Write the annual carrying cost function.

b. Write the annual setup cost function.

c. Write the annual total cost function.

d. What is the EOQ?

e. What is the significance of the EOQ?

f. What is the total annual expense of producing the EOQ every time?

g. How many production runs will be required per year?

h. What is the total annual expense of manufacturing 3,000 pairs of

bumpers per production run? How much is saved per year by producing

the EOQ every time?

1. a. Use the instantaneous model.

b. The annual carrying cost = HQ/2 = 3(12)Q/2 = 18Q.

c. The annual ordering cost = DS/Q = 60000(25)/Q = 1500000/Q.

d. The annual total cost = 18Q + 1500000/Q.

e. Image97 Image98 » 289 pairs of bumpers.

f. Every time the company places an order, it should order 289 pairs of bumpers.

g. The annual total expense = (Q/2)H + (D/Q)S = (289/2)36 + (60,000/289)25 = $10,392.00

per year.

h. The number of orders = D/Q = 60000/289 » 208 per year.

i. The annual total expense = 18(600) + 1500000/600 = $13,300. The annual savings are

$13,300 - $10,392 = $2,908.00.

2. a. Use the noninstantaneous model.

b. The annual carrying cost = (HQ/2)[(P-U)/P] = (2.50(12)Q/2)[(400 - 60000/240)]/400 =

5.625Q.

c. The annual setup cost = DS/Q = 60000(250)/Q = 15000000/Q.

d. The annual total cost = 5.625Q + 15000000/Q.

e. EOQ = Image99 Image100 = Image101 x =

Image102 1,633 pairs of bumpers.

f. The company should place a production order for 1,633 pairs of bumpers every time.

g. The annual total cost = 5.625EOQ + 15000000/EOQ = 5.625(1633) + 15000000/1633 »

$18,371.00 per year.

h. The number of production runs = D/EOQ = 60000/1633 = 36.74 runs per year.

i. The annual total cost = 5.625(3000) + 15000000/3000 = $21,875.00. The annual savings

are $21,875.00 - $18,371.00 = $3,504.00.

i.

You might also like

- Inventory Sample ProbsDocument5 pagesInventory Sample ProbsSreekanth Nagloor100% (3)

- Economics - FE Review Problems and Solutions 2012Document154 pagesEconomics - FE Review Problems and Solutions 2012Blake Reeves50% (2)

- ACTG243 Practice Quiz 7Document4 pagesACTG243 Practice Quiz 7GuruBaluLeoKing0% (1)

- GP080 120VXDocument814 pagesGP080 120VXSilvio0% (1)

- Problems EcoDocument2 pagesProblems EcoMuhammad BilalNo ratings yet

- InventoryDocument6 pagesInventorysaaz77No ratings yet

- 1 Ass-2Document13 pages1 Ass-2Kim SooanNo ratings yet

- ACCA F5 2015 Study MaterialDocument31 pagesACCA F5 2015 Study MaterialyoloNo ratings yet

- Copia de O&O Costs Estimating FormDocument8 pagesCopia de O&O Costs Estimating FormMónica Rada UrbinaNo ratings yet

- Literature Review 1 PageDocument9 pagesLiterature Review 1 PageMahbub HussainNo ratings yet

- CH 04Document13 pagesCH 04Shaiful Hussain100% (2)

- Breakeven and EOQ Exercises (With Answers)Document6 pagesBreakeven and EOQ Exercises (With Answers)Charlene ChorNo ratings yet

- EOQ QuestionDocument8 pagesEOQ QuestionSaurav ShawNo ratings yet

- Practice Problems For The FinalDocument20 pagesPractice Problems For The FinalThanh Ngân0% (2)

- ch5 ABC-2Document13 pagesch5 ABC-2k62sb.2312451002No ratings yet

- Tutorial 4Document6 pagesTutorial 4FEI FEINo ratings yet

- Acct1003 Midsemester Exam08-09 SOLUTIONSDocument7 pagesAcct1003 Midsemester Exam08-09 SOLUTIONSKimberly KangalooNo ratings yet

- Management Advisory Services - MidtermDocument7 pagesManagement Advisory Services - MidtermROB101512No ratings yet

- 305 Final Exam Cram Question PackageDocument14 pages305 Final Exam Cram Question PackageGloriana FokNo ratings yet

- Homework Chapter 3Document3 pagesHomework Chapter 3cakesbybeth19No ratings yet

- Capacity Problem1Document3 pagesCapacity Problem1Ahmed ZamanNo ratings yet

- Assignment Chapter 4/6Document4 pagesAssignment Chapter 4/6Muhammad Tahir NawazNo ratings yet

- Actg 10 - MAS Midterm ExamDocument24 pagesActg 10 - MAS Midterm Examjoemel091190100% (1)

- CAPE AccountingDocument10 pagesCAPE Accountingget thosebooksNo ratings yet

- Batch CostingDocument8 pagesBatch CostingVarun TiwariNo ratings yet

- BDC Preboard Feb 2011 - MasDocument10 pagesBDC Preboard Feb 2011 - Mas1hewlett100% (1)

- CH2 QuizkeyDocument5 pagesCH2 QuizkeyiamacrusaderNo ratings yet

- F2 MockDocument23 pagesF2 MockH Hafiz Muhammad AbdullahNo ratings yet

- Accounting 203 Chapter 11 TestDocument5 pagesAccounting 203 Chapter 11 TestKate Angelic Diaz PintoNo ratings yet

- Ex 04 Inventory ManagementDocument4 pagesEx 04 Inventory ManagementZulhaily Suaille100% (1)

- Print TRA - 12Document65 pagesPrint TRA - 12Timothy RogatusNo ratings yet

- 2MGMT 3000 Tute Set 2 2019 (V1final)Document3 pages2MGMT 3000 Tute Set 2 2019 (V1final)SahanNo ratings yet

- Mid Term AccountingDocument40 pagesMid Term AccountingVanessa Pacheco100% (3)

- MGT Chap 6Document5 pagesMGT Chap 6tomNo ratings yet

- PracticeDocument20 pagesPracticeAnbang Xiao100% (1)

- OP QuestionsDocument14 pagesOP QuestionsAhmad EssamNo ratings yet

- Phiếu Giao Bài Tập Số 3Document3 pagesPhiếu Giao Bài Tập Số 3Phạm Thị Thúy HằngNo ratings yet

- Cagayan State University - AndrewsDocument4 pagesCagayan State University - AndrewsWynie AreolaNo ratings yet

- 111年會考 成管會題庫Document21 pages111年會考 成管會題庫張巧薇No ratings yet

- Lecture Engineering Economics FE Review ProblemsDocument23 pagesLecture Engineering Economics FE Review ProblemsLee Song HanNo ratings yet

- Exercises Chapter07 PricingDocument11 pagesExercises Chapter07 PricingQuỳnh ChâuNo ratings yet

- Classroom Exercises - BSCDocument4 pagesClassroom Exercises - BSCAdrian Gabriel Sincero LuceroNo ratings yet

- Practice QuestionsDocument3 pagesPractice QuestionsNeha SardanaNo ratings yet

- Engineering Economy 16th Edition Sullivan Test BankDocument5 pagesEngineering Economy 16th Edition Sullivan Test BankThomas Seamon100% (44)

- Chapter 4-Differential Analysis (Q)Document10 pagesChapter 4-Differential Analysis (Q)Vanessa HaliliNo ratings yet

- Sheet 2 Engineering Economy 2018-2019Document3 pagesSheet 2 Engineering Economy 2018-2019حسن علي جاسمNo ratings yet

- Cost AccountingDocument64 pagesCost AccountingKrestyl Ann GabaldaNo ratings yet

- St. Mary Sabah 2013 M3 (Q) PDFDocument2 pagesSt. Mary Sabah 2013 M3 (Q) PDFSTPMmathsNo ratings yet

- ExamDocument8 pagesExamDestruelNo ratings yet

- Managerial AccountingDocument3 pagesManagerial Accountingsani02No ratings yet

- Assignment 5 (Economics Exercises)Document5 pagesAssignment 5 (Economics Exercises)OlyvianurmaharaniNo ratings yet

- Final Managerial 2014 SolutionDocument8 pagesFinal Managerial 2014 SolutionRanim HfaidhiaNo ratings yet

- Assignment For EconomicsDocument5 pagesAssignment For EconomicstarekNo ratings yet

- Demo LMS FE ExamDocument2 pagesDemo LMS FE ExamKaram SalahNo ratings yet

- PM Sunway Test July-Sept 2023 PTDocument11 pagesPM Sunway Test July-Sept 2023 PTFarahAin FainNo ratings yet

- QuizletDocument11 pagesQuizletjoanna mercadoNo ratings yet

- CH 8 and 9Document37 pagesCH 8 and 9hamdanmakNo ratings yet

- Economic Insights from Input–Output Tables for Asia and the PacificFrom EverandEconomic Insights from Input–Output Tables for Asia and the PacificNo ratings yet

- HihihiDocument9 pagesHihihiHoàng Ngọc LanNo ratings yet

- 005 Chapter Five Trade 2Document23 pages005 Chapter Five Trade 2Hoàng Ngọc LanNo ratings yet

- Business Research SkillDocument33 pagesBusiness Research SkillHoàng Ngọc Lan100% (1)

- Seadragon Logistics - Container Packing List - EvergreenDocument1 pageSeadragon Logistics - Container Packing List - EvergreenHoàng Ngọc LanNo ratings yet

- Mini Case - The McGee Cake CompanyDocument1 pageMini Case - The McGee Cake CompanyHoàng Ngọc LanNo ratings yet

- Kau, AK Loh, EWY 2006, The Effects of Service Recovery On Consumer Satisfaction. A Comparison Between Complainants and Non ComplainantsDocument16 pagesKau, AK Loh, EWY 2006, The Effects of Service Recovery On Consumer Satisfaction. A Comparison Between Complainants and Non ComplainantsHoàng Ngọc LanNo ratings yet

- Mini Case - Blades - Management of Transaction ExposureDocument3 pagesMini Case - Blades - Management of Transaction ExposureHoàng Ngọc LanNo ratings yet

- Mini Case - Blades - Exposure To International Flow of FundDocument2 pagesMini Case - Blades - Exposure To International Flow of FundHoàng Ngọc LanNo ratings yet

- Unit 3 - Market AccessDocument69 pagesUnit 3 - Market AccessHoàng Ngọc LanNo ratings yet

- Unit 3 - DSUDocument46 pagesUnit 3 - DSUHoàng Ngọc LanNo ratings yet

- Schedules A B C D and HDocument38 pagesSchedules A B C D and HPiyuesh SharmaNo ratings yet

- Trailler On JettyDocument4 pagesTrailler On JettyFuad Andaru BaskaraNo ratings yet

- JCBDocument29 pagesJCBAtul Kumar80% (5)

- Evs WorksheetDocument3 pagesEvs WorksheetJaya mohanNo ratings yet

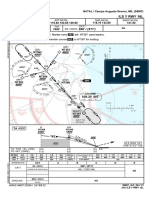

- SBNT Ils-Y-Rwy-16l Iac 20220224Document1 pageSBNT Ils-Y-Rwy-16l Iac 20220224Francisco SilvaNo ratings yet

- Transportation Infrastructure in The United StatesDocument2 pagesTransportation Infrastructure in The United StatesCato InstituteNo ratings yet

- 2Document2 pages2shohratNo ratings yet

- LTA Code of Practice Street Work Proposals To Development Works (Ver. 2019)Document203 pagesLTA Code of Practice Street Work Proposals To Development Works (Ver. 2019)Gary LokeNo ratings yet

- Tennoji Station MapDocument1 pageTennoji Station MapcecilegotamcoNo ratings yet

- Easa Ad 2023-0125 2Document3 pagesEasa Ad 2023-0125 2drajatNo ratings yet

- SSAB Trailer Design GuidelineDocument28 pagesSSAB Trailer Design GuidelineGerard Piedra García100% (1)

- Construction Sites Fatalities and InjuriesDocument7 pagesConstruction Sites Fatalities and InjurieseyassadailehNo ratings yet

- Event Data RecorderDocument9 pagesEvent Data RecorderAleksandar KnezevicNo ratings yet

- Malaysia Airlines Flight 370Document1 pageMalaysia Airlines Flight 370Ana Gabriela Gonzalez RNo ratings yet

- MRT TTDI Taman Tun DR Ismail: T814 Bus Time Schedule & Line MapDocument2 pagesMRT TTDI Taman Tun DR Ismail: T814 Bus Time Schedule & Line MapQimie WeaksNo ratings yet

- Mo Ta 4Document39 pagesMo Ta 4MaiChiVuNo ratings yet

- Hybrid EngineDocument20 pagesHybrid EngineThirumaaran GopalanNo ratings yet

- Yamaha F40 Owners Manual PDFDocument92 pagesYamaha F40 Owners Manual PDFErick DinkleNo ratings yet

- Rail Traction: Locomotive WorkingDocument40 pagesRail Traction: Locomotive WorkingDigillex DigillexNo ratings yet

- T CP H0G A110 DDocument12 pagesT CP H0G A110 DAnonymous J1OArR8M1No ratings yet

- AutoFren Pistons by Diameter 2017 SeinsaDocument67 pagesAutoFren Pistons by Diameter 2017 SeinsaJose Garcia MenchonNo ratings yet

- Oakajee Structure Plan ReportDocument72 pagesOakajee Structure Plan ReportHiddenDNo ratings yet

- Lift Brochure 2 PageDocument2 pagesLift Brochure 2 Pagesuporte colorgrafixNo ratings yet

- Lightside Darkside Essay 3Document9 pagesLightside Darkside Essay 3api-512176706No ratings yet

- Module 3Document21 pagesModule 3Isaac SenyohNo ratings yet

- Conference Events - Information PackDocument4 pagesConference Events - Information PackFrancesco AccollaNo ratings yet

- Shockwave TheoryDocument41 pagesShockwave TheoryChiranjaya HulangamuwaNo ratings yet

- Bob Kerrey Pedestrian Bridge Facts RevisedDocument1 pageBob Kerrey Pedestrian Bridge Facts Revisedfrajam79No ratings yet

- Group 3 HandoutDocument5 pagesGroup 3 HandoutAHR NICOLE PANGILINANNo ratings yet