Professional Documents

Culture Documents

BHMY 2x1 Flowgrid SP FS 34016A 1120 English

BHMY 2x1 Flowgrid SP FS 34016A 1120 English

Uploaded by

Luis Alberto Portugal MariacalCopyright:

Available Formats

You might also like

- Hamworthy Cargo Pump Manual PDFDocument140 pagesHamworthy Cargo Pump Manual PDFspamalstublieft1832No ratings yet

- Astm A234 PDFDocument8 pagesAstm A234 PDFhans30No ratings yet

- KSBB-BS Breather Valve Data SheetDocument2 pagesKSBB-BS Breather Valve Data Sheetfathonix0% (1)

- Mooney Flowgrid Valve: Technical Specifications 12/2018Document2 pagesMooney Flowgrid Valve: Technical Specifications 12/2018Luis Yovany Aldana PonceNo ratings yet

- Catalogo 2 WHxrbcyDocument2 pagesCatalogo 2 WHxrbcyOmar Equihua LinaresNo ratings yet

- Mooney 1" Flowgrid Regulator: With Shutoff ValveDocument2 pagesMooney 1" Flowgrid Regulator: With Shutoff ValveLuis Alberto Portugal MariacalNo ratings yet

- Rate of Flow and Fuel Shut Off Valve: ModelDocument2 pagesRate of Flow and Fuel Shut Off Valve: Modelanon_867776278No ratings yet

- V260 Control ValveDocument12 pagesV260 Control ValvenwabukingzNo ratings yet

- Pneumatically Operated With Manual Reset Deluge Valve For Freshwater and Seawater ServiceDocument2 pagesPneumatically Operated With Manual Reset Deluge Valve For Freshwater and Seawater ServicedmitosNo ratings yet

- Клапан Регулирующий Поворотный Finetrol Fc Fg 5ft20 EnDocument12 pagesКлапан Регулирующий Поворотный Finetrol Fc Fg 5ft20 EnAli KianersiNo ratings yet

- dsbv88 r15Document4 pagesdsbv88 r15Ricardo TurinNo ratings yet

- Rate of Flow Non-Surge Check Valve: ModelDocument2 pagesRate of Flow Non-Surge Check Valve: ModelAndrzej BąkałaNo ratings yet

- E4036Document2 pagesE4036Pablo Cardenas SandovalNo ratings yet

- CKEB Full en Metric LetterDocument2 pagesCKEB Full en Metric LetterRafalNo ratings yet

- Model Pilot-To-Open Check Valve With Standard Pilot: Series 2 / Capacity: 30 GPM / Cavity: T-2ADocument2 pagesModel Pilot-To-Open Check Valve With Standard Pilot: Series 2 / Capacity: 30 GPM / Cavity: T-2AVEERAMANINo ratings yet

- VG221 - 2 Port Control ValveDocument4 pagesVG221 - 2 Port Control ValveNoah MusundiNo ratings yet

- MVCDDocument15 pagesMVCDTrunghieu LeNo ratings yet

- Mooney Flexflo 887 Surge RelieversDocument6 pagesMooney Flexflo 887 Surge RelieversSajjad MehdiNo ratings yet

- Digital Control Valve Model BV88: Technical DataDocument4 pagesDigital Control Valve Model BV88: Technical Datajoana ramirezNo ratings yet

- CTO 1050 230 Current TransformerDocument3 pagesCTO 1050 230 Current Transformersagar ramaniNo ratings yet

- Documentatie Flowserve NAF 2 4 Vana Bila Model Setball FK SIALCO (2) 11Document8 pagesDocumentatie Flowserve NAF 2 4 Vana Bila Model Setball FK SIALCO (2) 11AntonNo ratings yet

- NH3 Compressor UnitDocument1 pageNH3 Compressor UnitdzungNo ratings yet

- Butterfly Valves - CatalogDocument30 pagesButterfly Valves - CatalogRamzi BEN AHMEDNo ratings yet

- Fisher Vee - Ball V150, V200, and V300 Noise AttenuatorDocument8 pagesFisher Vee - Ball V150, V200, and V300 Noise AttenuatorSergio SousaNo ratings yet

- Nautilus XMLA160D2S11Document2 pagesNautilus XMLA160D2S11Nazar AbbasNo ratings yet

- Fisher™ Type 1290 Vapor Recovery RegulatorDocument12 pagesFisher™ Type 1290 Vapor Recovery RegulatorBEJOY KBNo ratings yet

- Seawater Service Pressure Relief Valve: ModelDocument2 pagesSeawater Service Pressure Relief Valve: ModelHemant RasamNo ratings yet

- C16601 Proinert®2 Selector ValveDocument2 pagesC16601 Proinert®2 Selector Valvevld20082No ratings yet

- BHMY 1in FlowgridSS Shutoff FS 34049A 0920 EnglishDocument2 pagesBHMY 1in FlowgridSS Shutoff FS 34049A 0920 EnglishBertin KamsipaNo ratings yet

- E30C - Globe Valves NewDocument20 pagesE30C - Globe Valves NewTaha FaNo ratings yet

- Manuals 1190 Low Pressure Gas Blanketing Regulator Instruction Manual Fisher en en 5985974Document24 pagesManuals 1190 Low Pressure Gas Blanketing Regulator Instruction Manual Fisher en en 5985974marinjerman6No ratings yet

- 5 - Counter Balance Valve TSCA 70-10 - CBCHDocument4 pages5 - Counter Balance Valve TSCA 70-10 - CBCHIvan MaltsevNo ratings yet

- Afv TDB 9610.6 Capacity TablesDocument24 pagesAfv TDB 9610.6 Capacity TablesJorge BaronNo ratings yet

- Fisherr Posi-Sealt A31A High-Performance Butterfly ValveDocument12 pagesFisherr Posi-Sealt A31A High-Performance Butterfly ValveThanapaet RittirutNo ratings yet

- Deluge Valve Installation ManualDocument7 pagesDeluge Valve Installation Manualrahull.miishraNo ratings yet

- Flexflo Surge Relief BrochureDocument8 pagesFlexflo Surge Relief BrochureOscar DelgadoNo ratings yet

- Fisher Controls: Tight Shutoff-Throttling-sleeve Design With TFEDocument14 pagesFisher Controls: Tight Shutoff-Throttling-sleeve Design With TFEfiguev2208No ratings yet

- A11 High Performance Butterfly Valve BulletinDocument28 pagesA11 High Performance Butterfly Valve BulletinRizalfariz HasbiNo ratings yet

- Fisher V500 Rotary Globe Control Valve: Scope of ManualDocument28 pagesFisher V500 Rotary Globe Control Valve: Scope of ManualEdwar VivasNo ratings yet

- Model Pilot-To-Open Check Valve With Standard Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11ADocument2 pagesModel Pilot-To-Open Check Valve With Standard Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11AErasmo LimaNo ratings yet

- PI144J - Technical Data SheetDocument8 pagesPI144J - Technical Data Sheetengmohsen.ramadanhotmail.comNo ratings yet

- A31A Butterfly Valve BulletinDocument12 pagesA31A Butterfly Valve BulletinRizalfariz HasbiNo ratings yet

- Pewwe75 12 405TDocument4 pagesPewwe75 12 405TgiopetrizzoNo ratings yet

- Asco Dust Collector Main Pulse Valves DC CatalogDocument4 pagesAsco Dust Collector Main Pulse Valves DC CatalogFelipe SalvatierraNo ratings yet

- Manual Valvula de Alivio RciDocument3 pagesManual Valvula de Alivio RciGonzalo DominguezNo ratings yet

- Reflux 819: Pressure RegulatorsDocument12 pagesReflux 819: Pressure RegulatorssivaintwitterNo ratings yet

- 2/2-Way Solenoid Valve Servo Operated For High PressureDocument3 pages2/2-Way Solenoid Valve Servo Operated For High PressuremhaioocNo ratings yet

- Electric Valve Actuator Type Car: For 2 & 3-Way Valves Type G/L/M/S 2Fm-T & G/L/M/S 3Fm-T Page 1 of 4 0-4.11.08-HDocument4 pagesElectric Valve Actuator Type Car: For 2 & 3-Way Valves Type G/L/M/S 2Fm-T & G/L/M/S 3Fm-T Page 1 of 4 0-4.11.08-HMuhd Khir RazaniNo ratings yet

- CV300 2Document13 pagesCV300 2Achariya ParpromNo ratings yet

- Dembla Globe Control Valve BrochureDocument19 pagesDembla Globe Control Valve BrochureArman MominNo ratings yet

- Reg 600XLDocument2 pagesReg 600XLChris PalmerNo ratings yet

- E2b060series Overcenter ParkerDocument11 pagesE2b060series Overcenter ParkerElisabet Carreras MarcosNo ratings yet

- Preset Valve Ocv Model Sheet 115 - 25 Aviation 2020Document2 pagesPreset Valve Ocv Model Sheet 115 - 25 Aviation 2020varadarajck893No ratings yet

- Acv ZW205FPDocument3 pagesAcv ZW205FPSamy El-BeheryNo ratings yet

- Av 05Document1 pageAv 05davidbejuNo ratings yet

- CR4000 Series Service Regulators: Technical BulletinDocument5 pagesCR4000 Series Service Regulators: Technical BulletinFRANKLIN RAMIREZNo ratings yet

- Pilot-To-Open Check Valve With Standard Pilot and Delrin SeatDocument2 pagesPilot-To-Open Check Valve With Standard Pilot and Delrin SeatDaniel TostaNo ratings yet

- SS2 8110 0600 07Document4 pagesSS2 8110 0600 07rullycosta85No ratings yet

- CTO 200 34.5 Current TransformerDocument3 pagesCTO 200 34.5 Current Transformersagar ramaniNo ratings yet

- 30 kVA - PI144GDocument8 pages30 kVA - PI144GMaxlabNo ratings yet

- AE Bolted CB EnclosuresDocument6 pagesAE Bolted CB EnclosuresMuhamad PriyatnaNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Bolted Cover Plate Splice Connection To BS5950Document5 pagesBolted Cover Plate Splice Connection To BS5950Ivan DimitrovNo ratings yet

- Technical Drawing - Duodos 15Document2 pagesTechnical Drawing - Duodos 15alang_businessNo ratings yet

- Johnson Pump SPX FLOWDocument85 pagesJohnson Pump SPX FLOWCWen Teow100% (1)

- Ds 4 in High Head Single Stage V4A60 BDocument2 pagesDs 4 in High Head Single Stage V4A60 BMarcos Chaves MagalhãesNo ratings yet

- AspenEconEvalV7 3 2-RelDocument91 pagesAspenEconEvalV7 3 2-RelEduardoNo ratings yet

- TFP1421 08 2023Document21 pagesTFP1421 08 2023Vivekanand SonavaneNo ratings yet

- Hpvr-15 Axial Piston Pumps: Pressure and Volume Adjustment SensitivityDocument6 pagesHpvr-15 Axial Piston Pumps: Pressure and Volume Adjustment Sensitivityenrique chavestaNo ratings yet

- 3.5. 5701F Rev 0Document19 pages3.5. 5701F Rev 0sumit kumarNo ratings yet

- Hdpe Pressure Test PDFDocument16 pagesHdpe Pressure Test PDFOlanrewaju Olalekan SaheedNo ratings yet

- Gear Pump (Auxiliary) - Disassemble PDFDocument6 pagesGear Pump (Auxiliary) - Disassemble PDFIvan PalominoNo ratings yet

- Cameron ChokeDocument20 pagesCameron ChokeMichael Haise0% (1)

- Material Borrow From F&DDocument1 pageMaterial Borrow From F&DRizkiHusniNo ratings yet

- Bahx IomDocument54 pagesBahx IomIsaac Flores100% (1)

- Katalog 2011Document68 pagesKatalog 2011Aziz ELNo ratings yet

- 12P160 Triplex Mud Pump Spec SheetDocument1 page12P160 Triplex Mud Pump Spec SheetWHWENNo ratings yet

- Separtor GT 60Document110 pagesSepartor GT 60Universal solutionsNo ratings yet

- Flange Size ChartDocument2 pagesFlange Size ChartCesco Indonesia100% (1)

- ERHARD Butterfly Valves enDocument32 pagesERHARD Butterfly Valves enMaryug HrNo ratings yet

- Pipe VibrationDocument12 pagesPipe Vibrationwsjouri2510No ratings yet

- Ring Type Joint Brochure 2016Document16 pagesRing Type Joint Brochure 2016perrychemNo ratings yet

- Re 4S Nuevo Manual de Partes PDFDocument82 pagesRe 4S Nuevo Manual de Partes PDFJavier15818100% (1)

- Manual NXR4Document20 pagesManual NXR4libertysyndrome2010No ratings yet

- KSB Valvula Diafragma SISTO10Document4 pagesKSB Valvula Diafragma SISTO10Sarah PerezNo ratings yet

- Manual 222 Toroidal Flow Through Conductivity Sensor Rosemount en 70738Document26 pagesManual 222 Toroidal Flow Through Conductivity Sensor Rosemount en 70738Yesid DiazNo ratings yet

- Installation, Operation and Maintenance Instructions: Model 3600 API 610 10th Edition (ISO 13709)Document92 pagesInstallation, Operation and Maintenance Instructions: Model 3600 API 610 10th Edition (ISO 13709)José Fernando TerronesNo ratings yet

- A 707 - A 707M - 02 Qtcwny9bnza3tqDocument5 pagesA 707 - A 707M - 02 Qtcwny9bnza3tqalucard375No ratings yet

BHMY 2x1 Flowgrid SP FS 34016A 1120 English

BHMY 2x1 Flowgrid SP FS 34016A 1120 English

Uploaded by

Luis Alberto Portugal MariacalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BHMY 2x1 Flowgrid SP FS 34016A 1120 English

BHMY 2x1 Flowgrid SP FS 34016A 1120 English

Uploaded by

Luis Alberto Portugal MariacalCopyright:

Available Formats

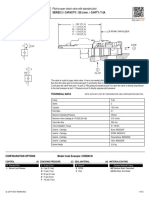

Mooney™

Flowgrid™ Valve

2" x 1" Single Port

FLanged CL 150-300 | NPT and SWE CL 600

The 2” x 1” Flowgrid Valve is an economical and easy to

maintain pilot operated valve for both gas and liquid

applications. The valve is designed to be used in conjunction

2“ x 1”Single Port Valve

with a self contained pilot control system as pictured. This

with Series 20 Pilot

valve combines a 2” flanged body with a 1” port producing

a very strong piping installation with low regulator outlet

velocity. It is ideal for skid mounted, vault and enclosure

installations.

Specifications

Size 2”

Body Style Single Port (1”)

2” CL 150, 300, 600 Flanged Sectional View

End Connections

2” CL 600 NPT, SWE

Working -20°F to 150°F

Temperature

Emergency -40°F to 175°F Overpressure Protection

Max. Operating Differential 1000 psi The Flowgrid Valve is bi-directional and has a full ASME

rating on both the inlet and outlet. Overpressure protection

Max. Emergency Differential 1500 psi

is required only if the pressure can exceed the flange or

Min. Differential Refer to graph on page 2

body rating.

Cracking Differential Refer to graph on page 2

The pilots, like most regulators, may have an outlet pressure

Max. Inlet Pressure 1480 psig1

rating lower than the inlet pressure rating. If this is the case,

Outlet Pressure Range Limited By Pilot then some external form of overpressure protection must be

Flow Direction Bi-Directional2 provided for the pilot.

Body Taps Two 1/4” - 18NPT Anytime the Flowgrid valve or pilot system is exposed to

1. Limited by pilot or flange rating. pressure in excess of its rating, it should be inspected for

2. Reverse flow by changing pilot connections and reversing spring case.

damage.

Materials of Construction Stock Numbers

Body and Spring Case ASTM A 216 GR WCB | Carbon Steel 2” x 1” Single Port Valve Stock Number Weight

7 - 4PH Stainless Steel or A515 150# Flanged FG-51 23 lbs.

Throttle Plate

Carbon Steel with ENC Coating

300# Flanged FG-52 26 lbs.

Nitrile/Nylon1

Diaphragm

Optional (Viton/Nylon) 600# Flanged FG-53 30 lbs.

O-Ring and Seals Nitrile, Optional (Viton) NPT CL 600 FG-49 14 lbs.

Bolting ASTM A 193 GR B7 or Equal SWE CL 600 FG-50 14 lbs.

Spring 301 Stainless Steel

1. Refer to diaphragm selection chart on page 2.

Dimensions

Minimum Pressure Differential vs. Capacity Flange Dimensions

Flange Class A B C D E F

Class 150 10.00 6.00 .75 .06 4 4.75

Class 300 10.50 6.50 .88 .06 8 5.00

Class 600 11.25 6.50 1.25 .25 8 5.00

Flow Coefficients and Constants

2“ x 1” Single Port Valve Swage Factor

% Capacity Cv C1 Cg 1.5:1 2:1

100% 13.4 37 500 0.96 0.93

75% 10.7 30 320 0.97 0.95

50% 9.1 27 245 0.98 0.96

35% 5.5 26 144 1.00 0.99

Note: Allow a 5% factor of safety when calculating relief capacity.

Diaphragm Selection

Temp. Range Maximum

Compound Characteristics Recommended Applications

(°F) Differential

75 Duro -20 to 150 1000 psid Best All Around Material 60 psid to Max. Differential

Low Differential (100 psid or less) or Low

60 Duro -25 to 150 300 psid Best Shutoff at Low Differential Pressure

Temperature

80 Duro High Differential (400 psid or higher) or Abrasive

-5 to 175 1000 psid Higher Abrasion and Swelling Resistance

High ACN Conditions with Distillates

80 Duro Higher Abrasion Resistance and Low High Differential (400 psid or higher) or Abrasive

-20 to 150 1000 psid

Low ACN Temperature Flexibility Conditions at Low Temperatures

Copyright 2020 Baker Hughes Company. All rights reserved.

valves.bakerhughes.com

BHMY-2x1-Flowgrid-SP-FS-34016A-1120 11/2020

You might also like

- Hamworthy Cargo Pump Manual PDFDocument140 pagesHamworthy Cargo Pump Manual PDFspamalstublieft1832No ratings yet

- Astm A234 PDFDocument8 pagesAstm A234 PDFhans30No ratings yet

- KSBB-BS Breather Valve Data SheetDocument2 pagesKSBB-BS Breather Valve Data Sheetfathonix0% (1)

- Mooney Flowgrid Valve: Technical Specifications 12/2018Document2 pagesMooney Flowgrid Valve: Technical Specifications 12/2018Luis Yovany Aldana PonceNo ratings yet

- Catalogo 2 WHxrbcyDocument2 pagesCatalogo 2 WHxrbcyOmar Equihua LinaresNo ratings yet

- Mooney 1" Flowgrid Regulator: With Shutoff ValveDocument2 pagesMooney 1" Flowgrid Regulator: With Shutoff ValveLuis Alberto Portugal MariacalNo ratings yet

- Rate of Flow and Fuel Shut Off Valve: ModelDocument2 pagesRate of Flow and Fuel Shut Off Valve: Modelanon_867776278No ratings yet

- V260 Control ValveDocument12 pagesV260 Control ValvenwabukingzNo ratings yet

- Pneumatically Operated With Manual Reset Deluge Valve For Freshwater and Seawater ServiceDocument2 pagesPneumatically Operated With Manual Reset Deluge Valve For Freshwater and Seawater ServicedmitosNo ratings yet

- Клапан Регулирующий Поворотный Finetrol Fc Fg 5ft20 EnDocument12 pagesКлапан Регулирующий Поворотный Finetrol Fc Fg 5ft20 EnAli KianersiNo ratings yet

- dsbv88 r15Document4 pagesdsbv88 r15Ricardo TurinNo ratings yet

- Rate of Flow Non-Surge Check Valve: ModelDocument2 pagesRate of Flow Non-Surge Check Valve: ModelAndrzej BąkałaNo ratings yet

- E4036Document2 pagesE4036Pablo Cardenas SandovalNo ratings yet

- CKEB Full en Metric LetterDocument2 pagesCKEB Full en Metric LetterRafalNo ratings yet

- Model Pilot-To-Open Check Valve With Standard Pilot: Series 2 / Capacity: 30 GPM / Cavity: T-2ADocument2 pagesModel Pilot-To-Open Check Valve With Standard Pilot: Series 2 / Capacity: 30 GPM / Cavity: T-2AVEERAMANINo ratings yet

- VG221 - 2 Port Control ValveDocument4 pagesVG221 - 2 Port Control ValveNoah MusundiNo ratings yet

- MVCDDocument15 pagesMVCDTrunghieu LeNo ratings yet

- Mooney Flexflo 887 Surge RelieversDocument6 pagesMooney Flexflo 887 Surge RelieversSajjad MehdiNo ratings yet

- Digital Control Valve Model BV88: Technical DataDocument4 pagesDigital Control Valve Model BV88: Technical Datajoana ramirezNo ratings yet

- CTO 1050 230 Current TransformerDocument3 pagesCTO 1050 230 Current Transformersagar ramaniNo ratings yet

- Documentatie Flowserve NAF 2 4 Vana Bila Model Setball FK SIALCO (2) 11Document8 pagesDocumentatie Flowserve NAF 2 4 Vana Bila Model Setball FK SIALCO (2) 11AntonNo ratings yet

- NH3 Compressor UnitDocument1 pageNH3 Compressor UnitdzungNo ratings yet

- Butterfly Valves - CatalogDocument30 pagesButterfly Valves - CatalogRamzi BEN AHMEDNo ratings yet

- Fisher Vee - Ball V150, V200, and V300 Noise AttenuatorDocument8 pagesFisher Vee - Ball V150, V200, and V300 Noise AttenuatorSergio SousaNo ratings yet

- Nautilus XMLA160D2S11Document2 pagesNautilus XMLA160D2S11Nazar AbbasNo ratings yet

- Fisher™ Type 1290 Vapor Recovery RegulatorDocument12 pagesFisher™ Type 1290 Vapor Recovery RegulatorBEJOY KBNo ratings yet

- Seawater Service Pressure Relief Valve: ModelDocument2 pagesSeawater Service Pressure Relief Valve: ModelHemant RasamNo ratings yet

- C16601 Proinert®2 Selector ValveDocument2 pagesC16601 Proinert®2 Selector Valvevld20082No ratings yet

- BHMY 1in FlowgridSS Shutoff FS 34049A 0920 EnglishDocument2 pagesBHMY 1in FlowgridSS Shutoff FS 34049A 0920 EnglishBertin KamsipaNo ratings yet

- E30C - Globe Valves NewDocument20 pagesE30C - Globe Valves NewTaha FaNo ratings yet

- Manuals 1190 Low Pressure Gas Blanketing Regulator Instruction Manual Fisher en en 5985974Document24 pagesManuals 1190 Low Pressure Gas Blanketing Regulator Instruction Manual Fisher en en 5985974marinjerman6No ratings yet

- 5 - Counter Balance Valve TSCA 70-10 - CBCHDocument4 pages5 - Counter Balance Valve TSCA 70-10 - CBCHIvan MaltsevNo ratings yet

- Afv TDB 9610.6 Capacity TablesDocument24 pagesAfv TDB 9610.6 Capacity TablesJorge BaronNo ratings yet

- Fisherr Posi-Sealt A31A High-Performance Butterfly ValveDocument12 pagesFisherr Posi-Sealt A31A High-Performance Butterfly ValveThanapaet RittirutNo ratings yet

- Deluge Valve Installation ManualDocument7 pagesDeluge Valve Installation Manualrahull.miishraNo ratings yet

- Flexflo Surge Relief BrochureDocument8 pagesFlexflo Surge Relief BrochureOscar DelgadoNo ratings yet

- Fisher Controls: Tight Shutoff-Throttling-sleeve Design With TFEDocument14 pagesFisher Controls: Tight Shutoff-Throttling-sleeve Design With TFEfiguev2208No ratings yet

- A11 High Performance Butterfly Valve BulletinDocument28 pagesA11 High Performance Butterfly Valve BulletinRizalfariz HasbiNo ratings yet

- Fisher V500 Rotary Globe Control Valve: Scope of ManualDocument28 pagesFisher V500 Rotary Globe Control Valve: Scope of ManualEdwar VivasNo ratings yet

- Model Pilot-To-Open Check Valve With Standard Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11ADocument2 pagesModel Pilot-To-Open Check Valve With Standard Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11AErasmo LimaNo ratings yet

- PI144J - Technical Data SheetDocument8 pagesPI144J - Technical Data Sheetengmohsen.ramadanhotmail.comNo ratings yet

- A31A Butterfly Valve BulletinDocument12 pagesA31A Butterfly Valve BulletinRizalfariz HasbiNo ratings yet

- Pewwe75 12 405TDocument4 pagesPewwe75 12 405TgiopetrizzoNo ratings yet

- Asco Dust Collector Main Pulse Valves DC CatalogDocument4 pagesAsco Dust Collector Main Pulse Valves DC CatalogFelipe SalvatierraNo ratings yet

- Manual Valvula de Alivio RciDocument3 pagesManual Valvula de Alivio RciGonzalo DominguezNo ratings yet

- Reflux 819: Pressure RegulatorsDocument12 pagesReflux 819: Pressure RegulatorssivaintwitterNo ratings yet

- 2/2-Way Solenoid Valve Servo Operated For High PressureDocument3 pages2/2-Way Solenoid Valve Servo Operated For High PressuremhaioocNo ratings yet

- Electric Valve Actuator Type Car: For 2 & 3-Way Valves Type G/L/M/S 2Fm-T & G/L/M/S 3Fm-T Page 1 of 4 0-4.11.08-HDocument4 pagesElectric Valve Actuator Type Car: For 2 & 3-Way Valves Type G/L/M/S 2Fm-T & G/L/M/S 3Fm-T Page 1 of 4 0-4.11.08-HMuhd Khir RazaniNo ratings yet

- CV300 2Document13 pagesCV300 2Achariya ParpromNo ratings yet

- Dembla Globe Control Valve BrochureDocument19 pagesDembla Globe Control Valve BrochureArman MominNo ratings yet

- Reg 600XLDocument2 pagesReg 600XLChris PalmerNo ratings yet

- E2b060series Overcenter ParkerDocument11 pagesE2b060series Overcenter ParkerElisabet Carreras MarcosNo ratings yet

- Preset Valve Ocv Model Sheet 115 - 25 Aviation 2020Document2 pagesPreset Valve Ocv Model Sheet 115 - 25 Aviation 2020varadarajck893No ratings yet

- Acv ZW205FPDocument3 pagesAcv ZW205FPSamy El-BeheryNo ratings yet

- Av 05Document1 pageAv 05davidbejuNo ratings yet

- CR4000 Series Service Regulators: Technical BulletinDocument5 pagesCR4000 Series Service Regulators: Technical BulletinFRANKLIN RAMIREZNo ratings yet

- Pilot-To-Open Check Valve With Standard Pilot and Delrin SeatDocument2 pagesPilot-To-Open Check Valve With Standard Pilot and Delrin SeatDaniel TostaNo ratings yet

- SS2 8110 0600 07Document4 pagesSS2 8110 0600 07rullycosta85No ratings yet

- CTO 200 34.5 Current TransformerDocument3 pagesCTO 200 34.5 Current Transformersagar ramaniNo ratings yet

- 30 kVA - PI144GDocument8 pages30 kVA - PI144GMaxlabNo ratings yet

- AE Bolted CB EnclosuresDocument6 pagesAE Bolted CB EnclosuresMuhamad PriyatnaNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Bolted Cover Plate Splice Connection To BS5950Document5 pagesBolted Cover Plate Splice Connection To BS5950Ivan DimitrovNo ratings yet

- Technical Drawing - Duodos 15Document2 pagesTechnical Drawing - Duodos 15alang_businessNo ratings yet

- Johnson Pump SPX FLOWDocument85 pagesJohnson Pump SPX FLOWCWen Teow100% (1)

- Ds 4 in High Head Single Stage V4A60 BDocument2 pagesDs 4 in High Head Single Stage V4A60 BMarcos Chaves MagalhãesNo ratings yet

- AspenEconEvalV7 3 2-RelDocument91 pagesAspenEconEvalV7 3 2-RelEduardoNo ratings yet

- TFP1421 08 2023Document21 pagesTFP1421 08 2023Vivekanand SonavaneNo ratings yet

- Hpvr-15 Axial Piston Pumps: Pressure and Volume Adjustment SensitivityDocument6 pagesHpvr-15 Axial Piston Pumps: Pressure and Volume Adjustment Sensitivityenrique chavestaNo ratings yet

- 3.5. 5701F Rev 0Document19 pages3.5. 5701F Rev 0sumit kumarNo ratings yet

- Hdpe Pressure Test PDFDocument16 pagesHdpe Pressure Test PDFOlanrewaju Olalekan SaheedNo ratings yet

- Gear Pump (Auxiliary) - Disassemble PDFDocument6 pagesGear Pump (Auxiliary) - Disassemble PDFIvan PalominoNo ratings yet

- Cameron ChokeDocument20 pagesCameron ChokeMichael Haise0% (1)

- Material Borrow From F&DDocument1 pageMaterial Borrow From F&DRizkiHusniNo ratings yet

- Bahx IomDocument54 pagesBahx IomIsaac Flores100% (1)

- Katalog 2011Document68 pagesKatalog 2011Aziz ELNo ratings yet

- 12P160 Triplex Mud Pump Spec SheetDocument1 page12P160 Triplex Mud Pump Spec SheetWHWENNo ratings yet

- Separtor GT 60Document110 pagesSepartor GT 60Universal solutionsNo ratings yet

- Flange Size ChartDocument2 pagesFlange Size ChartCesco Indonesia100% (1)

- ERHARD Butterfly Valves enDocument32 pagesERHARD Butterfly Valves enMaryug HrNo ratings yet

- Pipe VibrationDocument12 pagesPipe Vibrationwsjouri2510No ratings yet

- Ring Type Joint Brochure 2016Document16 pagesRing Type Joint Brochure 2016perrychemNo ratings yet

- Re 4S Nuevo Manual de Partes PDFDocument82 pagesRe 4S Nuevo Manual de Partes PDFJavier15818100% (1)

- Manual NXR4Document20 pagesManual NXR4libertysyndrome2010No ratings yet

- KSB Valvula Diafragma SISTO10Document4 pagesKSB Valvula Diafragma SISTO10Sarah PerezNo ratings yet

- Manual 222 Toroidal Flow Through Conductivity Sensor Rosemount en 70738Document26 pagesManual 222 Toroidal Flow Through Conductivity Sensor Rosemount en 70738Yesid DiazNo ratings yet

- Installation, Operation and Maintenance Instructions: Model 3600 API 610 10th Edition (ISO 13709)Document92 pagesInstallation, Operation and Maintenance Instructions: Model 3600 API 610 10th Edition (ISO 13709)José Fernando TerronesNo ratings yet

- A 707 - A 707M - 02 Qtcwny9bnza3tqDocument5 pagesA 707 - A 707M - 02 Qtcwny9bnza3tqalucard375No ratings yet