Professional Documents

Culture Documents

Instruction Manual FLAF 1215

Instruction Manual FLAF 1215

Uploaded by

rjv.premi74Copyright:

Available Formats

You might also like

- Tandem Mooring & OffloadingDocument12 pagesTandem Mooring & OffloadingJim StrakerNo ratings yet

- Rut CourseDocument97 pagesRut CourseSajeev NerurkarNo ratings yet

- Topaz Annual Report 2017 PDFDocument92 pagesTopaz Annual Report 2017 PDFEhsan AlimNo ratings yet

- MCQ CollectionDocument614 pagesMCQ Collectionanil kumar0% (1)

- Brochure Cinta Hermética ENRAFDocument4 pagesBrochure Cinta Hermética ENRAFCESARNo ratings yet

- Drawing 70003 (Flame Filter Housing) : Item ListDocument1 pageDrawing 70003 (Flame Filter Housing) : Item ListVinicius AraujoNo ratings yet

- Marine Portable Fire ExtinguishersDocument7 pagesMarine Portable Fire ExtinguishersTan Zhi WeiNo ratings yet

- UTI TypeDocument9 pagesUTI TypeSuresh VinzudaNo ratings yet

- Method Statement For Floating Hose TestingDocument1 pageMethod Statement For Floating Hose Testinggusstiawan saputraNo ratings yet

- UTImeterDocument9 pagesUTImeterWisnu KusumaNo ratings yet

- Kikeh Marine TerminalDocument8 pagesKikeh Marine TerminalBob TigerNo ratings yet

- 0460-0015 Brazilian Legislation - ENSRDocument47 pages0460-0015 Brazilian Legislation - ENSRvagabond26No ratings yet

- RP G103 2007Document82 pagesRP G103 2007Robert SmallwoodNo ratings yet

- Guidelines For Corrosion Protetion and Coating Systems WWW - Gl-Group - Com Infoservices Rules Pdfs GL Vi-10-2 eDocument42 pagesGuidelines For Corrosion Protetion and Coating Systems WWW - Gl-Group - Com Infoservices Rules Pdfs GL Vi-10-2 ewilfran villegas100% (1)

- Intecsea Lm-FpsoDocument40 pagesIntecsea Lm-FpsomuhamadsaffuanNo ratings yet

- Verification of Lifting Appliances For The Oil and Gas IndustryDocument46 pagesVerification of Lifting Appliances For The Oil and Gas IndustryPinco PalloNo ratings yet

- GT Camlock R V10Document2 pagesGT Camlock R V10Daniel Leonardo Barrera EspartaNo ratings yet

- Seaways-November 2020 PDFDocument42 pagesSeaways-November 2020 PDFCristi CoroamaNo ratings yet

- OPITO and Other CoursesDocument17 pagesOPITO and Other Coursesrony_lesbtNo ratings yet

- Introduction To Ship-Shaped Offshore StructureDocument13 pagesIntroduction To Ship-Shaped Offshore StructureMohamad FaezeNo ratings yet

- Ectc Guide e AbsDocument7 pagesEctc Guide e AbsCanumalla RamkumarNo ratings yet

- Turret Calm Buoy PDFDocument6 pagesTurret Calm Buoy PDFvpandya1981No ratings yet

- Burea Veritas - Rules On Materials Ans Welding For The Classification On Marine Units PDFDocument236 pagesBurea Veritas - Rules On Materials Ans Welding For The Classification On Marine Units PDFAnonymous 7tBrl8No ratings yet

- 02 ERRV Crew Advanced Medical AidDocument36 pages02 ERRV Crew Advanced Medical AidRonny AndalasNo ratings yet

- BPCL Kochi SPM Pig Study 01Document9 pagesBPCL Kochi SPM Pig Study 01Arun Kumar PancharajNo ratings yet

- Carbothane 134 HG - Urethane Converter 811 MSDS Part BDocument6 pagesCarbothane 134 HG - Urethane Converter 811 MSDS Part BAyman JadNo ratings yet

- Marine Breakaway Coupling - FinalDocument15 pagesMarine Breakaway Coupling - FinalSafi Safi100% (1)

- Document Instruction Offtake OC 039 (MT - Samos-Subs)Document2 pagesDocument Instruction Offtake OC 039 (MT - Samos-Subs)Ihwan AsrulNo ratings yet

- NOFIRNO Pipe Catalog Marine March 2010 PDFDocument36 pagesNOFIRNO Pipe Catalog Marine March 2010 PDFMohammed JassimNo ratings yet

- QPR20-0367T LSP Life Support PackageDocument11 pagesQPR20-0367T LSP Life Support PackageJames LimNo ratings yet

- IACS Req Pipes Pressure VesselDocument69 pagesIACS Req Pipes Pressure VesselFrancesco CauzNo ratings yet

- Volume TM Machinery Fire Fighting and Environment Protection Equipment 2012-11-30Document54 pagesVolume TM Machinery Fire Fighting and Environment Protection Equipment 2012-11-30buddhansamrat100% (1)

- RLM 252 MODU 8 06 WDocument5 pagesRLM 252 MODU 8 06 WzaladsNo ratings yet

- CenpesDocument20 pagesCenpesnskumarmNo ratings yet

- OTC13999 Development For A Deep Sea FPSO Suitable For The GoMDocument8 pagesOTC13999 Development For A Deep Sea FPSO Suitable For The GoMAnil ChananaNo ratings yet

- ISO TS 18683-2021 Ed.2 Id.76811 Publication PDF (En)Document49 pagesISO TS 18683-2021 Ed.2 Id.76811 Publication PDF (En)napoleonmNo ratings yet

- Effect of H2-Injection On The Thermodynamic and Transportation Schouten2004Document8 pagesEffect of H2-Injection On The Thermodynamic and Transportation Schouten2004YvesfNo ratings yet

- Amends To SDs 2011Document214 pagesAmends To SDs 2011duaankushNo ratings yet

- Fal 6-Circ 14-Rev 1Document70 pagesFal 6-Circ 14-Rev 1SaeedNo ratings yet

- Yokohama FENDER PRODUCT LITERATURE PDFDocument8 pagesYokohama FENDER PRODUCT LITERATURE PDFitaaliyenNo ratings yet

- No.11 1 PASSENGER SHIPS - Guidelines For Preparation of Hull Structural Surveys No. 111Document10 pagesNo.11 1 PASSENGER SHIPS - Guidelines For Preparation of Hull Structural Surveys No. 111Long NguyenNo ratings yet

- BWM Electrolysis TypeDocument4 pagesBWM Electrolysis TypeAldo Sitorus100% (1)

- MSC.267 (85) Adoption Int Code On Intact StabilityDocument94 pagesMSC.267 (85) Adoption Int Code On Intact StabilityAfdnam StnadactnamNo ratings yet

- C 4 FfaDocument35 pagesC 4 Ffaanjuman ara100% (1)

- Guidance Notes On High Tensile Steel: Tanker Structure Cooperative ForumDocument29 pagesGuidance Notes On High Tensile Steel: Tanker Structure Cooperative ForumxeyranNo ratings yet

- SPM - Rules 2023 PDFDocument126 pagesSPM - Rules 2023 PDFbobuncle03No ratings yet

- USCG Proceedings MM IssueDocument124 pagesUSCG Proceedings MM IssueUSCGMMCExpert100% (1)

- Uscg Inspection ProceduresDocument148 pagesUscg Inspection Proceduresluckystrike9008100% (2)

- Butterfly Valve User ManualDocument10 pagesButterfly Valve User ManualEduardoAscencioNo ratings yet

- MooringDocument151 pagesMooringHafizh AmazonNo ratings yet

- Condition Assessment Programme (CAP) : Guidance Note NI 465 DT R01 EDocument24 pagesCondition Assessment Programme (CAP) : Guidance Note NI 465 DT R01 EFarhanNo ratings yet

- OCP 6-Gas Cutting - Oxy-AcetyleneDocument1 pageOCP 6-Gas Cutting - Oxy-AcetyleneFaisal Raza100% (1)

- Convencion Sar PDFDocument3 pagesConvencion Sar PDFpappazappaNo ratings yet

- Hwang, J.K., Et Al. - 2009 - Detailed Design and Construction of The Hull of An FPSODocument8 pagesHwang, J.K., Et Al. - 2009 - Detailed Design and Construction of The Hull of An FPSOVeeraiah AnbuNo ratings yet

- Bunkering Operation Training - Cercs-2Document25 pagesBunkering Operation Training - Cercs-2Julia AbalosNo ratings yet

- Design of TankersDocument203 pagesDesign of TankersnoeleosinagaNo ratings yet

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityFrom EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNo ratings yet

- Maintenance Manual VAPV 1225 SeriesDocument20 pagesMaintenance Manual VAPV 1225 Seriesrjv.premi74No ratings yet

- Instruction and Maintenance Manual Bay Valves 90001Document39 pagesInstruction and Maintenance Manual Bay Valves 90001rjv.premi74No ratings yet

- EU 2015 559 Amending Council Directive 96 98 ECDocument66 pagesEU 2015 559 Amending Council Directive 96 98 ECrjv.premi74No ratings yet

- Hydrocarbon Gas Detection Alarm System DiagramDocument3 pagesHydrocarbon Gas Detection Alarm System Diagramrjv.premi74No ratings yet

- Compressed Air-Dryer Buran Class Ultrapulse SD 0100 Ap - SD 1650 ApDocument38 pagesCompressed Air-Dryer Buran Class Ultrapulse SD 0100 Ap - SD 1650 Aprjv.premi74No ratings yet

- Outlined For Mooring Test & Sea Trial (Hull Part)Document9 pagesOutlined For Mooring Test & Sea Trial (Hull Part)rjv.premi74No ratings yet

- RR2009 - Generale-RrDocument39 pagesRR2009 - Generale-Rrhemant9315No ratings yet

- IZenBridge PMI ACP Program PDFDocument4 pagesIZenBridge PMI ACP Program PDFadetolahNo ratings yet

- 6292A: Installing and Configuring Windows® 7 Client Microsoft® Hyper-V Classroom Setup GuideDocument14 pages6292A: Installing and Configuring Windows® 7 Client Microsoft® Hyper-V Classroom Setup GuideMichael DavisNo ratings yet

- Gas LiftDocument43 pagesGas LiftAhmad FaizilNo ratings yet

- DNV Oss-102Document70 pagesDNV Oss-102Olinser BacelisNo ratings yet

- Formal Language and Automata Theory (CS21004) : Soumyajit Dey CSE, IIT KharagpurDocument23 pagesFormal Language and Automata Theory (CS21004) : Soumyajit Dey CSE, IIT KharagpurManad MishraNo ratings yet

- Data Base Management System LabDocument21 pagesData Base Management System LabUsmanyusufNo ratings yet

- Corrosion Magazine Issue117 LowresDocument36 pagesCorrosion Magazine Issue117 Lowressaminasritn100% (2)

- Transistor MCQDocument5 pagesTransistor MCQMark BelasaNo ratings yet

- Exercícios - Resistência Dos MateriaisDocument7 pagesExercícios - Resistência Dos MateriaisVinícius AntunesNo ratings yet

- Parts List 38 269 22 95: Helical-Bevel Gear Unit KA107, KH107, KV107, KT107, KA107B, KH107B, KV107B, KT107BDocument4 pagesParts List 38 269 22 95: Helical-Bevel Gear Unit KA107, KH107, KV107, KT107, KA107B, KH107B, KV107B, KT107BFotografia PopularNo ratings yet

- RC Beam Design Using MCDXDocument20 pagesRC Beam Design Using MCDXChanthy RathedNo ratings yet

- Rolls-Royce Corporation AE 3007A Service Bulletin (SB) Technical Publications IndexDocument70 pagesRolls-Royce Corporation AE 3007A Service Bulletin (SB) Technical Publications IndexAnubhuti GhaiNo ratings yet

- Topic 2 Beam DesignDocument32 pagesTopic 2 Beam DesignMuhd FareezNo ratings yet

- Z-Functional Programming in HaskellDocument26 pagesZ-Functional Programming in HaskellSurangma ParasharNo ratings yet

- Sting-S4 Poh UlDocument63 pagesSting-S4 Poh UlJorge E. Arias VargasNo ratings yet

- Miele Appliances Electrical Connection OverviewDocument3 pagesMiele Appliances Electrical Connection Overviewhappy_jonNo ratings yet

- CV Engr. Md. HasmotuzzamanDocument7 pagesCV Engr. Md. HasmotuzzamanEngr SwapanNo ratings yet

- Software Slope Stabilty Analysis FinalDocument1 pageSoftware Slope Stabilty Analysis FinalETTL UDAIPURNo ratings yet

- WATER FILL UP Procedure - Rev.01Document6 pagesWATER FILL UP Procedure - Rev.01shivanshsovNo ratings yet

- RK3399 EVB User Guide: Release Version: V1.0 Release Date: Aug 22, 2016Document35 pagesRK3399 EVB User Guide: Release Version: V1.0 Release Date: Aug 22, 2016NarendranVenkatramaniNo ratings yet

- Air Terminals and FixingsDocument8 pagesAir Terminals and FixingsIgho AhmedNo ratings yet

- BenzoinDocument7 pagesBenzoinLeah ThomasNo ratings yet

- The Nature of MaterialsDocument11 pagesThe Nature of MaterialscdymlkNo ratings yet

- PBE1202Document2 pagesPBE1202Marco London100% (1)

- Eye Movement-Based Human Computer Interaction TechniquesDocument5 pagesEye Movement-Based Human Computer Interaction TechniquesSreekanth MarlapatiNo ratings yet

- Catalog Bencomp Brosura Engleza 2018Document12 pagesCatalog Bencomp Brosura Engleza 2018sergiu9886No ratings yet

- Why It Does Not MatterDocument31 pagesWhy It Does Not MatterDavid I AgogoNo ratings yet

- MASTER FLOW p2 - BB - 6000 - NewDocument4 pagesMASTER FLOW p2 - BB - 6000 - NewJosé Daniel ArenasNo ratings yet

Instruction Manual FLAF 1215

Instruction Manual FLAF 1215

Uploaded by

rjv.premi74Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Instruction Manual FLAF 1215

Instruction Manual FLAF 1215

Uploaded by

rjv.premi74Copyright:

Available Formats

BAY Valves ApS bay@bayvalves.com Tel.: +45 7022 1892 Fax.

: +45 7014 1892

Valve order No.: 13102-1215 Date: 09/07/2015 Page 1 of 15

Cargo tank Safety valves & Flame protection equipment

Flame arrester FLAF 1215

MAINTENANCE -

MANUAL NO.: 13102 -1215

Project: OCTP

IMO type: FPSO

Size: 300000 DWT

Shipyard: SHAN G HAI

HUARUIDAD ON G

Owner: YINSON PROD UCTION

Consultant: -

Agent: OCEAN IC OFF -SHORE

BAY Valves ApS, are pleased to have delivered the latest generation state of the art equipment according to the

specification as follows.

For easy reference to the mandatory Rules and Regulations that have been used to determine the specific design

and size of equipment, please look at the following pages where the applicable ones have been marked.

Exact calculations are likewise in-cooperated in this document where appropriate.

Should you have any questions, or require further information related to our delivery or any other cargo tank

ventilation issue, please do not hesitate to contact the undersigned or our office, and we will be pleased to assist

you.

Best regards,

BAY Valves ApS

BAY Valves ApS – Falstervej 10G - 5800 Nyborg - Denmark

BAY Valves ApS bay@bayvalves.com Tel.: +45 7022 1892 Fax.: +45 7014 1892

Valve order No.: 13102-1215 Date: 09/07/2015 Page 2 of 15

Index

Index .............................................................................................................................................................................................2

Rules & Regulations ...................................................................................................................................................................3

System design ..............................................................................................................................................................................4

Questionnaire .....................................................................................................................................................................4

Application: Flame screen................................................................................................................................................5

TAG No. 64SP0019 / 64SP0119 / 64SP0217 .............................................................................................................5

Documentation & Certificates .............................................................................................................................................. 10

Piping lay-out .................................................................................................................................................................. 11

Pressure drop calculation .............................................................................................................................................. 11

Test report ....................................................................................................................................................................... 11

Installation ....................................................................................................................................................................... 11

Operation:........................................................................................................................................................................ 11

Maintenance: ................................................................................................................................................................... 12

Spares: .............................................................................................................................................................................. 12

Name plate marking: ...................................................................................................................................................... 12

Ordering spare-parts – just return this page ....................................................................................................................... 13

........................................................................................................................................................................................... 14

Corrosion protection system............................................................................................................................................. 14

Contact ...................................................................................................................................................................................... 15

BAY Valves ApS – Falstervej 10G - 5800 Nyborg - Denmark

BAY Valves ApS bay@bayvalves.com Tel.: +45 7022 1892 Fax.: +45 7014 1892

Valve order No.: 13102-1215 Date: 09/07/2015 Page 3 of 15

Rules & Regulations

1.1 System Design.

SOLAS 74 chapter II-2 REG 59

Venting, purging, gas-freeing and ventilation.

IMO MSC/CIRC 731

Revised factors to be taken into consideration when designing cargo tank venting and

gas-freeing arrangements.

USCG CFR 46 part 39 –Vapour control system.

ISO 15364:2000

Ships and marine technology – Pressure/vacuum valves for cargo tanks.

ADNR 2003

Transport of Hazardous Material / Dangerous Goods on the river Rhein.

1.2 Test Standards

IMO MSC/CIRC 677

Revised standards for the design, testing and locating of Devices to prevent the Passage

of Flames into cargo tanks in tankers.

IMO MSC/CIRC 1009

Amendments to the revised standards for the design, testing and locating of Devices to

prevent the Passage of Flames into cargo tanks in tankers.

CEN European Standard EN 12874

Flame arresters – Performance requirements, test methods and limits for use.

BAY Valves ApS – Falstervej 10G - 5800 Nyborg - Denmark

BAY Valves ApS bay@bayvalves.com Tel.: +45 7022 1892 Fax.: +45 7014 1892

Valve order No.: 13102-1215 Date: 09/07/2015 Page 4 of 15

System design

Questionnaire

According to SOLAS 74 II Reg. 59 a system for cargo tank ventilation can be either a common or an individual

one which in both cases has to be protected by a Device to prevent the passage of flame as specified in IMO

MSC/Circ 677/1009.

A common system consists of a branch line from each cargo or slop tank connected to a common venting line.

An individual system is equipped with approved equipment on each tank in order to secure full flow capacity,

breathing capabilities and full cargo segregation.

The system in question has been either informed or estimated as having the following characteristic:

INFORMED ESTIMATE INFORMED ESTIMATE

IMO Designation OIL Cargo tanks -

Cargo Gas-group IIB Slop tanks -

MESG 0,65 Other tanks -

USCG VCS YES Gas-freeing covers -

Common YES Gas freeing blower IGS

Individual NO Setting – pressure 0,014 Mpa

Cargo Segregation Setting Vacuum 0,0035 Mpa

Venting rate 9375 Nm3/h Material Ductile CI

Un-loading rate 9375 Nm3/h Flange ANSI B16.5

Please feel free to return this page only, which will be identified by the quotation No. listed at the top of

the page. For corrections or comments just mark with- or in writing in the text box below.

IMO Designation: III II I Cargo segregation:

Gas Group: IIA IIB IIC Loading rate:

MESG: 0.90 0,65 0,50 Un-loading rate:

Setting Pressure: Cargo Density:

Setting Vacuum: USCG VCS: Yes/No

Flange standard: Gas freeing blower: N m3/h

Material:

Comments:

Please change accordingly:

Date: Name: Company:

BAY Valves ApS – Falstervej 10G - 5800 Nyborg - Denmark

BAY Valves ApS bay@bayvalves.com Tel.: +45 7022 1892 Fax.: +45 7014 1892

Valve order No.: 13102-1215 Date: 09/07/2015 Page 5 of 15

Application: Flame screen

TAG No. 64SP0019 / 64SP0119 / 64SP0217

Units: 3

Size: 400

Flange standard: ANSI B16.5 #150 (RF)

Type: End of line deflagration proof

Limitation: NA

Material-Housing: Fabricated steel plate / Epoxy coated to spec.

NORSOK M-501/11

Material-Inner parts: Stainless steel AISI 316

Setting – Pressure: N.A.

Setting – Vacuum: N.A.

Loading Rate: - m3/h

Capacity : 25000 Nm3/h @ 5 Kpa

Drawing: 90003

- Flange drawing is based on DIN standard - please inform

specific size and quantity for D, DC, N, De

Flow curve: 90003-1215-400-001

Gas Group: IIB / MESG 0,65

Temp. range: 180 degr. C normal operating / 220 degr. C Design temp.

Features: Vertically free flow.

Test standard: IMO MSC/Circ 677

BAY Valves ApS – Falstervej 10G - 5800 Nyborg - Denmark

BAY Valves ApS bay@bayvalves.com Tel.: +45 7022 1892 Fax.: +45 7014 1892

Valve order No.: 13102-1215 Date: 09/07/2015 Page 6 of 15

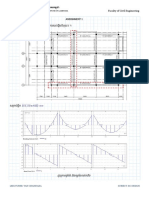

Drawing No.: 90003 Designation

Description: Deflagration End of Line FLAF

Flame arrester 1215

1 Lifting eye bolt Available in all material combinations e.g. from Cast

iron to Duplex stainless steel.

2 Cover

Approved according to IMO MSC / Circ 677

3 Housing

4 Flame screen holder

Type examination according to MED 96/98 latest

2002/75 EC provided by Bureau Veritas under Cert.

5 Flame screen No.19876/AO EC

A D Dc Dn N De Face SIZE Kg

400 597 540 400 16 28,5 Raised 400 79,8

Drain Option DN Dd Ddc dd nd

connection 1 25 115 85 14 4

BAY Valves ApS – Falstervej 10G - 5800 Nyborg - Denmark

BAY Valves ApS bay@bayvalves.com Tel.: +45 7022 1892 Fax.: +45 7014 1892

Valve order No.: 13102-1215 Date: 09/07/2015 Page 7 of 15

BAY Valves ApS – Falstervej 10G - 5800 Nyborg - Denmark

BAY Valves ApS bay@bayvalves.com Tel.: +45 7022 1892 Fax.: +45 7014 1892

Valve order No.: 13102-1215 Date: 09/07/2015 Page 8 of 15

BAY Valves ApS – Falstervej 10G - 5800 Nyborg - Denmark

BAY Valves ApS bay@bayvalves.com Tel.: +45 7022 1892 Fax.: +45 7014 1892

Valve order No.: 13102-1215 Date: 09/07/2015 Page 9 of 15

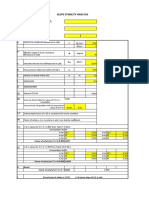

Document type: Document No.: Notified Body: Certificate No.:

Flow diagram 90003-1215-400-001 DNV To be informed

END OF LINE FLAME ARRESTER

mm WG

1000

900

800

700

600

500

400

300

200

100

0

0 2500 5000 7500 10000 12500 15000 17500 20000 22500 25000

Nm³/h

Valve setting: Lowest setting: Valve capacity: Conditions:

N.A. N.A. 20000 Nm3/h @ 5 Kpa Standard air 21°C / 1013 hPa

Applicable rules Valve data Data

√ IMO MSC/Circ 677 Name FLAF

ISO 15364 No. 1215 Signature / Stamp

√ MED 96/98 Size 400

√ SOLAS 74 Restrictions: Lenght [m] Bends [No]

√ API 2000 DN > N.A. N.A.

√ API 520 DN

DN

MESG 0,65

BAY Valves ApS – Falstervej 10G - 5800 Nyborg - Denmark

BAY Valves ApS bay@bayvalves.com Tel.: +45 7022 1892 Fax.: +45 7014 1892

Valve order No.: 13102-1215 Date: 09/07/2015 Page 10 of 15

Documentation & Certificates

SCOPE OF SUPPLY:

- Name plate.

- Lifting eye-bolts

- Paint Inside : Phenolic epoxy

- Paint outside : Phenolic epoxy

- All required sizing calculations and engineering activities.

- Supply of drawings and documents according documentation

requirements.

- MED Type Examination certificate – latest amendment.

- Quality control, testing and inspection.

- Surface preparation and painting.

- Packing and preservation for 6 months outdoor offshore storage.

- Required calibration and test certificates.

- Extended guarantee 48 month

Flag: -

Classification Society: DNV

Certificate 1: Final Inspection Certificate - DNV

Certificate 2: EC- MED 96/98 Type Examination Certificate -DNV

Guarantee: 48 month from delivery

Documentation:

Compliance/Final Inspection Clearance

BAY Valves ApS – Falstervej 10G - 5800 Nyborg - Denmark

BAY Valves ApS bay@bayvalves.com Tel.: +45 7022 1892 Fax.: +45 7014 1892

Valve order No.: 13102-1215 Date: 09/07/2015 Page 11 of 15

Piping lay-out

See drawing in PDC – Pressure Drop Calculation Scheme

Pressure drop calculation

See separate scheme (Pressure drop calculation are not within the standard scope of supply and therefore it does

not form part of this manual)

Test report

Please, make a request at our office

Installation

INSTALLATION

Each flame arrester is supplied fully assembled and tested, with no further work required to render the unit operative.

Installation is accomplished by bolting the flange of each unit to its corresponding tank vent pipe mating flange.

As per SOLAS 1974, Reg 59 + 62, the flame arrester shall be located 6 m above the cargo tank deck level, and the

discharge shall be vertically upwards.

Operation:

OPERATION

The flame arrester type FLAF 1215, operates automatically, thus is does not require any attendance during loading,

discharging and ballasting.

BAY Valves ApS – Falstervej 10G - 5800 Nyborg - Denmark

BAY Valves ApS bay@bayvalves.com Tel.: +45 7022 1892 Fax.: +45 7014 1892

Valve order No.: 13102-1215 Date: 09/07/2015 Page 12 of 15

Maintenance:

MAINTENANCE

With regular intervals, depending on the frequency of loading, discharging, and the type of cargo, the internal parts of

the flame arrester should be inspected.

The net must be free from damages, and dust or deposits must be removed. For cleaning we recommend thin

lubrication oil as solvent and a brush.

In case of damaged nets, the flame arrester can no longer serve as a Device to prevent the passage of flames,

and therefore must be replaced with genuine parts. Please refer to drawing no. 90003

Spares:

SPARES

There are no class requirements for carrying spares on board.

If spares are required, please use the following procedure:

1. Identify the component/part on the inserted drawing no. 90003

2. Advise builder of ship

3. Advise new building number.

4. Advise Serial No. as stated on the nameplate (page 8)

When ordering spare parts, please call our office in Denmark or just fill in the

Name plate marking:

The marking of the device is made according to IMO MSC/Circ 677

Nameplate:

BAY Valves ApS – Falstervej 10G - 5800 Nyborg - Denmark

BAY Valves ApS bay@bayvalves.com Tel.: +45 7022 1892 Fax.: +45 7014 1892

Valve order No.: 13102-1215 Date: 09/07/2015 Page 13 of 15

Ordering spare-parts – just return this page

All items are identified by its position No. on the drawing and valve order No. Please return this page or

alternatively remember to write the valve order No. above. The No. can also be located on the name plate of each

valve.

Drawing No. Revision Part name Size Valve No. Description Material

Drawing No. Revision Part name Valve No. Description Material

Drawing No. Revision Part name Size Valve No. Description Material

Drawing No. Revision Part name Valve No. Description Material

Drawing No. Revision Part name Size Valve No. Description Material

Drawing No. Revision Part name Valve No. Description Material

Date / Name Title: Company:

Vessel name e-mail: Phone / Fax:

BAY Valves ApS – Falstervej 10G - 5800 Nyborg - Denmark

BAY Valves ApS bay@bayvalves.com Tel.: +45 7022 1892 Fax.: +45 7014 1892

Valve order No.: 13102-1215 Date: 09/07/2015 Page 14 of 15

BAY Valves ApS

FLAF 1215

DN XXX

XXXXX

IMO MSC/Circ. 677

EN 12874

To be located on the side of the housing mrk.3 drawing 90003

1. Manufacturer and Test laboratory

2. Type

3. Size

4. Serial No.

5. Compliance with the requirement of MSC/Circ. 677 & EN 12874

Corrosion protection system

Please consult the paint manufacturer for maintenance of the paint system identified as:

For Oil tankers

Hempel Hempadur 1540

For Chemical tankers

Hempel Hempadur 1550

Paint description

LAYER NUMBER NAME THICKNESS COLOUR

FIRST

SECOND

THIRD

BAY Valves ApS – Falstervej 10G - 5800 Nyborg - Denmark

BAY Valves ApS bay@bayvalves.com Tel.: +45 7022 1892 Fax.: +45 7014 1892

Valve order No.: 13102-1215 Date: 09/07/2015 Page 15 of 15

Contact

BAY Valves ApS

DK-5800 Nyborg,

Denmark

bay@bayvalves.com

Tel. +45 7022 1892

Fax. +45 7014 1892

BAY Valves ApS – Falstervej 10G - 5800 Nyborg - Denmark

You might also like

- Tandem Mooring & OffloadingDocument12 pagesTandem Mooring & OffloadingJim StrakerNo ratings yet

- Rut CourseDocument97 pagesRut CourseSajeev NerurkarNo ratings yet

- Topaz Annual Report 2017 PDFDocument92 pagesTopaz Annual Report 2017 PDFEhsan AlimNo ratings yet

- MCQ CollectionDocument614 pagesMCQ Collectionanil kumar0% (1)

- Brochure Cinta Hermética ENRAFDocument4 pagesBrochure Cinta Hermética ENRAFCESARNo ratings yet

- Drawing 70003 (Flame Filter Housing) : Item ListDocument1 pageDrawing 70003 (Flame Filter Housing) : Item ListVinicius AraujoNo ratings yet

- Marine Portable Fire ExtinguishersDocument7 pagesMarine Portable Fire ExtinguishersTan Zhi WeiNo ratings yet

- UTI TypeDocument9 pagesUTI TypeSuresh VinzudaNo ratings yet

- Method Statement For Floating Hose TestingDocument1 pageMethod Statement For Floating Hose Testinggusstiawan saputraNo ratings yet

- UTImeterDocument9 pagesUTImeterWisnu KusumaNo ratings yet

- Kikeh Marine TerminalDocument8 pagesKikeh Marine TerminalBob TigerNo ratings yet

- 0460-0015 Brazilian Legislation - ENSRDocument47 pages0460-0015 Brazilian Legislation - ENSRvagabond26No ratings yet

- RP G103 2007Document82 pagesRP G103 2007Robert SmallwoodNo ratings yet

- Guidelines For Corrosion Protetion and Coating Systems WWW - Gl-Group - Com Infoservices Rules Pdfs GL Vi-10-2 eDocument42 pagesGuidelines For Corrosion Protetion and Coating Systems WWW - Gl-Group - Com Infoservices Rules Pdfs GL Vi-10-2 ewilfran villegas100% (1)

- Intecsea Lm-FpsoDocument40 pagesIntecsea Lm-FpsomuhamadsaffuanNo ratings yet

- Verification of Lifting Appliances For The Oil and Gas IndustryDocument46 pagesVerification of Lifting Appliances For The Oil and Gas IndustryPinco PalloNo ratings yet

- GT Camlock R V10Document2 pagesGT Camlock R V10Daniel Leonardo Barrera EspartaNo ratings yet

- Seaways-November 2020 PDFDocument42 pagesSeaways-November 2020 PDFCristi CoroamaNo ratings yet

- OPITO and Other CoursesDocument17 pagesOPITO and Other Coursesrony_lesbtNo ratings yet

- Introduction To Ship-Shaped Offshore StructureDocument13 pagesIntroduction To Ship-Shaped Offshore StructureMohamad FaezeNo ratings yet

- Ectc Guide e AbsDocument7 pagesEctc Guide e AbsCanumalla RamkumarNo ratings yet

- Turret Calm Buoy PDFDocument6 pagesTurret Calm Buoy PDFvpandya1981No ratings yet

- Burea Veritas - Rules On Materials Ans Welding For The Classification On Marine Units PDFDocument236 pagesBurea Veritas - Rules On Materials Ans Welding For The Classification On Marine Units PDFAnonymous 7tBrl8No ratings yet

- 02 ERRV Crew Advanced Medical AidDocument36 pages02 ERRV Crew Advanced Medical AidRonny AndalasNo ratings yet

- BPCL Kochi SPM Pig Study 01Document9 pagesBPCL Kochi SPM Pig Study 01Arun Kumar PancharajNo ratings yet

- Carbothane 134 HG - Urethane Converter 811 MSDS Part BDocument6 pagesCarbothane 134 HG - Urethane Converter 811 MSDS Part BAyman JadNo ratings yet

- Marine Breakaway Coupling - FinalDocument15 pagesMarine Breakaway Coupling - FinalSafi Safi100% (1)

- Document Instruction Offtake OC 039 (MT - Samos-Subs)Document2 pagesDocument Instruction Offtake OC 039 (MT - Samos-Subs)Ihwan AsrulNo ratings yet

- NOFIRNO Pipe Catalog Marine March 2010 PDFDocument36 pagesNOFIRNO Pipe Catalog Marine March 2010 PDFMohammed JassimNo ratings yet

- QPR20-0367T LSP Life Support PackageDocument11 pagesQPR20-0367T LSP Life Support PackageJames LimNo ratings yet

- IACS Req Pipes Pressure VesselDocument69 pagesIACS Req Pipes Pressure VesselFrancesco CauzNo ratings yet

- Volume TM Machinery Fire Fighting and Environment Protection Equipment 2012-11-30Document54 pagesVolume TM Machinery Fire Fighting and Environment Protection Equipment 2012-11-30buddhansamrat100% (1)

- RLM 252 MODU 8 06 WDocument5 pagesRLM 252 MODU 8 06 WzaladsNo ratings yet

- CenpesDocument20 pagesCenpesnskumarmNo ratings yet

- OTC13999 Development For A Deep Sea FPSO Suitable For The GoMDocument8 pagesOTC13999 Development For A Deep Sea FPSO Suitable For The GoMAnil ChananaNo ratings yet

- ISO TS 18683-2021 Ed.2 Id.76811 Publication PDF (En)Document49 pagesISO TS 18683-2021 Ed.2 Id.76811 Publication PDF (En)napoleonmNo ratings yet

- Effect of H2-Injection On The Thermodynamic and Transportation Schouten2004Document8 pagesEffect of H2-Injection On The Thermodynamic and Transportation Schouten2004YvesfNo ratings yet

- Amends To SDs 2011Document214 pagesAmends To SDs 2011duaankushNo ratings yet

- Fal 6-Circ 14-Rev 1Document70 pagesFal 6-Circ 14-Rev 1SaeedNo ratings yet

- Yokohama FENDER PRODUCT LITERATURE PDFDocument8 pagesYokohama FENDER PRODUCT LITERATURE PDFitaaliyenNo ratings yet

- No.11 1 PASSENGER SHIPS - Guidelines For Preparation of Hull Structural Surveys No. 111Document10 pagesNo.11 1 PASSENGER SHIPS - Guidelines For Preparation of Hull Structural Surveys No. 111Long NguyenNo ratings yet

- BWM Electrolysis TypeDocument4 pagesBWM Electrolysis TypeAldo Sitorus100% (1)

- MSC.267 (85) Adoption Int Code On Intact StabilityDocument94 pagesMSC.267 (85) Adoption Int Code On Intact StabilityAfdnam StnadactnamNo ratings yet

- C 4 FfaDocument35 pagesC 4 Ffaanjuman ara100% (1)

- Guidance Notes On High Tensile Steel: Tanker Structure Cooperative ForumDocument29 pagesGuidance Notes On High Tensile Steel: Tanker Structure Cooperative ForumxeyranNo ratings yet

- SPM - Rules 2023 PDFDocument126 pagesSPM - Rules 2023 PDFbobuncle03No ratings yet

- USCG Proceedings MM IssueDocument124 pagesUSCG Proceedings MM IssueUSCGMMCExpert100% (1)

- Uscg Inspection ProceduresDocument148 pagesUscg Inspection Proceduresluckystrike9008100% (2)

- Butterfly Valve User ManualDocument10 pagesButterfly Valve User ManualEduardoAscencioNo ratings yet

- MooringDocument151 pagesMooringHafizh AmazonNo ratings yet

- Condition Assessment Programme (CAP) : Guidance Note NI 465 DT R01 EDocument24 pagesCondition Assessment Programme (CAP) : Guidance Note NI 465 DT R01 EFarhanNo ratings yet

- OCP 6-Gas Cutting - Oxy-AcetyleneDocument1 pageOCP 6-Gas Cutting - Oxy-AcetyleneFaisal Raza100% (1)

- Convencion Sar PDFDocument3 pagesConvencion Sar PDFpappazappaNo ratings yet

- Hwang, J.K., Et Al. - 2009 - Detailed Design and Construction of The Hull of An FPSODocument8 pagesHwang, J.K., Et Al. - 2009 - Detailed Design and Construction of The Hull of An FPSOVeeraiah AnbuNo ratings yet

- Bunkering Operation Training - Cercs-2Document25 pagesBunkering Operation Training - Cercs-2Julia AbalosNo ratings yet

- Design of TankersDocument203 pagesDesign of TankersnoeleosinagaNo ratings yet

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityFrom EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNo ratings yet

- Maintenance Manual VAPV 1225 SeriesDocument20 pagesMaintenance Manual VAPV 1225 Seriesrjv.premi74No ratings yet

- Instruction and Maintenance Manual Bay Valves 90001Document39 pagesInstruction and Maintenance Manual Bay Valves 90001rjv.premi74No ratings yet

- EU 2015 559 Amending Council Directive 96 98 ECDocument66 pagesEU 2015 559 Amending Council Directive 96 98 ECrjv.premi74No ratings yet

- Hydrocarbon Gas Detection Alarm System DiagramDocument3 pagesHydrocarbon Gas Detection Alarm System Diagramrjv.premi74No ratings yet

- Compressed Air-Dryer Buran Class Ultrapulse SD 0100 Ap - SD 1650 ApDocument38 pagesCompressed Air-Dryer Buran Class Ultrapulse SD 0100 Ap - SD 1650 Aprjv.premi74No ratings yet

- Outlined For Mooring Test & Sea Trial (Hull Part)Document9 pagesOutlined For Mooring Test & Sea Trial (Hull Part)rjv.premi74No ratings yet

- RR2009 - Generale-RrDocument39 pagesRR2009 - Generale-Rrhemant9315No ratings yet

- IZenBridge PMI ACP Program PDFDocument4 pagesIZenBridge PMI ACP Program PDFadetolahNo ratings yet

- 6292A: Installing and Configuring Windows® 7 Client Microsoft® Hyper-V Classroom Setup GuideDocument14 pages6292A: Installing and Configuring Windows® 7 Client Microsoft® Hyper-V Classroom Setup GuideMichael DavisNo ratings yet

- Gas LiftDocument43 pagesGas LiftAhmad FaizilNo ratings yet

- DNV Oss-102Document70 pagesDNV Oss-102Olinser BacelisNo ratings yet

- Formal Language and Automata Theory (CS21004) : Soumyajit Dey CSE, IIT KharagpurDocument23 pagesFormal Language and Automata Theory (CS21004) : Soumyajit Dey CSE, IIT KharagpurManad MishraNo ratings yet

- Data Base Management System LabDocument21 pagesData Base Management System LabUsmanyusufNo ratings yet

- Corrosion Magazine Issue117 LowresDocument36 pagesCorrosion Magazine Issue117 Lowressaminasritn100% (2)

- Transistor MCQDocument5 pagesTransistor MCQMark BelasaNo ratings yet

- Exercícios - Resistência Dos MateriaisDocument7 pagesExercícios - Resistência Dos MateriaisVinícius AntunesNo ratings yet

- Parts List 38 269 22 95: Helical-Bevel Gear Unit KA107, KH107, KV107, KT107, KA107B, KH107B, KV107B, KT107BDocument4 pagesParts List 38 269 22 95: Helical-Bevel Gear Unit KA107, KH107, KV107, KT107, KA107B, KH107B, KV107B, KT107BFotografia PopularNo ratings yet

- RC Beam Design Using MCDXDocument20 pagesRC Beam Design Using MCDXChanthy RathedNo ratings yet

- Rolls-Royce Corporation AE 3007A Service Bulletin (SB) Technical Publications IndexDocument70 pagesRolls-Royce Corporation AE 3007A Service Bulletin (SB) Technical Publications IndexAnubhuti GhaiNo ratings yet

- Topic 2 Beam DesignDocument32 pagesTopic 2 Beam DesignMuhd FareezNo ratings yet

- Z-Functional Programming in HaskellDocument26 pagesZ-Functional Programming in HaskellSurangma ParasharNo ratings yet

- Sting-S4 Poh UlDocument63 pagesSting-S4 Poh UlJorge E. Arias VargasNo ratings yet

- Miele Appliances Electrical Connection OverviewDocument3 pagesMiele Appliances Electrical Connection Overviewhappy_jonNo ratings yet

- CV Engr. Md. HasmotuzzamanDocument7 pagesCV Engr. Md. HasmotuzzamanEngr SwapanNo ratings yet

- Software Slope Stabilty Analysis FinalDocument1 pageSoftware Slope Stabilty Analysis FinalETTL UDAIPURNo ratings yet

- WATER FILL UP Procedure - Rev.01Document6 pagesWATER FILL UP Procedure - Rev.01shivanshsovNo ratings yet

- RK3399 EVB User Guide: Release Version: V1.0 Release Date: Aug 22, 2016Document35 pagesRK3399 EVB User Guide: Release Version: V1.0 Release Date: Aug 22, 2016NarendranVenkatramaniNo ratings yet

- Air Terminals and FixingsDocument8 pagesAir Terminals and FixingsIgho AhmedNo ratings yet

- BenzoinDocument7 pagesBenzoinLeah ThomasNo ratings yet

- The Nature of MaterialsDocument11 pagesThe Nature of MaterialscdymlkNo ratings yet

- PBE1202Document2 pagesPBE1202Marco London100% (1)

- Eye Movement-Based Human Computer Interaction TechniquesDocument5 pagesEye Movement-Based Human Computer Interaction TechniquesSreekanth MarlapatiNo ratings yet

- Catalog Bencomp Brosura Engleza 2018Document12 pagesCatalog Bencomp Brosura Engleza 2018sergiu9886No ratings yet

- Why It Does Not MatterDocument31 pagesWhy It Does Not MatterDavid I AgogoNo ratings yet

- MASTER FLOW p2 - BB - 6000 - NewDocument4 pagesMASTER FLOW p2 - BB - 6000 - NewJosé Daniel ArenasNo ratings yet