Professional Documents

Culture Documents

Expt No 4 Trial On Vapor Absorption System

Expt No 4 Trial On Vapor Absorption System

Uploaded by

timepass9580Copyright:

Available Formats

You might also like

- Ammonia - Catalysis and Manufacture PDFDocument352 pagesAmmonia - Catalysis and Manufacture PDFNilker González100% (2)

- Calcium Nitrate Fertilizer Lecture PDFDocument5 pagesCalcium Nitrate Fertilizer Lecture PDFAnonymous NxpnI6jCNo ratings yet

- Unit 2 RacDocument40 pagesUnit 2 Racozair arshadNo ratings yet

- VarsDocument25 pagesVarsRuturaj UmaranikarNo ratings yet

- Vapour Absorption System NotesDocument12 pagesVapour Absorption System NotesManik SharmaNo ratings yet

- Non-Conventional Refrigeration SystemsDocument21 pagesNon-Conventional Refrigeration SystemsNishit ParmarNo ratings yet

- Vapour AbsorptionDocument15 pagesVapour AbsorptionSatheesh ChandranNo ratings yet

- Vapour Absorption Refrigeration SystemDocument12 pagesVapour Absorption Refrigeration SystemHarshNo ratings yet

- Vapour Absorption Systen For StudentsDocument49 pagesVapour Absorption Systen For StudentsbernabasNo ratings yet

- Chapter 3 RACDocument26 pagesChapter 3 RACSameer AhmadNo ratings yet

- 2 To Study VASDocument5 pages2 To Study VASAnand GujaratiNo ratings yet

- Vapour Absorption Refrigeration Test RigDocument7 pagesVapour Absorption Refrigeration Test RigSwapnil DeyNo ratings yet

- Unit IvDocument39 pagesUnit IvKalyan KalapalaNo ratings yet

- Basic Civil and Mechanical Engineering Unit V Refrigeration and Airconditioning Support NotesDocument9 pagesBasic Civil and Mechanical Engineering Unit V Refrigeration and Airconditioning Support NotesA.R. Pradeep Kumar100% (1)

- Vapour Absorption Refrigeration SystemDocument26 pagesVapour Absorption Refrigeration SystemRushikesh Dandagwhal100% (8)

- Simple Vapor-Absorption Refrigeration SystemDocument49 pagesSimple Vapor-Absorption Refrigeration SystemnaccfrancNo ratings yet

- Basic Civil and Mechanical Engineering Unit VDocument37 pagesBasic Civil and Mechanical Engineering Unit VA.R. Pradeep Kumar100% (1)

- Absorption Refrigeration - AKMDocument19 pagesAbsorption Refrigeration - AKMTahmid HossainNo ratings yet

- What Is Vapour Absorption Refrigeration System Working of Vapour Absorption Refrigeration System Components in Vapour AbsorDocument1 pageWhat Is Vapour Absorption Refrigeration System Working of Vapour Absorption Refrigeration System Components in Vapour Absordhoom 760No ratings yet

- Unit6 N 7Document46 pagesUnit6 N 7Shanku Raajashree100% (1)

- Rac CH 2.2Document13 pagesRac CH 2.2Gemechu DelesaNo ratings yet

- Rac, Module 3-NoteDocument81 pagesRac, Module 3-NoteShan Mathews VettikuzhiyilNo ratings yet

- Refrigeration and Air-Conditioning: Unit - 3Document30 pagesRefrigeration and Air-Conditioning: Unit - 3SAATVIK JAINNo ratings yet

- Absorption Refrigeration System@SNISTDocument10 pagesAbsorption Refrigeration System@SNISTshaukat779sdNo ratings yet

- Ammonia AbsorptionDocument5 pagesAmmonia Absorptionfarzad100% (1)

- Lab 11Document6 pagesLab 11T RexNo ratings yet

- 3.4 Three Fluid RefDocument3 pages3.4 Three Fluid RefShaik mahammad ArifNo ratings yet

- Thermal Engineering Unit 5Document23 pagesThermal Engineering Unit 5MohanCool100% (1)

- Vapor Absorption Refrigeration System: Technical DescriptionDocument6 pagesVapor Absorption Refrigeration System: Technical Descriptionbilal buttNo ratings yet

- Vapour Absorption SystemDocument5 pagesVapour Absorption Systemhwaj100% (1)

- Refrigeration and Air ConditioningDocument6 pagesRefrigeration and Air ConditioningIbrahim HossainNo ratings yet

- ME41516 AlokeKumarMozumder S05 Absorption-RefrigerationDocument5 pagesME41516 AlokeKumarMozumder S05 Absorption-Refrigerationnuhash nowshadNo ratings yet

- 6 Absorption Refrigeration System PDFDocument28 pages6 Absorption Refrigeration System PDFJITENDRA PATIL100% (1)

- Vapour Absorption Refrigeration SystemDocument27 pagesVapour Absorption Refrigeration Systemvinayaka93No ratings yet

- Notes - VAPOUR-ABSORPTION-SYSTEMDocument9 pagesNotes - VAPOUR-ABSORPTION-SYSTEMpiyush palNo ratings yet

- Ijert: Design Analysis of 3 TR Aqua Ammoniavapour Absorption Refrigeration SystemDocument6 pagesIjert: Design Analysis of 3 TR Aqua Ammoniavapour Absorption Refrigeration SystemnandaNo ratings yet

- Ammonia - Water Vapour Absorption Refrigeration SystemDocument19 pagesAmmonia - Water Vapour Absorption Refrigeration SystemAarjab GhimireNo ratings yet

- 13.vapour Absorption Refrigeration (H2O-NH3)Document4 pages13.vapour Absorption Refrigeration (H2O-NH3)Anas AlbasarhNo ratings yet

- Study of Vapour Absorption RefrigeratorDocument5 pagesStudy of Vapour Absorption RefrigeratorMohdQasimNo ratings yet

- Experimental Investigation of A Vapor Absorption Refrigeration SystemDocument7 pagesExperimental Investigation of A Vapor Absorption Refrigeration Systemakibmahmud392No ratings yet

- Lab 11Document7 pagesLab 11huzaifa zainNo ratings yet

- Adsorption Cycle ExperimentDocument6 pagesAdsorption Cycle Experimentas asNo ratings yet

- VCRS, Vars, Air Refrigiration, SteamjetDocument18 pagesVCRS, Vars, Air Refrigiration, Steamjetdawit abebualNo ratings yet

- Absorption Refrigeration: Group MemberDocument24 pagesAbsorption Refrigeration: Group MemberanshdivyNo ratings yet

- Vapour Absorption Refrigeration SystemDocument4 pagesVapour Absorption Refrigeration SystemAmith KumarNo ratings yet

- Report On Vapor Absorption Refrigeration System: Ubmited by Sourav Mondal B. E. Power Engg. Jadavpur UniversityDocument14 pagesReport On Vapor Absorption Refrigeration System: Ubmited by Sourav Mondal B. E. Power Engg. Jadavpur UniversitysouravNo ratings yet

- REPORTDocument3 pagesREPORTEdrielleNo ratings yet

- Lab 9Document5 pagesLab 9axe furyNo ratings yet

- Unit 5.1 RefrigrationDocument11 pagesUnit 5.1 RefrigrationPalanichamy MuruganNo ratings yet

- Refrigeration and Air ConditioningDocument9 pagesRefrigeration and Air ConditioningLuis Enrique Cervantes DominguezNo ratings yet

- RacDocument59 pagesRacAnas AsharafNo ratings yet

- FinalDocument19 pagesFinalMuzammalRehmanNo ratings yet

- Test On Vapor Compression Refrigeration FINALDocument8 pagesTest On Vapor Compression Refrigeration FINALUdara ManawaduNo ratings yet

- Vol5 (1) 2014 P71 80Document10 pagesVol5 (1) 2014 P71 80KishoreNo ratings yet

- 12 Chapter 03Document37 pages12 Chapter 03Eman El DsoukyNo ratings yet

- Rac VarcDocument8 pagesRac VarcAmit singhNo ratings yet

- Different Refrigeration systems-AKMDocument23 pagesDifferent Refrigeration systems-AKMRafia RizwanaNo ratings yet

- Vapor Jet RefrigeratorDocument11 pagesVapor Jet RefrigeratorAlyan YousafNo ratings yet

- Absorption Refrigeration SystemDocument8 pagesAbsorption Refrigeration SystemSajjadullah BaigNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Chemcad Reactor Design TutorialDocument4 pagesChemcad Reactor Design TutorialErich EscobarNo ratings yet

- SDS - Sodium - Hypochlorite - Brenntag PDFDocument11 pagesSDS - Sodium - Hypochlorite - Brenntag PDFCHRISTOPHER WEALTHNo ratings yet

- Rubber Chemical Resistance Chart V001MAR17Document27 pagesRubber Chemical Resistance Chart V001MAR17Deepak patilNo ratings yet

- Influence of Stocking Density and Temperature On The Growth and Survival of Seahorse Juveniles, Hippocampus Barbouri (Jordan and Richardson, 1908)Document12 pagesInfluence of Stocking Density and Temperature On The Growth and Survival of Seahorse Juveniles, Hippocampus Barbouri (Jordan and Richardson, 1908)riniNo ratings yet

- Experiment 2: Elemental Analysis by Sodium FusionDocument11 pagesExperiment 2: Elemental Analysis by Sodium FusionSandra Nicole RiveraNo ratings yet

- BKLTF 09Document13 pagesBKLTF 09gffgffggNo ratings yet

- CSEC Chemistry June 2013 P1 PDFDocument9 pagesCSEC Chemistry June 2013 P1 PDFJeff LamboNo ratings yet

- Acid Cleaning ProcedureDocument6 pagesAcid Cleaning ProcedureMadhan RajNo ratings yet

- States of MatterDocument7 pagesStates of MatterShubhra MoreNo ratings yet

- Chemistry Form 4 PDF UPLOADDocument18 pagesChemistry Form 4 PDF UPLOADRahmat Syafiq MuhammadNo ratings yet

- Experiment 2 OrgChem - EditedDocument8 pagesExperiment 2 OrgChem - EditedAntonio CharismaNo ratings yet

- Ammonia Revamp Webinar For DownloadDocument37 pagesAmmonia Revamp Webinar For Downloadtatoo1No ratings yet

- Wattyl Killrust Cold Galvit 5053-41Document11 pagesWattyl Killrust Cold Galvit 5053-41Jerry ChanNo ratings yet

- Sulphuric Acid - Specification: Indian StandardDocument20 pagesSulphuric Acid - Specification: Indian Standard8085roNo ratings yet

- Structure of Amorphous MoS3Document7 pagesStructure of Amorphous MoS3POONAM SHARMANo ratings yet

- Lesson Plan: Lesson: Uses of AmmoniaDocument3 pagesLesson Plan: Lesson: Uses of AmmoniaMarcTnn100% (1)

- J. Biol. Chem.-1926-Sumner-435-41Document8 pagesJ. Biol. Chem.-1926-Sumner-435-41AndresManriqueNo ratings yet

- United States Patent (19) : Attorney-Harry M. Saragovitz, Edward J. Kelly, HerDocument7 pagesUnited States Patent (19) : Attorney-Harry M. Saragovitz, Edward J. Kelly, Herwilly dwinovNo ratings yet

- GM32 Sick Manual PDFDocument4 pagesGM32 Sick Manual PDFMotorola AndroidNo ratings yet

- Design1 of A Plant For The Production of Ammonia and Urea Using Aspen Hysys1Document18 pagesDesign1 of A Plant For The Production of Ammonia and Urea Using Aspen Hysys1Aji PratamaNo ratings yet

- 04.s Block (Theory) Module-2-1Document17 pages04.s Block (Theory) Module-2-1Raju SinghNo ratings yet

- Ammonia (Rev 3) 266 - 27591Document4 pagesAmmonia (Rev 3) 266 - 27591dyah ayuNo ratings yet

- Ammonia Combustion Catalysts - Review by HinokumaDocument8 pagesAmmonia Combustion Catalysts - Review by HinokumaAnanthakishnanNo ratings yet

- Edexcel AS Chemistry (Hodder) Data FilesDocument20 pagesEdexcel AS Chemistry (Hodder) Data Filesdiscordsammy2No ratings yet

- Carp CultureDocument12 pagesCarp CultureNarasimha MurthyNo ratings yet

- Mirizadeh Et Al. 2014Document9 pagesMirizadeh Et Al. 2014Guillermo GaviriaNo ratings yet

- Preparation of Buffer Solutions - Pharmaceutical GuidelinesDocument4 pagesPreparation of Buffer Solutions - Pharmaceutical Guidelinesahmed samyNo ratings yet

- Pim 1300Document17 pagesPim 1300abdelillahNo ratings yet

Expt No 4 Trial On Vapor Absorption System

Expt No 4 Trial On Vapor Absorption System

Uploaded by

timepass9580Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Expt No 4 Trial On Vapor Absorption System

Expt No 4 Trial On Vapor Absorption System

Uploaded by

timepass9580Copyright:

Available Formats

EXPERIMENT NO.

4

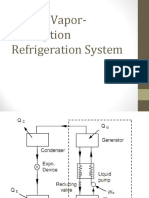

Vapour Absorption system

Aim: 1. To study of Refrigeration effect.

2. To calculate coefficient of performance.

System Components:

Electrolux refrigerator

Bulb

Voltmeter

Ammeter

Temp indicator with pt 100 sensors

Wattmeter

Dimmer

THEORY

Simple Electrolux System: This system was invented by two Swedish engineers Carl Munters

and Baltzer Von Platen developed

the domestic absorption type

refrigerator from an invention.

The main purpose of this system

is to eliminate the pump so that in

the absence of moving parts, the

machine becomes noise-less.

Ammonia is used as a refrigerant.

The operation of this system is

based on the concept of Dalton’s

Law. The ammonia vapor in the

condenser is condensed to liquid

and flows to evaporator by

gravity. The whole plant is

charged to a pressure of about 15

bars. In the evaporator the liquid ammonia meets an atmosphere of hydrogen at about 12 bars.

VIIT/ MED/ RAC/ 2017-18 pg. 1

Thus the partial pressure of ammonia falls to about 3 bar, keeping the same total pressure, and

the temperature falls to about - 100c. The vaporization of ammonia at this temperature produces

refrigeration. Water is used as a solvent for ammonia. It absorbs ammonia readily. If liquid

ammonia is introduced at the top of the system it passes on to the evaporator and vaporizes.

Hydrogen flows upwards in the evaporator counter - flows to liquid ammonia that falls from the

top. The ammonia vapor and hydrogen leave the top of the evaporator and flow through the gas

heat exchange getting warmed by the warmer hydrogen flowing through the evaporator. Both the

gases flow to the absorber. Weak aqua ammonia solution enters at the top of the absorber and

absorbs ammonia gas as it passes counter flow through the absorber. The hydrogen is not soluble

in weak aqua ammonia solution and gets separated and flows up to the evaporator through the

heat exchanger. Strong aqua ammonia solution leaves the bottom of the absorber and passes on

the generator.

Heat is supplied to the generator from external source by gas burner etc.,

expelling ammonia vapor out from the strong solution. Here the problem is to raise the elevation

of week solution of ammonia also so that it can pass to the separator and flow back to the

absorber. Principle of bubble pump is used here. The delivery tube from the generator is

immersed below the liquid level in the generator. Thus as ammonia vaporizes in the tube, they

carry slugs of week solution also into the separating vessel. From the separating vessel, weak

solution flows to the absorber and ammonia vapor passes on to the condenser.

Thus cycle is completed. The total pressure in the condenser is approximately the

same as in evaporator. Since, in the condenser there is pure ammonia, the vapor pressure there is

more or less same as the total pressure. In the evaporator, there exists a mixture of ammonia

vapor and hydrogen gas. Thus ammonia vapor pressure is much less, this being equal to total

pressure minus the partial pressure of hydrogen. Being at a pressure below saturation pressure,

the ammonia readily evaporates in the evaporator and refrigerates. Thus temperature equal to the

saturation temperature of ammonia at its partial pressure is theoretically obtained in the

evaporator.

VIIT/ MED/ RAC/ 2017-18 pg. 2

RECTIFIER

ANALYSER

CONDENSER

HEATER

H2

EVAPO-

RATOR

HEAT

EXCHANGER

(H2 + NH3)VAPOUR

WEAK SOLUTION

ABSORBER

STRONG SOLUTION

Working:

1. The arrangement of the components of the system is as shown above figure.

2. This type of refrigerator is known as three fluid absorption system in which refrigerant is

ammonia, solution used is aqua ammonia and third fluid used in evaporator is hydrogen gas.

The solution circulation pump is taken out of the system and test-rig is made noiseless.

3. Circulation of system is achieved by providing high pressure in condenser and generator and

low pressure in evaporator and absorber.

4. The liquid ammonia flows under gravity into evaporator. As soon as ammonia liquid enters

the evaporator the partial pressure of ammonia decreases to 2 bars due to presence of

hydrogen and by absorbing latent heat ammonia converts into vapor.

5. The heavy mixture of ammonia vapor and hydrogen vapor coming out of evaporator is

passed to absorber. The weak solution of aqua ammonia is sprayed into the absorber where it

absorbs ammonia vapors and gets converted into strong solution of aqua ammonia. The

hydrogen left is recirculated into evaporator.

VIIT/ MED/ RAC/ 2017-18 pg. 3

6. The strong solution of aqua ammonia from the absorber again enters into generator through

heat exchanger. The purpose of heat exchanger is to transfer the heat of weak aqua ammonia

solution to strong aqua ammonia solution to improve the overall performance of system.

7. The strong aqua ammonia solution is heated in generator by electric heater. Due to addition

of heat ammonia vapors are released and strong solution gets converted into weak solution,

which is passed to absorber. Analyzer and rectifier remove moisture in ammonia vapor and

dehydrated ammonia vapors are passed to condenser.

8. The chief advantage of Electrolux refrigerator is that it has no moving parts. As no

compressor or pump is required it is very quiet in operation.

Experimental Procedure:

1. Switch ON the supply to the trainer and switch ON the main switch to start the trainer.

2. Check all the temperatures (i.e. 1,2,3,4,5,6)

3. Let the system run for some period (till the temperature in the evaporator tank starts

decreasing)

4. Now note down the readings as per the observation table.

5. When cabinet temperature (T6) reaches around 15˚C, switch on dimmer. Adjust the load

between 75 – 100 Volts. Ensure that the cabinet temperature does not increase when bulb

is switched on.

6. If T6 increases, reduce the power supplied to bulb.

7. Note down 5 – 6 readings at interval of 10 minutes.

8. Calculate the results as per the calculation procedure.

SPECIFICATION &OBSERVATION TABLE

SR. T1 T2 T3 T4 T5 T6 V I POWER TIME

NO. (ºC) (ºC) (ºC) (ºC) (ºC) (ºC) (V) (A) (watt) DURATION

Where,

T1: temperature before generator.

T2: temperature after generator

T3: evaporator temperature

T4: condenser temperature

VIIT/ MED/ RAC/ 2017-18 pg. 4

T5: temperature before absorber

T6: cabinet temperature

CALCULATION & RESULT TABLE

1) COP (Theoretical) = T3 (T2 – T5) / T2 (T5 – T3)

Where

T2: temperature after generator

T3: evaporator temperature

T5: temperature before absorber

2) COP (actual) = load applied / Heat supplied to generator

RESULT TABLE:

Sr. No. C. O. P. (Th) C.O.P.(Actual)

Conclusion:

Comparison between Vapour Absorption and Vapour Compression

system.

Sr Vapour Absorption System Vapour Compression System.

No.

1 Cheaper form of energy is Relatively costlier form of energy

used to operate the cycle. like mechanical or electrical energy

is required.

2 The only moving part involved Compressor and motor are required

in the system is small pump and that too of higher capacity.

used to deliver the strong Because of vibrations of

mixture. compressor strong foundation is

also required.

VIIT/ MED/ RAC/ 2017-18 pg. 5

3 The vapour temperature In vapour compression system the

leaving the generator is slightly degree of superheat is governed by

superheated and is controlled the suction state of vapour.

by the heat exchangers

provided after the generator.

4 Smaller condenser is required. Bigger condenser is required.

5 The capacity of the absorption Capacity of the compression system

system is controlled by decreases rapidly with the reduced

generator temperature even if evaporator pressure.

the evaporator pressure falls.

6 The COP of absorption system The COP of compression system is

is generally much lower. generally much higher.

7 The capacity of absorption For higher capacity the parameters

system may run into hundreds like inertial force of reciprocating

of tons and there is no bar on masses has to be considered and

the capacity. hence for higher capacity plants the

system becomes costly.

8 Requires very less Requires greater maintenance

maintenance as the only compared to vapour absorption

moving part is small capacity system.

pump.

Sr Vapour Absorption System Vapour Compression System.

No.

9 There is less wastage of Comparatively more amount of

refrigerant. refrigerant is wasted due to

leakage through shaft seal.

10 For small units the absorption For small units the compression

system is much bulkier as system is much compact as

compared to compression compared to absorption system.

system. But for high capacity But for high capacity plants the

plants the system becomes system becomes bulkier than

compact than compression absorption system.

system.

VIIT/ MED/ RAC/ 2017-18 pg. 6

You might also like

- Ammonia - Catalysis and Manufacture PDFDocument352 pagesAmmonia - Catalysis and Manufacture PDFNilker González100% (2)

- Calcium Nitrate Fertilizer Lecture PDFDocument5 pagesCalcium Nitrate Fertilizer Lecture PDFAnonymous NxpnI6jCNo ratings yet

- Unit 2 RacDocument40 pagesUnit 2 Racozair arshadNo ratings yet

- VarsDocument25 pagesVarsRuturaj UmaranikarNo ratings yet

- Vapour Absorption System NotesDocument12 pagesVapour Absorption System NotesManik SharmaNo ratings yet

- Non-Conventional Refrigeration SystemsDocument21 pagesNon-Conventional Refrigeration SystemsNishit ParmarNo ratings yet

- Vapour AbsorptionDocument15 pagesVapour AbsorptionSatheesh ChandranNo ratings yet

- Vapour Absorption Refrigeration SystemDocument12 pagesVapour Absorption Refrigeration SystemHarshNo ratings yet

- Vapour Absorption Systen For StudentsDocument49 pagesVapour Absorption Systen For StudentsbernabasNo ratings yet

- Chapter 3 RACDocument26 pagesChapter 3 RACSameer AhmadNo ratings yet

- 2 To Study VASDocument5 pages2 To Study VASAnand GujaratiNo ratings yet

- Vapour Absorption Refrigeration Test RigDocument7 pagesVapour Absorption Refrigeration Test RigSwapnil DeyNo ratings yet

- Unit IvDocument39 pagesUnit IvKalyan KalapalaNo ratings yet

- Basic Civil and Mechanical Engineering Unit V Refrigeration and Airconditioning Support NotesDocument9 pagesBasic Civil and Mechanical Engineering Unit V Refrigeration and Airconditioning Support NotesA.R. Pradeep Kumar100% (1)

- Vapour Absorption Refrigeration SystemDocument26 pagesVapour Absorption Refrigeration SystemRushikesh Dandagwhal100% (8)

- Simple Vapor-Absorption Refrigeration SystemDocument49 pagesSimple Vapor-Absorption Refrigeration SystemnaccfrancNo ratings yet

- Basic Civil and Mechanical Engineering Unit VDocument37 pagesBasic Civil and Mechanical Engineering Unit VA.R. Pradeep Kumar100% (1)

- Absorption Refrigeration - AKMDocument19 pagesAbsorption Refrigeration - AKMTahmid HossainNo ratings yet

- What Is Vapour Absorption Refrigeration System Working of Vapour Absorption Refrigeration System Components in Vapour AbsorDocument1 pageWhat Is Vapour Absorption Refrigeration System Working of Vapour Absorption Refrigeration System Components in Vapour Absordhoom 760No ratings yet

- Unit6 N 7Document46 pagesUnit6 N 7Shanku Raajashree100% (1)

- Rac CH 2.2Document13 pagesRac CH 2.2Gemechu DelesaNo ratings yet

- Rac, Module 3-NoteDocument81 pagesRac, Module 3-NoteShan Mathews VettikuzhiyilNo ratings yet

- Refrigeration and Air-Conditioning: Unit - 3Document30 pagesRefrigeration and Air-Conditioning: Unit - 3SAATVIK JAINNo ratings yet

- Absorption Refrigeration System@SNISTDocument10 pagesAbsorption Refrigeration System@SNISTshaukat779sdNo ratings yet

- Ammonia AbsorptionDocument5 pagesAmmonia Absorptionfarzad100% (1)

- Lab 11Document6 pagesLab 11T RexNo ratings yet

- 3.4 Three Fluid RefDocument3 pages3.4 Three Fluid RefShaik mahammad ArifNo ratings yet

- Thermal Engineering Unit 5Document23 pagesThermal Engineering Unit 5MohanCool100% (1)

- Vapor Absorption Refrigeration System: Technical DescriptionDocument6 pagesVapor Absorption Refrigeration System: Technical Descriptionbilal buttNo ratings yet

- Vapour Absorption SystemDocument5 pagesVapour Absorption Systemhwaj100% (1)

- Refrigeration and Air ConditioningDocument6 pagesRefrigeration and Air ConditioningIbrahim HossainNo ratings yet

- ME41516 AlokeKumarMozumder S05 Absorption-RefrigerationDocument5 pagesME41516 AlokeKumarMozumder S05 Absorption-Refrigerationnuhash nowshadNo ratings yet

- 6 Absorption Refrigeration System PDFDocument28 pages6 Absorption Refrigeration System PDFJITENDRA PATIL100% (1)

- Vapour Absorption Refrigeration SystemDocument27 pagesVapour Absorption Refrigeration Systemvinayaka93No ratings yet

- Notes - VAPOUR-ABSORPTION-SYSTEMDocument9 pagesNotes - VAPOUR-ABSORPTION-SYSTEMpiyush palNo ratings yet

- Ijert: Design Analysis of 3 TR Aqua Ammoniavapour Absorption Refrigeration SystemDocument6 pagesIjert: Design Analysis of 3 TR Aqua Ammoniavapour Absorption Refrigeration SystemnandaNo ratings yet

- Ammonia - Water Vapour Absorption Refrigeration SystemDocument19 pagesAmmonia - Water Vapour Absorption Refrigeration SystemAarjab GhimireNo ratings yet

- 13.vapour Absorption Refrigeration (H2O-NH3)Document4 pages13.vapour Absorption Refrigeration (H2O-NH3)Anas AlbasarhNo ratings yet

- Study of Vapour Absorption RefrigeratorDocument5 pagesStudy of Vapour Absorption RefrigeratorMohdQasimNo ratings yet

- Experimental Investigation of A Vapor Absorption Refrigeration SystemDocument7 pagesExperimental Investigation of A Vapor Absorption Refrigeration Systemakibmahmud392No ratings yet

- Lab 11Document7 pagesLab 11huzaifa zainNo ratings yet

- Adsorption Cycle ExperimentDocument6 pagesAdsorption Cycle Experimentas asNo ratings yet

- VCRS, Vars, Air Refrigiration, SteamjetDocument18 pagesVCRS, Vars, Air Refrigiration, Steamjetdawit abebualNo ratings yet

- Absorption Refrigeration: Group MemberDocument24 pagesAbsorption Refrigeration: Group MemberanshdivyNo ratings yet

- Vapour Absorption Refrigeration SystemDocument4 pagesVapour Absorption Refrigeration SystemAmith KumarNo ratings yet

- Report On Vapor Absorption Refrigeration System: Ubmited by Sourav Mondal B. E. Power Engg. Jadavpur UniversityDocument14 pagesReport On Vapor Absorption Refrigeration System: Ubmited by Sourav Mondal B. E. Power Engg. Jadavpur UniversitysouravNo ratings yet

- REPORTDocument3 pagesREPORTEdrielleNo ratings yet

- Lab 9Document5 pagesLab 9axe furyNo ratings yet

- Unit 5.1 RefrigrationDocument11 pagesUnit 5.1 RefrigrationPalanichamy MuruganNo ratings yet

- Refrigeration and Air ConditioningDocument9 pagesRefrigeration and Air ConditioningLuis Enrique Cervantes DominguezNo ratings yet

- RacDocument59 pagesRacAnas AsharafNo ratings yet

- FinalDocument19 pagesFinalMuzammalRehmanNo ratings yet

- Test On Vapor Compression Refrigeration FINALDocument8 pagesTest On Vapor Compression Refrigeration FINALUdara ManawaduNo ratings yet

- Vol5 (1) 2014 P71 80Document10 pagesVol5 (1) 2014 P71 80KishoreNo ratings yet

- 12 Chapter 03Document37 pages12 Chapter 03Eman El DsoukyNo ratings yet

- Rac VarcDocument8 pagesRac VarcAmit singhNo ratings yet

- Different Refrigeration systems-AKMDocument23 pagesDifferent Refrigeration systems-AKMRafia RizwanaNo ratings yet

- Vapor Jet RefrigeratorDocument11 pagesVapor Jet RefrigeratorAlyan YousafNo ratings yet

- Absorption Refrigeration SystemDocument8 pagesAbsorption Refrigeration SystemSajjadullah BaigNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Chemcad Reactor Design TutorialDocument4 pagesChemcad Reactor Design TutorialErich EscobarNo ratings yet

- SDS - Sodium - Hypochlorite - Brenntag PDFDocument11 pagesSDS - Sodium - Hypochlorite - Brenntag PDFCHRISTOPHER WEALTHNo ratings yet

- Rubber Chemical Resistance Chart V001MAR17Document27 pagesRubber Chemical Resistance Chart V001MAR17Deepak patilNo ratings yet

- Influence of Stocking Density and Temperature On The Growth and Survival of Seahorse Juveniles, Hippocampus Barbouri (Jordan and Richardson, 1908)Document12 pagesInfluence of Stocking Density and Temperature On The Growth and Survival of Seahorse Juveniles, Hippocampus Barbouri (Jordan and Richardson, 1908)riniNo ratings yet

- Experiment 2: Elemental Analysis by Sodium FusionDocument11 pagesExperiment 2: Elemental Analysis by Sodium FusionSandra Nicole RiveraNo ratings yet

- BKLTF 09Document13 pagesBKLTF 09gffgffggNo ratings yet

- CSEC Chemistry June 2013 P1 PDFDocument9 pagesCSEC Chemistry June 2013 P1 PDFJeff LamboNo ratings yet

- Acid Cleaning ProcedureDocument6 pagesAcid Cleaning ProcedureMadhan RajNo ratings yet

- States of MatterDocument7 pagesStates of MatterShubhra MoreNo ratings yet

- Chemistry Form 4 PDF UPLOADDocument18 pagesChemistry Form 4 PDF UPLOADRahmat Syafiq MuhammadNo ratings yet

- Experiment 2 OrgChem - EditedDocument8 pagesExperiment 2 OrgChem - EditedAntonio CharismaNo ratings yet

- Ammonia Revamp Webinar For DownloadDocument37 pagesAmmonia Revamp Webinar For Downloadtatoo1No ratings yet

- Wattyl Killrust Cold Galvit 5053-41Document11 pagesWattyl Killrust Cold Galvit 5053-41Jerry ChanNo ratings yet

- Sulphuric Acid - Specification: Indian StandardDocument20 pagesSulphuric Acid - Specification: Indian Standard8085roNo ratings yet

- Structure of Amorphous MoS3Document7 pagesStructure of Amorphous MoS3POONAM SHARMANo ratings yet

- Lesson Plan: Lesson: Uses of AmmoniaDocument3 pagesLesson Plan: Lesson: Uses of AmmoniaMarcTnn100% (1)

- J. Biol. Chem.-1926-Sumner-435-41Document8 pagesJ. Biol. Chem.-1926-Sumner-435-41AndresManriqueNo ratings yet

- United States Patent (19) : Attorney-Harry M. Saragovitz, Edward J. Kelly, HerDocument7 pagesUnited States Patent (19) : Attorney-Harry M. Saragovitz, Edward J. Kelly, Herwilly dwinovNo ratings yet

- GM32 Sick Manual PDFDocument4 pagesGM32 Sick Manual PDFMotorola AndroidNo ratings yet

- Design1 of A Plant For The Production of Ammonia and Urea Using Aspen Hysys1Document18 pagesDesign1 of A Plant For The Production of Ammonia and Urea Using Aspen Hysys1Aji PratamaNo ratings yet

- 04.s Block (Theory) Module-2-1Document17 pages04.s Block (Theory) Module-2-1Raju SinghNo ratings yet

- Ammonia (Rev 3) 266 - 27591Document4 pagesAmmonia (Rev 3) 266 - 27591dyah ayuNo ratings yet

- Ammonia Combustion Catalysts - Review by HinokumaDocument8 pagesAmmonia Combustion Catalysts - Review by HinokumaAnanthakishnanNo ratings yet

- Edexcel AS Chemistry (Hodder) Data FilesDocument20 pagesEdexcel AS Chemistry (Hodder) Data Filesdiscordsammy2No ratings yet

- Carp CultureDocument12 pagesCarp CultureNarasimha MurthyNo ratings yet

- Mirizadeh Et Al. 2014Document9 pagesMirizadeh Et Al. 2014Guillermo GaviriaNo ratings yet

- Preparation of Buffer Solutions - Pharmaceutical GuidelinesDocument4 pagesPreparation of Buffer Solutions - Pharmaceutical Guidelinesahmed samyNo ratings yet

- Pim 1300Document17 pagesPim 1300abdelillahNo ratings yet