Professional Documents

Culture Documents

AZO-LMP-QMS-F-024 Rev 3 Risk Register

AZO-LMP-QMS-F-024 Rev 3 Risk Register

Uploaded by

anarasb5Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AZO-LMP-QMS-F-024 Rev 3 Risk Register

AZO-LMP-QMS-F-024 Rev 3 Risk Register

Uploaded by

anarasb5Copyright:

Available Formats

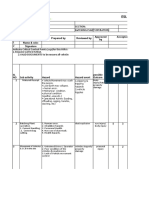

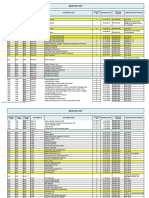

RISK ASSESSMENT BD D

Date of preparation: 07.11.2017

FAILURE MO

LAST REVIEWED: 11.09.2020

POTENTIAL POTENTIAL

NO PROCESS FAILURE / RISK EFFECT OF SEVERITY CAUSE OF

FAILURE FAILURE

inaccurate

Volume meter of OBM unexpected

1 OBM tank 2 indication of 2

storage tank 2 failure malfunctioning

the product

Weight scale 3000 kg gap of unexpected

2 Bulk plant Silo 3 product loss 4

Bulk Plant tank malfunctioning

Productive

lack of protection

Energy escalation from energy damage electric devices and time Loss,

3 agains instable

supplier equipment Equiment

energy supply

failure

3

Productive

Centrifugal pump time Loss,

4 Mud preparation

1&2 failure Equiment excessive

failure heavy mud

4 deployment

Productive delay in

Barite received in poor time Loss, realization,

5 Material receiving to warehouse

condition Equiment impediments in

failure 3 pipework

Productive

Air compressor stopped time Loss,

6

functioning Equiment

Air compressor failure 3

Productive

High rate specific gravity time Loss,

7 Mud preparation mud deployed in operation Equiment

failure Equipment

3 damage

Poor lightening around bulk plant Injure to

employees,

area where forklift movement poor visibility for forklift Light posts

8 loss time,

takes place in barite cutting operator and operators damage to around the

operation in evening times equipment plant do not

4 function

AZO-LMP-QMS-F-024; Rev.0; 24.07.2018

Forecast on increasing

loss time,

weight failed product received

damage to

Barite utilized in operation Quality of product decreased without

9 equipment,da

without APİ standard Reputation of the COA/COC,

mage to

organization has been Barite is not

reputation,

impacted compliant with

4 API stdrd.

possible

Azorel does not have the Marine

10 administrative

spill response plan in place liability

spill respopnse

Marine pollution 4 plan is available

Insufficient

delay in storage of barite

Bulk barite was not sufficient in specific sacks in

gravity halliburton

Silos on request time. Adequate loss time, damage to 4 warehouse.

increase

volume is maintained after bulk reputation, legal subsequently Inability to

barite request. threat to well provide barite

stability, big bags in due

time.

AZO-LMP-QMS-F-024; Rev.0; 24.07.2018

RISK ASSESSMENT BD DEPARTMENT

FAILURE MODE & EFFECT ANALYSIS (FMEA) REGISTER

RESPONSIBLE

PERSON AND

CURRENT

PROBABILITY DETECTABILITY RPN TARGET

CONTROLS

COMPLETION

DATE

External Commercial team

2 consultancy 2 16

services December 2020

External LMP Supervisor;

4 recalibration, 2 32 Top Management

recertification

LMP Supervisor;

outsourced 36 Top Management

service

4 3

LMP superviser,

24 October 2019

2 internal service 3

LMP superviser,

18 October 2019

3 internal service 2

18 LMP superviser

January 2020

3 external service 2

LMP Supervisor;

27 Top Management

January 2020

3 3

Electric Ramin,

36 Emin.

December 2020

3 N/A 3

AZO-LMP-QMS-F-024; Rev.0; 24.07.2018

36 Toghrul, Anar

September 2020

3 N/A 3

18 involve expertise

to create the plan.

Top management.

3 N/A 2 November 2020

3 NA 3 36

Commercial

Department,

02.2020

AZO-LMP-QMS-F-024; Rev.0; 24.07.2018

) REGISTER

ACTIONS TAKEN SEVERITY PROBABILITY DETECTABILITY RPN

maintenance/repair 2 2 2 8

maintenance/repair 2 2 2 8

switch off electricity in the end of working day

Install a device on affected equipment for protection

against energy rise

2 2 2 8

Pump 1 was repaired 2 2 2

2 2 2

Pipes were cleaned more frequently than usual,

equipment maintenance non-routine 8

2 2 2

Order spare parts and maintenance from Halliburton 8

Maintenance and replace failed spare parts 2 2 2

Change spare parts 2 2 2 8

AZO-LMP-QMS-F-024; Rev.0; 24.07.2018

Write an NCR to the partner company 2 2 2 8

verbal complaint to Halliburton 4 2 2 16

AZO-LMP-QMS-F-024; Rev.0; 24.07.2018

RISK ASSESSMENT BD D

Date of preparation: 07.11.2017

FAILURE MO

LAST REVIEWED: 11.09.2020

POTENTIAL POTENTIAL

NO PROCESS FAILURE / RISK EFFECT OF SEVERITY CAUSE OF

FAILURE FAILURE

Not able to

Receiving

Material received without trace back the

Inspection not

Material Receiving required documentation non- 4

conducted

(COA/COC etc) conforming

correctly

product

Not approapriate

Damaged material Financial loss 3 storage

conditions

2 Material Storage and Preservation

Inccorrect

conditions for

storage;

Ongoing site

Restricted storage area Not able to 4

development

receive

required

material

Incorrect measurements of Non- Non-calibrated

3 Production components in mixing conforming 4 measuring

process final product devices

Delayed Failure to

delivery of perform PM

Failure of equipment during

4 Shipping final product; 3 activities as per

shipping

Customer manufacturer's

complaints guidelines

Incorrect

planning of

procurement of

Production

5 Maintenance Equipment is non-functional 4 spare parts;

downtime

Failure to find

external

providers

AZO-LMP-QMS-F-024; Rev.0; 24.07.2018

Not conforming

to tender

requirements;

7 Customer-related process Loss of customers Financial loss 4

Not effective

marketing

strategy

inaccurate

Volume meter of OBM unexpected

8 OBM tank 2 indication of 2

storage tank 2 failure malfunctioning

the product

Weight scale 3000 kg gap of unexpected

9 Bulk plant Silo 3 product loss 4

Bulk Plant tank malfunctioning

Productive

lack of protection

Energy escalation from energy damage electric devices and time Loss,

10 agains instable

supplier equipment Equiment

energy supply

failure

3

Productive

Centrifugal pump time Loss,

Mud preparation

1&2 failure Equiment excessive

failure heavy mud

11 4 deployment

Productive delay in

Barite received in poor time Loss, realization,

12 Material receiving to warehouse

condition Equiment impediments in

failure 3 pipework

Productive

Air compressor stopped time Loss,

functioning Equiment

13 Air compressor failure 3

Productive

High rate specific gravity time Loss,

14 Mud preparation mud deployed in operation Equiment

failure Equipment

3 damage

power generatorwas received

without relevant certificates 3

Poor lightening around bulk plant Injure to

employees,

area where forklift movement poor visibility for forklift Light posts

loss time,

takes place in barite cutting operator and operators damage to around the

operation in evening times equipment plant do not

15 4 function

Forecast on increasing

loss time,

weight failed product received

damage to

Barite utilized in operation Quality of product decreased without

16 equipment,da

without APİ standard Reputation of the COA/COC,

mage to

organization has been Barite is not

reputation,

impacted compliant with

4 API stdrd.

AZO-LMP-QMS-F-024; Rev.0; 24.07.2018

possible

Azorel does not have the Marine

administrative

spill response plan in place liability

spill respopnse

17 Marine pollution 4 plan is available

AZO-LMP-QMS-F-024; Rev.0; 24.07.2018

RISK ASSESSMENT BD DEPARTMENT

FAILURE MODE & EFFECT ANALYSIS (FMEA) REGISTER

RESPONSIBLE

PERSON AND

CURRENT

PROBABILITY DETECTABILITY RPN TARGET

CONTROLS

COMPLETION

DATE

QHSE; LMP

Supervisor;

Partner

Receiving

3 relationship with 4 54

Inspector

existing supplier

September 2018

Follow Partner's

QHSE; LMP

recs for material

Supervisor; Top

storage;

2 2 12 Management

Periodic

inspections of

Oct-Dec 2018

storage area

QHSE; LMP

Supervisor; Top

3 N/A 2 24 Management

Oct-Dec 2018

LMP Supervisor

3 N/A 4 54

August 2018

Established PM

Plan; LMP Supervisor

2 2 16

Engage Partner August 2020

in PM

Effective stock

Orkhan

2 management for 2 16

October 2019

spare parts

AZO-LMP-QMS-F-024; Rev.0; 24.07.2018

External Commercial team

4 consultancy 2 32

services December 2018

External Commercial team

2 consultancy 2 16

services December 2020

External LMP Supervisor;

4 recalibration, 2 32 Top Management

recertification

LMP Supervisor;

outsourced

Top Management

service

4 3 36

LMP superviser,

October 2019

2 internal service 3 24

LMP superviser,

October 2019

3 internal service 2 18

LMP superviser

January 2020

3 external service 2 18

LMP Supervisor;

Top Management

January 2020

3 3 27

Warehouse man

3 3 27 April 2020

Electric Ramin,

Emin.

December 2020

3 N/A 3 36

Toghrul, Anar

September 2020

3 N/A 3 36

AZO-LMP-QMS-F-024; Rev.0; 24.07.2018

involve expertise

to create the plan.

Top management.

3 N/A 2 18 November 2020

AZO-LMP-QMS-F-024; Rev.0; 24.07.2018

) REGISTER

ACTIONS TAKEN SEVERITY PROBABILITY DETECTABILITY RPN

Implement Material Receiving procedure and checklists; 8

4 1 2

Train Receiving Inspector

NCR to a supplier, replace with new material 2 1 2 4

New tanks acquired for storage of base oil 16

4 2 2

Plans for expanding storage area

Measuring devices have been calibrated by external 4

4 1 1

body

create PM plan, and approve with Halliburton 5

3 1 2

representative

Hire halliburton maintenance team. Repair equipment 4 1 2 8

AZO-LMP-QMS-F-024; Rev.0; 24.07.2018

Prepare marketing strategy for 2019

maintenance/repair 2 2 2 8

maintenance/repair 2 2 2 8

switch off electricity in the end of working day

Install a device on affected equipment for protection

against energy rise

2 2 2 8

Pump 1 was repaired 2 2 2

2 2 2

Pipes were cleaned more frequently than usual,

equipment maintenance non-routine 8

2 2 2

Order spare parts and maintenance from Halliburton 8

Maintenance and replace failed spare parts 2 2 2

8

Contact with supplier obtain cert 2 2 2

8

Change spare parts 2 2 2 8

Write an NCR to the partner company 2 2 2 8

AZO-LMP-QMS-F-024; Rev.0; 24.07.2018

You might also like

- Draft IKEA Quality Management Nguyen Thu Huong 11182135Document9 pagesDraft IKEA Quality Management Nguyen Thu Huong 11182135Xuân HươngNo ratings yet

- MGMT1101 Fall 2021: Mgmt1101 Assignment 1 PESTEL Analysis and Four Functions ApproachDocument8 pagesMGMT1101 Fall 2021: Mgmt1101 Assignment 1 PESTEL Analysis and Four Functions ApproachVitor MartinsNo ratings yet

- 4488 Bowl DentDocument4 pages4488 Bowl DentRohit QualityNo ratings yet

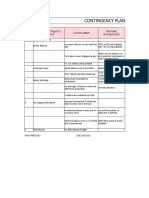

- Contingency Plan RDocument6 pagesContingency Plan RtrikjohNo ratings yet

- 13 Glavnih Gubitaka - DefinicijeDocument4 pages13 Glavnih Gubitaka - DefinicijeHusoNo ratings yet

- Pilar Kobetsu Kaizen (Focused Improvement)Document70 pagesPilar Kobetsu Kaizen (Focused Improvement)Edwin WahidNo ratings yet

- Fmea ExampleDocument6 pagesFmea ExampleSandeepNo ratings yet

- DMP (05.07) Dep Fuj Anchor.Document2 pagesDMP (05.07) Dep Fuj Anchor.김순혁No ratings yet

- FMEA Base Roof 7779-617Document19 pagesFMEA Base Roof 7779-617RidwanNo ratings yet

- 850T - CPK ImprovementDocument11 pages850T - CPK ImprovementMansoor ShaikhNo ratings yet

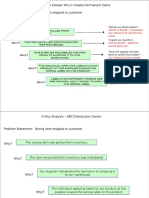

- Why Why - Analysis (06.08.2023)Document3 pagesWhy Why - Analysis (06.08.2023)Saptarshi BarikNo ratings yet

- Contingency Planning: Current Status Sr. No. Type of Contingency Reviewed Alternate ArrangementsDocument2 pagesContingency Planning: Current Status Sr. No. Type of Contingency Reviewed Alternate ArrangementsSead ZejnilovicNo ratings yet

- 2953 Thrad TightDocument6 pages2953 Thrad TightRohit QualityNo ratings yet

- K012556370 PDFDocument8 pagesK012556370 PDFVan ToanNo ratings yet

- Potential Failure Mode and Effects Analysis Process FmeaDocument24 pagesPotential Failure Mode and Effects Analysis Process Fmearodeth marquezNo ratings yet

- Failure Mode and Effects Analysis (Process Fmea) : Wrong Grade of Material ReeivedDocument6 pagesFailure Mode and Effects Analysis (Process Fmea) : Wrong Grade of Material Reeiveddada kolekarNo ratings yet

- Aida 300T DecemberDocument10 pagesAida 300T DecemberAkshay PowarNo ratings yet

- RCA FormatDocument293 pagesRCA FormatONMPlanning EngineerPT. GPOSKPSiteNo ratings yet

- CAPA Incomplete Part MixDocument16 pagesCAPA Incomplete Part MixRohtash fastnerNo ratings yet

- Supplier Quality Issues Report: Stud Tilt MoldedDocument5 pagesSupplier Quality Issues Report: Stud Tilt MoldedJ P ENTERPRISESNo ratings yet

- HIRA Batching PlanDocument9 pagesHIRA Batching Plannitish tiwariNo ratings yet

- 5 WhyDocument4 pages5 WhyJoaquim ReisNo ratings yet

- Maintenance Management PlanDocument5 pagesMaintenance Management PlanEvans MandinyanyaNo ratings yet

- FMEADocument2 pagesFMEAricardomoraisNo ratings yet

- Shyam Enterprises - Unit - Ii Contingency Plan For Abnormal ConditionsDocument4 pagesShyam Enterprises - Unit - Ii Contingency Plan For Abnormal Conditionsঅর্ঘ্য রায়No ratings yet

- Improvements PPT FEB'24Document7 pagesImprovements PPT FEB'24Surajnath SinghNo ratings yet

- Cost Based Process Failure Mode Effect Analysis of Blanking, Forming and Piercing of Hinge L NovaDocument6 pagesCost Based Process Failure Mode Effect Analysis of Blanking, Forming and Piercing of Hinge L NovaRahul MishraNo ratings yet

- 5 Why Format For Multiple CausesDocument2 pages5 Why Format For Multiple CausesAmrNo ratings yet

- QUESTIONNAIREDocument3 pagesQUESTIONNAIREHannah delos ReyesNo ratings yet

- Letter For Validator and QuestionnaireDocument3 pagesLetter For Validator and QuestionnaireHannah delos ReyesNo ratings yet

- PR RFR IS 08-01 v1.1 Refractory Management StandardDocument8 pagesPR RFR IS 08-01 v1.1 Refractory Management StandardJuan Nacimba NacimbaNo ratings yet

- HIRA of Batching Plant Erection.Document3 pagesHIRA of Batching Plant Erection.Gyanendra SrivastavaNo ratings yet

- CAPAIA-Kasmy - FlyDocument1 pageCAPAIA-Kasmy - FlyZaheer AbbasNo ratings yet

- Evaluation Chart For Ranking Equipment Edge MillingDocument6 pagesEvaluation Chart For Ranking Equipment Edge MillingParesh ValaNo ratings yet

- 001 Lifting Work (Mobile Crane)Document3 pages001 Lifting Work (Mobile Crane)hanasskepolNo ratings yet

- MM 15-9-2021Document1 pageMM 15-9-2021Fateh Ali KhanNo ratings yet

- 028,029,034,057,066 - A Day in Life of Frederic GodeDocument12 pages028,029,034,057,066 - A Day in Life of Frederic Godejaimin khatriNo ratings yet

- Overall Equipment Effectiveness: GuideDocument13 pagesOverall Equipment Effectiveness: GuideJunjie ChenNo ratings yet

- Maintenance Patterns and Fmea AnalysisDocument11 pagesMaintenance Patterns and Fmea AnalysisAdaaNo ratings yet

- Action Plan For Aug - 2020 Production: SHEET - 1/1Document9 pagesAction Plan For Aug - 2020 Production: SHEET - 1/1Yuvaraj SNo ratings yet

- UntitledDocument5 pagesUntitledPranayNo ratings yet

- Capacity Utization Contributors To Low Capacity UtilizationDocument2 pagesCapacity Utization Contributors To Low Capacity UtilizationemaxNo ratings yet

- Techno Feasibility Report LAIL 1 PDFDocument28 pagesTechno Feasibility Report LAIL 1 PDFGarad MadhukarNo ratings yet

- Contingency Plan ProcessDocument8 pagesContingency Plan ProcessRohit SinghNo ratings yet

- Bashundhara Bitumen Plant: Section Name Where To Use Purpose No of Bicycle RequiredDocument4 pagesBashundhara Bitumen Plant: Section Name Where To Use Purpose No of Bicycle Requiredমোঃ মেজবাউর রহমান সোহেলNo ratings yet

- Batching Plant VisitdetailsDocument3 pagesBatching Plant VisitdetailsSandeep JoshiNo ratings yet

- (F-PR-10) Contingency PlanDocument3 pages(F-PR-10) Contingency PlanshalinmishraNo ratings yet

- Out Side FMDocument1 pageOut Side FMaslamNo ratings yet

- 53B Intro To TPM Six Big LossesDocument32 pages53B Intro To TPM Six Big Lossesechsan dwi nugrohoNo ratings yet

- Notch Damage in 79903206 Cover Assy: One Pager Problem StatementDocument2 pagesNotch Damage in 79903206 Cover Assy: One Pager Problem StatementRohit QualityNo ratings yet

- Risk Analysis & Contigency Plan For Devlivery of ProductDocument1 pageRisk Analysis & Contigency Plan For Devlivery of Producttavhare kisanNo ratings yet

- Risk Analysis & Contigency Plan For Devlivery of ProductDocument1 pageRisk Analysis & Contigency Plan For Devlivery of Producttavhare kisanNo ratings yet

- Equipment Turndown OperationsDocument1 pageEquipment Turndown OperationssbeniwalNo ratings yet

- 8D Cairn Energy PDFDocument2 pages8D Cairn Energy PDFWassim Mansour100% (1)

- Charts For IDT For May 17 - HorizontalDocument12 pagesCharts For IDT For May 17 - HorizontalRishabh GuptaNo ratings yet

- 5 Why SampleDocument4 pages5 Why SampleadninNo ratings yet

- 5-Why Analysis For Multiple CausesDocument4 pages5-Why Analysis For Multiple Causesbodeks dexNo ratings yet

- Mock-Up Risk Assessment (0075) - Rev-00Document14 pagesMock-Up Risk Assessment (0075) - Rev-00Muhammad OsamaNo ratings yet

- PRD Controil Pouches - PubDocument1 pagePRD Controil Pouches - PubProf C.S.PurushothamanNo ratings yet

- RCFA Report For Pellet Mill (July 28 Trouble )Document7 pagesRCFA Report For Pellet Mill (July 28 Trouble )Neil TaneoNo ratings yet

- E-85 Risk RegisterDocument8 pagesE-85 Risk RegisterKapil ReddyNo ratings yet

- Xoş Gəlmişsiniz: Təqdimatı Hazırladı Anar Hacıyev, QHSE CoordinatorDocument45 pagesXoş Gəlmişsiniz: Təqdimatı Hazırladı Anar Hacıyev, QHSE Coordinatoranarasb5No ratings yet

- AZO-LMP-QMS-F-031 Internal Audit Report 2020 - First DraftDocument10 pagesAZO-LMP-QMS-F-031 Internal Audit Report 2020 - First Draftanarasb5No ratings yet

- Azo-Lmp-Qms-F-001 Master ListDocument4 pagesAzo-Lmp-Qms-F-001 Master Listanarasb5No ratings yet

- Employee (Labourers-Quayside Personnel) Competency-Azorel LMPDocument7 pagesEmployee (Labourers-Quayside Personnel) Competency-Azorel LMPanarasb5No ratings yet

- Akkreditasiya Attestatı TCSDocument2 pagesAkkreditasiya Attestatı TCSanarasb5No ratings yet

- ORCA of TEchnical EvaluationDocument1 pageORCA of TEchnical Evaluationanarasb5No ratings yet

- CHE-QMS-F-014 PM PlanDocument3 pagesCHE-QMS-F-014 PM Plananarasb5No ratings yet

- Aatmanirbhar BharatDocument12 pagesAatmanirbhar BharatmakewithshreyaNo ratings yet

- Legal Profession:: 1-Legal Professions in The Romano-Germanic SystemDocument4 pagesLegal Profession:: 1-Legal Professions in The Romano-Germanic SystemElmostafa Zakaria HamdoucheNo ratings yet

- Develop and Implement Marketing StrategiesDocument23 pagesDevelop and Implement Marketing StrategiesJyoti VermaNo ratings yet

- Alemayehu Woldie Second ProposaDocument27 pagesAlemayehu Woldie Second ProposaMehari Temesgen100% (2)

- Marketing Research Involves All of The Following RDocument7 pagesMarketing Research Involves All of The Following RSalem BawazirNo ratings yet

- Weaccess Enrollment SAMPLEDocument4 pagesWeaccess Enrollment SAMPLERuby ResurreccionNo ratings yet

- STANDARD PROCEDURE AND FORMULA FOR PRICE ADJUSTMENT Revised Edition 2022Document25 pagesSTANDARD PROCEDURE AND FORMULA FOR PRICE ADJUSTMENT Revised Edition 2022faridwazir100% (1)

- Chapter 06: Dividend Decision: ................ Md. Jobayair Ibna Rafiq.............Document62 pagesChapter 06: Dividend Decision: ................ Md. Jobayair Ibna Rafiq.............Mohammad Salim Hossain0% (1)

- CEAT Limited Integrated Annual Report FY23 PG 85 85Document177 pagesCEAT Limited Integrated Annual Report FY23 PG 85 85sumitminocha00No ratings yet

- Intellectual Property Rights: Unit-IDocument93 pagesIntellectual Property Rights: Unit-ILalita snigdhaNo ratings yet

- ASTM A194: ScopeDocument3 pagesASTM A194: ScopetylerstearnsNo ratings yet

- Forging and Its TypesDocument9 pagesForging and Its TypesHarinath GowdNo ratings yet

- VPT Student Concession Card and Myki Application FormsDocument9 pagesVPT Student Concession Card and Myki Application FormsTea PotNo ratings yet

- Module - 5 - PPPQMS - Lifecycle Management 2018Document11 pagesModule - 5 - PPPQMS - Lifecycle Management 2018Indra Maghfurin100% (1)

- Statement - 3Document4 pagesStatement - 3Gavin GoodNo ratings yet

- Sami Work BanksDocument10 pagesSami Work Bankssaaminadeem9366No ratings yet

- Dish Head Forming DivisonDocument13 pagesDish Head Forming DivisonFaraz KhalidNo ratings yet

- Angela Simatupang - IIADocument18 pagesAngela Simatupang - IIAWelin KusumaNo ratings yet

- International Trade & Multinational CorporationsDocument14 pagesInternational Trade & Multinational CorporationsOjan MayaNo ratings yet

- Underground CABLEDocument48 pagesUnderground CABLEYsraels Santisteban DurandNo ratings yet

- Brandingdlp PDFDocument9 pagesBrandingdlp PDFChristian Rey NuevoNo ratings yet

- NguyenManhHung HRM ASSIGNMENT2 BTEC-B01K12Document19 pagesNguyenManhHung HRM ASSIGNMENT2 BTEC-B01K12quốc hùng nguyễnNo ratings yet

- Petitioner vs. VS.: First DivisionDocument9 pagesPetitioner vs. VS.: First DivisionMaureen AntallanNo ratings yet

- Literature Review On Credit CardsDocument5 pagesLiterature Review On Credit Cardsafdtfgkbv100% (1)

- Business Strategy Report 500 WordsDocument7 pagesBusiness Strategy Report 500 WordsRameen Arshad RajaNo ratings yet

- CMA MicroprojectDocument21 pagesCMA Microprojectshubhampawar99900No ratings yet

- Derivatives and Risk Management: What Does Forward Contract MeanDocument9 pagesDerivatives and Risk Management: What Does Forward Contract MeanMd Hafizul HaqueNo ratings yet

- XIM University Mail - UG Student Activity Council Fee (2023-24)Document2 pagesXIM University Mail - UG Student Activity Council Fee (2023-24)Manas ChoudhuryNo ratings yet