Professional Documents

Culture Documents

SHK-ME-ET-M81-0002 Material Handling Report Rev 0 Comment NZM

SHK-ME-ET-M81-0002 Material Handling Report Rev 0 Comment NZM

Uploaded by

Nazim RosliOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SHK-ME-ET-M81-0002 Material Handling Report Rev 0 Comment NZM

SHK-ME-ET-M81-0002 Material Handling Report Rev 0 Comment NZM

Uploaded by

Nazim RosliCopyright:

Available Formats

FINAL

(Few comments are not implemented, see NOV response or CRS)

PROJECT / JOB TITLE : SHWE PROJECT PHASE 3 DEVELOPMENT

DOCUMENT TITLE : MECHANICAL AND MATERIAL HANDLING REPORT

DOCUMENT NUMBER : SHK-ME-ET-M81-0002

ITEM /PO NO. : A-1091/Q553-C5J0-1503910-001

MEG RECLAMATION AND REGENERATION PACKAGE

EQUIPMENT :

AND PACKAGE (1Q-51)

Contractor Documentation Status

Revision Revision

Prepared Checked Approved

Number Status

AA PT CCC

AFC (Approved For

0

Construction)

12-October-21 12-October-21 12-October-21

STRICTLY CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Revision History

Revision Date Section Page(s) Brief Description of Change Author of

Number (s) Change

A 20-August-21 All All IFC AA

0 12-October-21 All All Incorporated IFC Comments AA

Hold List

Hold No. Section Hold Item Hold Description

REVISION 0 SHK-ME-ET-M81-0002 Page 2 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

CONTENTS

1.0 INTRODUCTION ........................................................................................................ 5

2.0 APPLICABLE STANDARDS ...................................................................................... 9

3.0 MEG RECLAMATION AND REGENERATION PACKAGE CONFIGURATION ....... 10

4.0 Material handling principles ................................................................................... 11

5.0 MATERIAL HANDLING EQUIPMENTS ................................................................... 13

6.0 REGISTER MATERIAL HANDLING APPLIANCES ................................................. 16

7.0 MATERIAL HANDLING WAYS ................................................................................ 17

8.0 MATERIAL HANDLING METHODS ......................................................................... 24

REVISION 0 SHK-ME-ET-M81-0002 Page 3 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

APPENDIX A - MATERIAL HANDLING LIST ........................................................................ 71

REVISION 0 SHK-ME-ET-M81-0002 Page 4 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

1.0 INTRODUCTION

Purpose

The purpose of this Material Handling report is to establish the main parameters and limiting

conditions for each type of material handling operation, enable safe and efficient handling of

all materials, supplies, components and equipment required for the MEG operations and

maintenance.

Scope

This report covers for all equipment and parts, above 25 kg in weight that will require

maintenance and its frequency or overhaul at some point during the 30 years’ service life and

define the minimum resources and devices to be provided in order to fulfill the handling needs

within MEG Regeneration & Reclamation Package.

Project Overview

The Shwe Project is a multiple gas-condensate field integrated development within Blocks A-

1 and A-3, located in the Bay of Bengal, offshore Myanmar. The Shwe development is being

undertaken by a consortium (the Company) of five companies: POSCO INTERNATIONAL

Corporation (PIC), Myanma Oil and Gas Enterprise (MOGE), Oil and Natural Gas Corporation

Videsh Limited (OVL), Gas Authority of India (GAIL) and Korea Gas Corporation (KOGAS).

REVISION 0 SHK-ME-ET-M81-0002 Page 5 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Figure 1 Location of Blocks A-1 and A-3, Offshore Myanmar

The Shwe development area consists of three major field areas: the central Shwe field, the

northern Shwe Phyu field and southerly Mya field. The central Shwe field is approximately 70

km from Sittwe, mainland Myanmar, and 105 km from Kyaukphyu on Ramree Island. The

water depth varies from 90m at Shwe Phyu in the north to approximately 950m at the southern

extremity of the Mya field. The central Shwe field is in approximately 140m water depth, with

the existing SHP located in 111m water depth.

REVISION 0 SHK-ME-ET-M81-0002 Page 6 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Phase 1 of the Shwe development consisted of a single, centrally located Shwe drilling and

production platform (SHP) at the Shwe field, with a multiphase subsea tieback from the Mya

North field area. Export specification gas is exported from the SHP facility via an export

pipeline to an onshore gas terminal at Kyaukphyu. The Phase 1 facilities are designed for a

peak wellhead gas flowrate of 640 MMscfd and commenced gas production in mid-2013.

In Phase 2, the development is currently being undertaken to expand the production of raw

gas to include the Shwe Subsea & Shwe Phyu fields and both fields are planned to start-up

in 2Q 2022.

LP compression is planned as part of Phase 3, to support ongoing production from the

existing and new fields and meet the required contracted quota.

Definitions

Abbreviations Descriptions

COMPANY or PIC POSCO INTERNATIONAL CORPORATION

CONTRACTOR or HHI HYUNDAI HEAVY INDUSTRIES CO., LTD

PROJECT or CONTRACT EPCIC Services for SHWE Project Phase 3 Development

REVISION 0 SHK-ME-ET-M81-0002 Page 7 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

SUB-CONTRACTOR Third Party who is providing subcontracting or Engineering Subcontractor.

SUPPLIER The party who supplies goods or services and awarded by CONTRACTOR

REVISION 0 SHK-ME-ET-M81-0002 Page 8 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

2.0 APPLICABLE STANDARDS

COMPANY Standard Specifications and Document Reference

No. Document No. Description

1 SHK-ME-EP-803-1003 SHK -Mechanical Handling Philosophy

2 SHP-ME-ET-303-0001 SHP-Mechanical Handling Report

3 SHK-ME-ET-303-1004 SHK-Maintenance Philosophy

4 SHK-PI-ET-303-1003 SHK-Layout Philosophy

5 SHK-ME-ED-303-1011 DS-Material Handling Equipment

International Standard

No. Document No. Description

1 L23 (4th Edition) Manual Handling Operation Regulation 1992

REVISION 0 SHK-ME-ET-M81-0002 Page 9 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

3.0 MEG RECLAMATION AND REGENERATION PACKAGE

CONFIGURATION

MEG Reclamation and Regeneration Package Configuration

Description Data Unit

Length 46.0 m

Width 8.0 m

Height 31.8 m

REVISION 0 SHK-ME-ET-M81-0002 Page 10 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

4.0 MATERIAL HANDLING PRINCIPLES

In Material Handling Philosophy chapter 7, the table is the Handling Matrix to define general

principle and the requirement for permanent or temporary install local handling, depending on the

weight of loads and the frequency of handling operation.

Table 4.1: Selection of Handling Equipment

In Zone H1, local maintenance handling for load greater 1000 kg where the handling operations

are expected to be frequent as in workshop or operational area. Power and permanent handling

equipment to be used

In Zone H2, local maintenance handling for load greater 1000kg where the handling operations are

expected to be rarely happen. Permanent structure such as monorail and lifting devices such as

beam claim, trolley hoist might be used. Otherwise portable device should be used.

In Zone H3, local maintenance handling for load greater 25kg to.1000kg. Portable material

handling might be used such as A-frame, jib crane and high lift pallet truck. Optionally, permanent

structure should be used.

In Zone H4/H5, local maintenance handling for load less than 25kg, for daily and weekly operation,

mobile lifting like portable jib crane might be used. Otherwise, it can carry manually

REVISION 0 SHK-ME-ET-M81-0002 Page 11 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

In the philosophy, the further table is for Mobile Transfer Equipment according to weight and

frequency.

Table 4.2: Selection of Transfer Mobile Equipment

For above transfer, it depends on the weight and frequent operation, but the type of

trolley is different.

All equipment and parts, above 25 kg in weight that will require maintenance and its

frequency or overhaul at some point during the 30 years’ service life will be identify

and handled manually and transferred to final material laydown area for maintenance.

The selection, design, sizing, capacities and locations of monorail, pad-eyes, lifting

appliance, transportation, removal clearance shall be finalized during detail design.

All handling and lifting means presented in this document are being designed to

enable transfer loads from their original location to the transfer or final laydown area

and back.

Specific handling and required tools shall be determined by material handling study

during the Detail Engineering Phase.

The following parameters were considered to identify type of methodology, appliance

to handle the specific equipment

a) Safety

b) Human Factor and Ergonomics study to comply to international code ISO 26800

c) Module Layout and final Layout drawing

d) Periodic mainternance Requirements, unforeseen failure, vendor

recommendation and service life

REVISION 0 SHK-ME-ET-M81-0002 Page 12 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

5.0 MATERIAL HANDLING EQUIPMENTS

Demounted A‐‐Frame type Gantry

A‐Frame / Gantry consist of portable parts such as standard A‐frame (1 nos.)

connected by a Cross bar and the same shall be assembled at the required handling

location. A trolley with hook will run over the cross bar.

A‐frames / Gantries shall be used along with the chain pulley block for lifting the

materials.

Refer to Table 6.1, item 1 for detail.

Chain hoist

Chain pulley blocks suspended from A‐frame, Pad‐eye and Beam‐clamp etc. are

used for vertical lifting of materials. The hand chain shall engage positively and with

free movement over the hand chain sprocket / wheel. Load chain and hand chain

shall be made of corrosion resistant, non‐sparking material. Hook‐on type Hoist and

appurtenances shall be designed to withstand all stresses imposed under normal

operating conditions while handling loads within rated capacity.

Chain Hoist shall be in accordance to international code & standard, and certification

as required.

Refer to Table 6.1, item 2 for detail.

Fixed Pad‐‐eye

Welded pad‐eyes are permanently welded to overhead beams of the respective

handling equipment’s for vertical lifting. Each pad‐eye shall be identified with its SWL

capacity. Chain pulley block is used along with the pad‐eye for vertical lifting and

further horizontal transport shall be carried by Floor trolley. Pad‐eyes are

recommended up to 2MT capacity.

Fixed Pad Eye shall be in accordance to international code & standard, and

certification as required.

Refer to Table 6.1, item 3 for detail.

Beam‐‐Clamp

Beam‐clamps are temporarily fixed to overhead beams of the respective handling

equipment’s. Chain pulley is suspended from the beam‐clamp for vertical lifting of the

material and floor trolley for further shifting of the materials. Beam‐clamps are

recommended up to 2MT.

Beam Clamp shall be in accordance to international code & standard, and certification

as required.

REVISION 0 SHK-ME-ET-M81-0002 Page 13 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Refer to Table 6.1, item 4 for detail.

Deck trolley

Floor trolley is used for horizontal transport of materials from its location to Laydown

area. Manual floor trolley is used for handling weights up to 2MT. For capacities above

2MT air driven floor trolley shall be used.

Refer to Table 6.1, item 10 for detail.

Special trolley for salt bin to carry salt bin to laydown area prior deck crane to pick up.

Refer to Table 6.1, item 5 for detail.

Manual Davit Arm

Fixed Swing Davit is used for shifting of materials between different levels (i.e.) from

elevated platform to weather deck.

Refer to Table 6.1, item 6 for detail.

Monorail

Monorails with trolley hoist are used for the vertical lifting and horizontal transportation

of items / materials and to lower this to deck below for further transportation via a

Floor Trolley to process deck laydown area.

Refer to Table 6.1, item 7 for detail.

Trolley hoist

Trolley hoist are used over the monorail for horizontal and vertical transportation of

items to process deck level. Hand chain operated hoist can be used for items 500kg

and less, however it is recommended to use power operated trolley / hoist assembly

for items above 500kg. Rack and pinion type trolley / hoist combination to be used.

Refer to Table 6.1, item 8 for detail.

Pedestal Crane

A 25MT@R20m with 3MT@R40m(auxiliary hoist), M-7310 capacity pedestal crane

at SHK South-West side of platform, is servicing MEG module maintenance items to

Laydown area

Portable Jib Crane

Jib Crane can be used for limited space area and medium size of handling items.

Refer to Table 6.1, item 11 for detail.

REVISION 0 SHK-ME-ET-M81-0002 Page 14 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Portable Pulling Post and Tirfor

Portable Pulling Post complete with trifor use for pulling bundle and salt bin

horizontally to move the item on the deck floor.

Refer to Table 6.1, item 12 for detail.

REVISION 0 SHK-ME-ET-M81-0002 Page 15 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

6.0 REGISTER MATERIAL HANDLING APPLIANCES

To be read in conjunction with Material Handling Register Appendix A. Note 1: Scope of supply

for below items to be confirmed.

Sl. SWL

No. DESCRIPTION (T)

1 Demounted A-frame 0.5‐2.0

2 Chain hoist 0.5‐2.0

3 Fixed Pad Eye 0.5‐2.0

4 Beam Clamp 0.5‐2.0

5 Deck trolley @ every level Trolley 2.0

6 Manual Davit Arm 0.5‐2.0

7 Monorail 0.5‐5.0

8 Trolley Hoist 0.5‐5.0

25MT@R20m

9 Deck Crane

3MT@R40m

10 Deck Trolley for Salt Bin 6.0

11 Portable Jib Crane 0.5

12 Tirfor 0.5-1.0

Table 6.1: Registered Material Handling Appliance

Note:

1. Chain hoist shall be supplied with 360° swivel hook.

2. Chain hoist shall be used with Swing Davit.

3. Floor trolley wheel size shall be sufficient for travelling on grating floor/plate.

REVISION 0 SHK-ME-ET-M81-0002 Page 16 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

7.0 MATERIAL HANDLING WAYS

Main Handling Ways are shown on the figures below. Dimension of handling ways shall be

determined by the largest component to be transferred.

In any case it cannot be lower than 0.75m width and 2.1m height. The handlings to allow the

transportation of loads to a lifting/laydown area. As a general the below principle to apply for

transfer of deck trolley from MEG platform to main SHK platform.

Together, it shows the maximum loading for transfer routing.

The legends that used in this chapter as below:

Transfer Route

Maximum Load on the

Transfer Route (Example

1T

1T)

Direction for deck trolley to

SHK Platform Laydown

Area

REVISION 0 SHK-ME-ET-M81-0002 Page 17 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Handling Way at Cellar Cellar Deck

FGJFLJGFLG

Figure 7.1.1: Handling way – Cellar Deck at SHK Platform

1T 2T

0.6T

2T

4T

0.6T 1T

1T

4T 0.6T

4T 1T

0.6T

Figure 7.1.2: Handling way -Cellar Deck at MEG Platform

REVISION 0 SHK-ME-ET-M81-0002 Page 18 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

0.6T

0.6T 2T

0.6T

0.6T

0.6T

2T

Figure 7.1.3: Handling way -Mezzanine Deck at MEG Platform

REVISION 0 SHK-ME-ET-M81-0002 Page 19 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Handling Way at Main Deck

Figure 7.2.1: Handling way – Main Deck at SHK Platform

0.6T

0.6T

0.6T

0.6T 0.6T

0.6T

Figure 7.2.2: Handling way – Main Deck at MEG Platform

REVISION 0 SHK-ME-ET-M81-0002 Page 20 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

0.6T

0.6T

0.6T

0.6T

Figure 7.2.3: Handling way – Main Deck Platform at MEG Platform

REVISION 0 SHK-ME-ET-M81-0002 Page 21 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Handling at Upper Deck

Figure 8.1.5(a)

Figure 8.1.5(a)

Figure 7.3.1: Handling way – Upper Deck at SHK Platform

0.6T

0.6T

3T

0.6T

Figure 7.3.1: Handling way – Upper Deck at MEG Platform

REVISION 0 SHK-ME-ET-M81-0002 Page 22 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Handling at Cooler Deck

Figure 7.4.1: Handling way – Cooler Deck at SHK Platform

0.6T

0.6T

Figure 7.4.1: Handling way – Cooler Deck at MEG Platform

REVISION 0 SHK-ME-ET-M81-0002 Page 23 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

8.0 MATERIAL HANDLING METHODS

This chapter describes detail of lifting and transfer method for each equipment in the

MEG package.

The legends that used in this chapter as below:

Lay down area

Deck trolley

Deck trolley for another

equipment in same location

Beam clamp/trolley hoist

Special trolley for electrical

heater bundle

Monorail beam

Deck trolley route

Pulling post

Jib crane

Demounted A-Frame

Portable Drop Object

Protection Housing

REVISION 0 SHK-ME-ET-M81-0002 Page 24 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Handling methods at Cellar Deck

8.1.1 Handling for pumps P-1911A/B

Lifting Method

1) Locate Deck Trolley 2T (as shown in Picture 1(a)).

2) Attach trolley hoist 1T at monorail and hook up pump suction and unbolt the spool flange.

Lower down the spool on the floor. Same method using for discharge spool. Precaution

to be taken care to support existing pipeline properly and use temporary pipe support if

necessary.

3) Provide Portable Drop Object Protection Housing to cover motor before lifting the pump.

4) Dismantle the pump, hook and lift up the pump toward motor side and lower down on the

deck trolley.

5) For motor, dismantle the motor, hook and lift up direct to the deck trolley nearby.

6) Same methods for another pumps.

Transfer Method

1) Move trolley to main SHK platform using the route (as shown).

Part to Handles Maximum Dimensions Maximum Weights

(L m x W m x H m) (kg)

Pump 0.6 x 0.8 x 1.2 550

Motor 0.6 x 0.8 x 1.2 358

P-1911A P-1911B

Picture 1(a): Lifting Method Picture 1(b): Lifting Method

REVISION 0 SHK-ME-ET-M81-0002 Page 25 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

P-1911B

P-1911A

Picture 2: Lifting Method

*Note: Drop Object Protection Cover shall be design for full drop load at minimum 1m, detail shall be done

during detail engineering.

REVISION 0 SHK-ME-ET-M81-0002 Page 26 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

8.1.2 Handling for pumps P-1913A/B and P-1916A/B

Lifting Method

1) Locate Deck Trolley 2T (as shown in Picture 1(a)).

2) Attached trolley hoist 1T at monorail and hook up pump suction and unbolt the spool

flange. Lower down the spool on the floor. Same method using for discharge spool.

Precaution to be taken care to support existing pipeline properly and use temporary pipe

support if necessary.

3) Provide Portable Drop Object Protection Cover before lifting the pump/motor if

necessary.

4) Dismantle the pump, hook and lift up the pump toward deck trolley and lower down on

the trolley.

5) For motor, use trolley hoist at motor monorail beam, hook up and dismantle the motor,

lift up direct to the deck trolley nearby.

6) Same methods for another pumps.

Transfer Method

1) Move trolley to main SHK platform using the route (as shown in Picture 2).

Part to Handles Maximum Dimensions Maximum Weights

(L m x W m x H m) (kg)

Pump 0.5 x 0.7 x 1.2 380

Motor 0.5 x 0.7 x 1.2 318

P-1916A P-1916B P-1913A P-1913B

Picture 1(a):Lifting Method Picture 1(b):Lifting Method

REVISION 0 SHK-ME-ET-M81-0002 Page 27 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Picture 2: Lifting Method

*Note: Drop Object Protection Cover shall be design for full drop load at minimum 1m, detail shall be done

during detail engineering.

REVISION 0 SHK-ME-ET-M81-0002 Page 28 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

8.1.3 Handling for pumps P-1915A/B and P-1919A/B

Lifting Method

1) Locate Deck Trolley 2T (as shown in Picture 1(a)).

2) Attached trolley hoist 1T at monorail and hook up pump suction spool and unbolt the

spool flange. Lower down the spool on the floor. Same method using for discharge spool.

Precaution to be taken care to support existing pipeline properly and use temporary pipe

support if necessary.

3) Provide Portable Drop Object Protection Cover to cover motor before lifting the pump.

4) Dismantle the pump, hook and lift up the pump toward motor side and lower down onto

the trolley.

5) For motor, dismantle the motor, hook and lift up direct to the deck trolley nearby.

6) Same methods for another pumps.

Transfer Method

1) Move trolley to main SHK platform using the route (as shown in Picture 2).

Part to Handles Maximum Dimensions Maximum Weights

(L m x W m x H m) (kg)

motor 1.6 x 1.6 x 2.0 180

pump 1.6 x 1.6 x 2.0 115

P-1915B

P-1919B P-1915A

P-1919A

Picture 1(a):Lifting Method

Picture 1(b):Lifting Method

REVISION 0 SHK-ME-ET-M81-0002 Page 29 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Picture 2: Lifting Method

*Note: Drop Object Protection Cover shall be design for full drop load at minimum 1m, detail shall be done

during detail engineering.

REVISION 0 SHK-ME-ET-M81-0002 Page 30 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

8.1.4 Handling for bundle E-1919

Lifting Method

1) Locate Safety container 2T (as shown in Picture 1).

2) Attached trolley hoist 1T at monorail and hook at the bundle. Install tirfor 0.5T at pulling

post to pulling bundle completely from vessel

3) Pull the bundle by using pulling post toward special trolley and lower down onto the

trolley.

Transfer Method

1) Move trolley to laydown area for deck crane to pick up (as shown in Picture 2).

Part to Handles Maximum Dimensions Maximum Weights

(L m x W m x H m) (kg)

Electrical Heater Bundle 0.6 x 0.6 x 4.2 1000

E-1919

E-1919

Picture 1:Lifting Method

Picture 2: Lifting Method

REVISION 0 SHK-ME-ET-M81-0002 Page 31 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

8.1.5 Handling for Salt Bins

Lifting Method

1) Attached trolley hoist at monorail beam 5T

2) Put salt bin on Safety Container 6T.

3) Hook the salt bin lug and lift up and suspend the bin a bit to allow some load to monorail

so that pulling the bin smoother. Use pulling post complete with tirfor 1T to move bin to

another monorail.

Transfer Method

1) Transfer bin manually via monorail to laydown area. Use portable pulling post complete

with tirfor 1T to move the bin to laydown area.

Part to Handles Maximum Dimensions Maximum Weights

(L m x W m x H m) (kg)

Salt Bin (Filled with Salt) 1.6 x 1.6 x 1.5 3800

SALT BINS

Picture 1:Lifting Method

REVISION 0 SHK-ME-ET-M81-0002 Page 32 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

8.1.6 Handling for Vertical Valves M81-144/124

Lifting Method

1) Install trolley hoist 0.5MT at monorail beam on the top of vertical valves. Locate deck

trolley near to valves (as shown in Picture 1(b)).

2) Hook the removal spool on top of valves, unbolt both sides and remove the spool and put

on the floor/safe area. Precaution to be taken care to support existing pipeline properly

and use temporary pipe support if necessary.

3) Hook valves at valve lug and unbolt the valve and lower down the valve onto the deck

trolley

4) Same method for other vertical valves.

Transfer Method

1) Move trolley to main SHK platform using the route (as shown in Picture 2).

Part to Handles Maximum Dimensions Maximum Weights

(L m x W m x H m) (kg)

Valves 0.6 x 0.6 x 0.8 282

P-1911A P-1911B

M-124 M-144

Picture 1(a):Lifting Method Picture 1(b):Lifting Method

REVISION 0 SHK-ME-ET-M81-0002 Page 33 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Picture 2: Lifting Method

REVISION 0 SHK-ME-ET-M81-0002 Page 34 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Handling methods at Mezzanine Deck

8.2.1 Handling for pumps P-1920A/B

Lifting Method

1) Locate Deck Trolley 2T (as shown in Picture 1).

2) Attached trolley hoist 2T at monorail and hook up pump suction and unbolt the spool

flange. Lower down the spool on the floor. Same method using for discharge spool.

Precaution to be taken care to support existing pipeline properly and use temporary pipe

support if necessary.

3) Provide Portable Drop Object Protection Cover to cover motor before lifting the pump.

4) Dismantle the pump, hook and lift up the pump toward motor side and lower down on the

trolley.

5) For motor, dismantle the motor, hook and lift up direct to the deck trolley nearby.

6) Same methods for another pumps..

Transfer Method

1) Move deck trolley to laydown area near to davit arm.(as shown in Picture 2(a))

2) Lower down motor/pump to deck trolley at Cellar Deck

3) Move trolley to main SHK platform using the route (as shown in Picture 2(b)).

Part to Handles Maximum Dimensions Maximum Weights

(L m x W m x H m) (kg)

motor 1.6 x 1.6 x 2.0 690

pump 1.6 x 1.6 x 2.0 1300

P-1920B

P-1920A

Picture 1:Lifting Method

REVISION 0 SHK-ME-ET-M81-0002 Page 35 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Picture 2(a): Transfer Method on Picture 2(b): Transfer Method on

Mezzanine Deck Cellar Deck

*Note: Drop Object Protection Cover shall be design for full drop load at minimum 1m, detail shall be done

during detail engineering.

REVISION 0 SHK-ME-ET-M81-0002 Page 36 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

8.2.2 Handling for pumps P-1912A/B

Lifting Method

1) Locate Deck Trolley 2T (as shown in Picture 1).

2) Attach beam clamp complete with chain hoist 1T at beam on the top of pump. Hook up

pump suction spool and unbolt the spool flange. Lower down the spool on the floor. Same

method using for discharge spool. Precaution to be taken care to support existing pipeline

properly and use temporary pipe support if necessary

3) Provide Portable Drop Object Protection Cover to cover motor before lifting the pump

4) Dismantle the pump, hook and lift up the pump toward deck trolley and lower down onto

the trolley.

5) For motor, dismantle the motor, hook and lift up direct to the deck trolley nearby.

6) Same methods for another pumps.

Transfer Method

1) Move deck trolley to laydown area near to davit arm (as shown in Picture 2(a))

2) Lower down motor/pump to deck trolley at Cellar Deck

3) Move trolley to main SHK platform using the route (as shown in Picture 2(b)).

Part to Handles Maximum Dimensions Maximum Weights

(L m x W m x H m) (kg)

motor 0.4 x 0.7 x 1.0 400

pump 0.4 x 0.7 x 1.0 330

P-1912A P-1912B

Picture 1: Lifting Method

REVISION 0 SHK-ME-ET-M81-0002 Page 37 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Picture 2(a): Transfer Method on Picture 2(b): Transfer Method on

Mezzanine Deck Cellar Deck

*Note: Drop Object Protection Cover shall be design for full drop load at minimum 1m, detail shall be done

during detail engineering.

REVISION 0 SHK-ME-ET-M81-0002 Page 38 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

8.2.3 Handling for pumps P-1910A/B

Lifting Method

1) Locate Deck Trolley 2T (as shown in Picture 1).

2) Attach beam clamp complete with chain hoist 1T at beam on the top of pump. Hook up

pump suction spool and unbolt the spool flange. Lower down the spool on the floor. Same

method using for discharge spool.

3) Provide Portable Drop Object Protection Cover to cover motor before lifting the pump.

4) Dismantle the pump, hook and lift up the pump toward deck trolley and lower down onto

the trolley.

5) For motor, dismantle the motor, hook and lift up direct to the deck trolley nearby.

6) Same methods for another pumps.

Transfer Method

1) Move deck trolley to laydown area near to davit arm (as shown in Picture 2(a))

2) Lower down motor/pump to deck trolley at Cellar Deck

3) Move trolley to main SHK platform using the route (as shown in Picture 2(b)).

Part to Handles Maximum Dimensions Maximum Weights

(L m x W m x H m) (kg)

motor 0.4 x 0.7 x 1.0 400

pump 0.4 x 0.7 x 1.0 330

P-1910A P-1910B

Picture 1:Lifting Method

REVISION 0 SHK-ME-ET-M81-0002 Page 39 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Picture 2(a): Transfer Method on Picture 2(b): Transfer Method on

Mezzanine Deck Cellar Deck

*Note: Drop Object Protection Cover shall be design for full drop load at minimum 1m, detail shall be done

during detail engineering.

REVISION 0 SHK-ME-ET-M81-0002 Page 40 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

8.2.4 Handling pumps in package A-1913

Lifting Method

1) Locate Deck Trolley 2T (as shown in Picture 1).

2) Attach beam clamp complete with chain hoist 1T at beam on the top of pump. Hook up

pump suction spool and unbolt the spool flange. Lower down the spool on the floor. Same

method using for discharge spool.

3) Provide Portable Drop Object Protection Cover to cover motor before lifting the pump.

4) Dismantle the pump, hook and lift up the pump toward deck trolley and lower down on

the trolley.

5) For motor, dismantle the motor, hook and lift up direct to the deck trolley nearby.

Transfer Method

1) Move deck trolley to laydown area near to davit arm (as shown in Picture 2(a))

2) Lower down motor/pump to deck trolley at Cellar Deck

3) Move trolley to main SHK platform using the route (as shown in Picture 2(b)).

Part to Handles Maximum Dimensions Maximum Weights

(L m x W m x H m) (kg)

motor 0.5 x 0.3 x 0.8 <150

pump 0.5 x 0.3 x 0.8 <150

A-1913

Picture 1:Lifting Method

REVISION 0 SHK-ME-ET-M81-0002 Page 41 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Picture 2(a): Transfer Method on Picture 2(b): Transfer Method on

Mezzanine Deck Cellar Deck

*Note: Drop Object Protection Cover shall be design for full drop load at minimum 1m, detail shall be done

during detail engineering.

REVISION 0 SHK-ME-ET-M81-0002 Page 42 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

8.2.5 Handling Motor for package M-1911A

Lifting Method

1) Install chain hoist 0.5T at davit arm and hook up the motor conveyor, unbolt and dismantle

it.

2) Lift up the motor and turn davit arm to drop zone area and lower down it on deck trolley

at Cellar Deck slowly.

Transfer Method

1) Move trolley to main SHK platform using the route (as shown in Picture 2).

Part to Handles Maximum Dimensions Maximum Weights

(L m x W m x H m) (kg)

motor 0.5 x 0.3 x 0.8 <150

M-1911

Picture 1:Lifting Method

REVISION 0 SHK-ME-ET-M81-0002 Page 43 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Picture 2: Transfer Method on Cellar Deck

REVISION 0 SHK-ME-ET-M81-0002 Page 44 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Handling methods at Main Deck

8.3.1 Handling pumps in Package A-1911

Lifting Method

1) Locate portable jib crane complete with chain hoist 0.5T and Deck Trolley 2T (as shown

in Picture 1).

2) Hook up pump suction spool and unbolt the spool flange. Lower down the spool on the

floor. Same method using for discharge spool.

3) Provide Portable Drop Object Protection Cover to cover motor before lifting the pump to

protect motor from drop object.

4) Dismantle the pump, hook up the pump and lift up the pump toward deck trolley and lower

down onto the trolley.

5) For motor, hook up the motor, dismantle and lift up direct to the deck trolley nearby.

6) Same method uses for accessories

Transfer Method

1) Move trolley to main SHK platform using the route (as shown in Picture 2).

Part to Handles Maximum Dimensions Maximum Weights

(L m x W m x H m) (kg)

motor 0.5 x 0.3 x 1.0 120

pump 0.5 x 0.3 x 1.0 90

A-1911 P-1914B

P-1914A

Picture 1:Lifting Method

REVISION 0 SHK-ME-ET-M81-0002 Page 45 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Picture 2: Transfer Method

*Note: Drop Object Protection Cover shall be design for full drop load at minimum 1m, detail shall be done

during detail engineering.

REVISION 0 SHK-ME-ET-M81-0002 Page 46 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

8.3.2 Handling for coalescer for V-1917

Lifting Method

1) Locate Jib Crane complete chain hoist 0.5Tand Deck Trolley 2T (as shown in Picture 1).

2) Lift the bundle up and push it towards to deck trolley and lower it down.

Transfer Method

1) Move trolley to main SHK platform using the route (as shown in Picture 2).

Part to Handles Maximum Dimensions Maximum Weights

(L m x W m x H m) (kg)

Coalescer VTA 50

V-1917

Picture 1: Lifting Method

Picture 2: Transfer Method

REVISION 0 SHK-ME-ET-M81-0002 Page 47 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

8.3.3 Handling pump in Package A-1910

Lifting Method

1) Locate A-frame complete with chain hoist 0.5Tand Deck Trolley 2T (as shown in Picture

1).

2) Hook up pump suction spool and unbolt the spool flange. Lower down the spool on the

floor. Same method using for discharge spool.

3) Provide Portable Drop Object Protection Cover to cover motor before lifting the pump.

4) Dismantle the pump, hook up the pump and lift up the pump toward deck trolley and lower

down onto the trolley.

5) For motor, dismantle the motor, hook and lift up direct to the deck trolley nearby.

6) Same method uses for another pump.

Transfer Method

1) Move trolley to main SHK platform using the route (as shown in Picture 2).

Part to Handles Maximum Dimensions Maximum Weights

(L m x W m x H m) (kg)

motor 0.8 x 0.36 x 1.2 180

pump 0.8 x 0.6 x 1.2 150

A-1910

Picture 1: Lifting Method

REVISION 0 SHK-ME-ET-M81-0002 Page 48 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Picture 2: Transfer Method

*Note: Drop Object Protection Cover shall be design for full drop load at minimum 1m, detail shall be done

during detail engineering.

REVISION 0 SHK-ME-ET-M81-0002 Page 49 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

8.3.4 Handling for Vertical valves M81-147/154

Lifting Method

1) Attach beam clamp complete with chain hoist 0.5MT at beam on the top of vertical valves.

Locate deck trolley near to valves (as shown in Picture 1(b)).

2) Hook the removal spool on top of valves, unbolt flange both sides and remove the spool

and put on the floor.

3) Hook valves at valve lug and unbolt the valve flange and lower down the valve onto the

deck trolley.

4) Same methods for other vertical valves.

Transfer Method

1) Move trolley to main SHK platform using the route (as shown in Picture 2).

Part to Handles Maximum Dimensions Maximum Weights

(L m x W m x H m) (kg)

Valves 0.5 x 0.5 x 0.5 77

M81-154

M81-147

Picture 1(a):Lifting Method Picture 1(b):Lifting Method

REVISION 0 SHK-ME-ET-M81-0002 Page 50 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Picture 2: Transfer Method

REVISION 0 SHK-ME-ET-M81-0002 Page 51 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Handling methods at Main Deck Platform

8.4.1 Handling for Valves

Lifting Method

1) Attach beam clamp complete with chain hoist 0.5T to beam on top of valve and Deck

Trolley 2T at nearest items to be handled (example as shown in Picture 1).

2) Hook up the valve and unbolt the valve flange. Lift the valve up and push it towards to

deck trolley and lower it down on the trolley.

3) Same method uses for another valves.

Transfer Method

1) Move deck trolley to laydown area near to davit arm.(as shown)

2) Lower down items to deck trolley at Main Deck

3) Move trolley to main SHK platform using the route (as shown).

Part to Handles Maximum Dimensions Maximum Weights

(L m x W m x H m) (kg)

Valves and PSVS 0.6 x 0.5 x 1.5 350

Picture 1: Lifting Method

REVISION 0 SHK-ME-ET-M81-0002 Page 52 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Picture 2(a): Transfer Method on Picture 2(b): Transfer Method on

Main Deck Platform Main Deck

REVISION 0 SHK-ME-ET-M81-0002 Page 53 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

8.4.2 Handling for Vertical Valves M51-158/161

1) Attach beam clamp complete with chain hoist 0.5MT at monorail beam on the top of

vertical valves. Locate deck trolley near to valves.

2) Hook the top removal spool, unbolt both sides and lower it on the floor.

3) Hook valves at valve lug and unbolt the valve and lower down the valve on the deck

trolley.

4) Same method for other vertical valves.

1) Transfer Method

1) Move deck trolley to laydown area near to davit arm (as shown in Picture 2(a))

2) Lower down items to deck trolley at Upper Deck

3) Move trolley to main SHK platform using the route (as shown in Picture 2(b)).

Part to Handles Maximum Dimensions Maximum Weights

(L m x W m x H m) (kg)

Valves 0.5 x 0.5 x 0.5 114

M81-161

M81-158

Picture 1:Lifting Method

REVISION 0 SHK-ME-ET-M81-0002 Page 54 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Picture 2(a): Transfer Method on Picture 2(b): Transfer Method on

Main Deck Platform Main Deck

REVISION 0 SHK-ME-ET-M81-0002 Page 55 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Handling methods at Upper Deck

8.5.1 Handling for Manual Valves and PSVs

Lifting Method

1) Attach beam clamp complete with chain hoist 0.5Tand Deck Trolley 2T at nearest items

to be handled (as shown in Picture 1).

2) For PSV, unbolt PSV flange, dismantle and lift the items up and push it slowly towards to

deck trolley and lower it down.

3) For valve at PSV inlet, once PSV completely dismantled. Hook up the reducer spool,

unbolt flange and lower it down on the floor. Then hook up the valve at valve lug, unbolt,

dismantle and lower it down on the deck trolley.

4) For vertical valve at PSV outlet. Hook up the top removal spool, unbolt and lower it down

on the floor. Then hook up the vertical valve at valve lug, unbolt, dismantle and lower it

down on the deck troll

Transfer Method

1) Move trolley to main SHK platform using the route (as shown in Picture 2).

Part to Handles Maximum Dimensions Maximum Weights

(L m x W m x H m) (kg)

Valves and PSVS 0.5 x 0.5 x 0.5 114

Picture 1: Lifting Method

REVISION 0 SHK-ME-ET-M81-0002 Page 56 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Picture 2: Transfer Method

REVISION 0 SHK-ME-ET-M81-0002 Page 57 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

8.5.2 Handling for pumps Tote Tank/Salt Bin

Lifting and Transfer Method

1) Deck Crane is used to lift and transfer the tote tank/Salt Bin

Part to Handles Maximum Dimensions Maximum Weights

(L m x W m x H m) (kg)

Alkalinity Tote Tank 2 x 2 x 2.5 1800

Salt Bin 1.6 x 1.6 x 1.5 3800

Oxygen Scavenger/Antifoam Tote Tank 1.2 x 1.0 x 1.2 1200 (estimated)

Picture 1: Lifting Method

REVISION 0 SHK-ME-ET-M81-0002 Page 58 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Handling methods at PSV Deck Platform

8.6.1 Handling for Valves and PSVs

Lifting Method

1) Wherever location that beam clamp cannot be used, attach jib crane complete with chain

hoist 0.5T and Deck Trolley 2T at nearest items to be handled (example as shown in

Picture 1).

2) Same method uses for handling PSV, valve and vertical valve that describe in handling

for PSV.

Transfer Method

1) Move deck trolley to laydown area near to davit arm (as shown in Picture 2(a))

2) Lower down items to deck trolley at PSV Deck

3) Move trolley to main SHK platform using the route (as shown in Picture 2(b)).

Part to Handles Maximum Dimensions Maximum Weights

(L m x W m x H m) (kg)

Valves and PSVs 0.5 x 0.5 x 0.5 114

Picture 1: Lifting Method

Picture 2(a):: Transfer Method on PSV Deck

REVISION 0 SHK-ME-ET-M81-0002 Page 59 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Picture 2(b): Transfer Method on Upper Deck

REVISION 0 SHK-ME-ET-M81-0002 Page 60 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

8.6.2 Handling for Motor and Cooler Accessories E-1913

Lifting Method

1) Handling and removal of motor/cooler accessories shall be included in cooler package.

Vendor to provide

2) Lift the items up and push it towards to deck trolley 2T and lower it down.

3) Same method uses for another items.

4) For handling removal bundle, barge crane with minimum Crane 20T capacity to be use

since deck crane cannot reach the bundle. Proper lifting arrangement for removal bundle

study detail shall be provided prior to lifting the bundle.

Transfer Method

1) Move deck trolley to laydown area near to davit arm (as shown in Picture 2(a))

2) Lower down items to deck trolley at PSV Deck

3) Move trolley to main SHK platform using the route (as shown in Picture 2(b)).

Part to Handles Maximum Dimensions Maximum Weights

(L m x W m x H m) (kg)

Motor and Cooler Accessories 0.5 x 0.5 x 0.5 330

Cooler Bundle 8.0 x 4.0 x 1.5 15000/bay (estimated)

E-1913

Cooler Bundle

Motor and Accessories

under bundle

Picture 1: Lifting Method

REVISION 0 SHK-ME-ET-M81-0002 Page 61 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Picture 2(a): Transfer Method on PSV Deck

Picture 2(b): Transfer Method on Upper Deck

REVISION 0 SHK-ME-ET-M81-0002 Page 62 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

8.6.3 Handling for PSV-19603A/B, removal spool and vertical valves

Lifting Method

1) Attach beam clamp complete with chain hoist 0.5T to top support beam and locate deck

Trolley 2T at nearest items to be handled.

2) For PSV, unbolt PSV flane, dismantle and lift the items up and push it slowly towards to

deck trolley and lower it down (as shown in Picture 1)

3) For valve at PSV inlet, once PSV completely dismantled. Hook up the reducer spool,

unbolt and lower it down on the floor. Then hook up the valve at valve lug, unbolt,

dismantle and lower it down on the deck trolley (as shown in Picture 1, item 1)

4) For vertical valve at PSV outlet. Hook up the top removal spool, unbolt and lower it down

on the floor. Then hook up the vertical valve at valve lug, unbolt, dismantle and lower it

down on the deck trolley (as shown in Picture 1, item 2)

Transfer Method

1) Move deck trolley to laydown area near to davit arm (as shown in Picture 2(a)).

2) Lower down items to deck trolley at Upper Deck

3) Move trolley to main SHK platform using the route (as shown in Picture 2(b)).

Part to Handles Maximum Dimensions Maximum Weights

(L m x W m x H m) (kg)

Valves and PSVs 0.5 x 0.5 x 0.5 114

PSV -19603A PSV -19603B

Picture 1: Lifting Method

REVISION 0 SHK-ME-ET-M81-0002 Page 63 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Picture 2(a): Transfer Method on PSV Deck

Picture 2(b): Transfer Method on Upper Deck

REVISION 0 SHK-ME-ET-M81-0002 Page 64 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

8.6.4 Handling for PSV-19613A/B, removal spool and vertical valves

Lifting Method

1) Attach beam clamp complete with chain hoist 0.5T to top support beam and locate deck

Trolley 2T at nearest items to be handled.

2) For PSV, unbolt PSV flange, dismantle and lift the items up and push it slowly towards to

deck trolley and lower it down (as shown in Picture 1)

3) For valve at PSV inlet, once PSV completely dismantled. Hook up the reducer spool,

unbolt and lower it down on the floor. Then hook up the valve at valve lug, unbolt,

dismantle and lower it down on the deck trolley (as shown in Picture 1, item 1)

4) For vertical valve at PSV outlet. Hook up the top removal spool, unbolt it and lower it

down on the floor. Then hook up the vertical valve at valve lug, unbolt, dismantle and

lower it down on the deck trolley (as shown in Picture 1, item 2)

Transfer Method

1) Move deck trolley to laydown area near to davit arm (as shown in Picture 2(a))

2) Lower down items to deck trolley at Upper Deck

3) Move trolley to main SHK platform using the route (as shown in Picture 2(b)).

Part to Handles Maximum Dimensions Maximum Weights

(L m x W m x H m) (kg)

Valves and PSVs 0.5 x 0.5 x 1.1 120 (estimated)

PSV -19613B

PSV -19613A

Picture 1:Lifting Method

REVISION 0 SHK-ME-ET-M81-0002 Page 65 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Picture 2(a): Transfer Method on PSV Deck

Picture 2(b): Transfer Method on Upper Deck

REVISION 0 SHK-ME-ET-M81-0002 Page 66 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

8.6.5 Handling for PSV-19661A/B, removal spool and vertical valves

Lifting Method

1) Attach beam clamp complete with chain hoist 0.5T to top support beam and Deck Trolley

2T at nearest items to be handled.

2) For PSV, unbolt PSV flange, dismantle and lift the items up and push it slowly towards to

deck trolley and lower it down (as shown in Picture 1)

3) For valve at PSV inlet, once PSV completely dismantled. Hook up the reducer spool,

unbolt and lower it down on the floor. Then hook up the valve at valve lug, unbolt,

dismantle and lower it down on the deck trolley (as shown in Picture 1, item 1)

4) For vertical valve at PSV outlet. Hook up the top removal spool, unbolt both side and

lower it down on the floor. Then hook up the vertical valve at valve lug, unbolt, dismantle

and lower it down on the deck trolley(as shown in Picture 1, item 2)

5) .

Transfer Method

1) Move deck trolley to laydown area near to davit arm.(as shown in Picture 2(a))

2) Lower down items to deck trolley at PSV Deck

3) Move trolley to main SHK platform using the route (as shown in Picture 2(b)).

4) Optional, the items can be directly picked up by deck crane at PSV Deck

Part to Handles Maximum Dimensions Maximum Weights

(L m x W m x H m) (kg)

Valves and PSVs 0.5 x 0.5 x 0.5 114

PSV -19661B

PSV -19661B

Picture 1:Lifting Method

REVISION 0 SHK-ME-ET-M81-0002 Page 67 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Picture 2(a): Transfer Method on PSV Deck

Picture 2(b):: Transfer Method on Upper Deck

REVISION 0 SHK-ME-ET-M81-0002 Page 68 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

8.6.6 Handling for PSV-19605, removal spool and vertical valves

Lifting Method

1) Attach beam clamp complete with chain hoist 0.5T to top support beam and Deck Trolley

2T at nearest items to be handled.

2) For PSV, unbolt PSV flange, dismantle and lift the items up and push it slowly towards to

deck trolley and lower it down (as shown in Picture 1)

3) For valve at PSV inlet, once PSV completely dismantled. Hook up the removal spool,

unbolt and lower it down on the floor. Then hook up the valve at valve lug, unbolt,

dismantle and lower it down on the deck trolley (as shown in Picture 1, item 1)

4) For vertical valve at PSV outlet. Hook up the top removal spool, unbolt both side and

lower it down on the floor. Then hook up the vertical valve at valve lug, unbolt, dismantle

and lower it down on the deck trolley (as shown in Picture 1, item 2)

5) .

Transfer Method

1) Move deck trolley to laydown area near to davit arm (as shown in Picture 2(a))

2) Lower down items to deck trolley at PSV Deck

3) Move trolley to main SHK platform using the route (as shown in Picture 2(b)).

4) Optional, the items can be directly picked up by deck crane at PSV Deck

Part to Handles Maximum Dimensions Maximum Weights

(L m x W m x H m) (kg)

Valves and PSVs 0.5 x 0.5 x 0.5 114

PSV -19605

Picture 1:Lifting Method

REVISION 0 SHK-ME-ET-M81-0002 Page 69 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

Picture 2(a): Transfer Method on PSV Deck

Picture 2(b): Transfer Method on Upper Deck

REVISION 0 SHK-ME-ET-M81-0002 Page 70 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

MECHANICAL AND MATERIAL HANDLING REPORT

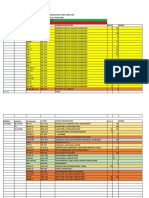

APPENDIX A - MATERIAL HANDLING LIST

REVISION 0 SHK-ME-ET-M81-0002 Page 71 of 71

CONFIDENTIAL – Do Not Disclose Without Authorisation

APPENDIX A - Material Handling Register

Equipment Package Description

Item No Tagging Approx.

Line Number Service Maintenance Component

Area Maintenance Item component Volume Handling Method Description of Material Handling Method

DutySpare Weight (Kg.)

Lm x Wm x Hm

Equipment Package Description

1 V-1910 Rich MEG Flash Drum Upper Deck NA NA - NA

2 V-1912 Rich MEG Degasser Main Deck NA NA - NA

3 C-1911 MEG Flash & Distillation Column Main/Upper Deck internal 20 TBA

4 V-1913 Reflux Drum Main Deck NA NA - NA

5 V-1915 Recovered MEG Surge Drum Mezzanine Deck NA NA - NA

6 V-1919 Heating Medium Expansion Drum Platform (Main Deck) NA NA - NA

1) Item is replaced manually

7 S-1916A/B Rich MEG Filter Upper Deck filter 20 MANUAL

JIB CRANE, 1) Locate Jib crane 0.5T to lift up items

8 V-1917 Rich MEG Coalescer Main Deck internal 50

DECK TROLLEY 2) Deck Trolley 0.5T brings items to client site.

1) Item is replaced manually

9 S-1920A/B Lean MEG Filters Upper Deck filter 20 MANUAL

10 V-1920 Lean MEG Injection Drum Main Deck NA NA - NA

11 V-1921 MEG Drain Drum Cellar Deck NA NA - NA

1) Attach trolley hoist 1T at monorail to lift up

pump/motor and lower down onto Deck Trolley

MONORAIL,

12 P-1911A/B MEG Flash Column Pump Cellar Deck pump 550 0.6 x 0.8 x 1.2 (Precaution: Avoid motor from drop object)

DECK TROLLEY

2) Deck Trolley bring bundle to SHK main

platform

1) Attach trolley hoist 1T at monorail to lift up

pump/motor and lower down onto Deck Trolley

MONORAIL,

13 P-1911A/B MEG Flash Column Pump Cellar Deck motor 358 0.6 x 0.8 x 1.2 (Precaution: Avoid motor from drop object)

DECK TROLLEY

2) Deck Trolley bring bundle to SHK main

platform

1) Attached trolley hoist 0.5T at monorail to lift up

MONORAIL

14 P-1916A/B Rich MEG Degasser Pump Cellar Deck pump 120 0.5 x 0.7 x 1.2 item and lower down onto deck trolley

DECK TROLLEY

2) Deck trolley bring item to SHK main platform.

1) Attached trolley hoist 0.5T at monorail to lift up

MONORAIL

15 P-1916A/B Rich MEG Degasser Pump Cellar Deck motor 74 0.5 x 0.7 x 1.2 item and lower down onto deck trolley

DECK TROLLEY

2) Deck trolley bring item to SHK main platform.

1) Attach beam clamp complete with chain hoist

0.5T at beam on top of pump.

2) Lift up pump/motor to lower down onto Deck

BEAM CLAMP

Trolley 0.5T and bring to near laydowm area

16 P-1912A/B Lean MEG Product Pump Mezzanine Deck pump 330 0.4 x 0.7 x 1.0 DECK TROLLEY

3) Drop down onto Deck Trolley 0.5T by Davit

DAVIT ARM

Arm 0.5T at Cellar Deck and bring to SHK

Platform

1) Attach beam clamp complete with chain hoist

0.5T at beam on top of pump.

2) Lift up pump/motor to lower down onto Deck

BEAM CLAMP

Trolley 0.5T and bring to near laydowm area

17 P-1912A/B Lean MEG Product Pump Mezzanine Deck motor 400 0.4 x 0.7 x 1.0 DECK TROLLEY

3) Drop down onto Deck Trolley 0.5T by Davit

DAVIT ARM

Arm 0.5T at Cellar Deck and bring to SHK

Platform

1) Attached trolley hoist 0.5T at monorail to lift up

MONORAIL

18 P-1913A/B Reflux Pump Cellar Deck pump 120 0.5 x 0.7 x 1.2 item and lower down onto deck trolley

DECK TROLLEY

2) Deck trolley bring item to SHK main platform.

1) Attached trolley hoist 0.5T at monorail to lift up

MONORAIL

19 P-1913A/B Reflux Pump Cellar Deck motor 74 0.5 x 0.7 x 1.2 item and lower down onto deck trolley

DECK TROLLEY

2) Deck trolley bring item to SHK main platform.

1) Attached trolley hoist 0.5T at monorail to lift up

MONORAIL

20 P-1915A/B Recovered MEG Return Pump Cellar Deck pump 180 0.5 x 0.7 x 1.2 item and lower down onto deck trolley

DECK TROLLEY

2) Deck trolley bring item to SHK main platform.

1) Attached trolley hoist 0.5T at monorail to lift up

MONORAIL

21 P-1915A/B Recovered MEG Return Pump Cellar Deck motor 118 0.5 x 0.7 x 1.2 item and lower down onto deck trolley

DECK TROLLEY

2) Deck trolley bring item to SHK main platform.

Equipment Package Description

Item No Tagging Approx.

Line Number Service Maintenance Component

Area Maintenance Item component Volume Handling Method Description of Material Handling Method

DutySpare Weight (Kg.)

Lm x Wm x Hm

1) Attached trolley hoist 0.5T at monorail to lift up

MONORAIL

22 P-1919A/B Heating Medium Pump Cellar Deck pump 180 0.5 x 0.7 x 1.2 item and lower down onto deck trolley

DECK TROLLEY

2) Deck trolley bring item to SHK main platform.

1) Attached trolley hoist 0.5T at monorail to lift up

MONORAIL

23 P-1919A/B Heating Medium Pump Cellar Deck motor 115 1.6 x 1.6 x 2.0 item and lower down onto deck trolley

DECK TROLLEY

2) Deck trolley bring item to SHK main platform.

1) Attach beam clamp complete with chain hoist

2T at beam on top of pump.

BEAM CLAMP 2) Lift up pump/motor to lower down onto Deck

24 P-1920A/B Lean MEG Injection Pump Mezzanine Deck pump 1600 1.6 x 1.6 x 2.0 DECK TROLLEY Trolley 2T and bring to near laydowm area

DAVIT ARM 3) Drop down onto Deck Trolley 2T by Davit Arm

2T at Cellar Deck and bring to SHK Platform

1) Attach beam clamp complete with chain hoist

2T at beam on top of pump.

BEAM CLAMP

2) Lift up pump/motor to lower down onto Deck

25 P-1920A/B Lean MEG Injection Pump Mezzanine Deck Motor 1400 1.6 x 1.6 x 2.0 DECK TROLLEY

Trolley 2T and bring to near laydowm area

DAVIT ARM

3) Drop down onto Deck Trolley 2T by Davit Arm

2T at Cellar Deck and bring to SHK Platform.

1) Beam clamp to lift up item and lower down

BEAM CLAMP

26 P-1921A/B MEG Drain Drum Pump Cellar Deck pump 80 0.5 x 0.3 x 0.8 onto Deck Trolley

DECK TROLLEY

2) Deck Trolley bring item to SHK main platform.

1) Beam clamp to lift up item and lower down

BEAM CLAMP

27 P-1921A/B MEG Drain Drum Pump Cellar Deck motor 50 0.5 x 0.7 x 1.2 onto Deck Trolley

DECK TROLLEY

2) Deck Trolley bring item to SHK main platform.

1) Attach beam clamp complete with chain hoist

0.5T at beam on top of pump.

2) Lift up pump/motor to lower down onto Deck

BEAM CLAMP

Trolley 0.5T and bring to near laydowm area

28 P-1910A/B Rich MEG Condensate Pump Mezzanine Deck pump 30 0.4 x 0.7 x 1.0 DECK TROLLEY

3) Drop down onto Deck Trolley 0.5T by Davit

DAVIT ARM

Arm 0.5T at Cellar Deck and bring to SHK

Platform

1) Attach beam clamp complete with chain hoist

0.5T at beam on top of pump.

2) Lift up pump/motor to lower down onto Deck

BEAM CLAMP

Trolley 0.5T and bring to near laydowm area

29 P-1910A/B Rich MEG Condensate Pump Mezzanine Deck motor 12 0.4 x 0.7 x 1.0 DECK TROLLEY

3) Drop down onto Deck Trolley 0.5T by Davit

DAVIT ARM

Arm 0.5T at Cellar Deck and bring to SHK

Platform

1) Attach chain hoist 0.5T at A-frame to lift up

A-1910 MEG Centrifuge Package A-FRAME, items

30 Main Deck motor 180 0.8 x 0.36 x 1.2

(M1910) (MEG Centrifuge) DECK TROLLEY 2) Deck Trolley 0.5T brings items to SHK

Platform.

1) Attach chain hoist 0.5T at A-frame to lift up

A-1910 MEG Centrifuge Package A-FRAME, items

31 Main Deck pump 150 0.8 x 0.6 x 1.2

(M1910) (MEG Centrifuge) DECK TROLLEY 2) Deck Trolley 0.5T brings items to SHK

Platform.

1) Attach beam clamp complete with chain hoist

0.5T at beam on top of pump.

2) Lift up pump/motor to lower down onto Deck

BEAM CLAMP

Trolley 0.5T and bring to near laydowm area

32 M-1911A Screw Conveyor Mezzanine Deck motor 50 0.5 x 0.3 x 1.0 DECK TROLLEY

3) Drop down onto Deck Trolley 0.5T by Davit

DAVIT ARM

Arm 0.5T at Cellar Deck and bring to SHK

Platform

1) Attach trolley hoist 1T at monorail beam brings

items along to Cellar Deck Laydown Area

MONORAIL,

33 TBA Salt Bin Cellar Deck Bin 3800 1.6x1.6x1.5 2) Deck Crane picks up items to SHK main

DECK CRANE

platform

MEG Vacuum Pump Package (consist of

JIB CRANE, 1) Jib crane to lift up items

34 A-1911 Vacuum Pump, Vacumm Pump Scrubber and Main Deck pump 90 0.5 x 0.3 x 0.8

DECK TROLLEY 2) Deck Trolley brings items to client site.

Liquid Ring Cooler)

MEG Vacuum Pump Package (consist of

JIB CRANE, 1) Jib crane to lift up items

35 A-1911 Vacuum Pump, Vacumm Pump Scrubber and Main Deck motor 120 0.8 x 0.36 x 1.2

DECK TROLLEY 2) Deck Trolley brings items to client site.

Liquid Ring Cooler)

Chemical Injection Package 1) Attach chain hoist 0.5T at A-frame to lift up

A-1912 (Alkalinity Tank A-FRAME, items

36 Main Deck pump package 150 0.8 x 0.6 x 1.2

Oxygen Scavenger Tank DECK TROLLEY 2) Deck Trolley 0.5T brings items to SHK

Antifoam Tank) Platform.

Equipment Package Description

Item No Tagging Approx.

Line Number Service Maintenance Component

Area Maintenance Item component Volume Handling Method Description of Material Handling Method

DutySpare Weight (Kg.)

Lm x Wm x Hm

1) Attach beam clamp complete with chain hoist

0.5T at beam on top of pump.

2) Lift up pump/motor to lower down onto Deck

BEAM CLAMP

Trolley 0.5T and bring to near laydowm area

37 A-1913 High Purity Nitrogen Package Mezzanine Deck motor <150 0.5 x 0.3 x 0.8 DECK TROLLEY

3) Drop down onto Deck Trolley 0.5T by Davit

DAVIT ARM

Arm 0.5T at Cellar Deck and bring to SHK

Platform

1) Attach beam clamp complete with chain hoist

0.5T at beam on top of pump.

2) Lift up pump/motor to lower down onto Deck

BEAM CLAMP

Trolley 0.5T and bring to near laydowm area

38 A-1913 High Purity Nitrogen Package Mezzanine Deck Pump <150 0.5 x 0.3 x 0.8 DECK TROLLEY

3) Drop down onto Deck Trolley 0.5T by Davit

DAVIT ARM

Arm 0.5T at Cellar Deck and bring to SHK

Platform

39 E-1910 Rich MEG Pre-heater (spiral type) Platform (Main Deck) NA (in situ cleaning) NA NA NA

1) Attach trolley hoist 1T at monorail lift up bundle

MONORAIL,

and lower down onto Deck Trolley

40 E-1919 Heating Medium Electrical Heater Cellar Deck bundle 1000 0.6 x 0.6 x 4.2 SPECIAL TROLLEY

2) Special Trolley bring bundle to laydown area

DECK CRANE

for Deck Crane to pick up.

1) Attach beam clamp complete with chain hoist

0.5T at beam on top of pump.

2) Lift up pump/motor to lower down onto Deck

BEAM CLAMP

Trolley 0.5T and bring to near laydowm area

41 M-1912 Centrifuge Lube Oil Skid Mezzanine Deck motor, pump, cooler fan 60 Varies DECK TROLLEY

3) Drop down onto Deck Trolley 0.5T by Davit

DAVIT ARM

Arm 0.5T at Cellar Deck and bring to SHK

Platform

42 E-1911 MEG Flash Column Heater (Spiral type) Main Deck NA (in situ cleaning) NA - NA

1) Install beam clamp complete chain hoist on

bottom structure frame at suitable location. Hook

BEAM CLAMP on maintenance item.

DECK TROLLEY, 2) Remove maintenance items and slowly lower

43 E-1912 Lean meg cooler PSV/Cooler Deck motor, gear and accessories 150 Varies

DECK CRANE down onto Deck Trolley.

2) Deck Trolley brings items to laydown area

3) Deck Crane picks items up from laydown area

to SHK main platform

1) Vendor to provide lifting device for removal

motor/accessories. location. Hook on

VENDOR maintenance item.

DECK TROLLEY, 2) Lower down onto Deck Trolley 0.5T.

44 E-1913 MEG Liquid Ring Cooler PSV/Cooler Deck motor, gear and accessories 330 0.5 x 0.5 x 0.5

DAVIT ARM 2) Deck Trolley brings items to laydown area near

to Davit Arm

3) Lower down the item onto deck trolley at PSV

deck and transfer to main SHK Platform

1) Batch crane with minimum Crane 20T capacity

to be use since deck crane cannot reach the

BATCH CRANE

45 E-1913 MEG Liquid Ring Cooler PSV/Cooler Deck Heater Bundle 15000/bay 8.0 x 4.0 x 1.5 bundle. lifting arrangement for bundle study detail

shall be made prior lifting the bundle.

1) Deck crane picks item up from laydown area to

46 TBA Tote Tank Upper Deck Tank 1800 2x2x2 DECK CRANE

SHK Platform

1) Attach beam clamp complete with chain hoist

0.5T at beam on top of pump.

2) Lift up pump/motor to lower down onto Deck

BEAM CLAMP

Trolley 0.5T and bring to near laydowm area

47 P-1924A/B Lean MEG Booster Pump Mezzanine Deck pump 300 0.5 x 0.7 x 1.2 DECK TROLLEY

3) Drop down onto Deck Trolley 0.5T by Davit

DAVIT ARM

Arm 0.5T at Cellar Deck and bring to SHK

Platform

1) Attach beam clamp complete with chain hoist

0.5T at beam on top of pump.

BEAM CLAMP

2) Lift up pump/motor to lower down onto Deck

48 P-1924A/B Lean MEG Booster Pump Mezzanine Deck motor 27 0.5 x 0.3 x 1.0 DECK TROLLEY

Trolley 0.5T and bring to near laydowm area

DAVIT ARM

3) Drop down onto Deck Trolley 0.5T by Davit

Arm 0.5T at Cellar Deck and bring to SHK

1) Install beam clamp complete chain hoist on

bottom structure frame at suitable location. Hook

on maintenance item.

BEAM CLAMP

2) Remove maintenance items and slowly lower

DECK TROLLEY,

49 E-1914 Platform (Main Deck) motor, gear and accessories 120 Varies down onto Deck Trolley.

DAVIT ARM

2) Deck Trolley brings items to davit arm area

3) Davit arm bring down the items onto Deck

Trolley at main deck and bring them to main SHK

platform

Equipment Package Description

Item No Tagging Approx.

Line Number Service Maintenance Component

Area Maintenance Item component Volume Handling Method Description of Material Handling Method

DutySpare Weight (Kg.)

Lm x Wm x Hm

50 V-1921 Rich MEG Drain Tank Cellar Deck NA

51 V-1921 Rich MEG Drain Tank Cellar Deck NA

Piping

1) Attach beam clamp complete with chain hoist

0.5T at beam on top of the valve.

2) Remove spool using the beam clamp

BEAM CLAMP

52 M81-802 8"-DH-19861-A13X-PP Main Deck 4" Manual Valve 150# WNRF 45 0.3 x 0.3 x 0.4 3) Hook to the valve and remove valve and lower

DECK TROLLEY

down onto Deck Trolley

4) Deck trolley bring to SHK Platform

1) Install beam clamp complete chain hoist on

bottom structure frame at suitable location. Hook

on maintenance item.

BEAM CLAMP

2) Remove maintenance items and slowly lower

DECK TROLLEY,

53 M81-078 4"-GL-19746-A13X-E Platform (Main Deck) 4" Manual Valve 150# WNRF 45 0.3 x 0.3 x 0.4 down onto Deck Trolley.

DAVIT ARM

2) Deck Trolley brings items to davit arm area

3) Davit arm bring down the items onto Deck

Trolley at main deck and bring them to main SHK

platform

1) Attach beam clamp complete with chain hoist

0.5T at beam on top of the valve.

2) Remove spool using the beam clamp

BEAM CLAMP

54 M81-076 4"-GL-19746-A13X-E Main Deck 4" Manual Valve 150# WNRF 45 0.3 x 0.3 x 0.4 3) Hook to the valve and remove valve and lower

DECK TROLLEY

down onto Deck Trolley

4) Deck trolley bring to SHK Platform

1) Attach beam clamp complete with chain hoist

0.5T at beam on top of the valve.

2) Remove spool using the beam clamp

BEAM CLAMP

55 M81-081 4"-GL-19746-A13X-E Main Deck 4" Manual Valve 150# WNRF 45 0.3 x 0.3 x 0.4 3) Hook to the valve and remove valve and lower

DECK TROLLEY

down onto Deck Trolley

4) Deck trolley bring to SHK Platform

1) Attach beam clamp complete with chain hoist

0.5T at beam on top of pump.

2) Lift up valve to lower down onto Deck Trolley

BEAM CLAMP

0.5T and bring to near laydowm area

56 M81-424 4"-GL-19886-A13X-E Mezzanine Deck 4" Manual Valve 150# WNRF 45 0.3 x 0.3 x 0.4 DECK TROLLEY

3) Drop down onto Deck Trolley 0.5T by Davit

DAVIT ARM

Arm 0.5T at Cellar Deck and bring to SHK

Platform

1) Attach beam clamp complete with chain hoist

0.5T at beam on top of pump.

2) Lift up valve to lower down onto Deck Trolley

BEAM CLAMP

0.5T and bring to near laydowm area

57 M81-432 4"-GL-19886-A13X-E Mezzanine Deck 4" Manual Valve 150# WNRF 45 0.3 x 0.3 x 0.4 DECK TROLLEY

3) Drop down onto Deck Trolley 0.5T by Davit

DAVIT ARM

Arm 0.5T at Cellar Deck and bring to SHK

Platform

1) Install beam clamp complete chain hoist on

bottom structure frame at suitable location. Hook

on maintenance item.

BEAM CLAMP

2) Remove maintenance items and slowly lower

DECK TROLLEY,

58 M81-431 4"-GL-19886-A13X-E Platform (Main Deck) 4" Manual Valve 300# WNRF 82 0.4 x 0.4 x 0.5 down onto Deck Trolley.

DAVIT ARM

2) Deck Trolley brings items to davit arm area

3) Davit arm bring down the items onto Deck

Trolley at main deck and bring them to main SHK

platform

1) Install beam clamp complete chain hoist on

bottom structure frame at suitable location. Hook

on maintenance item.

BEAM CLAMP

2) Remove maintenance items and slowly lower

DECK TROLLEY,

59 M81-019 4"-GL-19892-B13X-IH Platform (Main Deck) 4" Manual Valve 300# WNRF 82 0.4 x 0.4 x 0.5 down onto Deck Trolley.

DAVIT ARM

2) Deck Trolley brings items to davit arm area

3) Davit arm bring down the items onto Deck

Trolley at main deck and bring them to main SHK

platform

1) Install beam clamp complete chain hoist on

bottom structure frame at suitable location. Hook

on maintenance item.

BEAM CLAMP

2) Remove maintenance items and slowly lower

DECK TROLLEY,

60 M81-054 4"-GL-19892-B13X-IH Platform (Main Deck) 4" Manual Valve 300# WNRF 82 0.4 x 0.4 x 0.5 down onto Deck Trolley.

DAVIT ARM

2) Deck Trolley brings items to davit arm area

3) Davit arm bring down the items onto Deck

Trolley at main deck and bring them to main SHK

platform

Equipment Package Description

Item No Tagging Approx.

Line Number Service Maintenance Component

Area Maintenance Item component Volume Handling Method Description of Material Handling Method

DutySpare Weight (Kg.)

Lm x Wm x Hm

1) Install beam clamp complete chain hoist on

bottom structure frame at suitable location. Hook

on maintenance item.

BEAM CLAMP

2) Remove maintenance items and slowly lower

DECK TROLLEY,

61 M81-020 4"-GL-19892-B13X-IH Platform (Main Deck) 4" Manual Valve 300# WNRF 82 0.4 x 0.4 x 0.5 down onto Deck Trolley.

DAVIT ARM

2) Deck Trolley brings items to davit arm area

3) Davit arm bring down the items onto Deck

Trolley at main deck and bring them to main SHK

platform

1) Install beam clamp complete chain hoist on

bottom structure frame at suitable location. Hook

on maintenance item.

BEAM CLAMP

2) Remove maintenance items and slowly lower

DECK TROLLEY,

62 M81-143 8"-GL-19730-A16X-E Platform (Main Deck) 6" Manual Valve 300# WNRF 82 0.5 x 0.5 x 0.5 down onto Deck Trolley.

DAVIT ARM

2) Deck Trolley brings items to davit arm area

3) Davit arm bring down the items onto Deck

Trolley at main deck and bring them to main SHK

platform

1) Install beam clamp complete chain hoist on

bottom structure frame at suitable location. Hook

on maintenance item.

BEAM CLAMP

2) Remove maintenance items and slowly lower

DECK TROLLEY,

63 FV-19003 8"-GL-19730-A16X-E Platform (Main Deck) 6" Manual Valve 300# WNRF 82 0.5 x 0.5 x 0.5 down onto Deck Trolley.

DAVIT ARM

2) Deck Trolley brings items to davit arm area

3) Davit arm bring down the items onto Deck

Trolley at main deck and bring them to main SHK

platform

1) Install beam clamp complete chain hoist on

bottom structure frame at suitable location. Hook

on maintenance item.

BEAM CLAMP

2) Remove maintenance items and slowly lower

DECK TROLLEY,

64 M81-162 6"-GL-19752-B16X-E Platform (Main Deck) 6" Manual Valve 300# WNRF 82 0.5 x 0.5 x 0.5 down onto Deck Trolley.

DAVIT ARM

2) Deck Trolley brings items to davit arm area

3) Davit arm bring down the items onto Deck

Trolley at main deck and bring them to main SHK

platform

1) Install beam clamp complete chain hoist on

bottom structure frame at suitable location. Hook

on maintenance item.

BEAM CLAMP

2) Remove maintenance items and slowly lower

DECK TROLLEY,

65 M81-162 6"-GL-19752-B16X-E Platform (Main Deck) 6" Manual Valve 300# WNRF 82 0.5 x 0.5 x 0.5 down onto Deck Trolley.

DAVIT ARM

2) Deck Trolley brings items to davit arm area

3) Davit arm bring down the items onto Deck

Trolley at main deck and bring them to main SHK

platform

1) Attach beam clamp complete with chain hoist

0.5T at beam on top of the valve.

2) Remove spool using the beam clamp

BEAM CLAMP

66 M81-154 6"-GL-19756-B16X-E Main Deck 6" Manual Valve 150# WNRF 77 0.5 x 0.5 x 0.5 3) Hook to the valve and remove valve and lower

DECK TROLLEY

down onto Deck Trolley

4) Deck trolley bring to SHK Platform

1) Attach beam clamp complete with chain hoist

0.5T at beam on top of the valve.

2) Remove spool using the beam clamp

BEAM CLAMP

67 M81-147 6"-GL-19756-B16X-E Main Deck 6" Manual Valve 150# WNRF 77 0.5 x 0.5 x 0.5 3) Hook to the valve and remove valve and lower

DECK TROLLEY

down onto Deck Trolley

4) Deck trolley bring to SHK Platform

1) Beam clamp to lift up item and lower down

BEAM CLAMP

68 M81-119 8"-GL-19774-A16X-E Cellar Deck 8" Manual Valve 150# WNRF 157 0.7 x 0.7 x 0.8 onto Deck Trolley

DECK TROLLEY

2) Deck Trolley bring item to SHK main platform.

1) Beam clamp to lift up item and lower down

BEAM CLAMP

INSTRUMENT

69 1 of BRANCH 8"-GL-19774-A16X-EB2

8"-GL-19774-A16X-E Cellar Deck 8" Manual Valve 150# WNRF 157 0.7 x 0.7 x 0.8 onto Deck Trolley

DECK TROLLEY

2) Deck Trolley bring item to SHK main platform.

1) Attach beam clamp complete with chain hoist

0.5T at beam on top of the valve.

2) Remove spool using the beam clamp

BEAM CLAMP

70 M81-757 6"-HM-19711-B13X-IH Main Deck 6" Manual Valve 300# WNRF 82 0.6 x 0.6 x 0.7 3) Hook to the valve and remove valve and lower

DECK TROLLEY

down onto Deck Trolley

4) Deck trolley bring to SHK Platform

1) Attach beam clamp complete with chain hoist