Professional Documents

Culture Documents

Uji XRD XRF Pasir Silika (Geoservice)

Uji XRD XRF Pasir Silika (Geoservice)

Uploaded by

burhanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Uji XRD XRF Pasir Silika (Geoservice)

Uji XRD XRF Pasir Silika (Geoservice)

Uploaded by

burhanCopyright:

Available Formats

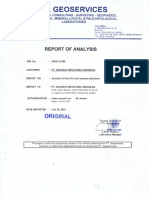

PT.

GEOSERVICES MINERALOGY LABORATORY

Jl Industri Selatan 2, Blok MM1, Jababeka 2, Cikarang Bekasi 17520, Indonesia

Technical Report

MLG.00058

"XRD & XRF Testwork on behalf of PT. Djabesmen"

Prepared for: Mrs. Josephine

External copy to: Mrs. Josephine

Company: PT. Djabesmen

Company Address: Jl. Lemah Abang KM.59

Cikarang Bekasi 17530

Project: Silica Sand

Mineralogist: Istiqomah

Author: Anita

Laboratory Job Number: MLG.00058

Client Submission Number: MLG_DJ_20180920

Receipt Date: October 01, 2018

Report Issue Date: October 15, 2018

Wayne Turner

Head of Mineral Division

Report No: MLG.00058 PT. Djabesmen Page | 1

PT. GEOSERVICES MINERALOGY LABORATORY

Jl Industri Selatan 2, Blok MM1, Jababeka 2, Cikarang Bekasi 17520, Indonesia

SUMMARY

XRD Bulk tabled in Paragraph 4.1 are summarized in bar graphs below for mineral identification and mineral

phase contribution.

MINERAL PHASE RIETVELD (WT%)

100.0

90.0

80.0

70.0

60.0

50.0

40.0

30.0

20.0

10.0

0.0

After BM 1 After BM 2 After BM 3 Pasir Belitung Pasir Belitung Pasir Belitung

Before BM 1 Before BM 2 Before BM 3

Quartz Cristobalite Ferrihydrite Gibbsite

Figure 1 – Summary Bar Graph of Mineral Identification

The minerals identified were classified by general mineral grouping and Reitveld% contribution summed and

tabled below:

Table 1 – Mineral General Grouping – Sum of Reitveld %

Report No: MLG.00058 PT. Djabesmen Page | 2

[Type here] [Type here] [Type here]

PT. GEOSERVICES MINERALOGY LABORATORY

Jl Industri Selatan 2, Blok MM1, Jababeka 2, Cikarang Bekasi 17520, Indonesia

DISCLAIMER

This report has been prepared for the Client by PT. Geoservices – Mineralogy Laboratory. Other parties, at

the discretion of the Client may be given access to the report or receive copies of the report, but only in full

including this page, the title page and appendices.

PT. Geoservices Ltd has performed the Mineralogy Services reported herein based on the

information provided by the Client to PT. Geoservices Ltd and PT. Geoservices Ltd understanding of the

Client’s requirements.

PT. Geoservices Ltd is not responsible for any loss or damage arising out of any inaccurate, incomplete or

misleading information that the Client gives to PT. Geoservices Ltd or any misunderstanding of the Client’s

requirements by PT. Geoservices Ltd.

PT. Geoservices Ltd is not responsible for any loss or damage arising out of the performance or non-

performance in connection with the Mineralogy Services by any third party that PT. Geoservices Ltd engages

to assist it in performing the Mineralogy Services.

PT. Geoservices Ltd has performed the Mineralogy Services and prepared this Report based only upon the

sample material that the Client provided to PT. Geoservices Ltd.

The results presented in this report pertain only to the samples as received.

Report No: MLG.00058 PT. Djabesmen Page | 3

[Type here] [Type here] [Type here]

PT. GEOSERVICES MINERALOGY LABORATORY

Jl Industri Selatan 2, Blok MM1, Jababeka 2, Cikarang Bekasi 17520, Indonesia

TABLE OF CONTENTS

SUMMARY ............................................................................................................................................... 2

DISCLAIMER ............................................................................................................................................. 3

TABLE OF CONTENTS ................................................................................................................................ 4

LIST OF FIGURES ...............................................................................................................................................5

LIST OF TABLES .................................................................................................................................................6

1.0 INTRODUCTION ............................................................................................................................ 7

2.0 SAMPLE INFORMATION................................................................................................................. 8

3.0 TEST METHODOLOGY .................................................................................................................... 9

3.1 TESTWORK FLOWCHART .............................................................................................................................9

3.2 TESTWORK METHOD SUMMARY ..................................................................................................................9

3.2.1 Sample Preparation for XRD testing .............................................................................................9

3.2.3 XRD Equipment Settings ...............................................................................................................9

3.2.4 XRF Fusion Analysis for Silica Sand ............................................................................................ 10

4.0 TESTWORK RESULTS.................................................................................................................... 11

4.1 XRD BULK SCAN MINERAL IDENTIFICATION ................................................................................................ 11

4.2 XRF FUSION – SILICA SAND RESULTS ......................................................................................................... 12

APPENDICES .......................................................................................................................................... 13

APPENDIX – XRD BULK DIFFRACTOGRAMS ............................................................................................................ 14

Report No: MLG.00058 PT. Djabesmen Page | 4

[Type here] [Type here] [Type here]

PT. GEOSERVICES MINERALOGY LABORATORY

Jl Industri Selatan 2, Blok MM1, Jababeka 2, Cikarang Bekasi 17520, Indonesia

LIST OF FIGURES

Figure 1 – Summary Bar Graph of Mineral Identification ....................................................................................2

Figure 2 – Sample “As Received” Photos..............................................................................................................8

Figure 3 – Testwork Flowchart .............................................................................................................................9

Figure 4 – XRD Bulk Diffractogram – After BM 1 ............................................................................................... 14

Figure 5 - XRD Bulk Diffractogram – After BM 2................................................................................................ 14

Figure 6 – XRD Bulk Diffractogram – After BM 3 ............................................................................................... 15

Figure 7 – XRD Bulk Diffractogram – Pasir Belitung Before BM 1 ..................................................................... 15

Figure 8 - XRD Bulk Diffractogram - Pasir Belitung Before BM 2 ....................................................................... 16

Figure 9 – XRD Bulk Diffractogram – Pasir Belitung Before BM 3 ..................................................................... 16

Figure 10 – XRD Bulk Diffractogram – After BM 1 REP...................................................................................... 17

Report No: MLG.00058 PT. Djabesmen Page | 5

[Type here] [Type here] [Type here]

PT. GEOSERVICES MINERALOGY LABORATORY

Jl Industri Selatan 2, Blok MM1, Jababeka 2, Cikarang Bekasi 17520, Indonesia

LIST OF TABLES

Table 1 – Mineral General Grouping – Sum of Reitveld % ...................................................................................2

Table 2 – Sample Identification ............................................................................................................................8

Table 3 – XRD Operating Conditions – Bulk Scan .............................................................................................. 10

Table 4 – XRD Bulk Scan Mineral Identification ................................................................................................ 11

Report No: MLG.00058 PT. Djabesmen Page | 6

[Type here] [Type here] [Type here]

PT. GEOSERVICES MINERALOGY LABORATORY

Jl Industri Selatan 2, Blok MM1, Jababeka 2, Cikarang Bekasi 17520, Indonesia

1.0 INTRODUCTION

The objective of this testing program was to provide data from XRD for Bulk Mineral Identification.

Six samples were received at Cikarang Mineralogy Laboratory on October 01, 2018.

Testing for the program is presented in flow diagrams in 3.1 Testwork Flowchart and included as follows:

Sample Preparation

XRD Bulk mineralogy

XRF Fusion – Silica Sand

Testing was concluded by 15/10/2018, after which this report was prepared.

This report summarizes key results from the test program, using data summaries and graphical

displays.

XRD Scan plots can be found in the Appendices as follows:

Appendix : XRD Bulk Diffractograms

Report No: MLG.00058 PT. Djabesmen Page | 7

[Type here] [Type here] [Type here]

PT. GEOSERVICES MINERALOGY LABORATORY

Jl Industri Selatan 2, Blok MM1, Jababeka 2, Cikarang Bekasi 17520, Indonesia

2.0 SAMPLE INFORMATION

A total of 6 samples were submitted for XRF and XRD Bulk analysis with sample identification as per

following table:

Table 2 – Sample Identification

No Sample Identification Weight (g)

1 After BM 1 565.7

2 After BM 2 537.0

3 After BM 3 604.3

4 Pasir Belitung Before BM 1 1446.4

5 Pasir Belitung Before BM 2 1305.8

6 Pasir Belitung Before BM 3 1396.0

Figure 2 – Sample “As Received” Photos

Report No: MLG.00058 PT. Djabesmen Page | 8

[Type here] [Type here] [Type here]

PT. GEOSERVICES MINERALOGY LABORATORY

Jl Industri Selatan 2, Blok MM1, Jababeka 2, Cikarang Bekasi 17520, Indonesia

3.0 TEST METHODOLOGY

3.1 Testwork Flowchart

Sample received from Client were prepared and analyzed as per flowchart below:

Figure 3 – Testwork Flowchart

3.2 Testwork Method Summary

3.2.1 Sample Preparation for XRD testing

MLG_PREP_XRD – The dried sample is ground in a tungsten carbide bowl/mortar bar to achieve fineness of

P100<53 microns.

3.2.3 XRD Equipment Settings

XRD - The XRD technique is non-destructive and involves placing a powdered sample in a holder, then

illuminate with x-rays of a fixed wave-length. X-ray diffraction relies on the dual wave/particle nature of X-

rays to obtain information about the structure of crystalline materials.

Report No: MLG.00058 PT. Djabesmen Page | 9

[Type here] [Type here] [Type here]

PT. GEOSERVICES MINERALOGY LABORATORY

Jl Industri Selatan 2, Blok MM1, Jababeka 2, Cikarang Bekasi 17520, Indonesia

Phase ID/Qualitative Analysis is performed using Diffrac EVA software with the ICDD PDF-4 database.

Quantitative Phase Analysis (QPA) is performed using Diffrac TOPAS software based on Rietveld

refinement, a technique devised by Hugo Rietveld for use in the characterization of crystalline materials.

The x-ray diffraction of powder samples results in a pattern characterized by reflections (peaks in intensity)

at certain positions. The height, width and position of these reflections can be used to determine many

aspects of the material's structure. The Rietveld method uses a least squares approach to refine a theoretical

line profile until it matches the measured profile. The introduction of this technique was a significant step

forward in the diffraction analysis of powder samples as it is able to deal reliably with strongly overlapping

reflections. The Rietveld Refinement does not take into account any amorphous or poorly crystalline phases

that may be present and do not contribute to diffraction peaks

The XRD equipment is operated under for following conditions for standard bulk scans.

Table 3 – XRD Operating Conditions – Bulk Scan

XRD OPERATING CONDITIONS - BULK SCAN

Info XRD Equipment Bruker XRD D8 Advance Davinci Drives Thets- Drive Number 1

Software TOPAS Diffrac Suite, ICDD PDF4 Theta - Encoder used No

Xray Tube Cobalt Theta - Position 0.5000(°)

Generator Voltage 30 Kv Theta - Oscillation No

Generator Current 50 mA 2Theta- Drive Number 2

Measurement Time 1:27:18 (h:mm:ss) 2Theta - Encoder used No

Ranges Scan Mode Continuous Scan 2Theta - Position 1.0000(°)

Start Position 1 2Theta - Oscillation No

Stop Position 100 Phi- Drive Number 3

Increment 0.0194603 Phi - Encoder used No

# Steps 5088 Phi - Position 0.0(°)

Time per Step 1 (s) Phi - Oscillation no

Motorized Slit Changer INSTALLED LYNXEYE Electronic Window 2.95 (deg)

Synchronous Rotation INSTALLED

Spinner Rotation 10 (rpm) 10(rpm)

3.2.4 XRF Fusion Analysis for Silica Sand

XRFFSI - A calcined or ignited sample is added to Lithium Borate Flux, mixed well and fused between 1050 -

1100°C. A flat molten glass disc is prepared from the resulting melt. The fused-glass disk specimen is

irradiated by a high-energy X-ray beam. Concentrations of the elements are determined by relating the

measured radiation of unknown specimens to analytical curves prepared from reference materials of known

composition.

Silica Sand - XRF 14 Element Suite - Al2O3, BaO, CaO, Cr2O3, Fe2O3, K2O, MgO, MnO, Na2O, P2O5, SiO2,

SO3, SrO, TiO2 + LOI

Report No: MLG.00058 PT. Djabesmen Page | 10

[Type here] [Type here] [Type here]

PT. GEOSERVICES MINERALOGY LABORATORY

Jl Industri Selatan 2, Blok MM1, Jababeka 2, Cikarang Bekasi 17520, Indonesia

4.0 TESTWORK RESULTS

4.1 XRD Bulk Scan Mineral Identification

XRD Bulk scan mineral identification on received samples tabled below.

Table 4 – XRD Bulk Scan Mineral Identification

RIETVELD REFINEMENT WT%

Mineral Mineral Mineral Chemical Mineral Pasir Belitung Pasir Belitung Pasir Belitung

After BM 1 After BM 2 After BM 3

Classification Group Formula Identification Before BM 1 Before BM 2 Before BM 3

Silicates Quartz Si O2 Quartz 97.5 97.1 97.6 99.1 98.8 98.9

Silicates Quartz Si O2 Cristobalite 0.3 0.3 0.3 0.3 0.3 0.3

Oxides/Hydroxides No Group 5 Fe2 O3. 9 H2 O Ferrihydrite 1.7 1.9 1.4 0.4 0.6 0.7

Oxides/Hydroxides No Group Al (O H)3 Gibbsite 0.5 0.7 0.7 0.2 0.2 0.2

Total 100.0 100.0 100.0 100.0 100.0 100.0

Report No: MLG.00058 PT. Djabesmen Page | 11

PT. GEOSERVICES MINERALOGY LABORATORY

Jl Industri Selatan 2, Blok MM1, Jababeka 2, Cikarang Bekasi 17520, Indonesia

4.2 XRF Fusion – Silica Sand Results

Major analytes determined by XRF fusion tabled below:

Table 6 - XRF Silica Sand Major Analytes

Report No: MLG.00058 PT. Djabesmen Page | 12

[Type here] [Type here] [Type here]

PT. GEOSERVICES MINERALOGY LABORATORY

Jl Industri Selatan 2, Blok MM1, Jababeka 2, Cikarang Bekasi 17520, Indonesia

APPENDICES

Report No: MLG.00058 PT. Djabesmen Page | 13

PT. GEOSERVICES MINERALOGY LABORATORY

Jl Industri Selatan 2, Blok MM1, Jababeka 2, Cikarang Bekasi 17520, Indonesia

Appendix – XRD Bulk Diffractograms

Figure 4 – XRD Bulk Diffractogram – After BM 1

Figure 5 - XRD Bulk Diffractogram – After BM 2

Report No: MLG.00058 PT. Djabesmen Page | 14

[Type here] [Type here] [Type here]

PT. GEOSERVICES MINERALOGY LABORATORY

Jl Industri Selatan 2, Blok MM1, Jababeka 2, Cikarang Bekasi 17520, Indonesia

Figure 6 – XRD Bulk Diffractogram – After BM 3

Figure 7 – XRD Bulk Diffractogram – Pasir Belitung Before BM 1

Report No: MLG.00058 PT. Djabesmen Page | 15

[Type here] [Type here] [Type here]

PT. GEOSERVICES MINERALOGY LABORATORY

Jl Industri Selatan 2, Blok MM1, Jababeka 2, Cikarang Bekasi 17520, Indonesia

Figure 8 - XRD Bulk Diffractogram - Pasir Belitung Before BM 2

Figure 9 – XRD Bulk Diffractogram – Pasir Belitung Before BM 3

Report No: MLG.00058 PT. Djabesmen Page | 16

[Type here] [Type here] [Type here]

PT. GEOSERVICES MINERALOGY LABORATORY

Jl Industri Selatan 2, Blok MM1, Jababeka 2, Cikarang Bekasi 17520, Indonesia

Figure 10 – XRD Bulk Diffractogram – After BM 1 REP

Report No: MLG.00058 PT. Djabesmen Page | 17

[Type here] [Type here] [Type here]

You might also like

- Technical & Commercial Proposal For Geological Asssessment at Kenyir DamDocument33 pagesTechnical & Commercial Proposal For Geological Asssessment at Kenyir DamFaridah HanomNo ratings yet

- Soil Bioeng ManualDocument99 pagesSoil Bioeng ManualJonas Kañombi MukwatuNo ratings yet

- Guide For Cast-in-Place Low-Density Cellular Concrete: ACI 523.1R-06Document25 pagesGuide For Cast-in-Place Low-Density Cellular Concrete: ACI 523.1R-06Gasoline L’orroreNo ratings yet

- Projects-ESIA Aek Sibundong EnergyDocument231 pagesProjects-ESIA Aek Sibundong EnergyIrman Ahadian100% (2)

- N1 43 110 Kingashy, Verhnekingasky and Kuyovsky Nickel Cooper DepositsDocument258 pagesN1 43 110 Kingashy, Verhnekingasky and Kuyovsky Nickel Cooper DepositsJuliana BuelvasNo ratings yet

- Industrial Attachment Report For Tunira AngellaDocument111 pagesIndustrial Attachment Report For Tunira Angellaangella67% (3)

- Specialty LDPE PolymersDocument6 pagesSpecialty LDPE Polymersmember1000No ratings yet

- TM4000 Capstone Design Weekly Project Topics #1Document30 pagesTM4000 Capstone Design Weekly Project Topics #1Siska Marsinta SiahaanNo ratings yet

- Proposal Responsi PFDocument28 pagesProposal Responsi PFRiska IndahNo ratings yet

- IMC EX P002 SOP EXPL Wellsite Geologist Work ProcedureDocument16 pagesIMC EX P002 SOP EXPL Wellsite Geologist Work ProcedureFebri Deni Firdiansyah100% (1)

- Esia Theata TF Solar PV NewDocument128 pagesEsia Theata TF Solar PV NewsparkCENo ratings yet

- English Version of New ComPro PT Envitek 2020 - 220614 - 082931 - RemovedDocument10 pagesEnglish Version of New ComPro PT Envitek 2020 - 220614 - 082931 - RemovedAdi ChaktiNo ratings yet

- MMP001-410-CV-SPC-2003 Specification For Steel StructureDocument39 pagesMMP001-410-CV-SPC-2003 Specification For Steel StructureMarco ValerianNo ratings yet

- PDS - JS Mining Nickel ProjectDocument230 pagesPDS - JS Mining Nickel ProjectAlliza LaoNo ratings yet

- Laporan PKLDocument42 pagesLaporan PKLRaya Fernanda AriantoNo ratings yet

- CIK - Min.16533 Final ReportDocument2 pagesCIK - Min.16533 Final ReportalfredNo ratings yet

- Shree Sayan Vibhag Sahakari Khand Udhyog Mandli LTD Srt65 Eia1Document300 pagesShree Sayan Vibhag Sahakari Khand Udhyog Mandli LTD Srt65 Eia1Sv KhanNo ratings yet

- Maganghila PT 2 ReportDocument49 pagesMaganghila PT 2 ReportMaganghila SamwelNo ratings yet

- 06 Lab Sample Analysis Report - 231115 - 212406Document31 pages06 Lab Sample Analysis Report - 231115 - 212406kuriganta yamiNo ratings yet

- Kelompok 17 Tgb2019 Tugas#1Document32 pagesKelompok 17 Tgb2019 Tugas#1Maria IndiraNo ratings yet

- Balabag TR 05152021 PDFDocument201 pagesBalabag TR 05152021 PDFJennifer HoNo ratings yet

- Proposal MME Project CUTDocument16 pagesProposal MME Project CUTAditNo ratings yet

- Tutorial GEOLOGYDocument43 pagesTutorial GEOLOGYFebri Deni Firdiansyah100% (2)

- F824-22 (Mestindo, 002-1919) MopDocument1 pageF824-22 (Mestindo, 002-1919) MopStaff AnkewaNo ratings yet

- 200 KTA Biodiesel Plant Operating Manual-Rev02Document67 pages200 KTA Biodiesel Plant Operating Manual-Rev02SYAMSUL BACHRIENo ratings yet

- 26071-100-583-GST-00002 - 001 - Emergency Air Compressor and Dryer Commissioning Procedure U335Document49 pages26071-100-583-GST-00002 - 001 - Emergency Air Compressor and Dryer Commissioning Procedure U335widionosucipto29No ratings yet

- Complete Mining ProposalDocument134 pagesComplete Mining ProposalWeldegebriel HaftuNo ratings yet

- JSC Bimonthly Report - Januari 2021Document21 pagesJSC Bimonthly Report - Januari 2021Arief FatkhurrokhmanNo ratings yet

- CA Project Cleaning Factory CMWI (Oktober'2021)Document14 pagesCA Project Cleaning Factory CMWI (Oktober'2021)Sulaiman mamadoNo ratings yet

- Foundation G5 Final ReportDocument58 pagesFoundation G5 Final ReportImran RozmanNo ratings yet

- ROA PT. AMI July 21Document3 pagesROA PT. AMI July 21Umar SuhaeNo ratings yet

- 7analisa Kebocoran Seal Grinding Roller 1 Raw MillDocument36 pages7analisa Kebocoran Seal Grinding Roller 1 Raw MillFitra BagusNo ratings yet

- Compro Amsak.Document21 pagesCompro Amsak.natannababan5No ratings yet

- Kipeto Power Station Appendix C-Geology and Soils StudyDocument37 pagesKipeto Power Station Appendix C-Geology and Soils StudyKennyNo ratings yet

- Well Logging Assignment ProjectDocument7 pagesWell Logging Assignment ProjectNurrahmisrNo ratings yet

- Draft Psak 24 PT Teknologi Weldim Indo - Tahun 2022 - RevisiDocument33 pagesDraft Psak 24 PT Teknologi Weldim Indo - Tahun 2022 - Revisibrosugi88No ratings yet

- Joseph Martin Thirdyear ReportDocument65 pagesJoseph Martin Thirdyear ReportJoe MartinNo ratings yet

- Re-Engineering & Rla: Floating Storage TK - Kapuas-118Document81 pagesRe-Engineering & Rla: Floating Storage TK - Kapuas-118Handhang Maulana Aji AkbarNo ratings yet

- Environmental Impact Assessment Report & Environmental Management PlanDocument225 pagesEnvironmental Impact Assessment Report & Environmental Management PlanSEEMA NIHALANINo ratings yet

- Laporan Kerja Praktek KBSDocument26 pagesLaporan Kerja Praktek KBSFadhillah MuttaqinNo ratings yet

- Pabrik Polyethylene Terephtalate (PET) : Laporan I Pendahuluan Dan Seleksi ProsesDocument8 pagesPabrik Polyethylene Terephtalate (PET) : Laporan I Pendahuluan Dan Seleksi Prosessongjihyo16111994No ratings yet

- Biochar Review Panahi2020Document29 pagesBiochar Review Panahi2020Khaled Abou AlfaNo ratings yet

- Draft PESIA On Gemstone ExplorationDocument46 pagesDraft PESIA On Gemstone ExplorationKayo ShankulieNo ratings yet

- Company Profile Cv. Jgs IujpDocument123 pagesCompany Profile Cv. Jgs Iujprasya azzamNo ratings yet

- EIMGP-I-ME-SPC-01-005 Specification For Thermal InsulationDocument30 pagesEIMGP-I-ME-SPC-01-005 Specification For Thermal InsulationSulwah OnoNo ratings yet

- MMP001-410-CV-SPC-2002 Specification For Reinforcing BarDocument20 pagesMMP001-410-CV-SPC-2002 Specification For Reinforcing BarMarco ValerianNo ratings yet

- Laporan Praktek Belajar Lapangan Konsultasi Gizi "Typoid" Di Puskesmas Pasar IkanDocument4 pagesLaporan Praktek Belajar Lapangan Konsultasi Gizi "Typoid" Di Puskesmas Pasar IkanKesi Juliana PutriNo ratings yet

- Jakarta Bay REA Compressed Jury Et Al.Document144 pagesJakarta Bay REA Compressed Jury Et Al.Akhmad SobirinNo ratings yet

- Coa JgiDocument2 pagesCoa JgiaromipattyrajaNo ratings yet

- APPENDIX-5-DRC-000-16540-0001 - 00-HSE PlanDocument57 pagesAPPENDIX-5-DRC-000-16540-0001 - 00-HSE PlanSaleem AkhtarNo ratings yet

- Studi Kelayakan Pltbs Sei Mangkei 1x15mw - Ptfi-PtkkbDocument228 pagesStudi Kelayakan Pltbs Sei Mangkei 1x15mw - Ptfi-PtkkbLidwina Vidya100% (1)

- Proposal GIS For 7MWp Solar PV Power Plant at SBI Tuban EMI027 - 232 - B01006 - R02Document36 pagesProposal GIS For 7MWp Solar PV Power Plant at SBI Tuban EMI027 - 232 - B01006 - R02Ezra DKNo ratings yet

- 1 LAPORAN 02311940005014 Ali Fakhri A Sistem Kendali Kinerja Mesin Batch Centrifugal CH 1Document81 pages1 LAPORAN 02311940005014 Ali Fakhri A Sistem Kendali Kinerja Mesin Batch Centrifugal CH 1nugraha candraNo ratings yet

- Sdarticle PDFDocument31 pagesSdarticle PDFDeisy Milena Martinez RugelesNo ratings yet

- Recent Developments in Photocatalytic Water Treatment Technology: A ReviewDocument31 pagesRecent Developments in Photocatalytic Water Treatment Technology: A ReviewNitesh ParmarNo ratings yet

- Report of Laboratory Analysis: Kdi - DosDocument1 pageReport of Laboratory Analysis: Kdi - DosM SolikinNo ratings yet

- T68 Q1681 EIAReportDocument449 pagesT68 Q1681 EIAReportDeepika RajpootNo ratings yet

- Scoping Report - R1 - CompleteDocument48 pagesScoping Report - R1 - Completejma6691No ratings yet

- CastleDocument299 pagesCastlejeffaustonNo ratings yet

- BBS - Working Procedure For Gathering Line PrecommissioningDocument34 pagesBBS - Working Procedure For Gathering Line PrecommissioningDarmawanNo ratings yet

- South Africa’s Renewable Energy IPP Procurement ProgramFrom EverandSouth Africa’s Renewable Energy IPP Procurement ProgramNo ratings yet

- MNO Manuale Vuoto IngleseDocument52 pagesMNO Manuale Vuoto Inglesen9bf9vrpg2No ratings yet

- 4 - New Perfluorinated Ionomer With Improved Oxygen Permeability ForDocument7 pages4 - New Perfluorinated Ionomer With Improved Oxygen Permeability ForFaseeh KKNo ratings yet

- Mcqs Solved Lec-16 Enzymes-Properties, Classification and NomenclatureDocument4 pagesMcqs Solved Lec-16 Enzymes-Properties, Classification and NomenclatureELAKKIYA .U BA Eng LitNo ratings yet

- Some Aspects of The Delayed Ettringite Formation in Concrete-A ReviewDocument9 pagesSome Aspects of The Delayed Ettringite Formation in Concrete-A ReviewRobertMaddenNo ratings yet

- PC 7048 - Asian Epoxy Dual CoatDocument3 pagesPC 7048 - Asian Epoxy Dual CoatGunjan GaganNo ratings yet

- Ionic Bonding WorksheetDocument5 pagesIonic Bonding WorksheetMaia IbrahimNo ratings yet

- Study Material Practical Manual Fundamental of Plant Biochemistry BiotechnologyDocument47 pagesStudy Material Practical Manual Fundamental of Plant Biochemistry BiotechnologySanket kharsadeNo ratings yet

- Solubilityof Carbon Dioxidein Aqueous Mixture Asadi 20Document7 pagesSolubilityof Carbon Dioxidein Aqueous Mixture Asadi 20enjpetNo ratings yet

- Form No: 066-00009-601QRP UC-2179Document37 pagesForm No: 066-00009-601QRP UC-2179Aloyce kampeleNo ratings yet

- Model For A Cascade Continuous Epoxidation ProcessDocument4 pagesModel For A Cascade Continuous Epoxidation ProcessDaniella DenleschiNo ratings yet

- Organic Name ReactionsDocument2 pagesOrganic Name ReactionsPratham ZalaNo ratings yet

- Gcse Maths Revision ChecklistDocument2 pagesGcse Maths Revision ChecklistA LNo ratings yet

- Chem 2 Homework 5Document3 pagesChem 2 Homework 5Albert YanNo ratings yet

- Electrochemistry (Paper-01) WYDocument12 pagesElectrochemistry (Paper-01) WYgreedy AsunaNo ratings yet

- Electron Configurations ReviewDocument24 pagesElectron Configurations ReviewSamantha Shane P. ConumNo ratings yet

- Solubility Curve WorksheetDocument5 pagesSolubility Curve WorksheetRohanee Hafsa KapusanNo ratings yet

- TM P-05 Fuel Oxidant CompositionDocument15 pagesTM P-05 Fuel Oxidant CompositionJeroen C.100% (1)

- 1 SM PDFDocument14 pages1 SM PDFMuhammad RafiNo ratings yet

- HEMATOLOGY 1 WEEK 7 PrintDocument4 pagesHEMATOLOGY 1 WEEK 7 PrintRose Neil LapuzNo ratings yet

- My M. Tech. Thesis Presentation - 2004 ADDocument39 pagesMy M. Tech. Thesis Presentation - 2004 ADरुद्र प्रताप सिंह ८२No ratings yet

- Body Fluid CompartmentsDocument26 pagesBody Fluid CompartmentsShameena KnNo ratings yet

- 2007 CE-CHEM (Chinese and English and Marking)Document95 pages2007 CE-CHEM (Chinese and English and Marking)plilian21No ratings yet

- JurnalDocument9 pagesJurnalRina Boenda QueenRayaNo ratings yet

- Cert 87A 88A Series CGA 3.16Document4 pagesCert 87A 88A Series CGA 3.16Andreco 210198No ratings yet

- Ml2128157-Rpt-210008939-Full ReportDocument3 pagesMl2128157-Rpt-210008939-Full ReportSameera SampathNo ratings yet

- Code Painting Steel PlantDocument34 pagesCode Painting Steel Planttri_purwadiNo ratings yet

- Cspe Xlpe Uhdpe CpeDocument34 pagesCspe Xlpe Uhdpe Cpesuranjana26No ratings yet

- Water Gas Shift (WGS)Document4 pagesWater Gas Shift (WGS)Gabriel Mendoza Santa CruzNo ratings yet