Professional Documents

Culture Documents

Stoody® 100HC

Stoody® 100HC

Uploaded by

Siddharth DasCopyright:

Available Formats

You might also like

- 1.9.1.2-75B - BondArc WireDocument6 pages1.9.1.2-75B - BondArc WireGiovanni Cervera FerriolNo ratings yet

- 1.heat Tint Poses Corrosion Hazard in Stainless SteelDocument3 pages1.heat Tint Poses Corrosion Hazard in Stainless SteelTree TaweeNo ratings yet

- Lincoln-Electric Wearshield ABRDocument2 pagesLincoln-Electric Wearshield ABRHughNo ratings yet

- Wearshield 60: Typical Applications Key FeaturesDocument2 pagesWearshield 60: Typical Applications Key FeaturesDieng MessatsuNo ratings yet

- Stoody® Build Up, - G, - oDocument1 pageStoody® Build Up, - G, - oSiddharth DasNo ratings yet

- Selectrode: Deep Penetrating For Dirty Steels International ClassificationsDocument2 pagesSelectrode: Deep Penetrating For Dirty Steels International ClassificationsMohamed AdelNo ratings yet

- Selectrode: Chromium Carbide Manufacturers of Custom Welding Lines For ResaleDocument3 pagesSelectrode: Chromium Carbide Manufacturers of Custom Welding Lines For ResalesareddytejaaeNo ratings yet

- Stoody 104TJ SAW005Document1 pageStoody 104TJ SAW005Juaros LeonNo ratings yet

- Kennametal Stellite - Cored Weld Wire DatasheetDocument2 pagesKennametal Stellite - Cored Weld Wire DatasheetharikrishnanNo ratings yet

- 131 - 1.9.1.2-01T - Aluminum WireDocument4 pages131 - 1.9.1.2-01T - Aluminum WireDiidaii MontañoNo ratings yet

- Stoody 105Document1 pageStoody 105JUAN DAVID ESPITIANo ratings yet

- Selectrode: 7018 Moisture Resistant Low HydrogenDocument3 pagesSelectrode: 7018 Moisture Resistant Low HydrogenbalamuruganNo ratings yet

- Abs AN620 20230519-1Document2 pagesAbs AN620 20230519-1phanplastic299No ratings yet

- Stoody 100HDDocument1 pageStoody 100HDKevin Quispe MarínNo ratings yet

- Stoody 104Document1 pageStoody 104JUAN DAVID ESPITIANo ratings yet

- Flexi EarthedDocument1 pageFlexi Earthedarsya_agasNo ratings yet

- Universal "DUPLEX" Electrode For Welding and Cladding of Austenitic/ferritic Microstruc-Ture StainlessesDocument2 pagesUniversal "DUPLEX" Electrode For Welding and Cladding of Austenitic/ferritic Microstruc-Ture StainlessesnurarifiantoNo ratings yet

- OSD Welding ProcedureDocument6 pagesOSD Welding ProcedureVijayakumar Chandran100% (1)

- FLEXmount 344 Series AdhesivesDocument4 pagesFLEXmount 344 Series Adhesiveshuynh thi y viNo ratings yet

- ES-1 Series - Proximity Switch - Magnetic Model:ES-1322Document1 pageES-1 Series - Proximity Switch - Magnetic Model:ES-1322BlahNo ratings yet

- Selectrode: 317L Flux Coated TigDocument3 pagesSelectrode: 317L Flux Coated TigUta GilangNo ratings yet

- Final Standerization of All Committee 02062016Document6 pagesFinal Standerization of All Committee 02062016pramod_jvNo ratings yet

- Mgt-Xlpe Oscr LSZH Swa LSZH 2.5 RedDocument2 pagesMgt-Xlpe Oscr LSZH Swa LSZH 2.5 RedJason Secret100% (1)

- Stainless SteelDocument1 pageStainless SteelSadashiva sahoo100% (1)

- Bolt Grade Markings and Strength ChartDocument2 pagesBolt Grade Markings and Strength ChartEldori1988No ratings yet

- Roll Form Strander - NEWDocument8 pagesRoll Form Strander - NEWAbdul HarisNo ratings yet

- KG TP, TFSDocument18 pagesKG TP, TFSbrandon abella gutierrezNo ratings yet

- Unidal PDFDocument1 pageUnidal PDFHenrique MarquesNo ratings yet

- Bolt Depot - Bolt Grade Markings and Strength ChartDocument2 pagesBolt Depot - Bolt Grade Markings and Strength ChartKiara Ticangan Argel100% (1)

- UMCo 50Document3 pagesUMCo 50San ReyNo ratings yet

- Abs sr101 DatasheetDocument2 pagesAbs sr101 Datasheetphanplastic299No ratings yet

- Primacore MW 71Document2 pagesPrimacore MW 71rjan7peNo ratings yet

- Technical Brief Galal Make SleevesDocument1 pageTechnical Brief Galal Make SleevesSELVAGANAPATHINo ratings yet

- 15 KV Voltage Transformer: Outdoor 60 HertzDocument2 pages15 KV Voltage Transformer: Outdoor 60 HertzRodNo ratings yet

- Merit S-G: Lincoln Electric China Gmaw Solid WireDocument2 pagesMerit S-G: Lincoln Electric China Gmaw Solid Wiredev-nullNo ratings yet

- CDP 4666Document2 pagesCDP 4666sareddytejaaeNo ratings yet

- Conarc85 EngDocument2 pagesConarc85 EngRaviTeja Bhamidi100% (1)

- Tech-Rod 630: DescriptionDocument1 pageTech-Rod 630: DescriptionRajendra ChoudharyNo ratings yet

- Cables-MIB0063H UnlockedDocument2 pagesCables-MIB0063H UnlockedJorge Armando Ysuiza RomeroNo ratings yet

- Somos PerFORM Datasheet Complete PDFDocument4 pagesSomos PerFORM Datasheet Complete PDFAdriano AraujoNo ratings yet

- Datasheet SD Ferralium 255 SD50 BarDocument4 pagesDatasheet SD Ferralium 255 SD50 Barpranav kariaNo ratings yet

- 199 Imi EkoguardDocument2 pages199 Imi EkoguardEngr KamalNo ratings yet

- Corrugated Conduit: Operating TemperaturesDocument1 pageCorrugated Conduit: Operating TemperaturesandiyuliusNo ratings yet

- Techdrain Gtg27.6: Drainage GeocompositeDocument1 pageTechdrain Gtg27.6: Drainage GeocompositeJORGE LUIS GAMARRA MIRANDANo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1023-1AA43-4AB4-ZDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1023-1AA43-4AB4-ZFredericks ACNo ratings yet

- Tairilac ABS Resin: Properties (1/3)Document3 pagesTairilac ABS Resin: Properties (1/3)DiegoTierradentroNo ratings yet

- Resin - ABS Tairalac PDFDocument3 pagesResin - ABS Tairalac PDFDiegoTierradentroNo ratings yet

- Toolcord (E 6 Um 65 GS, e Fe4)Document1 pageToolcord (E 6 Um 65 GS, e Fe4)brunizzaNo ratings yet

- Ds - INTERDRAIN GM & GMG 27.6 - enDocument1 pageDs - INTERDRAIN GM & GMG 27.6 - enThameem SharaafNo ratings yet

- Selectrode: High Deposition 316L Stainless Steel International ClassificationsDocument2 pagesSelectrode: High Deposition 316L Stainless Steel International ClassificationsMohamed AdelNo ratings yet

- EE Rejillas Magnéticas (SB-200DD)Document24 pagesEE Rejillas Magnéticas (SB-200DD)angelsiddhartaNo ratings yet

- Union TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20Document2 pagesUnion TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20brunizzaNo ratings yet

- Bondstrand 2400Document17 pagesBondstrand 2400Pinakin PatelNo ratings yet

- Spheric Trafalgar: General InformationDocument1 pageSpheric Trafalgar: General Information15155783No ratings yet

- Abs Ap102 Datasheet-2Document2 pagesAbs Ap102 Datasheet-2phanplastic299No ratings yet

- Busbar Deisgn GuideDocument9 pagesBusbar Deisgn Guideali ridhoNo ratings yet

- Stoody Super 20Document1 pageStoody Super 20JUAN DAVID ESPITIANo ratings yet

- PA6G MoSDocument1 pagePA6G MoSjhax90No ratings yet

- Epoxy Resin Medium Voltage InsulatorsDocument8 pagesEpoxy Resin Medium Voltage InsulatorsDavid ALVESNo ratings yet

- Surface Coating Quick Guide Glass Mould 0463hogDocument1 pageSurface Coating Quick Guide Glass Mould 0463hogSiddharth DasNo ratings yet

- Surface Coating Thermal Surfacing Glass Mould Industry Solutions 1949hogDocument16 pagesSurface Coating Thermal Surfacing Glass Mould Industry Solutions 1949hogSiddharth DasNo ratings yet

- Wall Colmonoy - Colmonoy 6 6PTA 6L TDS - July2021Document4 pagesWall Colmonoy - Colmonoy 6 6PTA 6L TDS - July2021Siddharth DasNo ratings yet

- Eutec Tinweld 1Document1 pageEutec Tinweld 1Siddharth DasNo ratings yet

- Code of Conduct (English)Document25 pagesCode of Conduct (English)Siddharth DasNo ratings yet

- List of Participating Airport Lounges :: S.No. City Lounge Name Airport TerminalDocument3 pagesList of Participating Airport Lounges :: S.No. City Lounge Name Airport TerminalSiddharth DasNo ratings yet

- Health Policy SiddharthDocument9 pagesHealth Policy SiddharthSiddharth DasNo ratings yet

- Application Form For Re-Kyc Updation Through Video Kyc (V-Kyc) (For Resident Individual Savings Account & Individual Current Account)Document4 pagesApplication Form For Re-Kyc Updation Through Video Kyc (V-Kyc) (For Resident Individual Savings Account & Individual Current Account)Siddharth DasNo ratings yet

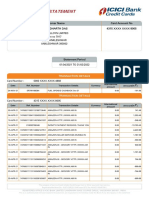

- Customer Name Card Account No MR Siddharth Das 4315 XXXX XXXX 8005Document8 pagesCustomer Name Card Account No MR Siddharth Das 4315 XXXX XXXX 8005Siddharth DasNo ratings yet

- Technical Specifications: 1. Technical Specifications For Wear Resistive Metallic Putty/pasteDocument2 pagesTechnical Specifications: 1. Technical Specifications For Wear Resistive Metallic Putty/pasteSiddharth DasNo ratings yet

- Astm No A 632-02 PDFDocument4 pagesAstm No A 632-02 PDFAgus Salim DarmaNo ratings yet

- Chapter 4 SteelDocument28 pagesChapter 4 SteelDiyar NezarNo ratings yet

- Notes - Workshop Practice (Fitting Shop)Document16 pagesNotes - Workshop Practice (Fitting Shop)Abubakar Ch100% (1)

- Module 1, Intro To Engg MaterialsDocument21 pagesModule 1, Intro To Engg MaterialsSayaf Khan PathanNo ratings yet

- Case Studies in Engineering Failure AnalysisDocument6 pagesCase Studies in Engineering Failure AnalysisSharwin NovNo ratings yet

- Welding ErrorsDocument42 pagesWelding ErrorsNDTInstructorNo ratings yet

- Melin High Performance - 8 PGDocument8 pagesMelin High Performance - 8 PGriversoundNo ratings yet

- DV03PUB124 Study Guide PDFDocument5 pagesDV03PUB124 Study Guide PDFraja020No ratings yet

- Input Rates Material 1st Bi Annual 2015, Government of PunjabDocument114 pagesInput Rates Material 1st Bi Annual 2015, Government of PunjabHamid NaveedNo ratings yet

- Manuf. Tech. - IntroductionDocument38 pagesManuf. Tech. - IntroductionManuel Tikongyin WundengbaNo ratings yet

- Dished End PDFDocument3 pagesDished End PDFrahmi yantiNo ratings yet

- Production of Magnesium by Electrolysis of Fused SaltsDocument134 pagesProduction of Magnesium by Electrolysis of Fused SaltsiMiklaeNo ratings yet

- Section II Par T A Fer Rous Material Specifications Sa 451 To End 2019 Asme Boiler and Pressure Vessel Code An International Code PDF Free - 5Document1 pageSection II Par T A Fer Rous Material Specifications Sa 451 To End 2019 Asme Boiler and Pressure Vessel Code An International Code PDF Free - 5洛霖No ratings yet

- 4 ReportDocument89 pages4 ReportRajesh KesapragadaNo ratings yet

- Engine Room Tools Part 1Document72 pagesEngine Room Tools Part 1raotalhaNo ratings yet

- Breather Valve - PV Valve - CNC380Document2 pagesBreather Valve - PV Valve - CNC380mhidayat108No ratings yet

- Acsr & AlloyDocument17 pagesAcsr & AlloyDev KumarNo ratings yet

- Kiruna Iron Drilling SuccessDocument12 pagesKiruna Iron Drilling SuccessHannans Reward LtdNo ratings yet

- BME Joining ProcessesDocument11 pagesBME Joining ProcessesalysonmicheaalaNo ratings yet

- 2012-13 AC Motors Starters PDFDocument20 pages2012-13 AC Motors Starters PDFkggganiNo ratings yet

- TM-HBI-00030-H0-VOESAL: Approved: Checked: Drawn: Date: DesignedDocument3 pagesTM-HBI-00030-H0-VOESAL: Approved: Checked: Drawn: Date: DesignedMarko's Brazon'No ratings yet

- C067Document49 pagesC067Gato Sesa0% (1)

- Importance of Welding: QA/QC DepartmentDocument55 pagesImportance of Welding: QA/QC Departmentimran jamil0% (1)

- Butterfly Flu01 Omb 04 11Document16 pagesButterfly Flu01 Omb 04 11ila_368684492No ratings yet

- Application and Processing of Metal AlloysDocument44 pagesApplication and Processing of Metal AlloysShaira DaleNo ratings yet

- SSC DWDocument4 pagesSSC DWsanketpavi21No ratings yet

- Uddeholm Pocket Book E2 PDFDocument76 pagesUddeholm Pocket Book E2 PDFwulfgang66No ratings yet

- Macalloy - 1030 BrochureDocument8 pagesMacalloy - 1030 BrochurejsbharadwajNo ratings yet

- Lotherme HandbookDocument226 pagesLotherme HandbookLalit Kumar100% (2)

Stoody® 100HC

Stoody® 100HC

Uploaded by

Siddharth DasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stoody® 100HC

Stoody® 100HC

Uploaded by

Siddharth DasCopyright:

Available Formats

®

STOODY 100HC

Open Arc Welding Wire

Stoody 100HC deposit is a high chromium-iron alloy OPERATIONAL CHARACTERISTICS / WELDING

recommended for application subject to severe abrasion PARAMETERS (DCEP)

and moderate impact and heat. It develops a tight (3/8" 3/32" (2.4 mm)

- 1/2") cross checking pattern and is frequently used Current DCEP, amp 200 – 350

in crushing applications. It is generally limited to two Voltage (volts) 25 – 28

Wire Extension, in (mm) 1 1/4 – 1 1/2 (32 – 38)

layers. In the rebuilding of coal pulverizer rolls, however, Shielding Gas None

multiple layers can be applied using specific welding Position Flat

procedures. It can be applied to carbon, low alloy, and

manganese steels. Deposits are not machinable or 7/64" (2.8 mm)

Current DCEP, amp 200 – 400

forgeable and can be used in hot wear applications up Voltage (volts) 25 – 31

to 900°F (482°C). Wire Extension, in (mm) 1 1/4 – 1 1/2 (32 – 38)

Shielding Gas None

Position Flat

1/8" (3.2 mm)

TYPICAL DEPOSIT CHARACTERISTICS Current DCEP, amp 400 – 550

Voltage (volts) 31 – 34

Abrasion Resistance Excellent Wire Extension, in (mm) 1 1/4 – 1 1/2 (32 – 38)

Impact Resistance Moderate Shielding Gas None

Deposit Layers 2 Position Flat

Hardness

On Carbon Steel, HRC 58 – 62

On Manganese Steel, HRC 51 – 55

Surface Cross Checks Yes

Machinability No STANDARD SIZES & PACKAGING

Magnetic

On Carbon Steel Slightly Diameter Packaging Part #

On Manganese Steel No 3/32" (2.4 mm) 25 lb (11.3 kg) Plastic Spool 11249700

Hot Wear Application Up to 900°F (482°C) 3/32" (2.4 mm) 60 lb (27.2 kg) Coil 11313400

3/32" (2.4 mm) 200 lb (90.7 kg) Half Pak 12022200

7/64" (2.8 mm) 60 lb (27.2 kg) Coil 11001000

7/64" (2.8 mm) 110 lb (50 kg) Quarter Pak 11144100

7/64" (2.8 mm) 200 lb (90.7 kg) Half Pak 11141700

7/64" (2.8 mm) 500 lb (226.8 kg) POP 11235400

ALLOY TYPE 7/64" (2.8 mm) 750 lb (340 kg) POP 11976900

1/8" (3.2 mm) 110 lb (50 kg) Quarter Pak 11867100

Primary Chromium Carbides in an Austenitic Matrix 1/8" (3.2 mm) 500 lb (226.8 kg) POP 11807700

TYPICAL APPLICATIONS

Gyratory mantles

Scrubbers

Large bucket lips and teeth

Impactor bars

Cage pins

Crusher rolls

Wear plates

NOTICE - Failure to follow manufacturer’s directions for use may result in equipment or material failure and void any applicable warranty. The data provided or

referenced herein is provided for informational purposes only, without guarantee or warranty and represents “typical” results when Stoody products are used in

PDS-CRC-W-008 accordance with internal Stoody procedures. Other tests and procedures may produce differing results. Stoody expressly disclaims any liability resulting from

Revision 2 reliance on this data.

February 9, 2016 PROTECT YOURSELF AND OTHERS - Users should read and follow all recommended guidance on health and safety from their employer, the supplier, the

manufacturer, and government authorities. These, at a minimum including the Warning Labels on the products and the Safety Data Sheets (“SDS”). The SDS

and additional safety information may be found on materials or links at: Stoody.com.

U.S. Customer Care: 800-426-1888 Canada Customer Care: 905-827-4515 International Customer Care: 940-381-1212

© 2015 ESAB Stoody.com Printed in U.S.A.

You might also like

- 1.9.1.2-75B - BondArc WireDocument6 pages1.9.1.2-75B - BondArc WireGiovanni Cervera FerriolNo ratings yet

- 1.heat Tint Poses Corrosion Hazard in Stainless SteelDocument3 pages1.heat Tint Poses Corrosion Hazard in Stainless SteelTree TaweeNo ratings yet

- Lincoln-Electric Wearshield ABRDocument2 pagesLincoln-Electric Wearshield ABRHughNo ratings yet

- Wearshield 60: Typical Applications Key FeaturesDocument2 pagesWearshield 60: Typical Applications Key FeaturesDieng MessatsuNo ratings yet

- Stoody® Build Up, - G, - oDocument1 pageStoody® Build Up, - G, - oSiddharth DasNo ratings yet

- Selectrode: Deep Penetrating For Dirty Steels International ClassificationsDocument2 pagesSelectrode: Deep Penetrating For Dirty Steels International ClassificationsMohamed AdelNo ratings yet

- Selectrode: Chromium Carbide Manufacturers of Custom Welding Lines For ResaleDocument3 pagesSelectrode: Chromium Carbide Manufacturers of Custom Welding Lines For ResalesareddytejaaeNo ratings yet

- Stoody 104TJ SAW005Document1 pageStoody 104TJ SAW005Juaros LeonNo ratings yet

- Kennametal Stellite - Cored Weld Wire DatasheetDocument2 pagesKennametal Stellite - Cored Weld Wire DatasheetharikrishnanNo ratings yet

- 131 - 1.9.1.2-01T - Aluminum WireDocument4 pages131 - 1.9.1.2-01T - Aluminum WireDiidaii MontañoNo ratings yet

- Stoody 105Document1 pageStoody 105JUAN DAVID ESPITIANo ratings yet

- Selectrode: 7018 Moisture Resistant Low HydrogenDocument3 pagesSelectrode: 7018 Moisture Resistant Low HydrogenbalamuruganNo ratings yet

- Abs AN620 20230519-1Document2 pagesAbs AN620 20230519-1phanplastic299No ratings yet

- Stoody 100HDDocument1 pageStoody 100HDKevin Quispe MarínNo ratings yet

- Stoody 104Document1 pageStoody 104JUAN DAVID ESPITIANo ratings yet

- Flexi EarthedDocument1 pageFlexi Earthedarsya_agasNo ratings yet

- Universal "DUPLEX" Electrode For Welding and Cladding of Austenitic/ferritic Microstruc-Ture StainlessesDocument2 pagesUniversal "DUPLEX" Electrode For Welding and Cladding of Austenitic/ferritic Microstruc-Ture StainlessesnurarifiantoNo ratings yet

- OSD Welding ProcedureDocument6 pagesOSD Welding ProcedureVijayakumar Chandran100% (1)

- FLEXmount 344 Series AdhesivesDocument4 pagesFLEXmount 344 Series Adhesiveshuynh thi y viNo ratings yet

- ES-1 Series - Proximity Switch - Magnetic Model:ES-1322Document1 pageES-1 Series - Proximity Switch - Magnetic Model:ES-1322BlahNo ratings yet

- Selectrode: 317L Flux Coated TigDocument3 pagesSelectrode: 317L Flux Coated TigUta GilangNo ratings yet

- Final Standerization of All Committee 02062016Document6 pagesFinal Standerization of All Committee 02062016pramod_jvNo ratings yet

- Mgt-Xlpe Oscr LSZH Swa LSZH 2.5 RedDocument2 pagesMgt-Xlpe Oscr LSZH Swa LSZH 2.5 RedJason Secret100% (1)

- Stainless SteelDocument1 pageStainless SteelSadashiva sahoo100% (1)

- Bolt Grade Markings and Strength ChartDocument2 pagesBolt Grade Markings and Strength ChartEldori1988No ratings yet

- Roll Form Strander - NEWDocument8 pagesRoll Form Strander - NEWAbdul HarisNo ratings yet

- KG TP, TFSDocument18 pagesKG TP, TFSbrandon abella gutierrezNo ratings yet

- Unidal PDFDocument1 pageUnidal PDFHenrique MarquesNo ratings yet

- Bolt Depot - Bolt Grade Markings and Strength ChartDocument2 pagesBolt Depot - Bolt Grade Markings and Strength ChartKiara Ticangan Argel100% (1)

- UMCo 50Document3 pagesUMCo 50San ReyNo ratings yet

- Abs sr101 DatasheetDocument2 pagesAbs sr101 Datasheetphanplastic299No ratings yet

- Primacore MW 71Document2 pagesPrimacore MW 71rjan7peNo ratings yet

- Technical Brief Galal Make SleevesDocument1 pageTechnical Brief Galal Make SleevesSELVAGANAPATHINo ratings yet

- 15 KV Voltage Transformer: Outdoor 60 HertzDocument2 pages15 KV Voltage Transformer: Outdoor 60 HertzRodNo ratings yet

- Merit S-G: Lincoln Electric China Gmaw Solid WireDocument2 pagesMerit S-G: Lincoln Electric China Gmaw Solid Wiredev-nullNo ratings yet

- CDP 4666Document2 pagesCDP 4666sareddytejaaeNo ratings yet

- Conarc85 EngDocument2 pagesConarc85 EngRaviTeja Bhamidi100% (1)

- Tech-Rod 630: DescriptionDocument1 pageTech-Rod 630: DescriptionRajendra ChoudharyNo ratings yet

- Cables-MIB0063H UnlockedDocument2 pagesCables-MIB0063H UnlockedJorge Armando Ysuiza RomeroNo ratings yet

- Somos PerFORM Datasheet Complete PDFDocument4 pagesSomos PerFORM Datasheet Complete PDFAdriano AraujoNo ratings yet

- Datasheet SD Ferralium 255 SD50 BarDocument4 pagesDatasheet SD Ferralium 255 SD50 Barpranav kariaNo ratings yet

- 199 Imi EkoguardDocument2 pages199 Imi EkoguardEngr KamalNo ratings yet

- Corrugated Conduit: Operating TemperaturesDocument1 pageCorrugated Conduit: Operating TemperaturesandiyuliusNo ratings yet

- Techdrain Gtg27.6: Drainage GeocompositeDocument1 pageTechdrain Gtg27.6: Drainage GeocompositeJORGE LUIS GAMARRA MIRANDANo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1023-1AA43-4AB4-ZDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1023-1AA43-4AB4-ZFredericks ACNo ratings yet

- Tairilac ABS Resin: Properties (1/3)Document3 pagesTairilac ABS Resin: Properties (1/3)DiegoTierradentroNo ratings yet

- Resin - ABS Tairalac PDFDocument3 pagesResin - ABS Tairalac PDFDiegoTierradentroNo ratings yet

- Toolcord (E 6 Um 65 GS, e Fe4)Document1 pageToolcord (E 6 Um 65 GS, e Fe4)brunizzaNo ratings yet

- Ds - INTERDRAIN GM & GMG 27.6 - enDocument1 pageDs - INTERDRAIN GM & GMG 27.6 - enThameem SharaafNo ratings yet

- Selectrode: High Deposition 316L Stainless Steel International ClassificationsDocument2 pagesSelectrode: High Deposition 316L Stainless Steel International ClassificationsMohamed AdelNo ratings yet

- EE Rejillas Magnéticas (SB-200DD)Document24 pagesEE Rejillas Magnéticas (SB-200DD)angelsiddhartaNo ratings yet

- Union TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20Document2 pagesUnion TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20brunizzaNo ratings yet

- Bondstrand 2400Document17 pagesBondstrand 2400Pinakin PatelNo ratings yet

- Spheric Trafalgar: General InformationDocument1 pageSpheric Trafalgar: General Information15155783No ratings yet

- Abs Ap102 Datasheet-2Document2 pagesAbs Ap102 Datasheet-2phanplastic299No ratings yet

- Busbar Deisgn GuideDocument9 pagesBusbar Deisgn Guideali ridhoNo ratings yet

- Stoody Super 20Document1 pageStoody Super 20JUAN DAVID ESPITIANo ratings yet

- PA6G MoSDocument1 pagePA6G MoSjhax90No ratings yet

- Epoxy Resin Medium Voltage InsulatorsDocument8 pagesEpoxy Resin Medium Voltage InsulatorsDavid ALVESNo ratings yet

- Surface Coating Quick Guide Glass Mould 0463hogDocument1 pageSurface Coating Quick Guide Glass Mould 0463hogSiddharth DasNo ratings yet

- Surface Coating Thermal Surfacing Glass Mould Industry Solutions 1949hogDocument16 pagesSurface Coating Thermal Surfacing Glass Mould Industry Solutions 1949hogSiddharth DasNo ratings yet

- Wall Colmonoy - Colmonoy 6 6PTA 6L TDS - July2021Document4 pagesWall Colmonoy - Colmonoy 6 6PTA 6L TDS - July2021Siddharth DasNo ratings yet

- Eutec Tinweld 1Document1 pageEutec Tinweld 1Siddharth DasNo ratings yet

- Code of Conduct (English)Document25 pagesCode of Conduct (English)Siddharth DasNo ratings yet

- List of Participating Airport Lounges :: S.No. City Lounge Name Airport TerminalDocument3 pagesList of Participating Airport Lounges :: S.No. City Lounge Name Airport TerminalSiddharth DasNo ratings yet

- Health Policy SiddharthDocument9 pagesHealth Policy SiddharthSiddharth DasNo ratings yet

- Application Form For Re-Kyc Updation Through Video Kyc (V-Kyc) (For Resident Individual Savings Account & Individual Current Account)Document4 pagesApplication Form For Re-Kyc Updation Through Video Kyc (V-Kyc) (For Resident Individual Savings Account & Individual Current Account)Siddharth DasNo ratings yet

- Customer Name Card Account No MR Siddharth Das 4315 XXXX XXXX 8005Document8 pagesCustomer Name Card Account No MR Siddharth Das 4315 XXXX XXXX 8005Siddharth DasNo ratings yet

- Technical Specifications: 1. Technical Specifications For Wear Resistive Metallic Putty/pasteDocument2 pagesTechnical Specifications: 1. Technical Specifications For Wear Resistive Metallic Putty/pasteSiddharth DasNo ratings yet

- Astm No A 632-02 PDFDocument4 pagesAstm No A 632-02 PDFAgus Salim DarmaNo ratings yet

- Chapter 4 SteelDocument28 pagesChapter 4 SteelDiyar NezarNo ratings yet

- Notes - Workshop Practice (Fitting Shop)Document16 pagesNotes - Workshop Practice (Fitting Shop)Abubakar Ch100% (1)

- Module 1, Intro To Engg MaterialsDocument21 pagesModule 1, Intro To Engg MaterialsSayaf Khan PathanNo ratings yet

- Case Studies in Engineering Failure AnalysisDocument6 pagesCase Studies in Engineering Failure AnalysisSharwin NovNo ratings yet

- Welding ErrorsDocument42 pagesWelding ErrorsNDTInstructorNo ratings yet

- Melin High Performance - 8 PGDocument8 pagesMelin High Performance - 8 PGriversoundNo ratings yet

- DV03PUB124 Study Guide PDFDocument5 pagesDV03PUB124 Study Guide PDFraja020No ratings yet

- Input Rates Material 1st Bi Annual 2015, Government of PunjabDocument114 pagesInput Rates Material 1st Bi Annual 2015, Government of PunjabHamid NaveedNo ratings yet

- Manuf. Tech. - IntroductionDocument38 pagesManuf. Tech. - IntroductionManuel Tikongyin WundengbaNo ratings yet

- Dished End PDFDocument3 pagesDished End PDFrahmi yantiNo ratings yet

- Production of Magnesium by Electrolysis of Fused SaltsDocument134 pagesProduction of Magnesium by Electrolysis of Fused SaltsiMiklaeNo ratings yet

- Section II Par T A Fer Rous Material Specifications Sa 451 To End 2019 Asme Boiler and Pressure Vessel Code An International Code PDF Free - 5Document1 pageSection II Par T A Fer Rous Material Specifications Sa 451 To End 2019 Asme Boiler and Pressure Vessel Code An International Code PDF Free - 5洛霖No ratings yet

- 4 ReportDocument89 pages4 ReportRajesh KesapragadaNo ratings yet

- Engine Room Tools Part 1Document72 pagesEngine Room Tools Part 1raotalhaNo ratings yet

- Breather Valve - PV Valve - CNC380Document2 pagesBreather Valve - PV Valve - CNC380mhidayat108No ratings yet

- Acsr & AlloyDocument17 pagesAcsr & AlloyDev KumarNo ratings yet

- Kiruna Iron Drilling SuccessDocument12 pagesKiruna Iron Drilling SuccessHannans Reward LtdNo ratings yet

- BME Joining ProcessesDocument11 pagesBME Joining ProcessesalysonmicheaalaNo ratings yet

- 2012-13 AC Motors Starters PDFDocument20 pages2012-13 AC Motors Starters PDFkggganiNo ratings yet

- TM-HBI-00030-H0-VOESAL: Approved: Checked: Drawn: Date: DesignedDocument3 pagesTM-HBI-00030-H0-VOESAL: Approved: Checked: Drawn: Date: DesignedMarko's Brazon'No ratings yet

- C067Document49 pagesC067Gato Sesa0% (1)

- Importance of Welding: QA/QC DepartmentDocument55 pagesImportance of Welding: QA/QC Departmentimran jamil0% (1)

- Butterfly Flu01 Omb 04 11Document16 pagesButterfly Flu01 Omb 04 11ila_368684492No ratings yet

- Application and Processing of Metal AlloysDocument44 pagesApplication and Processing of Metal AlloysShaira DaleNo ratings yet

- SSC DWDocument4 pagesSSC DWsanketpavi21No ratings yet

- Uddeholm Pocket Book E2 PDFDocument76 pagesUddeholm Pocket Book E2 PDFwulfgang66No ratings yet

- Macalloy - 1030 BrochureDocument8 pagesMacalloy - 1030 BrochurejsbharadwajNo ratings yet

- Lotherme HandbookDocument226 pagesLotherme HandbookLalit Kumar100% (2)