Professional Documents

Culture Documents

Parafuso ASTM194HM

Parafuso ASTM194HM

Uploaded by

Fernando BragancaCopyright:

Available Formats

You might also like

- WashPipe Data SheetDocument1 pageWashPipe Data SheetAman Aayra Srivastava100% (4)

- MSDS For PN 3000671, Beacon Replacement Kit (Part 1) PDFDocument15 pagesMSDS For PN 3000671, Beacon Replacement Kit (Part 1) PDFAndrianoNo ratings yet

- Whitworth BSW BSF PDFDocument2 pagesWhitworth BSW BSF PDFLaural MarshallNo ratings yet

- Torque Chart For ASTM A193 Grade B7 StudsDocument3 pagesTorque Chart For ASTM A193 Grade B7 StudsEmmanuel100% (1)

- Pricing Your Work Corporate and Industrial PhotographyDocument15 pagesPricing Your Work Corporate and Industrial PhotographyManu Mnau MnauNo ratings yet

- Y8 Textiles WorkbookDocument68 pagesY8 Textiles WorkbookCharlene Joy100% (1)

- Editing Coding and Tabulation of Data-Marketing ResearchDocument16 pagesEditing Coding and Tabulation of Data-Marketing ResearchArivanandan Get Going100% (1)

- FASTORQ-Torque-Estimating-Chart - Barra RoscadaDocument1 pageFASTORQ-Torque-Estimating-Chart - Barra RoscadaLucas RezendeNo ratings yet

- Steel Bolt TorqueDocument1 pageSteel Bolt TorqueMohamed el attarNo ratings yet

- Cost Machine Shop-April 2015Document18 pagesCost Machine Shop-April 2015azadsingh1No ratings yet

- Standard Wire Gauge To Inches and MillimetresDocument4 pagesStandard Wire Gauge To Inches and MillimetresAREA 7 MAINTENANCENo ratings yet

- Hydril Tubing ConnectionsDocument1 pageHydril Tubing ConnectionslagcordovaNo ratings yet

- #1. Torque Table - Spiral Wound Gasket (1) - 1Document6 pages#1. Torque Table - Spiral Wound Gasket (1) - 1jose del carmen rodriguez contrerasNo ratings yet

- Astm A193 B7Document2 pagesAstm A193 B7groshan20No ratings yet

- Wilson Drill PipeDocument2 pagesWilson Drill PipeFabian Andres Torres BolañosNo ratings yet

- Heavy Hex Nuts Dimensions, Weight Imperial Metric SizesDocument5 pagesHeavy Hex Nuts Dimensions, Weight Imperial Metric SizesEnyNo ratings yet

- TWH27N TWH54N TWH120N TWH210N TWH430NDocument1 pageTWH27N TWH54N TWH120N TWH210N TWH430Nmohamed salahNo ratings yet

- Whitworth BSW BSF PDFDocument2 pagesWhitworth BSW BSF PDFsrinuNo ratings yet

- Whitworth BSW BSFDocument2 pagesWhitworth BSW BSFGourav SharmaNo ratings yet

- Top-Mech TX Serie Eot Cranes Pricelist-25tdg-Fem2mDocument1 pageTop-Mech TX Serie Eot Cranes Pricelist-25tdg-Fem2mfaisal3arainNo ratings yet

- Prevailing Torque Guide: Inch SizesDocument1 pagePrevailing Torque Guide: Inch Sizeskarthi.indya9274No ratings yet

- Line Pipe - Standard Weight, Threaded - Dimensional DataDocument1 pageLine Pipe - Standard Weight, Threaded - Dimensional Datatarno12No ratings yet

- Hydraulic Torque Wrench - Square Drive For Use With Tools: Tws17N, Tws45N, TWS100N, TWS150N AND TWS370NDocument1 pageHydraulic Torque Wrench - Square Drive For Use With Tools: Tws17N, Tws45N, TWS100N, TWS150N AND TWS370NThomaz JuniorNo ratings yet

- ASTM A307: Diámetro Paso Carga de Prueba (LBS) Fuerza de Apriete (LBS) Torque (FT LBS) Lubricado Galv NegroDocument1 pageASTM A307: Diámetro Paso Carga de Prueba (LBS) Fuerza de Apriete (LBS) Torque (FT LBS) Lubricado Galv NegroGutierrez FerchoNo ratings yet

- A193 B7M Bolt PropertiesDocument1 pageA193 B7M Bolt PropertiesRichard HockleyNo ratings yet

- Torque de Trepanos Smith (PDC - Tricono) PDFDocument1 pageTorque de Trepanos Smith (PDC - Tricono) PDFPither ZuritaNo ratings yet

- Pipe and Tube Bursting PressuresDocument2 pagesPipe and Tube Bursting PressuresRaymond MetselaarNo ratings yet

- 8531 S. Freeway Drive - Macedonia, Ohio 44056 (800) 232 - 2659 - Fax: (330) 468-3302Document1 page8531 S. Freeway Drive - Macedonia, Ohio 44056 (800) 232 - 2659 - Fax: (330) 468-3302bcanilkumar007No ratings yet

- A FastenerTorqueCharts PDFDocument2 pagesA FastenerTorqueCharts PDFJusril HidayatNo ratings yet

- Momente Strangere Suruburi Americane - ASTM A574Document1 pageMomente Strangere Suruburi Americane - ASTM A574tracam500No ratings yet

- Torque-Tension Relationship For ASTM A574 Socket Head Cap ScrewsDocument1 pageTorque-Tension Relationship For ASTM A574 Socket Head Cap ScrewsRodrigo GutierrezNo ratings yet

- 6 × 19 & 6 × 37 Class Wire Rope, Bright & GalvanizedDocument3 pages6 × 19 & 6 × 37 Class Wire Rope, Bright & GalvanizedCody GeisendorferNo ratings yet

- 10 1008 PDFDocument1 page10 1008 PDFtuzarraNo ratings yet

- 10 1008 PDFDocument1 page10 1008 PDFPrasadNo ratings yet

- Equipment CatalogDocument26 pagesEquipment CatalogadaNo ratings yet

- Engineering Information - Pipe Thread DataDocument1 pageEngineering Information - Pipe Thread DataShony ErdinalNo ratings yet

- Standard Guideline Driving Chart PileDocument4 pagesStandard Guideline Driving Chart PileSyed ZamanNo ratings yet

- Standard SteelDocument13 pagesStandard SteelYvan Nuñez EscobedoNo ratings yet

- Kian Huat Metal Catalogue PlatesDocument4 pagesKian Huat Metal Catalogue PlatesChaitanya Sai TNo ratings yet

- Red Metals Red Metals: Brass, Copper & Bronze ProductsDocument32 pagesRed Metals Red Metals: Brass, Copper & Bronze Productsizz qhaleefNo ratings yet

- Table 1 / Torque FT-LBS - ASTM A193 and ASTM A320 Grade B8, CL2 Stud Bolts Torque FT-LBSDocument16 pagesTable 1 / Torque FT-LBS - ASTM A193 and ASTM A320 Grade B8, CL2 Stud Bolts Torque FT-LBSEduardo Antonio Rojas Araya100% (1)

- R410a Fixed Speed RotaryDocument2 pagesR410a Fixed Speed RotaryashokindeedNo ratings yet

- Xích 2062H PDFDocument29 pagesXích 2062H PDFTuấn NguyễnNo ratings yet

- COMPRESORES ALTERNATIVOS MT - MTM - MTZ - LTZ - Seleccion - Rapida - PistonDocument10 pagesCOMPRESORES ALTERNATIVOS MT - MTM - MTZ - LTZ - Seleccion - Rapida - PistonAnonymous HrXPSgQ32TNo ratings yet

- Bolt Torque ChartDocument7 pagesBolt Torque ChartVìctor ChicaìzaNo ratings yet

- Fastener Torque Table SAE Grade - Engineers Edge PDFDocument1 pageFastener Torque Table SAE Grade - Engineers Edge PDFnate anantathatNo ratings yet

- Fastener Torque Table SAE Grade - Engineers Edge PDFDocument1 pageFastener Torque Table SAE Grade - Engineers Edge PDFnate anantathatNo ratings yet

- Inch To CM ChartDocument2 pagesInch To CM ChartDave DaveNo ratings yet

- 2BE1 Liquid Ring Vacuum Pump - Guomei PumpDocument7 pages2BE1 Liquid Ring Vacuum Pump - Guomei PumpOscarNo ratings yet

- Guia Parafusos, Arruelas E Porcas 1Document156 pagesGuia Parafusos, Arruelas E Porcas 1Adrian VerattiNo ratings yet

- 011 BrassDocument10 pages011 BrassYirlany Mesén MejíasNo ratings yet

- Design of Slab: Two WayDocument3 pagesDesign of Slab: Two WaySyeda NafeezaNo ratings yet

- Design of Slab: Two WayDocument3 pagesDesign of Slab: Two WaySyeda NafeezaNo ratings yet

- Cortland SlingsDocument12 pagesCortland SlingsafafaNo ratings yet

- Bolt Torque ChartDocument7 pagesBolt Torque ChartRuben GutierrezNo ratings yet

- Weights Rod PDFDocument2 pagesWeights Rod PDFSales HBS SolutionsNo ratings yet

- Stainless Stee Pipe Burst PressureDocument1 pageStainless Stee Pipe Burst PressurerijalharunNo ratings yet

- 1/C CU 15KV 220 NL-EPR 133% TS SIM Pull PVC MV-105Document2 pages1/C CU 15KV 220 NL-EPR 133% TS SIM Pull PVC MV-105RodNo ratings yet

- Wire Rope, Rigging and Mooring For Offshore Construction: A Subsidiary of KTL Global LTDDocument2 pagesWire Rope, Rigging and Mooring For Offshore Construction: A Subsidiary of KTL Global LTDTeck Tiong HuanNo ratings yet

- Basic Dimensions For NPT American National Taper Pipe ThreadsDocument2 pagesBasic Dimensions For NPT American National Taper Pipe Threadsdeepak kumarNo ratings yet

- 2 - Casing Slip Type UC-3Document1 page2 - Casing Slip Type UC-3leoNo ratings yet

- STRG CapacitiesDocument1 pageSTRG Capacitiesislam atifNo ratings yet

- United States Census Figures Back to 1630From EverandUnited States Census Figures Back to 1630No ratings yet

- SPE 163723 Pressure Transient Analysis of Data From Permanent Downhole GaugesDocument24 pagesSPE 163723 Pressure Transient Analysis of Data From Permanent Downhole GaugesLulut Fitra FalaNo ratings yet

- 1.2 FMCC221 - Introduction To International Businesss - Part 1Document19 pages1.2 FMCC221 - Introduction To International Businesss - Part 1Bernie D. TeguenosNo ratings yet

- Elrc 4507 Unit PlanDocument4 pagesElrc 4507 Unit Planapi-284973023No ratings yet

- Natural Gas - Pipe SizingDocument6 pagesNatural Gas - Pipe SizinglekakasNo ratings yet

- Application of Buoyancy-Power Generator For Compressed Air Energy Storage Using A Fluid-Air Displacement System - ScienceDirectDocument7 pagesApplication of Buoyancy-Power Generator For Compressed Air Energy Storage Using A Fluid-Air Displacement System - ScienceDirectJoel Stanley TylerNo ratings yet

- PAYROLLMANAGEMENTDocument5 pagesPAYROLLMANAGEMENTSai Prabhav (Sai Prabhav)No ratings yet

- Alarm Security Pic - Google ShoppingDocument1 pageAlarm Security Pic - Google Shoppingleeleeleebc123No ratings yet

- US Gasification DatabaseDocument9 pagesUS Gasification DatabaseAhmad DaoodNo ratings yet

- STEWART Briony Kumiko and The Dragon FINAL2010Document8 pagesSTEWART Briony Kumiko and The Dragon FINAL2010Tahnee HallNo ratings yet

- Toward The Efficient Impact Frontier: FeaturesDocument6 pagesToward The Efficient Impact Frontier: Featuresguramios chukhrukidzeNo ratings yet

- Asmaa Mamdouh CVDocument1 pageAsmaa Mamdouh CVAsmaa MamdouhNo ratings yet

- 2.20 Optimizing Control: F. G. Shinskey C. G. Laspe B. G. Lipták M. RuelDocument10 pages2.20 Optimizing Control: F. G. Shinskey C. G. Laspe B. G. Lipták M. RueljigjigawNo ratings yet

- Optimizing The Lasing Quality of Diode Lasers by Anti-Reflective CoatingDocument21 pagesOptimizing The Lasing Quality of Diode Lasers by Anti-Reflective CoatingDannyNo ratings yet

- Cell Structure & Cell OrganisationDocument35 pagesCell Structure & Cell OrganisationNaida Mohd SalehNo ratings yet

- Predica Billy GrahamDocument4 pagesPredica Billy GrahamJenkis Cam GuerraNo ratings yet

- Assignment 5 - Profile and Cross Section LevelingDocument3 pagesAssignment 5 - Profile and Cross Section LevelingKeanna Marie TorresNo ratings yet

- Assessment System: Take Assessment - EWAN Chapter 8 - CCNA Exploration: Accessing The WAN (Version 4.0)Document9 pagesAssessment System: Take Assessment - EWAN Chapter 8 - CCNA Exploration: Accessing The WAN (Version 4.0)asceric4363No ratings yet

- SummaryDocument2 pagesSummaryRosida IdaNo ratings yet

- Oma TS MLP V3 - 2 20110719 ADocument128 pagesOma TS MLP V3 - 2 20110719 AkennychanklNo ratings yet

- Informe Sobre El Manejo de CostasDocument88 pagesInforme Sobre El Manejo de CostasMetro Puerto RicoNo ratings yet

- Rock Mass Characterization by High-Resolution SoniDocument17 pagesRock Mass Characterization by High-Resolution SoniJose AleNo ratings yet

- Tuyển Sinh 10 - đề 1 -KeyDocument5 pagesTuyển Sinh 10 - đề 1 -Keynguyenhoang17042004No ratings yet

- HSC 11 Scalars and Vectors Ch2Document5 pagesHSC 11 Scalars and Vectors Ch2Snehal PanchalNo ratings yet

- GEO01 - CO1.2 - Introduction To Earth Science (Geology)Document14 pagesGEO01 - CO1.2 - Introduction To Earth Science (Geology)Ghia PalarcaNo ratings yet

- Mathematics Past Paper QuestionsDocument174 pagesMathematics Past Paper Questionsnodicoh572100% (2)

Parafuso ASTM194HM

Parafuso ASTM194HM

Uploaded by

Fernando BragancaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Parafuso ASTM194HM

Parafuso ASTM194HM

Uploaded by

Fernando BragancaCopyright:

Available Formats

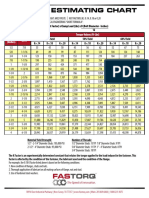

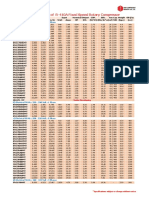

SUGGESTED ASSEMBLY TORQUE VALUES TO

PRODUCE CORRESPONDING BOLT LOADS

SA193 & ASTM 193 B7 Studs with SA193 & ASTM 193 B7M Studs with

Tensile A194 2H Heavy Hex Nuts A194 2HM Heavy Hex Nuts

Stress Area

Size Tightening Torque Size Tightening Torque

AS

Clamp Load Dry Lubed Clamp Load Dry Lubed

Square Inch P. Lb.s K= .223 K = .167 P. Lb.s K= .223 K = .167

Ft. Lbs. Ft. Lbs. Ft. Lbs. Ft. Lbs.

1/2 - 13 0.138 10,350 96 72 1/2 - 13 7,866 73 55

9/16 - 12 0.177 13,275 139 104 9/16 - 12 10,089 105 79

5/8 - 11 0.220 16,500 192 143 5/8 - 11 12,540 146 109

3/4 - 10 0.327 24,525 342 256 3/4 - 10 18,639 260 194

7/8 - 9 0.452 33,900 551 413 7/8 - 9 25,764 419 314

1-8 0.594 44,550 828 620 1-8 33,858 629 471

1-1/8 - 8 0.776 58,200 1217 911 1-1/8 - 8 44,232 925 692

1-1/4 - 8 0.984 73,800 1714 1284 1-1/4 - 8 56,088 1303 976

1-3/8 - 8 1.215 91,125 2328 1744 1-3/8 - 8 69,255 1770 1325

1-1/2 - 8 1.471 110,325 3076 2303 1-1/2 - 8 83,847 2337 1750

1-5/8 - 8 1.769 132,675 4006 3000 1-5/8 - 8 100,833 3045 2280

1-3/4 - 8 2.06 154,500 5024 3763 1-3/4 - 8 177,420 3818 2860

1-7/8 - 8 2.41 180,750 6298 4716 1-7/8 - 8 137,370 4786 3584

2-8 2.74 205,500 7638 5720 2-8 156,180 5805 4347

2-1/4 - 8 3.52 264,000 11,038 8266 2-1/4 - 8 200,640 8389 6282

2-1/2 - 8 4.40 330,000 15,331 11,481 2-1/2 - 8 250,800 11,652 8726

SA320 & ASTM A320 L7 Studs with SA320 & ASTM A320 L7M Studs with

Tensile A194 Grade 4 or Grade L7 Heavy Hex Nuts A194 L7M Heavy Hex Nuts

Size Stress Area Tightening Torque Size Tightening Torque

AS Clamp Load Dry Lubed Clamp Load Dry Lubed

P. Lb.s K= .223 K = .167 P. Lb.s K= .223 K = .167

Square Inch

Ft. Lbs. Ft. Lbs. Ft. Lbs. Ft. Lbs.

1/2 - 13 0.138 10,350 96 72 1/2 - 13 7,866 73 55

9/16 - 12 0.177 13,275 139 104 9/16 - 12 10,089 105 79

5/8 - 11 0.220 16,500 192 143 5/8 - 11 12,540 146 109

3/4 - 10 0.327 24,525 342 256 3/4 - 10 18,639 260 194

7/8 - 9 0.452 33,900 551 413 7/8 - 9 25,764 419 314

1-8 0.594 44,550 828 620 1-8 33,858 629 471

1-1/8 - 8 0.776 58,200 1217 911 1-1/8 - 8 44,232 925 692

1-1/4 - 8 0.984 73,800 1714 1284 1-1/4 - 8 56,088 1303 976

1-3/8 - 8 1.215 91,125 2328 1744 1-3/8 - 8 69,255 1770 1325

1-1/2 - 8 1.471 110,325 3076 2303 1-1/2 - 8 83,847 2337 1750

1-5/8 - 8 1.769 132,675 4006 3000 1-5/8 - 8 100,833 3045 2280

1-3/4 - 8 2.06 154,500 5024 3763 1-3/4 - 8 177,420 3818 2860

1-7/8 - 8 2.41 180,750 6298 4716 1-7/8 - 8 137,370 4786 3584

2-8 2.74 205,500 7638 5720 2-8 156,180 5805 4347

2-1/4 - 8 3.52 264,000 11,038 8266 2-1/4 - 8 200,640 8389 6282

2-1/2 - 8 4.40 330,000 15,331 11,481 2-1/2 - 8 250,800 11,652 8726

NOTES:

1. Tightening torque values from the formula T=KDP, where T = tightening torque, lb. ft. K - torque friction coefficient,

D = nominal bolt diameter, in.; and P = bolt clamping load developed by tightening, lb.

2. Clamp load is also known as preload or initial load in tension on bolt. Clamp load (lb.) is calculated by arbitrarily assuming useable

bolt strength is 75% of bolt proof load (PSI) times the stress area (sq. in.) of threaded section of each bolt size. Higher or lower

values of clamp load can be used depending on the application requirements and the judgement of the designer.

3. No proof load has been established by ASTM. Value shown in table are assumed at 95% of yield strength.

*Grade 7M nuts at a hardness not exceeding 235HB (or equivalent) shall be used with Grade B7M studs.

Ph: 780-440-2737 • 1-800-661-6923

M & Z INDUSTRIAL SUPPLY LTD.

You might also like

- WashPipe Data SheetDocument1 pageWashPipe Data SheetAman Aayra Srivastava100% (4)

- MSDS For PN 3000671, Beacon Replacement Kit (Part 1) PDFDocument15 pagesMSDS For PN 3000671, Beacon Replacement Kit (Part 1) PDFAndrianoNo ratings yet

- Whitworth BSW BSF PDFDocument2 pagesWhitworth BSW BSF PDFLaural MarshallNo ratings yet

- Torque Chart For ASTM A193 Grade B7 StudsDocument3 pagesTorque Chart For ASTM A193 Grade B7 StudsEmmanuel100% (1)

- Pricing Your Work Corporate and Industrial PhotographyDocument15 pagesPricing Your Work Corporate and Industrial PhotographyManu Mnau MnauNo ratings yet

- Y8 Textiles WorkbookDocument68 pagesY8 Textiles WorkbookCharlene Joy100% (1)

- Editing Coding and Tabulation of Data-Marketing ResearchDocument16 pagesEditing Coding and Tabulation of Data-Marketing ResearchArivanandan Get Going100% (1)

- FASTORQ-Torque-Estimating-Chart - Barra RoscadaDocument1 pageFASTORQ-Torque-Estimating-Chart - Barra RoscadaLucas RezendeNo ratings yet

- Steel Bolt TorqueDocument1 pageSteel Bolt TorqueMohamed el attarNo ratings yet

- Cost Machine Shop-April 2015Document18 pagesCost Machine Shop-April 2015azadsingh1No ratings yet

- Standard Wire Gauge To Inches and MillimetresDocument4 pagesStandard Wire Gauge To Inches and MillimetresAREA 7 MAINTENANCENo ratings yet

- Hydril Tubing ConnectionsDocument1 pageHydril Tubing ConnectionslagcordovaNo ratings yet

- #1. Torque Table - Spiral Wound Gasket (1) - 1Document6 pages#1. Torque Table - Spiral Wound Gasket (1) - 1jose del carmen rodriguez contrerasNo ratings yet

- Astm A193 B7Document2 pagesAstm A193 B7groshan20No ratings yet

- Wilson Drill PipeDocument2 pagesWilson Drill PipeFabian Andres Torres BolañosNo ratings yet

- Heavy Hex Nuts Dimensions, Weight Imperial Metric SizesDocument5 pagesHeavy Hex Nuts Dimensions, Weight Imperial Metric SizesEnyNo ratings yet

- TWH27N TWH54N TWH120N TWH210N TWH430NDocument1 pageTWH27N TWH54N TWH120N TWH210N TWH430Nmohamed salahNo ratings yet

- Whitworth BSW BSF PDFDocument2 pagesWhitworth BSW BSF PDFsrinuNo ratings yet

- Whitworth BSW BSFDocument2 pagesWhitworth BSW BSFGourav SharmaNo ratings yet

- Top-Mech TX Serie Eot Cranes Pricelist-25tdg-Fem2mDocument1 pageTop-Mech TX Serie Eot Cranes Pricelist-25tdg-Fem2mfaisal3arainNo ratings yet

- Prevailing Torque Guide: Inch SizesDocument1 pagePrevailing Torque Guide: Inch Sizeskarthi.indya9274No ratings yet

- Line Pipe - Standard Weight, Threaded - Dimensional DataDocument1 pageLine Pipe - Standard Weight, Threaded - Dimensional Datatarno12No ratings yet

- Hydraulic Torque Wrench - Square Drive For Use With Tools: Tws17N, Tws45N, TWS100N, TWS150N AND TWS370NDocument1 pageHydraulic Torque Wrench - Square Drive For Use With Tools: Tws17N, Tws45N, TWS100N, TWS150N AND TWS370NThomaz JuniorNo ratings yet

- ASTM A307: Diámetro Paso Carga de Prueba (LBS) Fuerza de Apriete (LBS) Torque (FT LBS) Lubricado Galv NegroDocument1 pageASTM A307: Diámetro Paso Carga de Prueba (LBS) Fuerza de Apriete (LBS) Torque (FT LBS) Lubricado Galv NegroGutierrez FerchoNo ratings yet

- A193 B7M Bolt PropertiesDocument1 pageA193 B7M Bolt PropertiesRichard HockleyNo ratings yet

- Torque de Trepanos Smith (PDC - Tricono) PDFDocument1 pageTorque de Trepanos Smith (PDC - Tricono) PDFPither ZuritaNo ratings yet

- Pipe and Tube Bursting PressuresDocument2 pagesPipe and Tube Bursting PressuresRaymond MetselaarNo ratings yet

- 8531 S. Freeway Drive - Macedonia, Ohio 44056 (800) 232 - 2659 - Fax: (330) 468-3302Document1 page8531 S. Freeway Drive - Macedonia, Ohio 44056 (800) 232 - 2659 - Fax: (330) 468-3302bcanilkumar007No ratings yet

- A FastenerTorqueCharts PDFDocument2 pagesA FastenerTorqueCharts PDFJusril HidayatNo ratings yet

- Momente Strangere Suruburi Americane - ASTM A574Document1 pageMomente Strangere Suruburi Americane - ASTM A574tracam500No ratings yet

- Torque-Tension Relationship For ASTM A574 Socket Head Cap ScrewsDocument1 pageTorque-Tension Relationship For ASTM A574 Socket Head Cap ScrewsRodrigo GutierrezNo ratings yet

- 6 × 19 & 6 × 37 Class Wire Rope, Bright & GalvanizedDocument3 pages6 × 19 & 6 × 37 Class Wire Rope, Bright & GalvanizedCody GeisendorferNo ratings yet

- 10 1008 PDFDocument1 page10 1008 PDFtuzarraNo ratings yet

- 10 1008 PDFDocument1 page10 1008 PDFPrasadNo ratings yet

- Equipment CatalogDocument26 pagesEquipment CatalogadaNo ratings yet

- Engineering Information - Pipe Thread DataDocument1 pageEngineering Information - Pipe Thread DataShony ErdinalNo ratings yet

- Standard Guideline Driving Chart PileDocument4 pagesStandard Guideline Driving Chart PileSyed ZamanNo ratings yet

- Standard SteelDocument13 pagesStandard SteelYvan Nuñez EscobedoNo ratings yet

- Kian Huat Metal Catalogue PlatesDocument4 pagesKian Huat Metal Catalogue PlatesChaitanya Sai TNo ratings yet

- Red Metals Red Metals: Brass, Copper & Bronze ProductsDocument32 pagesRed Metals Red Metals: Brass, Copper & Bronze Productsizz qhaleefNo ratings yet

- Table 1 / Torque FT-LBS - ASTM A193 and ASTM A320 Grade B8, CL2 Stud Bolts Torque FT-LBSDocument16 pagesTable 1 / Torque FT-LBS - ASTM A193 and ASTM A320 Grade B8, CL2 Stud Bolts Torque FT-LBSEduardo Antonio Rojas Araya100% (1)

- R410a Fixed Speed RotaryDocument2 pagesR410a Fixed Speed RotaryashokindeedNo ratings yet

- Xích 2062H PDFDocument29 pagesXích 2062H PDFTuấn NguyễnNo ratings yet

- COMPRESORES ALTERNATIVOS MT - MTM - MTZ - LTZ - Seleccion - Rapida - PistonDocument10 pagesCOMPRESORES ALTERNATIVOS MT - MTM - MTZ - LTZ - Seleccion - Rapida - PistonAnonymous HrXPSgQ32TNo ratings yet

- Bolt Torque ChartDocument7 pagesBolt Torque ChartVìctor ChicaìzaNo ratings yet

- Fastener Torque Table SAE Grade - Engineers Edge PDFDocument1 pageFastener Torque Table SAE Grade - Engineers Edge PDFnate anantathatNo ratings yet

- Fastener Torque Table SAE Grade - Engineers Edge PDFDocument1 pageFastener Torque Table SAE Grade - Engineers Edge PDFnate anantathatNo ratings yet

- Inch To CM ChartDocument2 pagesInch To CM ChartDave DaveNo ratings yet

- 2BE1 Liquid Ring Vacuum Pump - Guomei PumpDocument7 pages2BE1 Liquid Ring Vacuum Pump - Guomei PumpOscarNo ratings yet

- Guia Parafusos, Arruelas E Porcas 1Document156 pagesGuia Parafusos, Arruelas E Porcas 1Adrian VerattiNo ratings yet

- 011 BrassDocument10 pages011 BrassYirlany Mesén MejíasNo ratings yet

- Design of Slab: Two WayDocument3 pagesDesign of Slab: Two WaySyeda NafeezaNo ratings yet

- Design of Slab: Two WayDocument3 pagesDesign of Slab: Two WaySyeda NafeezaNo ratings yet

- Cortland SlingsDocument12 pagesCortland SlingsafafaNo ratings yet

- Bolt Torque ChartDocument7 pagesBolt Torque ChartRuben GutierrezNo ratings yet

- Weights Rod PDFDocument2 pagesWeights Rod PDFSales HBS SolutionsNo ratings yet

- Stainless Stee Pipe Burst PressureDocument1 pageStainless Stee Pipe Burst PressurerijalharunNo ratings yet

- 1/C CU 15KV 220 NL-EPR 133% TS SIM Pull PVC MV-105Document2 pages1/C CU 15KV 220 NL-EPR 133% TS SIM Pull PVC MV-105RodNo ratings yet

- Wire Rope, Rigging and Mooring For Offshore Construction: A Subsidiary of KTL Global LTDDocument2 pagesWire Rope, Rigging and Mooring For Offshore Construction: A Subsidiary of KTL Global LTDTeck Tiong HuanNo ratings yet

- Basic Dimensions For NPT American National Taper Pipe ThreadsDocument2 pagesBasic Dimensions For NPT American National Taper Pipe Threadsdeepak kumarNo ratings yet

- 2 - Casing Slip Type UC-3Document1 page2 - Casing Slip Type UC-3leoNo ratings yet

- STRG CapacitiesDocument1 pageSTRG Capacitiesislam atifNo ratings yet

- United States Census Figures Back to 1630From EverandUnited States Census Figures Back to 1630No ratings yet

- SPE 163723 Pressure Transient Analysis of Data From Permanent Downhole GaugesDocument24 pagesSPE 163723 Pressure Transient Analysis of Data From Permanent Downhole GaugesLulut Fitra FalaNo ratings yet

- 1.2 FMCC221 - Introduction To International Businesss - Part 1Document19 pages1.2 FMCC221 - Introduction To International Businesss - Part 1Bernie D. TeguenosNo ratings yet

- Elrc 4507 Unit PlanDocument4 pagesElrc 4507 Unit Planapi-284973023No ratings yet

- Natural Gas - Pipe SizingDocument6 pagesNatural Gas - Pipe SizinglekakasNo ratings yet

- Application of Buoyancy-Power Generator For Compressed Air Energy Storage Using A Fluid-Air Displacement System - ScienceDirectDocument7 pagesApplication of Buoyancy-Power Generator For Compressed Air Energy Storage Using A Fluid-Air Displacement System - ScienceDirectJoel Stanley TylerNo ratings yet

- PAYROLLMANAGEMENTDocument5 pagesPAYROLLMANAGEMENTSai Prabhav (Sai Prabhav)No ratings yet

- Alarm Security Pic - Google ShoppingDocument1 pageAlarm Security Pic - Google Shoppingleeleeleebc123No ratings yet

- US Gasification DatabaseDocument9 pagesUS Gasification DatabaseAhmad DaoodNo ratings yet

- STEWART Briony Kumiko and The Dragon FINAL2010Document8 pagesSTEWART Briony Kumiko and The Dragon FINAL2010Tahnee HallNo ratings yet

- Toward The Efficient Impact Frontier: FeaturesDocument6 pagesToward The Efficient Impact Frontier: Featuresguramios chukhrukidzeNo ratings yet

- Asmaa Mamdouh CVDocument1 pageAsmaa Mamdouh CVAsmaa MamdouhNo ratings yet

- 2.20 Optimizing Control: F. G. Shinskey C. G. Laspe B. G. Lipták M. RuelDocument10 pages2.20 Optimizing Control: F. G. Shinskey C. G. Laspe B. G. Lipták M. RueljigjigawNo ratings yet

- Optimizing The Lasing Quality of Diode Lasers by Anti-Reflective CoatingDocument21 pagesOptimizing The Lasing Quality of Diode Lasers by Anti-Reflective CoatingDannyNo ratings yet

- Cell Structure & Cell OrganisationDocument35 pagesCell Structure & Cell OrganisationNaida Mohd SalehNo ratings yet

- Predica Billy GrahamDocument4 pagesPredica Billy GrahamJenkis Cam GuerraNo ratings yet

- Assignment 5 - Profile and Cross Section LevelingDocument3 pagesAssignment 5 - Profile and Cross Section LevelingKeanna Marie TorresNo ratings yet

- Assessment System: Take Assessment - EWAN Chapter 8 - CCNA Exploration: Accessing The WAN (Version 4.0)Document9 pagesAssessment System: Take Assessment - EWAN Chapter 8 - CCNA Exploration: Accessing The WAN (Version 4.0)asceric4363No ratings yet

- SummaryDocument2 pagesSummaryRosida IdaNo ratings yet

- Oma TS MLP V3 - 2 20110719 ADocument128 pagesOma TS MLP V3 - 2 20110719 AkennychanklNo ratings yet

- Informe Sobre El Manejo de CostasDocument88 pagesInforme Sobre El Manejo de CostasMetro Puerto RicoNo ratings yet

- Rock Mass Characterization by High-Resolution SoniDocument17 pagesRock Mass Characterization by High-Resolution SoniJose AleNo ratings yet

- Tuyển Sinh 10 - đề 1 -KeyDocument5 pagesTuyển Sinh 10 - đề 1 -Keynguyenhoang17042004No ratings yet

- HSC 11 Scalars and Vectors Ch2Document5 pagesHSC 11 Scalars and Vectors Ch2Snehal PanchalNo ratings yet

- GEO01 - CO1.2 - Introduction To Earth Science (Geology)Document14 pagesGEO01 - CO1.2 - Introduction To Earth Science (Geology)Ghia PalarcaNo ratings yet

- Mathematics Past Paper QuestionsDocument174 pagesMathematics Past Paper Questionsnodicoh572100% (2)