Professional Documents

Culture Documents

Highway Engineering Model QP-16CV7G2

Highway Engineering Model QP-16CV7G2

Uploaded by

Varuna MCopyright:

Available Formats

You might also like

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Elective-II: Pavement Analysis & Design: B.E. (Civil Engineering) Eighth Semester (C.B.S.)Document4 pagesElective-II: Pavement Analysis & Design: B.E. (Civil Engineering) Eighth Semester (C.B.S.)Adesh DeshbhratarNo ratings yet

- 2019 Dec. CE467-C - Ktu QbankDocument2 pages2019 Dec. CE467-C - Ktu QbankAthira RaghavanNo ratings yet

- 07a80106 Pavement Analysis and DesignDocument8 pages07a80106 Pavement Analysis and DesignSharanya ThirichinapalliNo ratings yet

- Pa&d JalanDocument9 pagesPa&d JalanIkram MuzhaffarNo ratings yet

- Elective-II: Pavement Analysis & Design: B.E. (Civil Engineering) Eighth Semester (C.B.S.)Document6 pagesElective-II: Pavement Analysis & Design: B.E. (Civil Engineering) Eighth Semester (C.B.S.)Adesh DeshbhratarNo ratings yet

- Term Paper: Course Title: Highway Design and Railways Course Code: CE 1002Document2 pagesTerm Paper: Course Title: Highway Design and Railways Course Code: CE 1002SabbirNo ratings yet

- Highway QBDocument4 pagesHighway QBPrashant PathyanNo ratings yet

- June 2011 NewDocument2 pagesJune 2011 NewSumithra RaviNo ratings yet

- Prelims QP Transportation EngineeringDocument2 pagesPrelims QP Transportation Engineeringce23resch11011No ratings yet

- Paper Solution 2Document22 pagesPaper Solution 2karanmohod383No ratings yet

- Cet433 QPDocument3 pagesCet433 QPREMYA Y.KNo ratings yet

- BRIDGE ENGINEERING S7 CE B.Tech Dec.2018 - Ktu QbankDocument2 pagesBRIDGE ENGINEERING S7 CE B.Tech Dec.2018 - Ktu QbankRavi RaneNo ratings yet

- Dss Paper 1Document2 pagesDss Paper 1hemalNo ratings yet

- Foundation EngineeringDocument12 pagesFoundation EngineeringSindhu Chowhan100% (1)

- Assignment - 1 Pavement Analysis and Design: (Units Covered: 1, 2, 3 & 4)Document2 pagesAssignment - 1 Pavement Analysis and Design: (Units Covered: 1, 2, 3 & 4)Praveen SamarthiNo ratings yet

- B.tech III-II All Branch Regular and Supple Previous Question Papers May 2018Document28 pagesB.tech III-II All Branch Regular and Supple Previous Question Papers May 2018bhanuprakeshNo ratings yet

- Elective - II: Pavement Analysis & Design: B.E. (Civil Engineering) Eighth Semester (C.B.S.)Document27 pagesElective - II: Pavement Analysis & Design: B.E. (Civil Engineering) Eighth Semester (C.B.S.)FalgunNo ratings yet

- Tutorial IIDocument2 pagesTutorial IINmNo ratings yet

- Model Questions - 2019Document9 pagesModel Questions - 2019Aliza SubediNo ratings yet

- Ce 451 Te Ii ('09-'13) PDFDocument36 pagesCe 451 Te Ii ('09-'13) PDFSakibNo ratings yet

- (Max - Marks:75: - TimeDocument2 pages(Max - Marks:75: - TimeGundrathi Narendra GoudNo ratings yet

- Analysis and Structure Design of Pavement May 2019Document1 pageAnalysis and Structure Design of Pavement May 2019mp SinghNo ratings yet

- Geotech3 LS11 PavementsDocument14 pagesGeotech3 LS11 PavementsRudiny FarabyNo ratings yet

- Pavement Design Methods 2 PDFDocument47 pagesPavement Design Methods 2 PDFShekh Muhsen Uddin AhmedNo ratings yet

- Transportation Engineering 1 Question Bank - Mumbai UniversityDocument10 pagesTransportation Engineering 1 Question Bank - Mumbai UniversityMegha Thomas0% (1)

- Design of Flexible Pavement - Irc MethodDocument9 pagesDesign of Flexible Pavement - Irc MethodOSIRIS EvilNo ratings yet

- MCESC 105-2 Bridge Engineering - Set2Document2 pagesMCESC 105-2 Bridge Engineering - Set2Aniket PolNo ratings yet

- Chapter 6-Part-II Introduction To Design of Rigid PavementsDocument22 pagesChapter 6-Part-II Introduction To Design of Rigid Pavementsznabu asefaNo ratings yet

- Last Yr Transportation Question PapersDocument11 pagesLast Yr Transportation Question PapersAditya RanaNo ratings yet

- Answer SheetsDocument4 pagesAnswer Sheetsforplayinggame120No ratings yet

- Sem 5-2Document13 pagesSem 5-2SATYAWANNo ratings yet

- RTU Previous Years PapersDocument41 pagesRTU Previous Years PapersDinesh Kumar0% (1)

- Transporation Engineering Kce 602Document2 pagesTransporation Engineering Kce 602s14alok2100003No ratings yet

- 15801321052Document13 pages15801321052Rakesh PalNo ratings yet

- Guidelines On The-Depth of Overlay On Roads-0Document43 pagesGuidelines On The-Depth of Overlay On Roads-0khourani1No ratings yet

- DesignDocument21 pagesDesignShabib AhmedNo ratings yet

- Ce 443 PDFDocument20 pagesCe 443 PDFAyatullah NawazNo ratings yet

- F G1153 Pages: 2: Answer Any Two Full Questions, Each Carries 15 MarksDocument2 pagesF G1153 Pages: 2: Answer Any Two Full Questions, Each Carries 15 MarksSachin KumarNo ratings yet

- Faculty of Engineering Department of Civil Engineering and SurveyingDocument3 pagesFaculty of Engineering Department of Civil Engineering and SurveyingWataNo ratings yet

- Bridge Deck DesignDocument32 pagesBridge Deck DesignChukwuma Ogbonna100% (2)

- 19021D2022 Analysis and Design of Deck Slabs 22Document21 pages19021D2022 Analysis and Design of Deck Slabs 22AravindNo ratings yet

- Gujarat Technological UniversityDocument5 pagesGujarat Technological Universitychirag mulchandaniNo ratings yet

- QP Internal 1 PD 1Document1 pageQP Internal 1 PD 1Mallikarjun IndiNo ratings yet

- Trial QuestionsDocument7 pagesTrial QuestionsndayambajedNo ratings yet

- 9A01602 Geotechnical Engineering - IDocument7 pages9A01602 Geotechnical Engineering - IsivabharathamurthyNo ratings yet

- Giroud 1981 and Noiray Unpaved Road and DSCN Corrected OCRDocument39 pagesGiroud 1981 and Noiray Unpaved Road and DSCN Corrected OCRRUBEIDYSNo ratings yet

- Ce 8042 Pavement Design Jun 2014Document2 pagesCe 8042 Pavement Design Jun 2014someshthakur0207No ratings yet

- C E1152 Pages: 2: Answer Any Two Full Questions, Each Carries 15 MarksDocument2 pagesC E1152 Pages: 2: Answer Any Two Full Questions, Each Carries 15 MarksirshadNo ratings yet

- Design of Rigid Road Pavement For Ainachiwadi Village in Patan TahsilDocument5 pagesDesign of Rigid Road Pavement For Ainachiwadi Village in Patan TahsilsathishNo ratings yet

- WWW - Manaresults.Co - In: B.Tech IV Year I Semester (R13) Supplementary Examinations June 2017Document2 pagesWWW - Manaresults.Co - In: B.Tech IV Year I Semester (R13) Supplementary Examinations June 2017mgrreddyNo ratings yet

- Bridges - Oct 2014 - 2008Document3 pagesBridges - Oct 2014 - 2008Sahil GandhiNo ratings yet

- 9A01502 Concrete TechnologyDocument4 pages9A01502 Concrete TechnologysietkcivilNo ratings yet

- CET305 GEOTECHNICAL ENGINEERING-II, DECEMBER 2021Document3 pagesCET305 GEOTECHNICAL ENGINEERING-II, DECEMBER 2021basiljoy787No ratings yet

- MACE60035 Principles of Structural Engineering Design 18-19Document12 pagesMACE60035 Principles of Structural Engineering Design 18-19KrisNo ratings yet

- CE - 303 - GE - End Sem-1Document3 pagesCE - 303 - GE - End Sem-1Anudeep KumarNo ratings yet

- Btech Ce 7 Sem Railways Airport and Waterways Rce076 2020Document2 pagesBtech Ce 7 Sem Railways Airport and Waterways Rce076 2020Funlife69 69No ratings yet

- Pavement Engineering Final QuestionDocument8 pagesPavement Engineering Final QuestionAfham AhmadNo ratings yet

- Elective - II: Pavement Analysis & Design: B.E.Eighth Semester (Civil Engineering) (C.B.S.)Document12 pagesElective - II: Pavement Analysis & Design: B.E.Eighth Semester (Civil Engineering) (C.B.S.)Uday PatilNo ratings yet

- Midterm Examination: Subject: Physics 2 (Fluid Mechanics and Thermal Physics) (ID: PH014IU)Document3 pagesMidterm Examination: Subject: Physics 2 (Fluid Mechanics and Thermal Physics) (ID: PH014IU)Anh TrầnNo ratings yet

- Stress Measurement Using Magnetic Barkhausen Noise and Metal MagneticDocument16 pagesStress Measurement Using Magnetic Barkhausen Noise and Metal MagneticSalem GarrabNo ratings yet

- Chloe Kho - Assignment 5 - MTT PracticeDocument5 pagesChloe Kho - Assignment 5 - MTT PracticeanthonyNo ratings yet

- TML Strain Gauge Catalog 2017 PDFDocument100 pagesTML Strain Gauge Catalog 2017 PDFAmitNo ratings yet

- Finite Element Analysis PDFDocument46 pagesFinite Element Analysis PDFrajani_bala15No ratings yet

- Allowable Nozzle LoadsDocument7 pagesAllowable Nozzle LoadsZulkarnain NasrullahNo ratings yet

- Construction and Design of Multi Storey Building by Abhimanyu ParidaDocument38 pagesConstruction and Design of Multi Storey Building by Abhimanyu Paridadriverx47100% (19)

- Low Thermal Expansion Coefficient Fe-Ni-Co Alloys-Plastic Deformation, Alloy Composition and Martensitic Transformation RelationshipsDocument8 pagesLow Thermal Expansion Coefficient Fe-Ni-Co Alloys-Plastic Deformation, Alloy Composition and Martensitic Transformation RelationshipspraveenkhatkaleNo ratings yet

- Mineral Casting As Material For Machine Base Frames of Precision MachinesDocument4 pagesMineral Casting As Material For Machine Base Frames of Precision MachinesrahulkumbharkarNo ratings yet

- 1991 - Tay - Finite Element Analysis of Thermoelastic Coupling in CompositesDocument6 pages1991 - Tay - Finite Element Analysis of Thermoelastic Coupling in CompositesPedro Filipe CunhaNo ratings yet

- Expansion ThermometersDocument28 pagesExpansion ThermometersKevin Nelson LoboNo ratings yet

- Engineering Materials and Metallurgy Notes PDFDocument0 pagesEngineering Materials and Metallurgy Notes PDFSenthilkumar Subbiah50% (2)

- Communicating With Instromet Q-Sonic Ultrasonic Gas FlowmetersDocument13 pagesCommunicating With Instromet Q-Sonic Ultrasonic Gas Flowmeterssyed jeelani ahmedNo ratings yet

- Non-Classical Creep Behavior of Fusion-Cast Alumina RefractoriesDocument8 pagesNon-Classical Creep Behavior of Fusion-Cast Alumina Refractoriesceramics100% (2)

- TG36 Version 3 January 2020Document7 pagesTG36 Version 3 January 2020PoornimaNo ratings yet

- Chapter - 2 Highway Ii PDFDocument74 pagesChapter - 2 Highway Ii PDFdilnessa azanawNo ratings yet

- Biohall Germany Catalouge-2021-22Document154 pagesBiohall Germany Catalouge-2021-22TRUCAL NABLNo ratings yet

- Processing Glass Property Data With Sciglass Information SystemDocument52 pagesProcessing Glass Property Data With Sciglass Information SystembryandownNo ratings yet

- STRESS AND STRAIN-thermal AsDocument7 pagesSTRESS AND STRAIN-thermal AsShaktivell LetchumananNo ratings yet

- National Training of Teachers For Critical Content in Grade 8 ScienceDocument45 pagesNational Training of Teachers For Critical Content in Grade 8 ScienceRaymond Reyes CuribangNo ratings yet

- Habasit Chain Engineering GuideDocument62 pagesHabasit Chain Engineering GuideScripts TeamNo ratings yet

- Thermal Stress Question PDFDocument15 pagesThermal Stress Question PDFrohitNo ratings yet

- Thermal ExpansionDocument12 pagesThermal ExpansionPrincess Xyrill Sena AndengNo ratings yet

- Physics p2 Revision Mr.a.salahDocument44 pagesPhysics p2 Revision Mr.a.salahmohammed mahdyNo ratings yet

- Heat Loss CalculationDocument12 pagesHeat Loss CalculationRajaramNo ratings yet

- Engineering Physics IDocument6 pagesEngineering Physics IHem RajNo ratings yet

- Thermo FormingDocument81 pagesThermo Formingsolidw3d100% (1)

- Measurement of A Thermal Expansion Coefficient For A Metal by Diffraction Patterns From A Narrow SlitDocument5 pagesMeasurement of A Thermal Expansion Coefficient For A Metal by Diffraction Patterns From A Narrow SlitHamza QayyumNo ratings yet

- Early Thermal Cracking in Concrete ExplainedDocument5 pagesEarly Thermal Cracking in Concrete ExplainedAshrafNo ratings yet

- Article Welding DistortionDocument9 pagesArticle Welding DistortionAnonymous l5PQDDkNo ratings yet

Highway Engineering Model QP-16CV7G2

Highway Engineering Model QP-16CV7G2

Uploaded by

Varuna MCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Highway Engineering Model QP-16CV7G2

Highway Engineering Model QP-16CV7G2

Uploaded by

Varuna MCopyright:

Available Formats

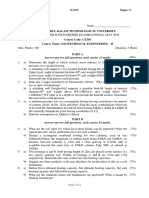

COURSE CODE

USN

RVCOLLEGE OF ENGINEERING®

(Autonomous Institution affiliated to VTU, Belagavi)

VII Semester B. E. Nov/Dec-19Examinations

DEPARTMENTOF CIVIL ENGINEERING

16CV7G2-PAVEMENT ANALYSIS AND DESIGN

Time: 03 Hours Maximum Marks: 100

Instructions to candidates:

1. Answer all questions from Part A. Part A questions should be answered

in first three pages of the answer book only.

2. Answer FIVE full questions from Part B. In Part B question number 2, 7

and 8 are compulsory. Answer any one full question from 3 and 4 & one

full question from 5 and 6

3. Use of IRC 37-2012, IRC 58-2015 and standard data book is allowed.

PART-A

1 1.1 Define vehicle damage factor. 2

1.2 Mention desirable properties of soil as highway material. 2

Determine the total thickness of flexible pavement assuming single

1.3 layer elastic theory using following data. 2

P=4200kg,p=6.0kg/cm2,E=150kg/cm2,∆=0.25cm.

1.4 List the types of layers assumed in three layer elastic theory. 2

1.5 Define radius of relative stiffness. 2

The spacing between the contraction joints of a CC pavement is

1.6 4.2m.Determine the tensile stress developed due to contraction if 2

f=1.1 and W=2400kg/m3

Write the critical combination of stresses during summer mid day for

1.7 2

CC pavements.

1.8 List the factors affecting temperature differential in rigid pavement. 2

The legal axle load limits adopted in India for Single and tandem axle

1.9 2

load is -------

Determine the radius of tyre contact if tyre pressure is 5.6kg/cm2 and

1.10 2

wheel load is 40kN?

PART-B

2 Draw a few typical configuration of axle and wheel of vehicles. Explain

a why tandem axles are preferred to single axles for truck load transfer 8

on to the pavement surface.

Discuss the factors to be considered for the design of flexible

b 8

pavement.

3 Enumerate the various approaches of flexible pavement design.

a 8

Briefly indicate the basis of design in each case.

Plate bearing tests were conducted using 30cm diameter plate on soil

subgrade and over a base course of thickness 45cm.The pressure

b 8

yielded at 0.5cm deflection on the subgrade and base course were

1.25kg/cm2 and 8.0 kg/cm2.

Design the thickness requirement of flexible pavement for a wheel

load of 5100kg with tyre pressure of 7.0 kg/cm2 for an allowable

deflection of 0.5cm using Burmister two layer deflection factor chart.

OR

4 a Discuss three layer elastic theory for design of flexible pavement. 8

Explain briefly the principle of Burmister two layer theory and

b mention the advantages over the single layer theory for the analysis of 8

flexible pavements.

5

Design the pavement for construction of a new flexible pavement as

per IRC 37:2001 with the following data:

(i) Four lane divided carriageway

(ii) Initial traffic in the year of completion of construction = 6000

a CVPD (Sum of both directions) 8

(iii) Traffic growth rate per annum = 7.0 per cent

(iv) Design life = 20 years

(v) Vehicle damage factor = 4.8 (Based on axle load survey)

(vi) CBR of soil-8%

b Write an overview of AASHTO method of flexible pavement design. 8

OR

6

Design the flexible pavement as per IRC 37-2012 for bituminous

pavement with untreated granular layer using following data:

(i) Four lane divided carriageway

(ii) Initial traffic in the year of completion of construction = 6000

CVPD (Sum of both directions)

(iii) Percentage of Single, Tandem, and Tridem axles are 40 per cent,

a 45 per cent and 15 per cent respectively 10

(iv) Traffic growth rate per annum = 7.0 per cent

(v) Design life = 20 years

(vi) Vehicle damage factor = 4.8 (Based on axle load survey)

(vii) CBR of soil below the 500 mm of the subgrade = 2 per cent

(viii) CBR of the 500 mm of the subgrade from borrow pits = 8 per

cent

b Write an overview of airfield method of pavement design 6

7 Design a rigid pavement making use of westergaards wheel load and

warping stress equations at edge region of the slab. The design data

are given below.

Design wheel load, P=7000kg,Pressure,p=7.5kg/cm2

Spacing between longitudinal joints=3.75m

Spacing between contraction joints=4.2m

a Elastic modulus of pavement material, E=3x105 kg/cm2 10

Poisson’s ratio=0.15

Thermal coefficient of CC per deg C, e=1x10-5

Flexural strength of CC=45 kg/cm2

Modulus, K of base course=30kg/cm2

Maximum temperature differential at the location for pavement

thickness values of 22, 24, 26 and 30cm are respectively 14.8, 15.6,

16.2 and 16.80C.

Desired factor of safety with respect to load stress+ warping stress at

edge region is 1.1 to 1.2

b What are the factors affecting warping stress in CC pavements? 6

8 Classify different types of joints in CC pavements and mention

a 8

objective of each.

A cement concrete pavement has a thickness of 26cm and lane width

of 3.5m.Design the tie bars along the longitudinal joints using the

data given below.

Allowable working stress in steel tie bars, SS=1250kg/cm2

b 8

Unit weight of CC,W=2400kg/m3

Maximum value of coefficient of friction=1.2

Allowable tensile stress in deformed tie bar, SS=2000kg/cm2

Allowable bond stress in deformed bars, Sb=24.6kg/cm2

You might also like

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Elective-II: Pavement Analysis & Design: B.E. (Civil Engineering) Eighth Semester (C.B.S.)Document4 pagesElective-II: Pavement Analysis & Design: B.E. (Civil Engineering) Eighth Semester (C.B.S.)Adesh DeshbhratarNo ratings yet

- 2019 Dec. CE467-C - Ktu QbankDocument2 pages2019 Dec. CE467-C - Ktu QbankAthira RaghavanNo ratings yet

- 07a80106 Pavement Analysis and DesignDocument8 pages07a80106 Pavement Analysis and DesignSharanya ThirichinapalliNo ratings yet

- Pa&d JalanDocument9 pagesPa&d JalanIkram MuzhaffarNo ratings yet

- Elective-II: Pavement Analysis & Design: B.E. (Civil Engineering) Eighth Semester (C.B.S.)Document6 pagesElective-II: Pavement Analysis & Design: B.E. (Civil Engineering) Eighth Semester (C.B.S.)Adesh DeshbhratarNo ratings yet

- Term Paper: Course Title: Highway Design and Railways Course Code: CE 1002Document2 pagesTerm Paper: Course Title: Highway Design and Railways Course Code: CE 1002SabbirNo ratings yet

- Highway QBDocument4 pagesHighway QBPrashant PathyanNo ratings yet

- June 2011 NewDocument2 pagesJune 2011 NewSumithra RaviNo ratings yet

- Prelims QP Transportation EngineeringDocument2 pagesPrelims QP Transportation Engineeringce23resch11011No ratings yet

- Paper Solution 2Document22 pagesPaper Solution 2karanmohod383No ratings yet

- Cet433 QPDocument3 pagesCet433 QPREMYA Y.KNo ratings yet

- BRIDGE ENGINEERING S7 CE B.Tech Dec.2018 - Ktu QbankDocument2 pagesBRIDGE ENGINEERING S7 CE B.Tech Dec.2018 - Ktu QbankRavi RaneNo ratings yet

- Dss Paper 1Document2 pagesDss Paper 1hemalNo ratings yet

- Foundation EngineeringDocument12 pagesFoundation EngineeringSindhu Chowhan100% (1)

- Assignment - 1 Pavement Analysis and Design: (Units Covered: 1, 2, 3 & 4)Document2 pagesAssignment - 1 Pavement Analysis and Design: (Units Covered: 1, 2, 3 & 4)Praveen SamarthiNo ratings yet

- B.tech III-II All Branch Regular and Supple Previous Question Papers May 2018Document28 pagesB.tech III-II All Branch Regular and Supple Previous Question Papers May 2018bhanuprakeshNo ratings yet

- Elective - II: Pavement Analysis & Design: B.E. (Civil Engineering) Eighth Semester (C.B.S.)Document27 pagesElective - II: Pavement Analysis & Design: B.E. (Civil Engineering) Eighth Semester (C.B.S.)FalgunNo ratings yet

- Tutorial IIDocument2 pagesTutorial IINmNo ratings yet

- Model Questions - 2019Document9 pagesModel Questions - 2019Aliza SubediNo ratings yet

- Ce 451 Te Ii ('09-'13) PDFDocument36 pagesCe 451 Te Ii ('09-'13) PDFSakibNo ratings yet

- (Max - Marks:75: - TimeDocument2 pages(Max - Marks:75: - TimeGundrathi Narendra GoudNo ratings yet

- Analysis and Structure Design of Pavement May 2019Document1 pageAnalysis and Structure Design of Pavement May 2019mp SinghNo ratings yet

- Geotech3 LS11 PavementsDocument14 pagesGeotech3 LS11 PavementsRudiny FarabyNo ratings yet

- Pavement Design Methods 2 PDFDocument47 pagesPavement Design Methods 2 PDFShekh Muhsen Uddin AhmedNo ratings yet

- Transportation Engineering 1 Question Bank - Mumbai UniversityDocument10 pagesTransportation Engineering 1 Question Bank - Mumbai UniversityMegha Thomas0% (1)

- Design of Flexible Pavement - Irc MethodDocument9 pagesDesign of Flexible Pavement - Irc MethodOSIRIS EvilNo ratings yet

- MCESC 105-2 Bridge Engineering - Set2Document2 pagesMCESC 105-2 Bridge Engineering - Set2Aniket PolNo ratings yet

- Chapter 6-Part-II Introduction To Design of Rigid PavementsDocument22 pagesChapter 6-Part-II Introduction To Design of Rigid Pavementsznabu asefaNo ratings yet

- Last Yr Transportation Question PapersDocument11 pagesLast Yr Transportation Question PapersAditya RanaNo ratings yet

- Answer SheetsDocument4 pagesAnswer Sheetsforplayinggame120No ratings yet

- Sem 5-2Document13 pagesSem 5-2SATYAWANNo ratings yet

- RTU Previous Years PapersDocument41 pagesRTU Previous Years PapersDinesh Kumar0% (1)

- Transporation Engineering Kce 602Document2 pagesTransporation Engineering Kce 602s14alok2100003No ratings yet

- 15801321052Document13 pages15801321052Rakesh PalNo ratings yet

- Guidelines On The-Depth of Overlay On Roads-0Document43 pagesGuidelines On The-Depth of Overlay On Roads-0khourani1No ratings yet

- DesignDocument21 pagesDesignShabib AhmedNo ratings yet

- Ce 443 PDFDocument20 pagesCe 443 PDFAyatullah NawazNo ratings yet

- F G1153 Pages: 2: Answer Any Two Full Questions, Each Carries 15 MarksDocument2 pagesF G1153 Pages: 2: Answer Any Two Full Questions, Each Carries 15 MarksSachin KumarNo ratings yet

- Faculty of Engineering Department of Civil Engineering and SurveyingDocument3 pagesFaculty of Engineering Department of Civil Engineering and SurveyingWataNo ratings yet

- Bridge Deck DesignDocument32 pagesBridge Deck DesignChukwuma Ogbonna100% (2)

- 19021D2022 Analysis and Design of Deck Slabs 22Document21 pages19021D2022 Analysis and Design of Deck Slabs 22AravindNo ratings yet

- Gujarat Technological UniversityDocument5 pagesGujarat Technological Universitychirag mulchandaniNo ratings yet

- QP Internal 1 PD 1Document1 pageQP Internal 1 PD 1Mallikarjun IndiNo ratings yet

- Trial QuestionsDocument7 pagesTrial QuestionsndayambajedNo ratings yet

- 9A01602 Geotechnical Engineering - IDocument7 pages9A01602 Geotechnical Engineering - IsivabharathamurthyNo ratings yet

- Giroud 1981 and Noiray Unpaved Road and DSCN Corrected OCRDocument39 pagesGiroud 1981 and Noiray Unpaved Road and DSCN Corrected OCRRUBEIDYSNo ratings yet

- Ce 8042 Pavement Design Jun 2014Document2 pagesCe 8042 Pavement Design Jun 2014someshthakur0207No ratings yet

- C E1152 Pages: 2: Answer Any Two Full Questions, Each Carries 15 MarksDocument2 pagesC E1152 Pages: 2: Answer Any Two Full Questions, Each Carries 15 MarksirshadNo ratings yet

- Design of Rigid Road Pavement For Ainachiwadi Village in Patan TahsilDocument5 pagesDesign of Rigid Road Pavement For Ainachiwadi Village in Patan TahsilsathishNo ratings yet

- WWW - Manaresults.Co - In: B.Tech IV Year I Semester (R13) Supplementary Examinations June 2017Document2 pagesWWW - Manaresults.Co - In: B.Tech IV Year I Semester (R13) Supplementary Examinations June 2017mgrreddyNo ratings yet

- Bridges - Oct 2014 - 2008Document3 pagesBridges - Oct 2014 - 2008Sahil GandhiNo ratings yet

- 9A01502 Concrete TechnologyDocument4 pages9A01502 Concrete TechnologysietkcivilNo ratings yet

- CET305 GEOTECHNICAL ENGINEERING-II, DECEMBER 2021Document3 pagesCET305 GEOTECHNICAL ENGINEERING-II, DECEMBER 2021basiljoy787No ratings yet

- MACE60035 Principles of Structural Engineering Design 18-19Document12 pagesMACE60035 Principles of Structural Engineering Design 18-19KrisNo ratings yet

- CE - 303 - GE - End Sem-1Document3 pagesCE - 303 - GE - End Sem-1Anudeep KumarNo ratings yet

- Btech Ce 7 Sem Railways Airport and Waterways Rce076 2020Document2 pagesBtech Ce 7 Sem Railways Airport and Waterways Rce076 2020Funlife69 69No ratings yet

- Pavement Engineering Final QuestionDocument8 pagesPavement Engineering Final QuestionAfham AhmadNo ratings yet

- Elective - II: Pavement Analysis & Design: B.E.Eighth Semester (Civil Engineering) (C.B.S.)Document12 pagesElective - II: Pavement Analysis & Design: B.E.Eighth Semester (Civil Engineering) (C.B.S.)Uday PatilNo ratings yet

- Midterm Examination: Subject: Physics 2 (Fluid Mechanics and Thermal Physics) (ID: PH014IU)Document3 pagesMidterm Examination: Subject: Physics 2 (Fluid Mechanics and Thermal Physics) (ID: PH014IU)Anh TrầnNo ratings yet

- Stress Measurement Using Magnetic Barkhausen Noise and Metal MagneticDocument16 pagesStress Measurement Using Magnetic Barkhausen Noise and Metal MagneticSalem GarrabNo ratings yet

- Chloe Kho - Assignment 5 - MTT PracticeDocument5 pagesChloe Kho - Assignment 5 - MTT PracticeanthonyNo ratings yet

- TML Strain Gauge Catalog 2017 PDFDocument100 pagesTML Strain Gauge Catalog 2017 PDFAmitNo ratings yet

- Finite Element Analysis PDFDocument46 pagesFinite Element Analysis PDFrajani_bala15No ratings yet

- Allowable Nozzle LoadsDocument7 pagesAllowable Nozzle LoadsZulkarnain NasrullahNo ratings yet

- Construction and Design of Multi Storey Building by Abhimanyu ParidaDocument38 pagesConstruction and Design of Multi Storey Building by Abhimanyu Paridadriverx47100% (19)

- Low Thermal Expansion Coefficient Fe-Ni-Co Alloys-Plastic Deformation, Alloy Composition and Martensitic Transformation RelationshipsDocument8 pagesLow Thermal Expansion Coefficient Fe-Ni-Co Alloys-Plastic Deformation, Alloy Composition and Martensitic Transformation RelationshipspraveenkhatkaleNo ratings yet

- Mineral Casting As Material For Machine Base Frames of Precision MachinesDocument4 pagesMineral Casting As Material For Machine Base Frames of Precision MachinesrahulkumbharkarNo ratings yet

- 1991 - Tay - Finite Element Analysis of Thermoelastic Coupling in CompositesDocument6 pages1991 - Tay - Finite Element Analysis of Thermoelastic Coupling in CompositesPedro Filipe CunhaNo ratings yet

- Expansion ThermometersDocument28 pagesExpansion ThermometersKevin Nelson LoboNo ratings yet

- Engineering Materials and Metallurgy Notes PDFDocument0 pagesEngineering Materials and Metallurgy Notes PDFSenthilkumar Subbiah50% (2)

- Communicating With Instromet Q-Sonic Ultrasonic Gas FlowmetersDocument13 pagesCommunicating With Instromet Q-Sonic Ultrasonic Gas Flowmeterssyed jeelani ahmedNo ratings yet

- Non-Classical Creep Behavior of Fusion-Cast Alumina RefractoriesDocument8 pagesNon-Classical Creep Behavior of Fusion-Cast Alumina Refractoriesceramics100% (2)

- TG36 Version 3 January 2020Document7 pagesTG36 Version 3 January 2020PoornimaNo ratings yet

- Chapter - 2 Highway Ii PDFDocument74 pagesChapter - 2 Highway Ii PDFdilnessa azanawNo ratings yet

- Biohall Germany Catalouge-2021-22Document154 pagesBiohall Germany Catalouge-2021-22TRUCAL NABLNo ratings yet

- Processing Glass Property Data With Sciglass Information SystemDocument52 pagesProcessing Glass Property Data With Sciglass Information SystembryandownNo ratings yet

- STRESS AND STRAIN-thermal AsDocument7 pagesSTRESS AND STRAIN-thermal AsShaktivell LetchumananNo ratings yet

- National Training of Teachers For Critical Content in Grade 8 ScienceDocument45 pagesNational Training of Teachers For Critical Content in Grade 8 ScienceRaymond Reyes CuribangNo ratings yet

- Habasit Chain Engineering GuideDocument62 pagesHabasit Chain Engineering GuideScripts TeamNo ratings yet

- Thermal Stress Question PDFDocument15 pagesThermal Stress Question PDFrohitNo ratings yet

- Thermal ExpansionDocument12 pagesThermal ExpansionPrincess Xyrill Sena AndengNo ratings yet

- Physics p2 Revision Mr.a.salahDocument44 pagesPhysics p2 Revision Mr.a.salahmohammed mahdyNo ratings yet

- Heat Loss CalculationDocument12 pagesHeat Loss CalculationRajaramNo ratings yet

- Engineering Physics IDocument6 pagesEngineering Physics IHem RajNo ratings yet

- Thermo FormingDocument81 pagesThermo Formingsolidw3d100% (1)

- Measurement of A Thermal Expansion Coefficient For A Metal by Diffraction Patterns From A Narrow SlitDocument5 pagesMeasurement of A Thermal Expansion Coefficient For A Metal by Diffraction Patterns From A Narrow SlitHamza QayyumNo ratings yet

- Early Thermal Cracking in Concrete ExplainedDocument5 pagesEarly Thermal Cracking in Concrete ExplainedAshrafNo ratings yet

- Article Welding DistortionDocument9 pagesArticle Welding DistortionAnonymous l5PQDDkNo ratings yet