Professional Documents

Culture Documents

DOWSIL+Q1-9226+Thermally+Conductive+Adhesive+TDS EN

DOWSIL+Q1-9226+Thermally+Conductive+Adhesive+TDS EN

Uploaded by

MisikEE0 ratings0% found this document useful (0 votes)

8 views3 pagesOriginal Title

DOWSIL+Q1-9226+Thermally+Conductive+Adhesive+TDS_EN (2)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

8 views3 pagesDOWSIL+Q1-9226+Thermally+Conductive+Adhesive+TDS EN

DOWSIL+Q1-9226+Thermally+Conductive+Adhesive+TDS EN

Uploaded by

MisikEECopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

Technical Data Sheet

DOWSIL™ Q1-9226 Thermally Conductive Adhesive

FEATURES & BENEFITS Two-part, semi-flowable thermally conductive adhesive

• Mix ratio: 1 to 1

• Accelerated heat cure APPLICATIONS

• Self priming adhesion to many • DOWSIL™ Q1-9226 Thermally Conductive Adhesive typical applications

substrates include bonding organic and ceramic substrates to heat sinks for control

• Long pot life for ease of use modules in automotive applications

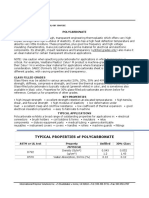

COMPOSITION TYPICAL PROPERTIES

• Thermally conductive filler Specification Writers: These values are not intended for use in preparing

specifications.

• Two part silicone adhesive

Property Unit Result

One Part or Two Part Two

Color Gray

Viscosity (Part A) cP 48,000

Pa-sec 48

mPa-sec 48,000

Viscosity (Part B) cP 43,000

Pa-sec 43

mPa-sec 43,000

Viscosity (Mixed) cP 59,000

Pa-sec 59

mPa-sec 59,000

Specific Gravity (Cured) 2.14

Durometer Shore A 67

Tensile Strength psi 600

MPa 4.15

kg/cm2 42

Elongation % 124

Unprimed Adhesion - Lap Shear (Al) psi 375

MPa 2.6

N/cm2 260

Dielectric Strength volts/mil 630

kV/mm 25

Thermal Conductivity (hot disk) btu/hr-ft-°F 0.46

W/mK 0.8

DESCRIPTION are continually designed to deliver

The heat-cure, thermally conductive higher performance. Especially in the

adhesives produce no by-products in area of consumer devices, there is also

the cure process, allowing their use in a continual trend towards smaller,

deep section and complete more compact designs. In combination

confinement. These adhesives will these factors typically mean that more

develop good, primerless adhesion to a heat is generated in the device.

variety of common substrates Thermal management of PCB system

including metals, ceramics, epoxy assemblies is a primary concern of

laminate boards, reactive materials and design engineers. A cooler device

filled plastics. PCB system assemblies allows for more efficient operation and

better

reliability over the life of the device. PROCESSING/CURING off after application. After

As such, thermally conductive Addition-cure silicones should be application, primers should be

compounds play an integral role cured at 100°C (212°F) or above. thoroughly air dried prior to

here. Thermally conductive materials The cure rate is rapidly accelerated application of the silicone elastomer.

act as a thermal “bridge” to remove with heat (see heat-cure times in Alternatively, use a low-viscosity

heat from a heat source (device) to Typical Properties table). For thicker primerless adhesive to pot your

the ambient via a heat transfer media sections, a pre-cure at 70°C (158°F) components. Poor adhesion can be

(i.e. heat sink). These materials have may be necessary to reduce voids in experienced on plastic or rubber

properties such as low thermal the elastomer. Length of pre-cure substrates that are highly plasticized,

resistance, high thermal will depend on section thickness and since the mobile plasticizers act as

conductivity, and can achieve thin confinement of adhesive. It is release agents. Small-scale

Bond Line Thicknesses (BLTs) recommended that 30 minutes at laboratory evaluation of all

which can help to improve the 70°C (158°F) be used as a starting substrates is recommended before

transfer of heat away from the point for determining necessary pre- production trials are made. In

device. cure time. Addition-curing materials general, increasing the cure

contain all the ingredients needed for temperature and/or cure time will

APPLICATION METHODS cure with no by-products from the improve the ultimate adhesion.

• Automated or manual dispensing cure mechanism. Deep-section or

confined cures are possible. Cure USEFUL TEMPERATURE

SUBSTRATE TESTING progresses evenly throughout the RANGES

To ensure maximum bond strength material. These products generally For most uses, silicone adhesives

for adhesives on a particular have long working times. should be operational over a

substrate, 100 percent cohesive temperature range of -45 to 200°C

failure of the adhesive in a lap shear POT LIFE AND CURE (-49 to 392°F) for long periods of

or similar adhesive strength test is RATE time. However, at both the low and

needed. This ensures compatibility Cure reaction begins with the mixing high temperature ends of the

of the adhesive with the substrate process. Initially, cure is evidenced spectrum, behavior of the materials

being considered. Also, this test can by a gradual increase in viscosity, and performance in particular

be used to determine minimum cure followed by gelation and conversion applications can become more

time or to detect the presence of to its final state. Pot life is defined as complex and require additional

surface contaminants such as mold the time required for viscosity to considerations. For low-temperature

release agents, oils, greases and double after Parts A and B (base and performance, thermal cycling to

oxide films. curing agent) are mixed. conditions such as -55°C (-67°F)

may be possible for most products,

MIXING AND DE-AIRING ADHESION but performance should be verified

Upon standing, some filler may for your parts or assemblies. Factors

Dow silicone adhesives are specially

settle to the bottom of the liquid after that may influence performance are

formulated to provide unprimed

several weeks. To ensure a uniform configuration and stress sensitivity

adhesion to many reactive metals,

product mix, the material in each of components, cooling rates and

ceramics and glass, as well as to

container should be thoroughly hold times, and prior temperature

selected laminates, resins and

mixed prior to use. Two-part history. At the high-temperature end,

plastics. However, good adhesion

materials should be mixed in the the durability of the cured silicone

cannot be expected on non-reactive

proper ratio either by weight or elastomer is time and temperature

metal substrates or non-reactive

dependent. As expected, the higher

volume. The presence of light- plastic surfaces such as Teflon®,

colored streaks or marbling indicates polyethylene or polypropylene. the temperature, the shorter the time

inadequate mixing. Automated Special surface treatments such as the material will remain useable.

airless dispense equipment can be chemical etching or plasma

used to reduce or avoid the need to treatment can sometimes provide a SOLVENT EXPOSURE

de-air. If de-airing is required to reactive surface and promote In general, the product is resistance

reduce voids in the cured elastomer, adhesion to these types of substrates. to minimal or intermittent solvent

consider a vacuum de-air schedule of Dow primers can be used to increase exposure, however best practice is to

> 8 inches Hg (or a residual pressure the chemical activity on difficult avoid solvent exposure altogether.

of 10–0 mm of Hg) for 10 minutes or substrates. For best results, the

until bubbling subsides. primer should be applied in a very

thin, uniform coating and then wiped

UNRESTRICTED – May be shared with anyone

®

™The DOW Diamond and DOWSIL are trademarks of The Dow Chemical Company

Teflon is a registered trademarks of E. I. du Pont de Nemours and Company or its affiliates.

DOWSIL™ Q1-9226 Thermally Conductive Adhesive

© 2017 The Dow Chemical Company. All rights reserved. Form No. 11-3059-01 A

2

USABLE LIFE AND LIMITED WARRANTY To discuss how we could work

STORAGE INFORMATION – PLEASE together to meet your specific needs,

The product should be stored in its go to www.consumer.dow.com for a

READ CAREFULLY contact close to your location. Dow

original packaging with the cover The information contained herein is

tightly attached to avoid any has customer service teams, science

offered in good faith and is believed to and technology centers, application

contamination. Store in accordance be accurate. However, because

with any special instructions listed support teams, sales offices, and

conditions and methods of use of our manufacturing sites around the globe.

on the product label. The product products are beyond our control, this

should be used by the indicated Exp. information should not be used in

Date found on the label. www.consumer.dow.com

substitution for customer’s tests to

ensure that our products are safe,

HANDLING effective, and fully satisfactory for the

PRECAUTIONS intended end use. Suggestions of use

PRODUCT SAFETY shall not be taken as inducements to

INFORMATION REQUIRED infringe any patent.

FOR SAFE USE IS NOT

INCLUDED IN THIS Dow’s sole warranty is that our

DOCUMENT. BEFORE products will meet the sales

HANDLING, READ PRODUCT specifications in effect at the time of

AND SAFETY DATA SHEETS shipment.

AND CONTAINER LABELS

FOR SAFE USE, PHYSICAL Your exclusive remedy for breach of

AND HEALTH HAZARD such warranty is limited to refund of

INFORMATION. THE SAFETY purchase price or replacement of any

DATA SHEET IS AVAILABLE product shown to be other than as

ON THE DOW WEBSITE AT warranted.

WWW.CONSUMER.DOW.COM,

OR FROM YOUR DOW SALES TO THE FULLEST EXTENT

APPLICATION ENGINEER, OR PERMITTED BY APPLICABLE

DISTRIBUTOR, OR BY LAW, DOW SPECIFICALLY

CALLING DOW CUSTOMER DISCLAIMS ANY OTHER

SERVICE. EXPRESS OR IMPLIED

WARRANTY OF FITNESS FOR A

LIMITATIONS PARTICULAR PURPOSE OR

This product is neither tested nor MERCHANTABILITY.

represented as suitable for medical or

pharmaceutical uses. DOW DISCLAIMS LIABILITY

FOR ANY INCIDENTAL OR

CONSEQUENTIAL DAMAGES.

HEALTH AND

ENVIRONMENTAL HOW CAN WE HELP YOU

INFORMATION TODAY?

To support customers in their product

Tell us about your performance,

safety needs, Dow has an extensive

design, and manufacturing challenges.

Product Stewardship organization and

Let us put our silicon-based materials

a team of product safety and

expertise, application knowledge, and

regulatory compliance specialists

processing experience to work for

available in each area.

you.

For further information, please see our

For more information about our

website, www.consumer.dow.com or

materials and capabilities, visit

consult your local Dow representative.

www.consumer.dow.com.

®

Trademark of The Dow Chemical Company Form No. 11-3059-01 A

You might also like

- Handrail CalculationDocument8 pagesHandrail Calculationsuresh_viki100% (1)

- SAEP-387 Design of Thermoplastic Tight Fit GroovedDocument23 pagesSAEP-387 Design of Thermoplastic Tight Fit GroovedFlorante Nobleza100% (4)

- Romualdi 1964Document16 pagesRomualdi 1964Isabela LauferNo ratings yet

- MTC-2 - Service STRCDocument1 pageMTC-2 - Service STRCHema NandhNo ratings yet

- PB Electr Conductive Adhesives e PDFDocument4 pagesPB Electr Conductive Adhesives e PDFMhand OughanemNo ratings yet

- Propagation of Sound PDFDocument16 pagesPropagation of Sound PDFHASAN SAIFNo ratings yet

- Elastoseal EPDM Tanking SystemDocument8 pagesElastoseal EPDM Tanking SystemStephen100% (1)

- 道康宁Dow DOWSIL™ SE 4430白色 导热硅脂 导热胶-附TDS下载Document3 pages道康宁Dow DOWSIL™ SE 4430白色 导热硅脂 导热胶-附TDS下载walter karl Nuñez AngoNo ratings yet

- SYLGARD™ 184 Silicone Elastomer: Features & Benefits ApplicationsDocument4 pagesSYLGARD™ 184 Silicone Elastomer: Features & Benefits ApplicationsZhan FangNo ratings yet

- DOWSIL™ 744 RTV Adhesive Sealant: Features & BenefitsDocument4 pagesDOWSIL™ 744 RTV Adhesive Sealant: Features & BenefitsSami LAHMIDINo ratings yet

- 11 3367 01 Dowsil TC 2035 Adhesive TdsDocument5 pages11 3367 01 Dowsil TC 2035 Adhesive TdsClausio MeloNo ratings yet

- Compoundssel GuideDocument2 pagesCompoundssel GuideAlexandreNo ratings yet

- Crystic PD9359 EN Dec17Document2 pagesCrystic PD9359 EN Dec17MoutikNo ratings yet

- Evonik-Amicure PACMDocument5 pagesEvonik-Amicure PACMuzzy2No ratings yet

- LOCTITE 315 en - GLDocument2 pagesLOCTITE 315 en - GLinigo.bretonNo ratings yet

- Nylon 6.6 Data SheetDocument2 pagesNylon 6.6 Data SheetAshish Mohurle100% (2)

- TDS Loctite Nordbak Wearing - CompoundDocument3 pagesTDS Loctite Nordbak Wearing - CompoundSadamNo ratings yet

- Tecanat™ Tecanat™ Gf20 (Polycarbonate and Glass Filled Polycarbonate)Document1 pageTecanat™ Tecanat™ Gf20 (Polycarbonate and Glass Filled Polycarbonate)David Matthew Kurniawan BEngNo ratings yet

- 3M™ Scotchkote™ Fusion-Bonded Epoxy Coating XC-6171Document2 pages3M™ Scotchkote™ Fusion-Bonded Epoxy Coating XC-6171UEL IndNo ratings yet

- TALLER PRESOSTATO 2 InglesDocument2 pagesTALLER PRESOSTATO 2 Inglesedisson garzonNo ratings yet

- Bergquist Sil Pad TSP 1600s-EnDocument2 pagesBergquist Sil Pad TSP 1600s-EnKim WayneNo ratings yet

- Ensinger Tecapeek® CF30 Polyetheretherketone, 30% Carbon Reinforced (PEEK)Document2 pagesEnsinger Tecapeek® CF30 Polyetheretherketone, 30% Carbon Reinforced (PEEK)Arthur EmidioNo ratings yet

- AHS 187 - Air Handling Systems Product Selector GuideDocument8 pagesAHS 187 - Air Handling Systems Product Selector GuideKhang NguyenNo ratings yet

- Electronics: Dow CorningDocument3 pagesElectronics: Dow CorningWandyy GonçalvesNo ratings yet

- DOWSIL™ 3-1944 RTV Coating: Features & BenefitsDocument4 pagesDOWSIL™ 3-1944 RTV Coating: Features & Benefitsquang trinhNo ratings yet

- CP 741-enUS-ISODocument1 pageCP 741-enUS-ISOjogo 1No ratings yet

- Loctite Nordbak Wear Resistant Putty: Product Description MixedDocument3 pagesLoctite Nordbak Wear Resistant Putty: Product Description MixedFurqan ShabbirNo ratings yet

- Loctite Stycast 2651MM Cat 9 TDS 1Document2 pagesLoctite Stycast 2651MM Cat 9 TDS 1steffan.henryNo ratings yet

- Apc-2 Peek 031912-01Document6 pagesApc-2 Peek 031912-01Angel LagrañaNo ratings yet

- Acetal Natural Data SheetDocument1 pageAcetal Natural Data SheetvijayNo ratings yet

- Arlon 38NDocument4 pagesArlon 38NRavindrakumar ParvathiniNo ratings yet

- 11 3046 01 Dowsil 3 1953 Conformal CoatingDocument3 pages11 3046 01 Dowsil 3 1953 Conformal CoatingmarciobispoalmeidaNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonatepuvitta sudeshilaNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateROHIT SHARMANo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateAdnan KhanNo ratings yet

- 253 PDS AiDocument4 pages253 PDS AiAchraf BoudayaNo ratings yet

- TecamidDocument2 pagesTecamidTejas HuddarNo ratings yet

- N42EH Grade Neodymium Magnets DataDocument1 pageN42EH Grade Neodymium Magnets DataSteve HsuNo ratings yet

- N42EH Grade Neodymium Magnets DataDocument1 pageN42EH Grade Neodymium Magnets DataSteve HsuNo ratings yet

- Material Data Sheet: HDPE NaturalDocument2 pagesMaterial Data Sheet: HDPE NaturalSyed MoinNo ratings yet

- HOMEY 8800 Two Parts Structural Sealant: Technical Data SheetDocument2 pagesHOMEY 8800 Two Parts Structural Sealant: Technical Data SheetKelly WuNo ratings yet

- PPS120 Rev10 0309 PDFDocument2 pagesPPS120 Rev10 0309 PDFArfanAliNo ratings yet

- Arkema PEKK Kkepstan 8001 TDSDocument3 pagesArkema PEKK Kkepstan 8001 TDSstartionlilNo ratings yet

- Pro Mastic Ste 87Document4 pagesPro Mastic Ste 87ahmedyahea181No ratings yet

- PBT GF30 - Vampter 3026 V0 DFDocument1 pagePBT GF30 - Vampter 3026 V0 DFarmandoNo ratings yet

- 226NDocument2 pages226NUmaibalanNo ratings yet

- Technical Information: Coextruded Biaxially Oriented Polypropylene FilmDocument1 pageTechnical Information: Coextruded Biaxially Oriented Polypropylene FilmAlzena badzlinNo ratings yet

- Atlac-580 001610Document2 pagesAtlac-580 001610flavio fiumiNo ratings yet

- Loctite 380 Black - Ficha TecnicaDocument3 pagesLoctite 380 Black - Ficha TecnicamonsepackNo ratings yet

- DOWSIL™ 340 Heat Sink Compound: Features & Benefits ApplicationsDocument2 pagesDOWSIL™ 340 Heat Sink Compound: Features & Benefits ApplicationsMauricio Fernandez GuevaraNo ratings yet

- Super Shield Nickel Epoxy Conductive Coating 841ER Technical Data SheetDocument8 pagesSuper Shield Nickel Epoxy Conductive Coating 841ER Technical Data Sheetsrikanth NakkaNo ratings yet

- Chersterton Arc 982 PDFDocument2 pagesChersterton Arc 982 PDFMohamed Nouzer100% (1)

- TDS Conbextra GP2 BFLDocument4 pagesTDS Conbextra GP2 BFLsabbirNo ratings yet

- CuClad Laminates Data SheetDocument4 pagesCuClad Laminates Data SheetDenis CarlosNo ratings yet

- DuraplateDocument4 pagesDuraplatelovaldes62No ratings yet

- Polypropylene CP 741: Sub-GroupDocument1 pagePolypropylene CP 741: Sub-GroupAnonymous m4MucCNo ratings yet

- H6105JUDocument1 pageH6105JUhunghiepvanNo ratings yet

- Technical Data: Plastic Steel Putty (A)Document4 pagesTechnical Data: Plastic Steel Putty (A)francisNo ratings yet

- 11 3508 01 Dowsil Ei 1184 Optical EncapsulantDocument5 pages11 3508 01 Dowsil Ei 1184 Optical Encapsulantyusuf KhanNo ratings yet

- TDS Hips 2551Document3 pagesTDS Hips 2551jokotrianto13No ratings yet

- TECAPET® PET and 1400® PET (Polyethylene Terephthalate) : Property ASTM Test Method Units Tecapet® PET 1400HI® PETDocument2 pagesTECAPET® PET and 1400® PET (Polyethylene Terephthalate) : Property ASTM Test Method Units Tecapet® PET 1400HI® PETFeby Shyntia AfirantiNo ratings yet

- 838 Silicone Adhesive SealantDocument3 pages838 Silicone Adhesive SealantMario Vargas VegaNo ratings yet

- Tesnit Ba 202 Donit1Document2 pagesTesnit Ba 202 Donit1steeluisNo ratings yet

- Loctite PC 7222: Technical Data SheetDocument3 pagesLoctite PC 7222: Technical Data Sheetfrancisca ferrerNo ratings yet

- 4.0 States of MatterDocument13 pages4.0 States of MatterTafadzwa MachongweNo ratings yet

- Shah Reinforced Concrete PropertiesDocument12 pagesShah Reinforced Concrete PropertiesMaria Fernanda LimaNo ratings yet

- Assignment 1Document5 pagesAssignment 1Johnny LopezNo ratings yet

- Rb5-Tbi Br3 Double & Tb1 Br3 SingleDocument6 pagesRb5-Tbi Br3 Double & Tb1 Br3 SinglekalpanaadhiNo ratings yet

- Aerosol Filtration by Fibrous Filters A StatisticaDocument7 pagesAerosol Filtration by Fibrous Filters A StatisticaВалерия КорнееваNo ratings yet

- Dirac Lecture PDFDocument6 pagesDirac Lecture PDFPuskesmas RawaloNo ratings yet

- AA283 Aircraft and Rocket Propulsion CH 09 BJ CantwellDocument49 pagesAA283 Aircraft and Rocket Propulsion CH 09 BJ CantwellSri VatsanNo ratings yet

- Chap04 A PDFDocument42 pagesChap04 A PDFelisNo ratings yet

- A 193 - A 193M - 04 Qte5my9bmtkztqDocument12 pagesA 193 - A 193M - 04 Qte5my9bmtkztqfekihassan100% (1)

- Astm A276Document7 pagesAstm A276Orlando Rojas100% (1)

- CV 303 Hydraulic Engineering - I: Course ContentsDocument2 pagesCV 303 Hydraulic Engineering - I: Course ContentsSushant WaghmareNo ratings yet

- Welding of Ferritic CreepDocument3 pagesWelding of Ferritic CreepMuhammed SulfeekNo ratings yet

- Knöll, L., W. Vogel, and D-G. Welsch. "Resonators in Quantum Optics: A First-Principles Approach." Physical Review A 43.1 (1991) : 543.Document11 pagesKnöll, L., W. Vogel, and D-G. Welsch. "Resonators in Quantum Optics: A First-Principles Approach." Physical Review A 43.1 (1991) : 543.Lucas RibeiroNo ratings yet

- 1 s2.0 S0925838822043845 MainDocument10 pages1 s2.0 S0925838822043845 MainLuz Idalia Ibarra RodriguezNo ratings yet

- Nanophysics NOTES 2017-2018Document173 pagesNanophysics NOTES 2017-2018joeyjojoNo ratings yet

- Technical Data Sheet Linen PhenolicDocument1 pageTechnical Data Sheet Linen PhenolicKissa DolautaNo ratings yet

- SCCL SyllabusDocument1 pageSCCL SyllabusSainathNo ratings yet

- Chemistry: S.No Name of The Chapter Weightage Marks Vsaq SAQ LAQDocument8 pagesChemistry: S.No Name of The Chapter Weightage Marks Vsaq SAQ LAQMoscowNo ratings yet

- 10MMDocument1 page10MMStructures ProductionNo ratings yet

- Introduction To Sand ControlDocument36 pagesIntroduction To Sand ControlmaharabdNo ratings yet

- Analysis of Kinematic Viscosity For Liquids by Varying TemperatureDocument5 pagesAnalysis of Kinematic Viscosity For Liquids by Varying TemperatureFionikaNo ratings yet

- Ffe 13069Document9 pagesFfe 13069Morteza AtaeiNo ratings yet

- Jima - RT RC 05Document2 pagesJima - RT RC 05buicocle90No ratings yet

- Investigating The Creep Behaviour of Polypropylene: Nir Bahadur MagarDocument44 pagesInvestigating The Creep Behaviour of Polypropylene: Nir Bahadur MagarMonica BoccaNo ratings yet