Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

11 viewsList of Equipments-Workshop ME PT AE-1

List of Equipments-Workshop ME PT AE-1

Uploaded by

uday chavanThe document provides a list of essential and desirable equipment for the Workshop Technology course with a focus on the Carpentry, Fitting, Smithy, Welding, Sheet Metal, Machine, and Foundry shops. It includes specifications for various tools, machines, and workbenches required for each shop. Some examples listed are a circular saw, wood planer, drilling machine, and hand tools for the Carpentry shop, a marking table, surface plate, measuring instruments and tap/die sets for the Fitting shop. Minimum quantities of equipment are specified.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Grade 10 Terms and DefinitionsDocument11 pagesGrade 10 Terms and Definitionskhotso86% (7)

- Maho MH 600 e enDocument8 pagesMaho MH 600 e enDragan PanovicNo ratings yet

- Elce4012 4Document8 pagesElce4012 4ameerNo ratings yet

- WS 54 Tool and Cutter Grinding Machine: Productivity Realised at Tool Cutting EdgeDocument4 pagesWS 54 Tool and Cutter Grinding Machine: Productivity Realised at Tool Cutting Edgejacksonholland8335No ratings yet

- EY Introduction To Financial ModellingDocument8 pagesEY Introduction To Financial ModellingPrashantKNo ratings yet

- Prepare Vegetable and Seafood DishesDocument120 pagesPrepare Vegetable and Seafood DishesJoeven Pantaleon67% (3)

- Purchase of Wood Working ToolsEquipment For GTVCB Balach ChitralDocument3 pagesPurchase of Wood Working ToolsEquipment For GTVCB Balach ChitralMuhammad AsgharNo ratings yet

- Sheet Metal Bending MachineDocument2 pagesSheet Metal Bending MachineAnup ChauhanNo ratings yet

- At 300Document11 pagesAt 300mne79054No ratings yet

- Annex I Minimum Equipment and Tools RequirementsDocument4 pagesAnnex I Minimum Equipment and Tools RequirementsCharlane GenalocNo ratings yet

- MR - Samaksh Jhalani Machinery-FinalDocument45 pagesMR - Samaksh Jhalani Machinery-FinalSamaksh JhalaniNo ratings yet

- S.no Item Name Specification QuantityDocument2 pagesS.no Item Name Specification QuantityAbayNo ratings yet

- Triumph SuperDocument1 pageTriumph SupernsimbakuntondiNo ratings yet

- Best Price of SMC650 Machining Center With Fanuc ControlDocument7 pagesBest Price of SMC650 Machining Center With Fanuc ControlRenato Cuadros MahaneyNo ratings yet

- Tool Room Machine ListDocument12 pagesTool Room Machine ListsachinNo ratings yet

- OMNI 6090 CNC Router QuotationDocument4 pagesOMNI 6090 CNC Router QuotationJosé PeNo ratings yet

- MR - Samaksh Jhalani-7-Ply-150-1800mm Automatic Corrugated Cardboard Production LineDocument43 pagesMR - Samaksh Jhalani-7-Ply-150-1800mm Automatic Corrugated Cardboard Production LineSamaksh JhalaniNo ratings yet

- ZX32GDocument29 pagesZX32Gkassa mamoNo ratings yet

- Mill Drill Bench Machine MD 20DASH25Document26 pagesMill Drill Bench Machine MD 20DASH25kassa mamoNo ratings yet

- Machineries SpecificationDocument12 pagesMachineries SpecificationRavi ChoudharyNo ratings yet

- Specification of CNC EDM Die Sinking EDM540Document4 pagesSpecification of CNC EDM Die Sinking EDM540kashifhabib6745No ratings yet

- Multifunctional Lathe Machine CQ6232GZDocument4 pagesMultifunctional Lathe Machine CQ6232GZAbdelbasset ZaraiNo ratings yet

- Dep IpeDocument16 pagesDep Ipebju.monitoring.controlNo ratings yet

- Company Products Catalogue - Machine Rev 3Document8 pagesCompany Products Catalogue - Machine Rev 3Bayumi Tirta JayaNo ratings yet

- Shaper Machine BC6066 ManualDocument36 pagesShaper Machine BC6066 Manualsecondharbour ChinaNo ratings yet

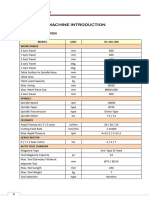

- Chapter 2 Machine IntroductionDocument4 pagesChapter 2 Machine IntroductionTech CIMNo ratings yet

- Specification L200 L400Document2 pagesSpecification L200 L400Ujwal PatilNo ratings yet

- CW61160Bx10000mm Horizontal Lathe Machine: Hebei Yawo Machinery Manufacturing Co., LTDDocument3 pagesCW61160Bx10000mm Horizontal Lathe Machine: Hebei Yawo Machinery Manufacturing Co., LTDaz marine servicesNo ratings yet

- Annexure III A of TCDocument20 pagesAnnexure III A of TCkishorNo ratings yet

- Surplex Auction 3564Document11 pagesSurplex Auction 3564SantoshNo ratings yet

- SPM-Blade Grinding MachineDocument5 pagesSPM-Blade Grinding MachineZarana BhattNo ratings yet

- ZN5050ADocument44 pagesZN5050ATHiz OCtavvNo ratings yet

- Details Spec 2Document14 pagesDetails Spec 2debsaikat00No ratings yet

- PRM Bench Mill Drill ManualDocument56 pagesPRM Bench Mill Drill ManualMatthew MattesonNo ratings yet

- Quote of FLASH FL400-Z20Q121207Document2 pagesQuote of FLASH FL400-Z20Q121207Mohammed SakhibNo ratings yet

- AS200 200L SeriesDocument24 pagesAS200 200L Seriescoronaqc100% (1)

- 1 - Proforma Invoice - HRAF20220606Document9 pages1 - Proforma Invoice - HRAF20220606GemmeNo ratings yet

- CT300 3 in 1 Multifunctional MachineDocument13 pagesCT300 3 in 1 Multifunctional MachineJorge Luis Morales ValenzuelaNo ratings yet

- GrinderDocument5 pagesGrinderfikahNo ratings yet

- Specification Agriculture ImplimentsDocument25 pagesSpecification Agriculture ImplimentsRavi MirzaNo ratings yet

- QUOTATIONS - 6 ROLLER 1 DDocument4 pagesQUOTATIONS - 6 ROLLER 1 DDrPawan BhardwajNo ratings yet

- Medium DutyDocument4 pagesMedium DutymateenNo ratings yet

- Offer (Plasma+fiber Laser +robot+laser Welding)Document13 pagesOffer (Plasma+fiber Laser +robot+laser Welding)jesus hurtadoNo ratings yet

- Drilling and Milling Machine WMD25VB From SYNTOP CNCDocument2 pagesDrilling and Milling Machine WMD25VB From SYNTOP CNCВладимир УсковNo ratings yet

- Updated CNB Brochure 2022Document14 pagesUpdated CNB Brochure 2022Abigail Myrra Magpayo DiazNo ratings yet

- Milling MachinesDocument27 pagesMilling MachinesAd Man GeTigNo ratings yet

- Needle Punching Production LineDocument13 pagesNeedle Punching Production LinematoportelaNo ratings yet

- List of Laboratory Equipments: Department of Mechanical Engineering 2014Document8 pagesList of Laboratory Equipments: Department of Mechanical Engineering 2014cparamesNo ratings yet

- Manufacturing LabDocument3 pagesManufacturing LabWaqas HassanNo ratings yet

- Tool Various: Professional Machine Manufacturers, Experts in Customized Production ofDocument3 pagesTool Various: Professional Machine Manufacturers, Experts in Customized Production ofHervis CyrilleNo ratings yet

- Quote of 1-3 Inches Nail Making Line - Huarui, AngelaDocument9 pagesQuote of 1-3 Inches Nail Making Line - Huarui, AngelazakNo ratings yet

- Rack Milling Machine RMDocument4 pagesRack Milling Machine RMAries N. RamadhanyNo ratings yet

- Milling Machine ToolDocument42 pagesMilling Machine ToolSai SashankNo ratings yet

- Drillsprint 310316aDocument4 pagesDrillsprint 310316amateenNo ratings yet

- Brochure Truong Thinh - enDocument18 pagesBrochure Truong Thinh - envinhquangbk10No ratings yet

- CNC Lathe List: Item CK0640 CK0660 CK0680Document10 pagesCNC Lathe List: Item CK0640 CK0660 CK0680MUHAMMAD NAUMANNo ratings yet

- Baxter 280M (08012017)Document2 pagesBaxter 280M (08012017)pc100xohmNo ratings yet

- Metal Sheet and Pipe Laser Cutting Machine Manufacturers - GoldenLaserDocument9 pagesMetal Sheet and Pipe Laser Cutting Machine Manufacturers - GoldenLaserJUAN DAVID GOMEZ OSORIONo ratings yet

- Quotation of Edge Banding Machines - Expert KitDocument3 pagesQuotation of Edge Banding Machines - Expert KitMary FelicianoNo ratings yet

- Specification-9D+WF800Document3 pagesSpecification-9D+WF800Chitranjan KumarNo ratings yet

- Suzhou Hanxin Machinery CatalogueDocument19 pagesSuzhou Hanxin Machinery CatalogueKhaled BOUALINo ratings yet

- Capture D'écran . 2023-08-08 À 14.23.27Document8 pagesCapture D'écran . 2023-08-08 À 14.23.27DIBRICONo ratings yet

- WIRGEN - 200iDocument8 pagesWIRGEN - 200iUrsut AngyNo ratings yet

- Proforma - PDocument2 pagesProforma - Puday chavanNo ratings yet

- Iajicte 2022 8 1 12Document11 pagesIajicte 2022 8 1 12uday chavanNo ratings yet

- Explicit Dynamics Crash Analysis of CarDocument8 pagesExplicit Dynamics Crash Analysis of Caruday chavanNo ratings yet

- Equipment List For Computer Group (CO, CM, IF, CD, IF)Document17 pagesEquipment List For Computer Group (CO, CM, IF, CD, IF)uday chavanNo ratings yet

- Report Guidelines FinalDocument22 pagesReport Guidelines Finaluday chavanNo ratings yet

- Intuitive Surgical JP Morgan PresentationDocument25 pagesIntuitive Surgical JP Morgan PresentationmedtechyNo ratings yet

- Exhibitors ListDocument4 pagesExhibitors ListGift N PrintNo ratings yet

- Guided Tutorial For Pentaho Data Integration Using MysqlDocument39 pagesGuided Tutorial For Pentaho Data Integration Using MysqlScorpNo ratings yet

- Homemade RicottaDocument3 pagesHomemade RicottaJules PaulkNo ratings yet

- A System View To Urban Planning: An IntroductionDocument34 pagesA System View To Urban Planning: An IntroductionAzad RazaNo ratings yet

- Hepatic Critical Care: EditorsDocument312 pagesHepatic Critical Care: EditorsAhmed HegazyNo ratings yet

- Electricity Bill Receipt (2674774111)Document1 pageElectricity Bill Receipt (2674774111)Ritesh KatariyaNo ratings yet

- RMT 11100Document63 pagesRMT 11100halle cNo ratings yet

- PN Initial Exam Form 2015 160629 5774473c03485Document2 pagesPN Initial Exam Form 2015 160629 5774473c03485Syam ChandrasekharanNo ratings yet

- 10 Question Related To InheritanceDocument4 pages10 Question Related To InheritancePrashant kumarNo ratings yet

- The Ancient Greece and RomeDocument2 pagesThe Ancient Greece and RomeQuenee MagbuhospvgmaNo ratings yet

- Adce Parameter of 2gDocument4 pagesAdce Parameter of 2gAmit DevNo ratings yet

- No Load CurrentDocument23 pagesNo Load CurrentRaja Desingu100% (1)

- Senzori de CurgereDocument128 pagesSenzori de CurgerebuturcasNo ratings yet

- DR SW Config Matrix - 6K0323 - January 2016Document62 pagesDR SW Config Matrix - 6K0323 - January 2016Mastin SneadNo ratings yet

- CRMDocument9 pagesCRMJITESH KHURANANo ratings yet

- COA RulesDocument22 pagesCOA RulesNoraiza Mae Keith TalbinNo ratings yet

- Mahesh Shinde Case 1Document3 pagesMahesh Shinde Case 1mahesh shindeNo ratings yet

- Are You Fit For ISO 16890?: Thomas SchrothDocument16 pagesAre You Fit For ISO 16890?: Thomas SchrothUdhayakumar Venkataraman100% (1)

- Lesson 7 Apeco 1sDocument5 pagesLesson 7 Apeco 1sCHRISTIAN JUNTONGNo ratings yet

- Material Safety Data SheetDocument4 pagesMaterial Safety Data SheetIvani SoaresNo ratings yet

- Daily Task of Disbursing OfficerDocument2 pagesDaily Task of Disbursing OfficerEijneb OptionalNo ratings yet

- Analytical1 100Document27 pagesAnalytical1 100kaushik4208No ratings yet

- Sanitary Permit (Front)Document1 pageSanitary Permit (Front)Darwin CustodioNo ratings yet

- Combined Stress Caclulation - PveliteDocument2 pagesCombined Stress Caclulation - Pveliterajeshvyas_510% (1)

- Written By: Unknown: Yardsticks To Value Stocks in Different SectorsDocument5 pagesWritten By: Unknown: Yardsticks To Value Stocks in Different SectorsKrs_Rs_4407No ratings yet

List of Equipments-Workshop ME PT AE-1

List of Equipments-Workshop ME PT AE-1

Uploaded by

uday chavan0 ratings0% found this document useful (0 votes)

11 views28 pagesThe document provides a list of essential and desirable equipment for the Workshop Technology course with a focus on the Carpentry, Fitting, Smithy, Welding, Sheet Metal, Machine, and Foundry shops. It includes specifications for various tools, machines, and workbenches required for each shop. Some examples listed are a circular saw, wood planer, drilling machine, and hand tools for the Carpentry shop, a marking table, surface plate, measuring instruments and tap/die sets for the Fitting shop. Minimum quantities of equipment are specified.

Original Description:

Original Title

List_of_Equipments-Workshop_ME_PT_AE-1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides a list of essential and desirable equipment for the Workshop Technology course with a focus on the Carpentry, Fitting, Smithy, Welding, Sheet Metal, Machine, and Foundry shops. It includes specifications for various tools, machines, and workbenches required for each shop. Some examples listed are a circular saw, wood planer, drilling machine, and hand tools for the Carpentry shop, a marking table, surface plate, measuring instruments and tap/die sets for the Fitting shop. Minimum quantities of equipment are specified.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

11 views28 pagesList of Equipments-Workshop ME PT AE-1

List of Equipments-Workshop ME PT AE-1

Uploaded by

uday chavanThe document provides a list of essential and desirable equipment for the Workshop Technology course with a focus on the Carpentry, Fitting, Smithy, Welding, Sheet Metal, Machine, and Foundry shops. It includes specifications for various tools, machines, and workbenches required for each shop. Some examples listed are a circular saw, wood planer, drilling machine, and hand tools for the Carpentry shop, a marking table, surface plate, measuring instruments and tap/die sets for the Fitting shop. Minimum quantities of equipment are specified.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 28

MAHARASHTRA STATE BOARD OF

TECHNICAL EDUCATION, MUMBAI

MSBTE NORMS AND STANDARDS

FOR EQUIPMENTS AND

MACHINERIES

2012-13

NAME OF THE COURSE / COURSE GROUP

Workshop Technology

(Mechanical Group)

(WS)

(AICTE Approved Course)

INDEX

MSBTE NORMS AND STANDARDS FOR EQUIPMENT

NAME OF COURSE : WORKSHOP

LIST OF EQUIPMENT & MACHINERY

Sr. No. Essential Equipments Lab wise Page No.

1 Carpentry Shop 1

2 Fitting Shop 3

3 Smithy Shop 5

4 Welding Shop 6

5 Sheet Metal Plumbing Shop 8

6 Machine Shop 10

7 Foundry Shop 15

Sr. No. Desirable Equipments Lab wise Page No.

1 Carpentry Shop 16

2 Fitting Shop 18

3 Smithy Shop 19

4 Welding Shop 20

5 Sheet Metal Plumbing Shop 21

6 Machine Shop 23

7 Foundry Shop 26

ANNEXURE - I

MSBTE NORMS AND STANDARDS FOR EQUIPMENT

LIST OF EQUIPMENT & MACHINERY (Essential Equipment/Hand Tools)

1. Name of Course/Department :- Workshop Department

2. Name of Laboratory :- Carpentry

Minimum

Remark

Sr. No. Name of Equipment Technical Specification Qty./Nos

If any

Required

Heavy duty motorised circular saw with

heavy machine table, circular saw blade

running on double row ball bearing, saw

guard ,rib fence etc. with motorisation

attachment with 5HP AC440 V,3/50

1 Circular saw 1

Hz.motor starter, switch, Blt with with

750mm dia saw Blade size of the table

about 1050mm x 680mm, maxmum

depth of cut 275mm

300mm x 300mm table

having depth of throat

2 Jig - saw 300mm, depth of cut 1

50mm with 1/2

HP motor, & starter.

2 HP / 440 V AC, 3 phase 50 Hz. Motor

with starter Heavy duty Maximum width

3 Wood Planer 1

of plank 300mm max planing height

200mm , length of table

1100mm

13mm capacity, motorised bench Drilling

Machine, 600 to 4000 r. p. m.,complete

Drilling Machine Bench

4 with motor pulley , V- belt, 1/4 HP AC 1

Type

220 V single phase 50Hz electric motor ,

size of table 250mm x 250mm .

14 in one wood working machine with

motor and operating tool circular saw

blade 203mm dia 28 teeth, Bandsaw Blade

10mm wide, 4mm thick, Spindle cutter

Universal wood working 12mm dia. Sanding disc 203mm, spindle

5 1

Machine sefety stop with top & side guide parallel

fence & auxilary fence for circular saw &

bandsaw . Operating Instruction & service

manual Disc drive motor 2880 rpm with

all attachments.

Double ended bench grinder with 1HP 3

Phase 50 cycles 440 V and one side rough

6 Bench Grinder and other side smooth 250mm x 25mm x 1

16mm grinding wheel complete with

wheel guard , tool rest and rotary switch.

Tools such as chisels of various Types &

Sizes and Auger Bit auger, handsaw,

7 Hand Tools Kit 20 Sets

Tenon saws Mallets, spoke shave, Hold

Fasts, Clamp etc .

8 Vice Carpentry Bench Vices, 20

Floor model,complete with standard

accessories & electricals

Leangth of bed :-1800mm

Height of centre:- 200mm

9 Wood Turning Lathe 5

Distance between centre :- 1200mm

H. P. of motor :- 1 AC 440 V. 50 hz

1440rpm Compound saddle, o/s turning

attachment, true chuck , live centre

Measuring Tools & Marking Gauge, Carpenter Scale, Foot

10 10 Sets

Gauges Rule, Measuring Tape etc.

Insulated combination Plyer-150mm,

Screw driver set, insulated connector,

Tester, insulated Nose Plyer, Rawal

11 Electrician Tool Kit punch, pooker, hand drill 2 set

machine,Portable reciprocating Saw

machine, elecrician knife, Digital

Multimeter, cold chisel, square rough file.

12 Work Bench 1800 x 1200 x 750 mm 10

ANNEXURE - I

MSBTE NORMS AND STANDARDS FOR EQUIPMENT

LIST OF EQUIPMENT & MACHINERY (Essential Equipment/Hand Tools)

1. Name of Course/Department :- Workshop Department

2. Name of Laboratory :- Fitting Shop

Minimum

Remark

Sr. No. Name of Equipment Technical Specification Qty./Nos

If any

Required

Black Granite surface flat, non magnatic

Marking Table with non glaring, planing accuracy as per IS-

1 2

scribers size 1000mm x 630mm x 150mm of

workshop grade with slab carbide scriber

150mm.

C. I. Surface plate , planed , hand swapped

and seasoned , Brown & sharp type

ribbing complete with handles for lifting

2 Surface plate 2

& wooden protector cover. Conforming to

IS- 2285 - 1963 .1) 450 mm x 450 mm.

or 2) 450 mm x 600 mm .

Vice block height gauges , vernier

calipers, outside and inside calipers,

micrometers, bevel protractor, files of

Measuring Instruments,

different sizes and grades, Hacksaw

3 Marking Instruments , 2 Each

frames, chisels, steel rules, trysquares,

Fitting Hand Tools

drills, surface gauge, Number punch, dot

panch, Divider , Angle plate screw

drivers, spanners etc.

Both tap and dia set complete in box with

accessories 0 - 10 BA , 1/4 " to 1 '' BSF,

4 Tap & dia set. 5 set

1/2" to 3/4" NF , 1/4" to 3/4 " NC,

6mm to 16mm metric, one set each .

13mm capacity, motorised Drilling

Machine, with 0. 5 HP / AC / 230 / 1 /

5 Bench Drilling Machine 1420 r. p. m., with motor starter switch 1

,13mm capacity drilling chuck, V belt

with 100 mm machine vice.

Double ended bench grinder wheel size

150mm x 16mm x 12mm with standard

6 Bench Grinder 1

accessories with single phase 0. 25 HP

motor high speed. .

7 Vice Bench Vice 150 mm 20

Electrically operated

8 mm caoacity steel drilling . Power Input

8 Hand Drilling Machine 2

300 - 400 W.

( pistol Type )

Machanical type hacksaw machine

equipped with coolant pump , vice, length

gauge, machine drive belt guard , with

capacity to cut / round materials upto

Power Hack Saw

9 175mm and square materials 150mm x 1

Machine

150mm,

Blade size 350mm x 25mm and 1 HP /

AC 440 / 3 / 50 / 1440 RPM Elctric motor

& starter.

200 mm Spindle speed 2600 to 3000 rpm,

10 Pedestal Grinder 1

diameter of wheel 200 mm width 25mm

Two speed flexible shaft, 370watts, full

11 Hand Grinder 1

load speed, 6410 rpm & 665 rpm.

12 Work Bench 1800 x 1200 x 750 mm 10

ANNEXURE - I

MSBTE NORMS AND STANDARDS FOR EQUIPMENT

LIST OF EQUIPMENT & MACHINERY (Essential Equipment/Hand Tools)

1. Name of Course/Department :- Workshop Department

2. Name of Laboratory :- Smithy Shop

Minimum

Remark

Sr. No. Name of Equipment Technical Specification Qty./Nos

If any

Required

Centralfugal motorised blower 3 HP / 440

/ 3 / 50 with Foeges, pipe Fittings vaives,

1 Hearth with blower Hearth Size Made of M. S. Sheets 750 mm 5

x 750 mm with water jacket, Height of 2.5

m ( with chimney )

Single Horn 150 kg malleable cast iron

2 Anvil 5

with stand .

3 Leg Vice 15 cm size . 5

Wrought Iron or Malleable cast Iron.

4 Swage Black 1) 450 x 450 x100 mm. Or 2

2 ) 500 x500 x 150 mm.

Hammers of different size , Tong, Chisels

5 Tools and Gauges Ls

flatteners pullers, Dies, Punch , Drift etc.

1 Tonne capacity, motorised, equipped

with foot lever operated, clutch to control

strokes, spring loaded hand lever for

adjustment of strokes, ram and C. I. anvil

and the vertical pull rod , 3HP / 440 V

6 Power Hammer 1

A.C. / 3 / 50 Hz. / 960 rpm electric motor

and starter. Having ram weight about 70

kgs. maximum lift 190mm, strokes /

minute 160 to 200, hammers upto

diameter 56 mm to 80 mm.

Double ended bench grinder with 1HP 3

Phase 50 cycles 440 V and one side rough

7 Bench Grinder and other side smooth 250mm x 25mm x 1

16mm grinding wheel complete with

wheel guard , tool rest and rotary switch.

8 Work Bench With vice 1800 x 1200 x 750 mm 2

ANNEXURE - I

MSBTE NORMS AND STANDARDS FOR EQUIPMENT

LIST OF EQUIPMENT & MACHINERY (Essential Equipment/Hand Tools)

1. Name of Course/Department :- Workshop Department

2. Name of Laboratory :- Welding Shop

Minimum

Remark

Sr. No. Name of Equipment Technical Specification Qty./Nos

If any

Required

Welding Trasformer to provide current

from 50 amps to 600 amps for Single

operator and 25 amps to 300 amps for two

operators at 80 v open current , alternate

voltage of 100 V open circuit provision

,rotary switch for quick selection of

current with following technical

specifications conforming to IS 1851 -

Oil Cooled Arc Welding

1975

Transformer Three Phase

1 Standard Accessories :- 2

With Standard

1) Copper cable single single core

Accessories

conforming to IS - 9857 / 1981 for 600

amps .

2) Electrode holder upto 600 amps.

3) Hand Screw .

4) Earth clamp, tommy bar type.

5) Pair of welders Goggles .

6) Welders apron .

7 ) Welders glass etc.

Single phase air cooled arc welding ,

Single Phase Aircooled transformer, stepless veriable current

2 arc Welding Transformer regulator for welding current range 40 to 2

with Accessories 300 amps. Conforrming to IS- 1851 - 1975

.

Portable type spot Welder rating 2.5 KVA

Light Duty Spot Welding

3 , for welding upto 2mm + 2mm M. S. 1

Machine

Sheet , Max throat depth 20 cms .

a) High pressure welding blow pipe , six

tip sizes, for weldingM. S. upto 10 mm

thick

b) Two stage oxygen regulator

conforming to IS 6901- 1981 ( Max. outlet

pr 2 kg / cm 2. )

c) Two stage acetylene regulator

conforming to IS - 6901-1981 ( Max.Pr 1

Oxy-Acetylene Gas

4 kg / cm2 ) 1

Welding Set

d) Pressure gauges to conform IS 36624 -

1979.

e ) Standard Accessories 2 x 5 mm length

8 mm bore hose, four hose clips, one pair

welders goggle, one pair leather hand

gloves, cylinder out fit - spindle keys,

spark lighter , leather apron, wire brush

etc .

Supply voltage 230 V / ! Phase / 50 Hz .

5 Soldering Irons Watts 500, complete insulation with 2

different types. Of copper soldering bits.

Double endd pedestal type grinder with

following specifications :-

Double Ended Pedestal 1 HP / Single phase / 230 V / 2800 RPM

6 1

Type Grinder ISI marked motor with wheel size 250 mm

x 25 mm x 18 mm. one side rough and

other side smooth , pedestal of C. I.

Welding fixtures, Wire brush , Chipping

7 Welding accessories 1

hammers, Clamps, etc.

Insulated combination Plyer-150mm,

Screw driver set, insulated connector,

Tester, insulated Nose Plyer, Rawal

8 Electrician Tool Kit punch, pooker, hand drill 2 set

machine,Portable reciprocating Saw

machine, elecrician knife, Digital

Multimeter, cold chisel, square rough file.

Power source with integral wire feeder

and rear stand for gas cylinder, for seam

welding, spot welding etc. current range

35-160 amp, open circuit voltage range 16-

31 V, 3 phase, input KVA 4.5 , current 9

MIG / Welding amp, with all accessories. Welding current

9 1

Equipment At 60 % duty cycle 160 A / 22 V, At 100

% duty cycle 125 A / 21 V. To weld

Ferrous and non ferrous metal alloys, with

pre heater, light and heavy duty

gunassembly, cooling system, and all

standard accessories.

Ac / DC Tig welding set for welding ferrous

and non ferrous alloys, Max. current capacity

150 amp. Control unit built in H. F. unit and

10 T . I . G. Welding set. controls, contractor , DC suppressor, water 1

circulatory unit, torch with accessories box, set

of tungsten electrodes, set of welding

accassores.

11 Work Bench With Vice 1800 x 1200 x 750 mm 2

12 Welding Table 1200 x 1200 x 750 mm With sliding tray 2

ANNEXURE - I

MSBTE NORMS AND STANDARDS FOR EQUIPMENT

LIST OF EQUIPMENT & MACHINERY (Essential Equipment/Hand Tools)

1. Name of Course/Department :- Workshop Department

2. Name of Laboratory :- Sheet Metal & Plumbing Shop

Minimum

Remark

Sr. No. Name of Equipment Technical Specification Qty./Nos

If any

Required

Geared type hand Shearing machine

complete with handle having the

following specification. Cuts steel sheet ,

1 Shearing Machine upto 4 mm. Maximum cut in one stroke 1

300mmCuts flate upto 50mm x 5mm.Cuts

M. S. bars upto 13mm Length of blade

400mm.

Hand operated, Maximum bending width

2 Sheet Bending Machine 1

1200 mm with thickness 10mm.

Hand operated bender, Bends round,

taper, flates, tubing, square & conduit,

3 Pipe Bending Devices 1

Complete with attachments for different

bending operation .

Electrical Soldering iron, Different types

of stakes, pneumatic chipping and

rivetting hammers, Scribes dividers,

trammel points, set square , punches, prick

punches, centre punches, hand groover,

Hand Tools and other rivet sets, chisels, hammers, ball pein

4 1

Equipment hammers , mallet, snip shears, pliers, hand

seamers, tongs, files, hand

shears,measuring instruments for sheet

metal work folding rule, common rule,

steel circumference rule, vernier calipers,

micrometer calipers, slip gauges.

Threading Wrench & Die Set of Assorted

5 Pipe Threading Dies 5

Sizes.

Light duty drill, 10 mm capacity, 235 V,

Portable Drilling

6 235 watts, 700 rpm, no load speed, 250 1

Machine

rpm full load speed .

7 Pipe Vice Holding capacity of pipe - 50 mm. 1

Consisting of hacksaw, dies, measuring

8 Plumber’s Tool Kit tape, hammer, files, pipe wrench, chain 5 sets

wrenches, adjustable spanner, etc.

9 Stoving Oven Std. size . 1

10 Work Bench 1800 x 1200 x 750 mm 2

ANNEXURE - I

MSBTE NORMS AND STANDARDS FOR EQUIPMENT

LIST OF EQUIPMENT & MACHINERY (Essential Equipment/Hand Tools)

1. Name of Course/Department :- Workshop Department

2. Name of Laboratory :- Machine Shop

Minimum

Remark

Sr. No. Name of Equipment Technical Specification Qty./Nos

If any

Required

Max. swing over bed : 450 mm. Max

swing in gap 770 mm Admit between

Centre Lathe

1 centers : 555 mm Spindle bore : 52 mm . 15

( General type )

Powar of motor : 3hp , 3 phase , 50 Hz.

With accessories.

Longth x with of working table 1200mm x

700mm. Number of T- slots 6.

Longitudinal Traverse 1200 mm. Cross

traverse 800 mm. Table height from floor

940 mm . Circular movement of table 360

Deg. No. of spindles 7. Manual vertical

adjustment of milling head 320 mm.

swivel of milling head on either side 45

deg. Throat clearance 915 Deg. (distance

Universal Milling between main spindle and column guide)

2 1

Machine Maximum diameter of circular milling

2600 mm . Manual & Automatic feed.

Accessories Draw bar, circular milling

head, High speed milling head, small

radius milling head, Micro- depth stop for

milling head , circular dividing

attachement for rotary table , coolant

equipment, special cutters, boring tools,

tool holder, form cutting , collets hand

clamping devices for wood working.

Table size 135 x 310 mm. Axis traverse

3 Vertical Milling Machine 800 x 265 x 400 Feed rate 0 - 800 rev / 1

min. ( Manual & Automatic )

Maximum grinding length 750 mm.

Maximum grinding width 250 mm.

Distance centre of wheel , over table 125

mm ( Maximum ) Longitudinal travel

speed 12 meters / minuts .Standard wheel

size 250 mm. x 25 mm x 762 mm. Speed

of wheel 2100 or 2625 rpm . Lubrication

Centralised Automatic . Accessories

Hydraulic Surface

4 Grinding wheel, wheel flange puller , 1

Grinding Machine

wheel balancing mandrel, Table guards

pump with fittings, machine lamp,

Instruction manual. Permanent magnetic

chuck , wheel balancing stand, coolant

equipment magnetic separator,

Demagnetiser, Universal machine vices,

dust and exhaust equipment unit, wheel

dressr over wheel head .

Double ended, fitted with grinding

wheels tool rest, on-off switch , 1 HP

5 Bench Grinder motor AC 3phase 400 / 440 V . Complete 2

with steel guard 300 mm x 40 mm x 25

mm grinding Wheel. Speed 1420 rpm.

Drilling capacity in steel 20 mm. Spindle

travrse 125 mm . Vertical adjustment of

spindle head 425 mm. Distance from

Drilling Machine

6 Centre of spindle to column front 200 1

( Piller Type )

mm. Speed range of spindle 375 - 3220

rpm. No of spindle speeds 5 . Power of

spindle 3 HP ( 3 phase ) .

Length of stroke ( Max. ) 200 mm. , for

cutting round and square material ( Max. )

300 mm speed 1440 rpm . Power of motor

Hydraulic Power 1.5 kw ( AC 3 phase 440 volt ) .

7 1

Hacksaw Machine Accessories Vice for holding bars, saw

blade, coolant pump with fittings limit

switchches, bar rest assembly, set of

wrenches and belts.

Max. length of stroke 630 mm. Length

and width of ram bearing 914 x 279 mm

Max. distanc Table to ram 490 mm . Min.

distance table to ram 100 mm. Max .

Horizontal travel of table 610 mm. Max.

vertical travel of table 390 mm. No of

8 Shaping Machine speeds of ram 4. Max. travel of tool slide 2

152 mm. Swivelling of tool slide on either

side of the vertical 60 Deg. Power of

main drive motor 3 HP ,440 V, 3 phase,

950 rpm. Accessories Auto Lubrication,

operating handle, Vice, key way cutting

attachment .

Vernier Caliper-0 to 300mm, Dial Caliper-

0-300mm, Vernier Depth Gauge-0 to 300

Measuring Instruments

9 mm, Digital Height Gauge-0 to 450mm, Ls

And Tools

Digital Micrometer-0 to 25mm,

Combination Set

10 Universal Dividing Head With centres, index plate, chuck . 1

11 CNC LATHE DNC based PC-controlled slant-bed lathe

1

for the universal CNC education.

Machine complete with fully enclosed

working area, safety units according to

CE-regulations, stepless adjustable main

drive, 8-station tool turret, manual

tailstock, automatic movement to the

reference position, electrical and

mechanical preparation for automation,

connection cable PC - machine, disk with

machine data, tool-set for operation,

operation manual with spare part list.

Must be programmable through

Control keyboard designed as per

industrial control & Control software

like:

Operation: Control keyboard same as

industrial control units, Preparation for the

exchange to other control systems:

Control Systems

1. SIEMENS & GE FANUC

2. CAD/CAM

Working area should not be less then

dimensions given below.

1. Swing over bed [mm] ø125

2. Swing over cross slide [mm] ø55

3. Max.machining diameter (chuck parts

with tailstock) [mm] ø50

4. Max. parts length [mm] 215

Travel

1. Travel in X-axis [mm] 45

2. Travel in Z-axis [mm] 225

Main spindle

1. Spindle nose according factory standard

2. Spindle bore [mm] ø 15

3. Chuck diameter [mm] 70

4. Hole to chuck [mm] ø 15

5. Speed range [rpm] 120-4000

6. Mechanical spindle speed 2

7. Max. torque [Nm] 14

Main drive

1. AC-motor,

2. Speed range [rpm] 1200 to 1400

Tool turret (Important)

1. Number of tool stations - 8

2. Tool holding inside / outside -4 / 4

Feed drives

1. 3-phase step motor

2. Rapid traverse in X / Z

Tailstock

1. Quill stroke [mm] 35

2. Quill diameter [mm] 22

3. Internal taper MT 1

DNC-Interface

1. For remote control via a software-

protocol. The communication is done via

the RS 232 Interface for the FMS/CIM -

operation

Safety equipment

Machine full covered, axis limit switch,

door limit switch, emergency off switch

according CE standard

DOCUMENTATION:

1) Machine description

2) Software manual

3) Electrical documentation

4) Training manuals

5) Teaching Material

12 CNC MILL TECHNICAL SPECIFICATIONS-

DNC based PC-controlled 4-axis Milling

Machine for universal CNC Training With

8-station tool turret. Machine complete

with fully enclosed working area, stepless

adjustable main drive, automatic 1

movement to the reference position,

electrical and mechanical preparation for

automation, connection cable for PC-

machine, machine lamp.

Must be programmable through

Control Keyboard & software like:

Operation: Control keyboard same as

industrial control units, Preparation for the

exchange to other control systems:

Control Systems

1) SIEMENS & GE FANUC

2) CAD/CAM

Technical Data of the Machine (Not

Less then)

Working area

1) Longitudinal travel (X-axis) [mm]

175

2) Cross travel (Y-axis) [mm] 125

3) Vertical travel (Z-axis) [mm] 250

Milling table

1) Clamping surface (L x W) [mm] 400

x 120

2) 2 T-slots

Tool system

1) Tool magazine Pick-up system with

swivel arm on the left of the milling head

placed; blow out facility

2) System drive: electr., mech.

3) Tool clamping automatic

4) Number of tool stations 8

Main drive

1) Asynchronous AC motor,

2) Speed range (stepless) [U/min] 150 -

3500

Feed drives

1) 3 phase step motor in X/Y/Z axis

2) Feed rate and rapid traverse in X/Y/Z

th

4 axis (C- axis)

1) continuously controlled

2) spindle height 40 mm

3) displacement 20 mm

4) retrofit able

DNC-Interface

1) For remote control via a software-

protocol. The communication is done via

the RS 232 Interface for the FMS/CIM -

operation

Safety equipment

1) Machine full covered, axis limit

switch,door limit switch, emergency off

switch

2) according CEstandard

DOCUMENTATION:

1) Machine description

2) Software manual

3) Electrical documentation

4) Training manuals

5) Teaching Material

ANNEXURE - I

MSBTE NORMS AND STANDARDS FOR EQUIPMENT

LIST OF EQUIPMENT & MACHINERY (Essential Equipment/Hand Tools)

1. Name of Course/Department :- Workshop Department

2. Name of Laboratory :- Foundry Shop

Minimum

Remark

Sr. No. Name of Equipment Technical Specification Qty./Nos

If any

Required

50kg Capacity with blower and electrical

1 Pit Furnace 1

heaters. Temperature rang 800 Deg. C.

with thermocouple & temperature control

2 Oil Fired Furnace 50 Kg Capacity 1

400X200X150mm Temperature 1200

Electric Resistance Deg. C. working temperature 960 Deg. C.

3 1

Furnace Accuracy +/- Deg. C. rating 6 KW,

thermocouple with automatic control.

4 Crucibles 10 to 20 kg Capacity 1 Set

5 Moulding Machine 600mm X 300mm X 150mm 1

Plat Form Weghing Machine, 100kg

6 Weighing Machine 1

Capacity

Size: 1800mm X 1200mm X 1200mm,

7 Drying Oven fitted with electric heater, blower and 1

temperature control

8 Sand Sieves 200, 300, 400 SWG 1 Set

C I moulding boxes witg pin & without

9 Moulding Boxes 25

pin type assorted Sizes.

10 Laddles 10 kg, 20 kg, Capacity 5

11 Tool Kits Moulder Standard Tool Kit. 20 Set

Quenching Tanks water

12 As per Requirement 1

or Oils

13 Portable Grinder Flexible shaft type output three speed, 1

14 Pedestal Grinder Double wheel 8" size, 1 HP motor 1

ANNEXURE - II

MSBTE NORMS AND STANDARDS FOR EQUIPMENT

LIST OF EQUIPMENT & MACHINERY (Desired Equipment/Hand Tools)

1. Name of Course/Department :- Workshop Department

2. Name of Laboratory :-Carpentry Shop

Minimum

Remark

Sr. No. Name of Equipment Technical Specification Qty./Nos

If any

Required

Heavy duty vertical bend saw machine,

size of cast iron table 600 mm x 600 mm,2

HP / AC , 440 V, 50 Hz,3 phase AC motor

1 Band Saw with starter , Dia of wheel 450mm , width 1

of wheel 38mm , depth of cut 300mm with

standard accessories including dust

collector .

150 mm to 1054 mm dia circular saw 06

mm to 150 mm width bend saw blades ,

alternate saw sharpening machine ,

equipped with roller swelling of arm

Band saw and Circular spindle having pivoting motion for level

2 1

Saw Sharpner of blade teeth. Feeds 40 and 80 teeth per

minute, provided with 1 HP / AC 440 v, 3

Phase 50 Hz , Electric motor with starter,

cast Iron pedestal grinding wheel . Motor

pulley and V Belt .

Floor model provided with endless chain

cutter or chisel , head stock counter

balanced,table having compound slide for

lateral movement by screw adjustment and

longitudinal traverse by hand wheel,

Chain And Chisel provided with quick screwclamp , having

3 1

Mortising Machine capacity maximum size pf chain 9mm to

19mm, max. size of chisel 9mm,depth of

bore 150mm,longitudinal table movement

225mm, lateral movement 150mm,

complete with 3ph A. C. 440 v 50 hz

electric motor & switch .

Vertical sander sands and polishes flat

surfaces capacity :- 180 mm

4 Vertical Sander Input (full load ) :- 500 watts 1

No load speed :- 2200 rpm

Full load speed :- 1200 rpm

1400watts / 5800 rpm. Compact and well

balanced . Powerful motor for maximum

HEAVY DUTY

5 performance . 100 % ball and roller 1

CIRCULAR SAW

bearings construction. Reversible inner

clamp flange.

640 watts / 0-2,400rpm, Variable speed

HEAVY DUTY

ball and roller bearings construction. Low

VARIABLE SPEED

6 vibration . Rubber boot . Flush cutting 1

RECIPROCATING SAW

blade position . Externally replaceable

KIT

brushes. Capacity-184 mm

Powerful motor for maximum

performance.Compact and well balanced .

Single Speed Impact Drill

7 Helical gear system . Bearing block for 1

.

precisiongear & spindle

alignment.Capacity-10mm

Powerful long life motor. Spindle lock .

Durable and reliable design . Maximum

8 ANGLE GRINDER . airflow with aero-dynamic fan system. 1

Compact gear case . External brush accass

panel. Capacity-100mm

7.2 V . Variable speed reversing . High

performance fan cooled motor .

CORDLESS DRILL (

9 Ergonomic mid-handle design . Electric 1

KEYED CHUCK )

brake . Adjustable clutch torque control

( for DW 920_2 only ). Capacity -2-10mm

170 watts / 13.500 rpm. Low vibration .

Heavy Duty palm grip Easy accessibility of brushes . Sealed dust-

10 1

sander proof switch. High orbital speed . Impact

resistance.

950 watts / 25.000 rpm 100 % ball

bearing construction. 6.35mm and 12.7

HEAVY DUTY

11 mm collet capacity. Precision rack & 1

ROUTER

pinion depth adjustment . Externally

replaceable brushes.

ANNEXURE - II

MSBTE NORMS AND STANDARDS FOR EQUIPMENT

LIST OF EQUIPMENT & MACHINERY (Desired Equipment/Hand Tools)

1. Name of Course/Department :- Workshop Department

2. Name of Laboratory :-Fitting Shop

Minimum

Remark

Sr. No. Name of Equipment Technical Specification Qty./Nos

If any

Required

Screw diameter 50 mm, total height 600

Hand Press Double

1 mm , Distance between pillars 250 mm 1

( Pillar Type )

L x B x H = 525 mm x 275 mm x 75 mm .

Hand operated , for driving mandrels in

and out of work, inserting & removing

bushes , bearings etc .Maximum pressure

exerted 250 kg. Centre to back :- 100 mm

2 Arbor Press 1

Approx Max. height from

base to guide 175 mm (

Approx ).Size of arbor round or square

130 mm (Approx ).

ANNEXURE - II

MSBTE NORMS AND STANDARDS FOR EQUIPMENT

LIST OF EQUIPMENT & MACHINERY (Desired Equipment/Hand Tools)

1. Name of Course/Department :- Workshop Department

2. Name of Laboratory :-Smithy Shop

Minimum

Remark

Sr. No. Name of Equipment Technical Specification Qty./Nos

If any

Required

High frequency generator 10 kw output

three phase 18 kva, input frequency 400

kilocycle/sec, incorporating variable

1 Induction Hardening 1

coupling transformer for controlling out

equipment

put power, with synchronus timer, water

cooled, fixture & platform for jobs

ANNEXURE - II

MSBTE NORMS AND STANDARDS FOR EQUIPMENT

LIST OF EQUIPMENT & MACHINERY (Desired Equipment/Hand Tools)

1. Name of Course/Department :- Workshop Department

2. Name of Laboratory :- Welding Shop

Minimum

Remark

Sr. No. Name of Equipment Technical Specification Qty./Nos

If any

Required

D. C. arc welding trasformer , rectifier

type providing D. C. current 50 to 400

amps. , Stepless Current selection, 3

phase 380 / 415 V, 50 Hz. , supply

conforming to IS -4559 - 1978 , With

following specifications. Input :- Supply

D. C.Arc Welding

voltage 380 / 415 V, 50 Hz, # Phase.

1 Transformer Rectifier 1

Rating continuous 24 KVA , 60 % duty

type 3 Phase

cycle 32 KVA . Output. Welding current

rang 50 - 400 amps . Max. hand welding

current at 60 % . duty cycle 400 amps . At

100 % . duty cycle 310 amps. with the

standard accessories same as 01 : 09 : 001

.

Brazing / Welding equipment for ferrous

and non ferrous welding / brazing gobs

with the help of a specially designed

Brazing Equipment and

2 carbon torch and copper coated carbon 1

Accessories

rods suitable for operation on A. C. 220 V

/ 1 Phase / 50 Hz. Supply for different

gobs,

2200 watts / 6300 rpm. Adjustable guard .

Heavy Duty Angle 3 position side handle . Spindle lock . Anti

3

Grinder. vibration side / back handle . Powerful

motor, Capacity.-100mm

Duil range 0-400/0-1,100 rpm.

Variablespeed, reversing . Adjustable

HEAVY DUTY 10MM

clutch torque control . High performance

4 VSR CORDLESS

fan cooled motor . Keyless chuck .

DRILL / DRIVER KIT .

Electronic brake . Two 9.6 V Battery

packs .

ANNEXURE - II

MSBTE NORMS AND STANDARDS FOR EQUIPMENT

LIST OF EQUIPMENT & MACHINERY (Desired Equipment/Hand Tools)

1. Name of Course/Department :- Workshop Department

2. Name of Laboratory :-Plumbing & Sheet Metal Shop

Minimum

Remark

Sr. No. Name of Equipment Technical Specification Qty./Nos

If any

Required

Self contained motorised deep throat

swaging Machine useful for curling and

wiring of cylindrical and plain sheets with

six set of rollers for different operations

with suitable stand , speed reduction gears

1 Swaging Machine 1

2HP, A. C. 440 / 3 / 50 pulley belt guard

and starter Maximum capacity in steel 16

SWG . Depth of gap to gauhe 450 mm .

Maximum centre distance between rollers

7.5 cm .

Swing beam type hand operated

Universal sheet and plate edging , bending

and folding machine . Maximum opening

between the upper and lower beams 35

mm. Adjustment to bending beam up and

Universal sheet Folding

2 down 13mm, adjustement to clamping 1

Machine

beam forward and back 13 mm, complete

with one sharp nose taper blade fitted,

adjustable angle selector with stop.

Maximum bending width - 1800 mm.

capacity 18 mm.

Heavy duty double column press with

adjestable stroke suitable for punching,

embossing, cutting work etc. machine

with motorosation attachment , motor

pulley ,gear guard along with AC / 3

Double Column Power

3 phase , 440 V, 50 Hz, electric motor 1

Press

starter and foot operated clutch . Capacity

in tons - 25 . Adjustability of stoke - 63

mm. Admit between bed to ram About

305 mm. Stroke per minute - 65, Power

required - 3 HP.

Steel Construction, hand operated

hydraulic press with two stage hand pump.

4 Hydraulic Press Capacity : 25 tons . 1

Admit between ram to bed 900 mm.

Admit beteen column : About 825 mm.

Bench type hand operared Circle cutting

machines suitable to cut circlets rings and

5 Circle Cutting Machines discs from mild steel sheet . 1

Capacity to cut circle - 75 mm. - 450 mm.

Capacity in M. S. 20 SWG.

ANNEXURE - II

MSBTE NORMS AND STANDARDS FOR EQUIPMENT

LIST OF EQUIPMENT & MACHINERY (Desired Equipment/Hand Tools)

1. Name of Course/Department :- Workshop Department

2. Name of Laboratory :-Machine Shop

Minimum

Remark

Sr. No. Name of Equipment Technical Specification Qty./Nos

If any

Required

Maximum Swing over bed 570 mm,

Maximum swing over saddle 545

mm.Maximum Swing over cross slide 317

.0 mm. Spindle Flange diameter 362 mm.

Dia. Of hole through spindle 108 mm.

Maximum distance spindle flange to turret

face 1505 mm. Minimum distance spindle

flange to turret face 1505 mm. Minimum

distance spindle flange to turret face 444

mm. Turret face size 210 x 219 mm.

Number of spindle speedes 32. Number of

automatic feeds 8. Accessories Saddle

1 Turret Lathe 1

changing mechanism, quick indexing

square turret, over head support bar, rear

splash guard levelling block for the bed ,

grease gun, spanners, suitable motor and

electrical equipment. coolant pump ,

fittings, front splash guard, low voltage

lighting equipment , combined internal

and external coolant supply to turret,

sliding chip guards, concentric chuck , air

operated chuck, Foot switch, compound

slide, Taper turning attachment , Leader

control to turret lathe, Tooling.

Swing 280 mm. Swing with raising locks

37.0 mm. Hight of centres 130 mm.

Distance between tail stock centres 760

mm. Distance between tail stock centres

and work head 615 mm. Swing on cutter

head 405 mm. Longitudinal traverse

510mm. Cross traverse 250mm. Wheel

speeds in either sense of rotation 280,

5600 rpm Main motor 0. 75 kw.

Universal Tool and

2 Accessories :- Electrical equipment for 3 1

Cutter Grinder

phase AC supply, grinding wheel arbor,

grinding wheel flanges, work head with

dividing disc , a pair of tail stocks,

clesrance angle setting device with carrier

wheel trueing devices fixed supporting

stand, clamping arbor for ISA taper set of

grinding wheels, wheel guards, set of

service tools and operations manual.

Different grinding attachment.

Drilling capacity in steel 50 mm. Drilling

capacity in casr iron 60 mm. No of spindle

speeds 12. speed range 40 - 1800 rpm. No

of feeds 6. Feed range 0.125 to 1.25 mm.

per revolution. Minimum drilling radius

520mm. Quill traverse 325 mm. Arm

3 Radial Drilling Machine traverse 740 mm. Power , main motor 4 1

kw. power , arm motor 1.5 kw. Electrical

equipment complete with wiring for 3

phase 415 volt. set of service tools,

operation manual. Special accessories

Universal table machine lamp, additional

bas e plate.

Centre Less Grinder with

4 Lapping Attacchment 160 mm x 200 mm x 400 mm. 1

with Guard

Length of stroke :- 1220 mm. Width

between arms : 762 mm Height cross rail :

762 mm No of T - slots : 4 Max. size of

tool shank : 50 mm x 50 mm. Main drive

5 Planing Machine 1

motor : 2. 2 kw . Accesscries :- Tool

post, side tool post, Auto tool lifting

arrangment, grinding attachment

Electricals.

Max. stroke : 105 mm. Dia . Of table :

250 mm. No. of strokes of ram / minute

6 Slotting Machine :55- 85- 115. Forward and backward 1

distance : 275 mm. Power : 0. 75 kw /

1440 rpm, 3 phase - 400 / 440 v.

Maximum capacity, round : 15 mm

Square : 10 mm. hexagon: 12 mm

Maximum turning length : 70 mm .

Single Spindle Spindle speeds : 900 to 6500 rpm. Power

7 1

Automatic Lathe of work spindle motor : 1.3 to 1. 5 kw.

Standard accessories & operating

Instructions Completely instrumented for

demonstration jobs.

Dia of bore upto : 75mm. Spindle speed :

250- 1000 rpm. Continously variable, with

Honing Machine (

8 coolant pump & filters. Motor: 1/2 hp / 3 1

Vertical )

phase, 1500 rpm, chuck : 4, way adjusting

with floating pad for self adjustment.

ANNEXURE - II

MSBTE NORMS AND STANDARDS FOR EQUIPMENT

LIST OF EQUIPMENT & MACHINERY (Desired Equipment/Hand Tools)

1. Name of Course/Department :- Workshop Department

2. Name of Laboratory :-Foundary Shop

Minimum

Remark

Sr. No. Name of Equipment Technical Specification Qty./Nos

If any

Required

As per IS: 30085, consisting of

1 Permeability Tester 1

permeability cell & water reservier

Portable Type, 135 X 65 X 25mm,

2 Mould Hardness Tester 1

Capacity 300kg

3 Fettling Machine Swing table, single door, 30 cm dia, 1

4 Thermocouple Temperature Range- 2000 to 3000 Deg. C. 1

Disapearing filament type at temp. above

5 Optical pyrometer 1

1400 Deg. C.

You might also like

- Grade 10 Terms and DefinitionsDocument11 pagesGrade 10 Terms and Definitionskhotso86% (7)

- Maho MH 600 e enDocument8 pagesMaho MH 600 e enDragan PanovicNo ratings yet

- Elce4012 4Document8 pagesElce4012 4ameerNo ratings yet

- WS 54 Tool and Cutter Grinding Machine: Productivity Realised at Tool Cutting EdgeDocument4 pagesWS 54 Tool and Cutter Grinding Machine: Productivity Realised at Tool Cutting Edgejacksonholland8335No ratings yet

- EY Introduction To Financial ModellingDocument8 pagesEY Introduction To Financial ModellingPrashantKNo ratings yet

- Prepare Vegetable and Seafood DishesDocument120 pagesPrepare Vegetable and Seafood DishesJoeven Pantaleon67% (3)

- Purchase of Wood Working ToolsEquipment For GTVCB Balach ChitralDocument3 pagesPurchase of Wood Working ToolsEquipment For GTVCB Balach ChitralMuhammad AsgharNo ratings yet

- Sheet Metal Bending MachineDocument2 pagesSheet Metal Bending MachineAnup ChauhanNo ratings yet

- At 300Document11 pagesAt 300mne79054No ratings yet

- Annex I Minimum Equipment and Tools RequirementsDocument4 pagesAnnex I Minimum Equipment and Tools RequirementsCharlane GenalocNo ratings yet

- MR - Samaksh Jhalani Machinery-FinalDocument45 pagesMR - Samaksh Jhalani Machinery-FinalSamaksh JhalaniNo ratings yet

- S.no Item Name Specification QuantityDocument2 pagesS.no Item Name Specification QuantityAbayNo ratings yet

- Triumph SuperDocument1 pageTriumph SupernsimbakuntondiNo ratings yet

- Best Price of SMC650 Machining Center With Fanuc ControlDocument7 pagesBest Price of SMC650 Machining Center With Fanuc ControlRenato Cuadros MahaneyNo ratings yet

- Tool Room Machine ListDocument12 pagesTool Room Machine ListsachinNo ratings yet

- OMNI 6090 CNC Router QuotationDocument4 pagesOMNI 6090 CNC Router QuotationJosé PeNo ratings yet

- MR - Samaksh Jhalani-7-Ply-150-1800mm Automatic Corrugated Cardboard Production LineDocument43 pagesMR - Samaksh Jhalani-7-Ply-150-1800mm Automatic Corrugated Cardboard Production LineSamaksh JhalaniNo ratings yet

- ZX32GDocument29 pagesZX32Gkassa mamoNo ratings yet

- Mill Drill Bench Machine MD 20DASH25Document26 pagesMill Drill Bench Machine MD 20DASH25kassa mamoNo ratings yet

- Machineries SpecificationDocument12 pagesMachineries SpecificationRavi ChoudharyNo ratings yet

- Specification of CNC EDM Die Sinking EDM540Document4 pagesSpecification of CNC EDM Die Sinking EDM540kashifhabib6745No ratings yet

- Multifunctional Lathe Machine CQ6232GZDocument4 pagesMultifunctional Lathe Machine CQ6232GZAbdelbasset ZaraiNo ratings yet

- Dep IpeDocument16 pagesDep Ipebju.monitoring.controlNo ratings yet

- Company Products Catalogue - Machine Rev 3Document8 pagesCompany Products Catalogue - Machine Rev 3Bayumi Tirta JayaNo ratings yet

- Shaper Machine BC6066 ManualDocument36 pagesShaper Machine BC6066 Manualsecondharbour ChinaNo ratings yet

- Chapter 2 Machine IntroductionDocument4 pagesChapter 2 Machine IntroductionTech CIMNo ratings yet

- Specification L200 L400Document2 pagesSpecification L200 L400Ujwal PatilNo ratings yet

- CW61160Bx10000mm Horizontal Lathe Machine: Hebei Yawo Machinery Manufacturing Co., LTDDocument3 pagesCW61160Bx10000mm Horizontal Lathe Machine: Hebei Yawo Machinery Manufacturing Co., LTDaz marine servicesNo ratings yet

- Annexure III A of TCDocument20 pagesAnnexure III A of TCkishorNo ratings yet

- Surplex Auction 3564Document11 pagesSurplex Auction 3564SantoshNo ratings yet

- SPM-Blade Grinding MachineDocument5 pagesSPM-Blade Grinding MachineZarana BhattNo ratings yet

- ZN5050ADocument44 pagesZN5050ATHiz OCtavvNo ratings yet

- Details Spec 2Document14 pagesDetails Spec 2debsaikat00No ratings yet

- PRM Bench Mill Drill ManualDocument56 pagesPRM Bench Mill Drill ManualMatthew MattesonNo ratings yet

- Quote of FLASH FL400-Z20Q121207Document2 pagesQuote of FLASH FL400-Z20Q121207Mohammed SakhibNo ratings yet

- AS200 200L SeriesDocument24 pagesAS200 200L Seriescoronaqc100% (1)

- 1 - Proforma Invoice - HRAF20220606Document9 pages1 - Proforma Invoice - HRAF20220606GemmeNo ratings yet

- CT300 3 in 1 Multifunctional MachineDocument13 pagesCT300 3 in 1 Multifunctional MachineJorge Luis Morales ValenzuelaNo ratings yet

- GrinderDocument5 pagesGrinderfikahNo ratings yet

- Specification Agriculture ImplimentsDocument25 pagesSpecification Agriculture ImplimentsRavi MirzaNo ratings yet

- QUOTATIONS - 6 ROLLER 1 DDocument4 pagesQUOTATIONS - 6 ROLLER 1 DDrPawan BhardwajNo ratings yet

- Medium DutyDocument4 pagesMedium DutymateenNo ratings yet

- Offer (Plasma+fiber Laser +robot+laser Welding)Document13 pagesOffer (Plasma+fiber Laser +robot+laser Welding)jesus hurtadoNo ratings yet

- Drilling and Milling Machine WMD25VB From SYNTOP CNCDocument2 pagesDrilling and Milling Machine WMD25VB From SYNTOP CNCВладимир УсковNo ratings yet

- Updated CNB Brochure 2022Document14 pagesUpdated CNB Brochure 2022Abigail Myrra Magpayo DiazNo ratings yet

- Milling MachinesDocument27 pagesMilling MachinesAd Man GeTigNo ratings yet

- Needle Punching Production LineDocument13 pagesNeedle Punching Production LinematoportelaNo ratings yet

- List of Laboratory Equipments: Department of Mechanical Engineering 2014Document8 pagesList of Laboratory Equipments: Department of Mechanical Engineering 2014cparamesNo ratings yet

- Manufacturing LabDocument3 pagesManufacturing LabWaqas HassanNo ratings yet

- Tool Various: Professional Machine Manufacturers, Experts in Customized Production ofDocument3 pagesTool Various: Professional Machine Manufacturers, Experts in Customized Production ofHervis CyrilleNo ratings yet

- Quote of 1-3 Inches Nail Making Line - Huarui, AngelaDocument9 pagesQuote of 1-3 Inches Nail Making Line - Huarui, AngelazakNo ratings yet

- Rack Milling Machine RMDocument4 pagesRack Milling Machine RMAries N. RamadhanyNo ratings yet

- Milling Machine ToolDocument42 pagesMilling Machine ToolSai SashankNo ratings yet

- Drillsprint 310316aDocument4 pagesDrillsprint 310316amateenNo ratings yet

- Brochure Truong Thinh - enDocument18 pagesBrochure Truong Thinh - envinhquangbk10No ratings yet

- CNC Lathe List: Item CK0640 CK0660 CK0680Document10 pagesCNC Lathe List: Item CK0640 CK0660 CK0680MUHAMMAD NAUMANNo ratings yet

- Baxter 280M (08012017)Document2 pagesBaxter 280M (08012017)pc100xohmNo ratings yet

- Metal Sheet and Pipe Laser Cutting Machine Manufacturers - GoldenLaserDocument9 pagesMetal Sheet and Pipe Laser Cutting Machine Manufacturers - GoldenLaserJUAN DAVID GOMEZ OSORIONo ratings yet

- Quotation of Edge Banding Machines - Expert KitDocument3 pagesQuotation of Edge Banding Machines - Expert KitMary FelicianoNo ratings yet

- Specification-9D+WF800Document3 pagesSpecification-9D+WF800Chitranjan KumarNo ratings yet

- Suzhou Hanxin Machinery CatalogueDocument19 pagesSuzhou Hanxin Machinery CatalogueKhaled BOUALINo ratings yet

- Capture D'écran . 2023-08-08 À 14.23.27Document8 pagesCapture D'écran . 2023-08-08 À 14.23.27DIBRICONo ratings yet

- WIRGEN - 200iDocument8 pagesWIRGEN - 200iUrsut AngyNo ratings yet

- Proforma - PDocument2 pagesProforma - Puday chavanNo ratings yet

- Iajicte 2022 8 1 12Document11 pagesIajicte 2022 8 1 12uday chavanNo ratings yet

- Explicit Dynamics Crash Analysis of CarDocument8 pagesExplicit Dynamics Crash Analysis of Caruday chavanNo ratings yet

- Equipment List For Computer Group (CO, CM, IF, CD, IF)Document17 pagesEquipment List For Computer Group (CO, CM, IF, CD, IF)uday chavanNo ratings yet

- Report Guidelines FinalDocument22 pagesReport Guidelines Finaluday chavanNo ratings yet

- Intuitive Surgical JP Morgan PresentationDocument25 pagesIntuitive Surgical JP Morgan PresentationmedtechyNo ratings yet

- Exhibitors ListDocument4 pagesExhibitors ListGift N PrintNo ratings yet

- Guided Tutorial For Pentaho Data Integration Using MysqlDocument39 pagesGuided Tutorial For Pentaho Data Integration Using MysqlScorpNo ratings yet

- Homemade RicottaDocument3 pagesHomemade RicottaJules PaulkNo ratings yet

- A System View To Urban Planning: An IntroductionDocument34 pagesA System View To Urban Planning: An IntroductionAzad RazaNo ratings yet

- Hepatic Critical Care: EditorsDocument312 pagesHepatic Critical Care: EditorsAhmed HegazyNo ratings yet

- Electricity Bill Receipt (2674774111)Document1 pageElectricity Bill Receipt (2674774111)Ritesh KatariyaNo ratings yet

- RMT 11100Document63 pagesRMT 11100halle cNo ratings yet

- PN Initial Exam Form 2015 160629 5774473c03485Document2 pagesPN Initial Exam Form 2015 160629 5774473c03485Syam ChandrasekharanNo ratings yet

- 10 Question Related To InheritanceDocument4 pages10 Question Related To InheritancePrashant kumarNo ratings yet

- The Ancient Greece and RomeDocument2 pagesThe Ancient Greece and RomeQuenee MagbuhospvgmaNo ratings yet

- Adce Parameter of 2gDocument4 pagesAdce Parameter of 2gAmit DevNo ratings yet

- No Load CurrentDocument23 pagesNo Load CurrentRaja Desingu100% (1)

- Senzori de CurgereDocument128 pagesSenzori de CurgerebuturcasNo ratings yet

- DR SW Config Matrix - 6K0323 - January 2016Document62 pagesDR SW Config Matrix - 6K0323 - January 2016Mastin SneadNo ratings yet

- CRMDocument9 pagesCRMJITESH KHURANANo ratings yet

- COA RulesDocument22 pagesCOA RulesNoraiza Mae Keith TalbinNo ratings yet

- Mahesh Shinde Case 1Document3 pagesMahesh Shinde Case 1mahesh shindeNo ratings yet

- Are You Fit For ISO 16890?: Thomas SchrothDocument16 pagesAre You Fit For ISO 16890?: Thomas SchrothUdhayakumar Venkataraman100% (1)

- Lesson 7 Apeco 1sDocument5 pagesLesson 7 Apeco 1sCHRISTIAN JUNTONGNo ratings yet

- Material Safety Data SheetDocument4 pagesMaterial Safety Data SheetIvani SoaresNo ratings yet

- Daily Task of Disbursing OfficerDocument2 pagesDaily Task of Disbursing OfficerEijneb OptionalNo ratings yet

- Analytical1 100Document27 pagesAnalytical1 100kaushik4208No ratings yet

- Sanitary Permit (Front)Document1 pageSanitary Permit (Front)Darwin CustodioNo ratings yet

- Combined Stress Caclulation - PveliteDocument2 pagesCombined Stress Caclulation - Pveliterajeshvyas_510% (1)

- Written By: Unknown: Yardsticks To Value Stocks in Different SectorsDocument5 pagesWritten By: Unknown: Yardsticks To Value Stocks in Different SectorsKrs_Rs_4407No ratings yet