Professional Documents

Culture Documents

Danish bc190400759

Danish bc190400759

Uploaded by

DaniOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Danish bc190400759

Danish bc190400759

Uploaded by

DaniCopyright:

Available Formats

Fall 2023

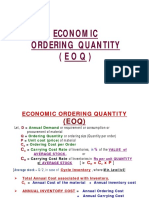

MTH601- Operations Research

Assignment No 1 Solution

Section In charge: Saima Kanwal

Muhammad Danish (bc190400759)

Question # 1

If the production of an item is instantaneous with storage cost of Rs.5 per item per

month. Other clerical and administrative costs associated to it are of Rs.30 per cycle.

Find the best time for replacement provided that its demand is Rs.250 units of items

per month.

Solution:

Demand (D) = 250 units per month

Storage cost of (C3) = Rs.5 per item per month

clerical and administrative costs associated to it are of Rs.30 per cycle

So

Ordering/purchasing/ setup cost= (C2) =0+30

By using EOQ formula we have

EOQ= √ 2 C2 D

C3

Putting values we get

EOQ= √

EOQ=√ 3000

5

2∗30∗250

EOQ= 54.77

Now the Formula of time is=D/EOQ

Best time for replacement = 250/54.77

Best time for replacement =4.56

Which is probably 5 months

Question # 2

Demand for an item in a company is 5,000 units per year and company can produce

at a rate of 1500 units per month. Cost of ordering is Rs 800 per setup and holding

cost is 20 units per year, the shortage cost is 1000 per unit per year If optimum

manufacturing quantity is 1400 then find the following

a. Time Between orders

b. Number of orders per year

Solution

As we are given with

Demand for an item in a company (D)=5000

Production (P)= 1500

Cost of ordering C2= 800

Holding cost C3=20

Shortage cost C3= 1000

Optimum manufacturing quantity (Q)= 1400

Now Time Between orders

Time Between orders TBO

The time between orders t* = Q*/ D

= 89.44/5000 (as Q* =

√ C3 √

2 C 2 D 2 x 5000 x 800

=

1000

=89.44)

=0.011 Almost

And

b. Number of orders per year

The optimum number of orders per year is determined from N* = D /Q*

N* = D /Q*

N* = 5000/89.44 (as Q* =

√ C3 √

2 C 2 D 2 x 5000 x 800

=

1000

=89.44)

=5000/89.44

N=55.9 per year

Which is approximately 56

You might also like

- Case Problem 1 Wagner Fabricating CompanyDocument3 pagesCase Problem 1 Wagner Fabricating CompanySomething ChicNo ratings yet

- TusmingmobDocument5 pagesTusmingmobRadinne Fakhri Al Wafa100% (1)

- GIA Rappaport PriceDocument2 pagesGIA Rappaport PriceAung Ye KyawNo ratings yet

- Chapter - 11a (Inventory Calculation)Document8 pagesChapter - 11a (Inventory Calculation)Kaneki Ken100% (1)

- Innovative Leadership For PresentationDocument18 pagesInnovative Leadership For PresentationAdli AlimiNo ratings yet

- SOLUTION#01:: WorkingDocument9 pagesSOLUTION#01:: Workingsameed iqbalNo ratings yet

- Inventory Management and Cash BudgetDocument3 pagesInventory Management and Cash BudgetRashi MehtaNo ratings yet

- Assignment 4 EoqDocument6 pagesAssignment 4 EoqPiyush BhandariNo ratings yet

- BC200203060Document3 pagesBC200203060Rahmeen ShahbazNo ratings yet

- Inventory Model Practice ProblemsDocument2 pagesInventory Model Practice ProblemsProfessorNo ratings yet

- 2122promana HW2 G5Document9 pages2122promana HW2 G5Dương NgNo ratings yet

- Wed - Đ Hoàng Trúc Linh - IELSIU19189Document5 pagesWed - Đ Hoàng Trúc Linh - IELSIU19189Linh DoNo ratings yet

- Network Management Homework2Document5 pagesNetwork Management Homework2Karam SalahNo ratings yet

- Inventory ModelDocument8 pagesInventory ModelCharlyn FloresNo ratings yet

- Inventory Management g6 AssignmentDocument8 pagesInventory Management g6 AssignmentLe Thi Nhu QuynhNo ratings yet

- Assignment 2Document5 pagesAssignment 2N.SNo ratings yet

- Chapter 2 Cost Concepts and Design Economics (Cont.)Document20 pagesChapter 2 Cost Concepts and Design Economics (Cont.)thuy duongNo ratings yet

- FB2201 Management Sciences II Week 3 Tutorial: Information About The TutorialDocument16 pagesFB2201 Management Sciences II Week 3 Tutorial: Information About The TutorialAshtar Ali BangashNo ratings yet

- Exercises of Inventory ManagementDocument7 pagesExercises of Inventory ManagementĐức NguyễnNo ratings yet

- MTH601Document3 pagesMTH601gulfamshafqat945No ratings yet

- Sample Final Questions: LT Daily DemandDocument4 pagesSample Final Questions: LT Daily DemandraymondNo ratings yet

- Aashita - Inventory Management Homework PDFDocument6 pagesAashita - Inventory Management Homework PDFAashita JainNo ratings yet

- June 2013 Inventory ManagementDocument68 pagesJune 2013 Inventory ManagementShasank JalanNo ratings yet

- Nguyễn Thị Như Quỳnh - IELSIU19252 - HW2Document6 pagesNguyễn Thị Như Quỳnh - IELSIU19252 - HW2Nguyễn QuỳnhNo ratings yet

- Comsats University Islamabad Abbottabad Campus Engineering Economics Assigment 04Document13 pagesComsats University Islamabad Abbottabad Campus Engineering Economics Assigment 04yaseen ayazNo ratings yet

- School of Industrial Engineering & Management (IEM) International University, VNU-HCM Inventory Management Instructor: Dr. Nguyen Van HopDocument4 pagesSchool of Industrial Engineering & Management (IEM) International University, VNU-HCM Inventory Management Instructor: Dr. Nguyen Van Hopngan tranNo ratings yet

- 29.11.2023 Inventory Mangement DetailsDocument5 pages29.11.2023 Inventory Mangement Detailsnatasha adyraNo ratings yet

- Thomas Kratzer SolutionDocument3 pagesThomas Kratzer SolutionHumphrey OsaigbeNo ratings yet

- Various Inventory Costs: - Holding / - Ordering Costs - Purchase Costs - Total CostDocument28 pagesVarious Inventory Costs: - Holding / - Ordering Costs - Purchase Costs - Total CostAditya Dashputre100% (2)

- Categories of Costing MethodsDocument9 pagesCategories of Costing Methodskitderoger_391648570No ratings yet

- Konsep Biaya Ekonomik Teknik 2021 CompressDocument21 pagesKonsep Biaya Ekonomik Teknik 2021 Compresssalsa febriantiNo ratings yet

- EEE - Assignment 2 Sanjeev 16001174 PDFDocument7 pagesEEE - Assignment 2 Sanjeev 16001174 PDFSanjeev Nehru100% (1)

- Test Exam Practice Questions and Answers Logistics 2 2012 2013 2014Document10 pagesTest Exam Practice Questions and Answers Logistics 2 2012 2013 2014طه احمدNo ratings yet

- 1 Given:: D Annual Demand Per Unit S Ordering Cost Per Purchse Order H Holding Cost Per UnitDocument13 pages1 Given:: D Annual Demand Per Unit S Ordering Cost Per Purchse Order H Holding Cost Per Unitkerie gashayeNo ratings yet

- Konsep Biaya - Ekonomik Teknik - 2021Document21 pagesKonsep Biaya - Ekonomik Teknik - 2021TPTL1CDzaky Fauzan Hilmy A.No ratings yet

- Sotero 5quiz! InventoryDocument2 pagesSotero 5quiz! Inventorybernadette soteroNo ratings yet

- F2 Mock Answers 201603Document6 pagesF2 Mock Answers 201603MD.Rakibul HasanNo ratings yet

- The Production Qauntity ModelDocument21 pagesThe Production Qauntity ModelVibhor AggarwalNo ratings yet

- Application of Differential CalculusDocument22 pagesApplication of Differential Calculusmahbub007No ratings yet

- Mine Economics PDFDocument28 pagesMine Economics PDFBelle Estal PalajosNo ratings yet

- Assignment #3 InventoryDocument13 pagesAssignment #3 InventoryAnkit SainiNo ratings yet

- Kyambogo University: Be 414: Analysis of Prices and EstimatingDocument9 pagesKyambogo University: Be 414: Analysis of Prices and EstimatingotimNo ratings yet

- MGMT 3100 CH 4 ExerciseDocument2 pagesMGMT 3100 CH 4 ExerciseJames Riley CaseNo ratings yet

- Slides-SC2Document17 pagesSlides-SC2atyam lekhazNo ratings yet

- PPP - Homework 4Document7 pagesPPP - Homework 4Wiratha Nungrat67% (3)

- Application of Differential CalculusDocument21 pagesApplication of Differential CalculusTareq Islam100% (1)

- Chapter 5 EOQDocument16 pagesChapter 5 EOQAmal ANo ratings yet

- EOQ Model PresentaionDocument18 pagesEOQ Model PresentaionNauman RashidNo ratings yet

- Chapter 2 Cost Concepts and Design Econo PDFDocument31 pagesChapter 2 Cost Concepts and Design Econo PDFMahammad YusifNo ratings yet

- Quantity DiscountDocument22 pagesQuantity Discountkevin royNo ratings yet

- T4 Quantitative Analysis 2 (A)Document6 pagesT4 Quantitative Analysis 2 (A)JIN FEN SOONo ratings yet

- Individual Assignment Chapter 12 - Aliza Safira S.PDocument4 pagesIndividual Assignment Chapter 12 - Aliza Safira S.PNatally LangfeldtNo ratings yet

- Problem Set - Week 11 - Class 2 Solutions ICGN104 Mathematics and Its Contemporary ApplicationsDocument4 pagesProblem Set - Week 11 - Class 2 Solutions ICGN104 Mathematics and Its Contemporary ApplicationsPatricia Arroyo oliverosNo ratings yet

- Engineering Management 3000/5039: Tutorial 2 - SolutionsDocument7 pagesEngineering Management 3000/5039: Tutorial 2 - SolutionsSahanNo ratings yet

- Simple Question (2 Marks) : A-How Many Engines Should Harley Load Onto Each Truck?Document3 pagesSimple Question (2 Marks) : A-How Many Engines Should Harley Load Onto Each Truck?عبد المجيد ياسر عبد المجيد غانمNo ratings yet

- EMBA Induction Session 3Document28 pagesEMBA Induction Session 3Dhananjay ShrivastavNo ratings yet

- Inventory MGMT Fitesa EjercicioDocument6 pagesInventory MGMT Fitesa EjercicioAriana Mato De La CruzNo ratings yet

- (Solution) 2324ProdMgmt HW2Document8 pages(Solution) 2324ProdMgmt HW2Như TâmNo ratings yet

- Fallsem2017-18 Bmt2013 TH Sjt601 Vl2017181002989 Reference Material I Course Matrl-3 SCM JPM F Sem 2017-18Document39 pagesFallsem2017-18 Bmt2013 TH Sjt601 Vl2017181002989 Reference Material I Course Matrl-3 SCM JPM F Sem 2017-18Pulkit JainNo ratings yet

- Final Managerial 2013 SolutionDocument6 pagesFinal Managerial 2013 SolutionRanim HfaidhiaNo ratings yet

- 3Q14 Results: Bualuang SecuritiesDocument9 pages3Q14 Results: Bualuang SecuritiesAj JaNo ratings yet

- How Visa Makes Money and Understaning Visa Business ModelDocument5 pagesHow Visa Makes Money and Understaning Visa Business ModelAchintya MittalNo ratings yet

- A Positioning Analysis of Hotel Brands - Based On Travel-ManagerDocument10 pagesA Positioning Analysis of Hotel Brands - Based On Travel-ManagerDavidLe50% (2)

- EMBA ClassDirectory 2014Document12 pagesEMBA ClassDirectory 2014sisqokcNo ratings yet

- Monthly HSE Report May - 2022Document2 pagesMonthly HSE Report May - 2022tv seriesNo ratings yet

- International Trade and Finance CrosswordInternational Trade and Finance Crossword - WordMint QuestıonsDocument2 pagesInternational Trade and Finance CrosswordInternational Trade and Finance Crossword - WordMint QuestıonsSandy SaddlerNo ratings yet

- Duty To ClientDocument8 pagesDuty To ClientLuqman HakeemNo ratings yet

- Question Paper Code 71072Document2 pagesQuestion Paper Code 71072puneetk20No ratings yet

- Entrepreneurship & Start-UpsDocument2 pagesEntrepreneurship & Start-UpsRocky RajNo ratings yet

- Motivation of SubordinatesDocument4 pagesMotivation of SubordinatesNeha SinghNo ratings yet

- Presentation On Parenting-Fit MatrixDocument9 pagesPresentation On Parenting-Fit MatrixSantanu Dutta100% (1)

- Case Study Chapter 4Document2 pagesCase Study Chapter 4Grace CaparinoNo ratings yet

- Aramco Audit Check ListDocument3 pagesAramco Audit Check ListHemaNo ratings yet

- Summary of Pas 16 NDocument5 pagesSummary of Pas 16 NJenny Hermosado100% (1)

- Swing Trading With The Help of Bollinger Band and ADX (Tue, May 7 2013)Document5 pagesSwing Trading With The Help of Bollinger Band and ADX (Tue, May 7 2013)Scalper2013100% (1)

- GB Template 01 Kano AnalysisDocument4 pagesGB Template 01 Kano AnalysisharshalNo ratings yet

- JA Business PlanDocument10 pagesJA Business PlanJenevey AlcoberNo ratings yet

- Vedk Village Ajmer AddressDocument16 pagesVedk Village Ajmer AddressNotoriousNo ratings yet

- Bjcorp 16Document336 pagesBjcorp 16Pmbelajaran Pmbelajaranz100% (1)

- ENG233 Ch2Document34 pagesENG233 Ch2Mikaela PadernaNo ratings yet

- Resume Chapter 1 Internal AuditDocument7 pagesResume Chapter 1 Internal AuditTommy Tia RaharjaNo ratings yet

- User Manual: Everything You Need To Know About Your New Digital Telephone Service!Document19 pagesUser Manual: Everything You Need To Know About Your New Digital Telephone Service!John S StoyNo ratings yet

- Ann's Tortillas VAT CERTIFICATEDocument1 pageAnn's Tortillas VAT CERTIFICATEgustron1No ratings yet

- 16 July 2013 2013/17 Compliance in Focus 2013Document6 pages16 July 2013 2013/17 Compliance in Focus 2013Political AlertNo ratings yet

- Principles of Good AdvertisingDocument17 pagesPrinciples of Good AdvertisingPankaj GuptaNo ratings yet

- 010 Maersk Line V CADocument3 pages010 Maersk Line V CAthornapple25100% (1)

- Sip G7Document6 pagesSip G7routemansNo ratings yet

- 3D Printing of MoldsDocument43 pages3D Printing of MoldsPramendra7No ratings yet