Professional Documents

Culture Documents

PC-ABS Bayblend FR3010

PC-ABS Bayblend FR3010

Uploaded by

countzeroaslCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PC-ABS Bayblend FR3010

PC-ABS Bayblend FR3010

Uploaded by

countzeroaslCopyright:

Available Formats

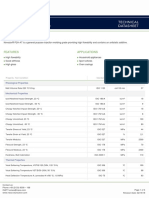

Bayblend® FR3010

Polycarbonate + ABS www.ulprospector.com

Covestro - Polycarbonates

Technical Data

Product Description

(PC+ABS)-Blend; flame retardant; Vicat/B 120 temperature = 110°C; increased heat resistance; UL recognition 94 V-0 at 1.5 mm; glow wire

temperature (GWFI): 960°C at 2.0 mm; improved chemical resistance and stress cracking behavior; successor to FR2010

General

Material Status • Commercial: Active

• Technical Datasheet (Chinese (Traditional))

• Technical Datasheet (Chinese)

Literature 1 • Technical Datasheet (English)

• Technical Datasheet (German)

• Technical Datasheet (Japanese)

UL Yellow Card 2 • E41613-268915

Search for UL Yellow Card

• Covestro - Polycarbonates

• Bayblend®

• Africa & Middle East • Europe

Availability • North America

• Asia Pacific • Latin America

Additive • Flame Retardant

• Chemical Resistant • High ESCR (Stress Crack

Features Resist.)

• Flame Retardant • Medium Heat Resistance

RoHS Compliance • RoHS Compliant

Physical Nominal Value (English) Nominal Value (SI) Test Method

Density (73°F (23°C)) 1.18 g/cm³ 1.18 g/cm³ ISO 1183

Melt Volume-Flow Rate (MVR) (240°C/5.0 kg) 0.915 in³/10min 15.0 cm³/10min ISO 1133

Molding Shrinkage 4 ISO 2577

Across Flow : 464°F (240°C), 0.118 in (3.00

0.50 to 0.70 % 0.50 to 0.70 %

mm)

Flow : 464°F (240°C), 0.118 in (3.00 mm) 0.50 to 0.70 % 0.50 to 0.70 %

Water Absorption ISO 62

Saturation, 73°F (23°C) 0.50 % 0.50 %

Equilibrium, 73°F (23°C), 50% RH 0.20 % 0.20 %

Mechanical Nominal Value (English) Nominal Value (SI) Test Method

Tensile Modulus (73°F (23°C)) 392000 psi 2700 MPa ISO 527-2/1

Tensile Stress ISO 527-2/50

Yield, 73°F (23°C) 8700 psi 60.0 MPa

Break, 73°F (23°C) 7250 psi 50.0 MPa

Tensile Strain ISO 527-2/50

Yield, 73°F (23°C) 4.0 % 4.0 %

Break, 73°F (23°C) > 50 % > 50 %

Impact Nominal Value (English) Nominal Value (SI) Test Method

Notched Izod Impact Strength ISO 180/A

-22°F (-30°C) 4.8 ft·lb/in² 10 kJ/m²

73°F (23°C) 17 ft·lb/in² 35 kJ/m²

Unnotched Izod Impact Strength (73°F (23°C)) No Break No Break ISO 180

1 of 4 Form No. TDS-102711-en

UL and the UL logo are trademarks of UL LLC © 2018. All Rights Reserved. Document Created: Monday, June 11, 2018

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: May 2007

Last Updated: 5/11/2018

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

Bayblend® FR3010

Polycarbonate + ABS

Covestro - Polycarbonates www.ulprospector.com

Thermal Nominal Value (English) Nominal Value (SI) Test Method

Heat Deflection Temperature

66 psi (0.45 MPa), Unannealed 212 °F 100 °C ISO 75-2/B

264 psi (1.8 MPa), Unannealed 194 °F 90.0 °C ISO 75-2/A

Vicat Softening Temperature

-- 226 °F 108 °C ISO 306/B50

-- 230 °F 110 °C ISO 306/B120

CLTE ISO 11359-2

Flow : 73 to 131°F (23 to 55°C) 4.2E-5 in/in/°F 7.6E-5 cm/cm/°C

Transverse : 73 to 131°F (23 to 55°C) 4.4E-5 in/in/°F 8.0E-5 cm/cm/°C

Electrical Nominal Value (English) Nominal Value (SI) Test Method

Surface Resistivity 1.0E+16 ohms 1.0E+16 ohms IEC 60093

Volume Resistivity (73°F (23°C)) 1.0E+16 ohms·cm 1.0E+16 ohms·cm IEC 60093

Electric Strength IEC 60243-1

73°F (23°C), 0.0394 in (1.00 mm) 890 V/mil 35 kV/mm

Relative Permittivity IEC 60250

73°F (23°C), 100 Hz 3.20 3.20

73°F (23°C), 1 MHz 3.10 3.10

Dissipation Factor IEC 60250

73°F (23°C), 100 Hz 5.0E-3 5.0E-3

73°F (23°C), 1 MHz 7.0E-3 7.0E-3

Comparative Tracking Index (Solution A) 350 V 350 V IEC 60112

Flammability Nominal Value (English) Nominal Value (SI) Test Method

Flame Rating UL 94

0.06 in (1.5 mm) V-0 V-0

0.08 in (2.0 mm) 5VB 5VB

0.12 in (3.0 mm) 5VA 5VA

Oxygen Index 5 32 % 32 % ISO 4589-2

Fill Analysis Nominal Value (English) Nominal Value (SI) Test Method

Melt Viscosity 6 (500°F (260°C)) 245 Pa·s 245 Pa·s ISO 11443-A

Additional Information Nominal Value (English) Nominal Value (SI)

ISO Shortname PC+ABS-FR(40) PC+ABS-FR(40)

Injection Nominal Value (English) Nominal Value (SI)

Drying Temperature - Dry Air Dryer 176 °F 80 °C

Drying Time - Dry Air Dryer 4.0 hr 4.0 hr

Suggested Max Moisture < 0.020 % < 0.020 %

Suggested Shot Size 30 to 70 % 30 to 70 %

Rear Temperature 428 to 446 °F 220 to 230 °C

Middle Temperature 437 to 455 °F 225 to 235 °C

Front Temperature 446 to 464 °F 230 to 240 °C

Nozzle Temperature 491 to 509 °F 255 to 265 °C

Processing (Melt) Temp 464 to 518 °F 240 to 270 °C

Mold Temperature 140 to 194 °F 60 to 90 °C

Back Pressure 725 to 2180 psi 5.00 to 15.0 MPa

Vent Depth 9.8E-4 to 3.0E-3 in 0.025 to 0.075 mm

Injection Notes

Standard Melt Temperature: 260°C

Hold Pressure (% of Injection Pressure): 50 - 75%

Peripheral Screw Speed: 0.05 - 0.2 m/s

2 of 4 Form No. TDS-102711-en

UL and the UL logo are trademarks of UL LLC © 2018. All Rights Reserved. Document Created: Monday, June 11, 2018

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: May 2007

Last Updated: 5/11/2018

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

Bayblend® FR3010

Polycarbonate + ABS

Covestro - Polycarbonates www.ulprospector.com

Notes

1 These links provide you with access to supplier literature. We work hard to keep them up to date; however you may find the most current literature

from the supplier.

2 A UL Yellow Card contains UL-verified flammability and electrical characteristics. UL Prospector continually works to link Yellow Cards to

individual plastic materials in Prospector, however this list may not include all of the appropriate links. It is important that you verify the association

between these Yellow Cards and the plastic material found in Prospector. For a complete listing of Yellow Cards, visit the UL Yellow Card Search.

3 Typical properties: these are not to be construed as specifications.

4 150x105x3mm,, MT 80°C

5 Procedure A

6 1000s-1

3 of 4 Form No. TDS-102711-en

UL and the UL logo are trademarks of UL LLC © 2018. All Rights Reserved. Document Created: Monday, June 11, 2018

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: May 2007

Last Updated: 5/11/2018

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

Bayblend® FR3010

Polycarbonate + ABS

Covestro - Polycarbonates www.ulprospector.com

Where to Buy

Supplier

Covestro - Polycarbonates

Leverkusen, Germany

Telephone: +49-214-6009-2000

Web: http://www.plastics.covestro.com/

Distributor

ALBIS Plastic

ALBIS Plastic is a global distribution and compounding company. Contact ALBIS Plastic for availability of individual products per country.

Telephone: +49-40-78105-0

Web: http://www.albis.com/

Availability: Algeria, Austria, Belgium, China, Czech Republic, Denmark, Estonia, Finland, France, Germany, Hong Kong, Hungary, Ireland,

Latvia, Lithuania, Luxembourg, Morocco, Netherlands, Norway, Poland, Portugal, Romania, Russian Federation, Slovakia, Spain, Sweden,

Switzerland, Tunisia, Turkey, United Kingdom

Amco Polymers

Telephone: 800-262-6685

Web: http://www.amcopolymers.com/

Availability: North America

M. Holland Company

Telephone: 855-497-1403

Web: http://www.mholland.com/

Availability: Mexico, United States

PolyOne Distribution

PolyOne Distribution is a global distribution company. Contact PolyOne Distribution for availability of individual products by country.

Telephone: 800-894-4266

Web: http://polyonedistribution.com/

Availability: Global

Reseller

A Reseller is not a distributor authorized by the Supplier.

Shanghai Jingyang New Material Technology Co., Ltd

Telephone: +86-021-80394788; Mr. Zhou: +86-15821998203

Web: http://www.basfppsu.com/

Availability: Asia Pacific, China

4 of 4 Form No. TDS-102711-en

UL and the UL logo are trademarks of UL LLC © 2018. All Rights Reserved. Document Created: Monday, June 11, 2018

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: May 2007

Last Updated: 5/11/2018

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

You might also like

- KM2V80 Service Manual PDFDocument55 pagesKM2V80 Service Manual PDFPacho Santacruz100% (2)

- SPI Customs Practices MoldmakingDocument21 pagesSPI Customs Practices MoldmakingcountzeroaslNo ratings yet

- CYCOLOY™ Resin - LG9000 - Europe - Technical - Data - SheetDocument2 pagesCYCOLOY™ Resin - LG9000 - Europe - Technical - Data - SheetmustafaNo ratings yet

- LNP Wear Resistant PlasticsDocument26 pagesLNP Wear Resistant PlasticscountzeroaslNo ratings yet

- Product PDF 102737Document5 pagesProduct PDF 102737vaibhav ShindeNo ratings yet

- Polyflam Rabs 90000 Uv5 LS (E128762)Document3 pagesPolyflam Rabs 90000 Uv5 LS (E128762)simonNo ratings yet

- Delrin® 127UV NC010Document3 pagesDelrin® 127UV NC010alejandrocharlescollNo ratings yet

- Toyolac® 920 555: Toray Industries, IncDocument2 pagesToyolac® 920 555: Toray Industries, IncVu TranNo ratings yet

- Ultradur® S 4090 G2Document4 pagesUltradur® S 4090 G2srinivasaNo ratings yet

- PC Makrolon 2405Document5 pagesPC Makrolon 2405countzeroaslNo ratings yet

- PP COPO GenericDocument4 pagesPP COPO GenericJames FaunceNo ratings yet

- Eurotec® Tecomid® NA40 MR15 NL IL PA6.6, 15% Mineral Filled, Impact Modified, NaturalDocument1 pageEurotec® Tecomid® NA40 MR15 NL IL PA6.6, 15% Mineral Filled, Impact Modified, NaturalmuthuNo ratings yet

- Torelina® A490MA50: Toray Resin CompanyDocument2 pagesTorelina® A490MA50: Toray Resin CompanyChunYenHuangNo ratings yet

- Ultraform W 2320 003 UNC Q600Document3 pagesUltraform W 2320 003 UNC Q600Patricio Bravo CastilloNo ratings yet

- Pulse A 35-105 BlackDocument3 pagesPulse A 35-105 BlackTaoufik KheddarNo ratings yet

- Victrex TDS 450GDocument3 pagesVictrex TDS 450GPRAMOD KUMARNo ratings yet

- Wonderlite® PC-110Document3 pagesWonderlite® PC-110Rhekron PlasticsNo ratings yet

- Evonik Corporation Vestamid X7293 Plasticized Nylon 12Document3 pagesEvonik Corporation Vestamid X7293 Plasticized Nylon 12Prabhu MohanNo ratings yet

- Styron ATECH 1175 DatasheetDocument3 pagesStyron ATECH 1175 DatasheetbobNo ratings yet

- Covestro Bayblend® FR3000 PC - ABS BlendDocument2 pagesCovestro Bayblend® FR3000 PC - ABS Blendavinashchauhan2695No ratings yet

- PC Lexan HP6NR Healthcare - ProspectorDocument5 pagesPC Lexan HP6NR Healthcare - ProspectorcountzeroaslNo ratings yet

- Styrolution PS 576H HIPSDocument3 pagesStyrolution PS 576H HIPSKevin AlvaradoNo ratings yet

- SABIC® PC Resin PC0703R - AsiaDocument4 pagesSABIC® PC Resin PC0703R - AsiaLong Trịnh ĐìnhNo ratings yet

- Titanvene™ HD6070EADocument2 pagesTitanvene™ HD6070EAputriNo ratings yet

- XENOY™ Resin - 5220U - Europe - Technical - Data - SheetDocument2 pagesXENOY™ Resin - 5220U - Europe - Technical - Data - SheetEduardo TreviñoNo ratings yet

- Styrolution PS 476LDocument3 pagesStyrolution PS 476LLong Trịnh ĐìnhNo ratings yet

- Santoprene™ 121-75M100: Thermoplastic VulcanizateDocument3 pagesSantoprene™ 121-75M100: Thermoplastic VulcanizateBrian García AguirreNo ratings yet

- Luran HH-120: Please SelectDocument3 pagesLuran HH-120: Please SelectDavid Costi da RosaNo ratings yet

- Abs Irpc Polimaxx SP100Document2 pagesAbs Irpc Polimaxx SP100countzeroaslNo ratings yet

- 300.002 Abs3416naDocument3 pages300.002 Abs3416naEnriqueNo ratings yet

- TPP40AE62BK Black - TDSDocument1 pageTPP40AE62BK Black - TDSlaboratorioNo ratings yet

- Evonik Corporation Vestamid® L1833 30% Glass Filled Nylon 12Document3 pagesEvonik Corporation Vestamid® L1833 30% Glass Filled Nylon 12ken bernard BurburanNo ratings yet

- Polyplastics TOPAS® 8007S-04 Cyclic Olefin Copolymer (COC)Document3 pagesPolyplastics TOPAS® 8007S-04 Cyclic Olefin Copolymer (COC)cir74636No ratings yet

- Novodur P2H-ATDocument3 pagesNovodur P2H-ATavinashchauhan2695No ratings yet

- Styrolution TDS401100270877Document3 pagesStyrolution TDS401100270877antonio.sevelarNo ratings yet

- Victrex - Peek Data SheetDocument2 pagesVictrex - Peek Data SheetM J VoraNo ratings yet

- TDS BorSafe ME3444 (E115026)Document2 pagesTDS BorSafe ME3444 (E115026)charlesNo ratings yet

- INVISTA U5101 PA66 Technical Data SheetDocument2 pagesINVISTA U5101 PA66 Technical Data SheetWARRAPONG THUNYAMANUKULNo ratings yet

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ISO)Document1 pageABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ISO)DiegoTierradentroNo ratings yet

- Product PDF 128Document3 pagesProduct PDF 128madkatteNo ratings yet

- 300.056 Magnum 3416 SCDocument3 pages300.056 Magnum 3416 SCEnrique ChavezNo ratings yet

- Sabic® PP 37MK10RDocument2 pagesSabic® PP 37MK10RGiang CaoNo ratings yet

- Styrolution PS 147F: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 147F: General Purpose Polystyrene (GPPS)Ayaan Anowar100% (1)

- Celstran® PA66-GF50-07Document1 pageCelstran® PA66-GF50-07Ankur PanwarNo ratings yet

- Resina Nueva Validacion SkytronDocument2 pagesResina Nueva Validacion SkytronAlbert FortunatoNo ratings yet

- INVISTA U4630HSL PA66 Technical Data Sheetv2Document2 pagesINVISTA U4630HSL PA66 Technical Data Sheetv2Lucas Valentim MendesNo ratings yet

- Victrex™ Peek 450G™: Product DescriptionDocument2 pagesVictrex™ Peek 450G™: Product DescriptionBerkant CangalNo ratings yet

- VictrexTDS150G 151GDocument2 pagesVictrexTDS150G 151GKumaar RanjanNo ratings yet

- Xydar® SRT-900 by Syensqo ADPDocument3 pagesXydar® SRT-900 by Syensqo ADPFAUSANo ratings yet

- Aashto Grade Bearing PadsDocument2 pagesAashto Grade Bearing PadsJose ManzanarezNo ratings yet

- PC Calibre Technical DataDocument4 pagesPC Calibre Technical DataMitja GorseNo ratings yet

- Hoja Tecnica Tairirex GP5000Document2 pagesHoja Tecnica Tairirex GP5000Jaimito Ramirez RodasNo ratings yet

- Styrolution PS 476L: Technical DatasheetDocument3 pagesStyrolution PS 476L: Technical DatasheetTRUONGNo ratings yet

- Diakon® ST35G8: Lucite International Holland BVDocument3 pagesDiakon® ST35G8: Lucite International Holland BVbobNo ratings yet

- Product PDF 181Document2 pagesProduct PDF 181RicardoNo ratings yet

- CAMPUS® Datasheet: Ultradur® B 4406 G6 Q798 SW 15138 - PBT-GF30 FR BasfDocument5 pagesCAMPUS® Datasheet: Ultradur® B 4406 G6 Q798 SW 15138 - PBT-GF30 FR BasfdivyarasinNo ratings yet

- Product PDF 301308Document2 pagesProduct PDF 301308Andrew JacksonNo ratings yet

- Hazardous Gas Monitoring, Fifth Edition: A Guide for Semiconductor and Other Hazardous OccupanciesFrom EverandHazardous Gas Monitoring, Fifth Edition: A Guide for Semiconductor and Other Hazardous OccupanciesNo ratings yet

- Plastics Testing and Characterization: Industrial ApplicationsFrom EverandPlastics Testing and Characterization: Industrial ApplicationsNo ratings yet

- Inductively Coupled Plasma-Mass Spectrometry: Practices and TechniquesFrom EverandInductively Coupled Plasma-Mass Spectrometry: Practices and TechniquesNo ratings yet

- PA BASF Ultramid B3ZG6 MSDSDocument5 pagesPA BASF Ultramid B3ZG6 MSDScountzeroaslNo ratings yet

- TPU Estane 2102-80ADocument1 pageTPU Estane 2102-80AcountzeroaslNo ratings yet

- RTPU LTL TPU11015 BK700 RoHS 3 2015-863-EUDocument1 pageRTPU LTL TPU11015 BK700 RoHS 3 2015-863-EUcountzeroaslNo ratings yet

- CA36B Mapping Guide Battle TilesDocument4 pagesCA36B Mapping Guide Battle TilescountzeroaslNo ratings yet

- PA BASF Ultramid 7523-2AM MSDSDocument5 pagesPA BASF Ultramid 7523-2AM MSDScountzeroaslNo ratings yet

- TPE-TPV Sarlink 4155 ProspectorDocument4 pagesTPE-TPV Sarlink 4155 ProspectorcountzeroaslNo ratings yet

- PC Lexan 500 10%GLDocument3 pagesPC Lexan 500 10%GLcountzeroaslNo ratings yet

- PA BASF Ultramid 8333GHI BK102 MSDSDocument5 pagesPA BASF Ultramid 8333GHI BK102 MSDScountzeroaslNo ratings yet

- PC Lexan HP6NR Healthcare - ProspectorDocument5 pagesPC Lexan HP6NR Healthcare - ProspectorcountzeroaslNo ratings yet

- PBT-PC Valox 357Document5 pagesPBT-PC Valox 357countzeroaslNo ratings yet

- HDPE Lupolen 5121Document3 pagesHDPE Lupolen 5121countzeroaslNo ratings yet

- ABS LTL Inelec ABSASDocument1 pageABS LTL Inelec ABSAScountzeroaslNo ratings yet

- Abs Irpc Polimaxx SP100Document2 pagesAbs Irpc Polimaxx SP100countzeroaslNo ratings yet

- 90ton Milacron - PLATENDocument1 page90ton Milacron - PLATENcountzeroaslNo ratings yet

- PA 66 Zytel 101Document2 pagesPA 66 Zytel 101countzeroaslNo ratings yet

- ABS RTP PermaStat 600 - RoHS 02-20-15Document1 pageABS RTP PermaStat 600 - RoHS 02-20-15countzeroaslNo ratings yet

- Cypher System Open License 2022 07 25Document2 pagesCypher System Open License 2022 07 25countzeroaslNo ratings yet

- 3d Graph PaperDocument1 page3d Graph PapercountzeroaslNo ratings yet

- Kenton HawthorneDocument3 pagesKenton HawthornecountzeroaslNo ratings yet

- Siemens SW The Executives Guide To Digital Manufacturing E Book Tcm27 100102Document20 pagesSiemens SW The Executives Guide To Digital Manufacturing E Book Tcm27 100102countzeroaslNo ratings yet

- Yellowing and Pinking of White PE & PPDocument6 pagesYellowing and Pinking of White PE & PPcountzeroaslNo ratings yet

- The Gospel and The Church - Ronald E. PoelmanDocument4 pagesThe Gospel and The Church - Ronald E. PoelmancountzeroaslNo ratings yet

- RuneQuest 4E - Legendary Heroes - Web EnhancementDocument6 pagesRuneQuest 4E - Legendary Heroes - Web EnhancementcountzeroaslNo ratings yet

- Paint Mate 200ia Series - 27Document4 pagesPaint Mate 200ia Series - 27countzeroaslNo ratings yet

- Exercise 2 Axial ElementDocument22 pagesExercise 2 Axial ElementwanpudinNo ratings yet

- Yard-Man: Operator'S ManualDocument20 pagesYard-Man: Operator'S ManualLarry CaldwellNo ratings yet

- Shore D Hardness of Cast PA6 Based CompositesDocument5 pagesShore D Hardness of Cast PA6 Based CompositesJigar M. UpadhyayNo ratings yet

- Surface Preparation Metallizing ProcedureDocument6 pagesSurface Preparation Metallizing ProcedureCorrosion FactoryNo ratings yet

- Tutorials - 1 To 12Document19 pagesTutorials - 1 To 12Subhash ChandraNo ratings yet

- Calculo Banda TrasnportadoraDocument10 pagesCalculo Banda TrasnportadoraHugo Mario Ariza PalacioNo ratings yet

- Garrett GT1544Document1 pageGarrett GT1544Patricio IvanNo ratings yet

- Hy Specs CatalogueDocument24 pagesHy Specs CatalogueJamyansuren TseveendorjNo ratings yet

- Ship Handling Principles PDFDocument3 pagesShip Handling Principles PDFClarence PieterszNo ratings yet

- 3615Document28 pages3615Aaron AngNo ratings yet

- 3TNV 76ggehDocument10 pages3TNV 76ggehhectorNo ratings yet

- Ch14 FluidMechanics-P2Document17 pagesCh14 FluidMechanics-P2Samir ZaghloolNo ratings yet

- Robotic Pick and Place ArmDocument32 pagesRobotic Pick and Place Armrock star100% (1)

- Waves Sound HWDocument1 pageWaves Sound HWaxiang88No ratings yet

- Anti-Peeling Rolling Bearing With Manganese Phosphate CoatingDocument6 pagesAnti-Peeling Rolling Bearing With Manganese Phosphate Coatingmans2014No ratings yet

- 3 Ton 36000 BTUs Split Air ConditionersDocument2 pages3 Ton 36000 BTUs Split Air ConditionersNayif MuhammedNo ratings yet

- FIAT KOBELCO Ex255t Service Manual PDFDocument971 pagesFIAT KOBELCO Ex255t Service Manual PDFjony89% (18)

- CastingDocument5 pagesCastingTahar DabbarNo ratings yet

- Tube Expansion ProcedureDocument3 pagesTube Expansion Procedurerudi 01100% (1)

- CL8552-23 4263443Document40 pagesCL8552-23 4263443Heran Gonzalez100% (1)

- O&M - Manual Index For ACBIL ProjectDocument10 pagesO&M - Manual Index For ACBIL ProjectMahendra Pratap SinghNo ratings yet

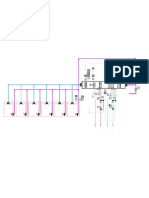

- 17MC-UL-DMH07-00 (P&ID System 1.1) - ModelDocument1 page17MC-UL-DMH07-00 (P&ID System 1.1) - Modelkhilifi chaoukiNo ratings yet

- Valve Sizing Worksheet InstructionsDocument14 pagesValve Sizing Worksheet Instructionsmilton1987No ratings yet

- A Review Paper On Abrasive Wear CharacteristicsDocument6 pagesA Review Paper On Abrasive Wear CharacteristicsSalem GarrabNo ratings yet

- Yamaha YJ50 Service Manual PDFDocument228 pagesYamaha YJ50 Service Manual PDFดิษย์ธีเดช ชีวาอัครพัฒน์No ratings yet

- Rock MechanicsDocument2 pagesRock MechanicsPrincess Morales TyNo ratings yet

- Day1 1 Airflow in A System Rad GaneshDocument28 pagesDay1 1 Airflow in A System Rad GaneshAzrinshah Abu BakarNo ratings yet

- Vacuum Unit Pressure Control PTQ Revamps 2006Document5 pagesVacuum Unit Pressure Control PTQ Revamps 2006majope1966No ratings yet

- Welding Processes and TechniqueDocument49 pagesWelding Processes and TechniqueRanendraNo ratings yet