Professional Documents

Culture Documents

CT03 De-Ox TIG

CT03 De-Ox TIG

Uploaded by

Rogério JuniorOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CT03 De-Ox TIG

CT03 De-Ox TIG

Uploaded by

Rogério JuniorCopyright:

Available Formats

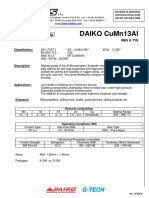

Copper Alloy

Tungsten Inert Gas (TIG) and Oxy-Fuel Rod Datasheet CT03

TALWELD De-Ox TIG

Classification

AWS.A5.7 ERCu

Description

TALWELD DE-OX (ER Cu) filler metal is deoxidized copper with small quantities of

phosphorus, silicon, tin and manganese. The phosphorus and silicon are primarily deoxidizers,

while silicon and other elements improve fluidity and ease of welding.

Application

This metal is normally used to weld deoxidized copper (C12000 and C12200) and

electrolytic tough pitch copper (C11000). Preheating is desirable for most work, but it is essential

for heavier gauge welding. Preheating temperatures of 205ºC to 540ºC are recommended.

Shielding Gas

Welding grade Argon for GTAW (TIG)

Chemical Composition of Solid Wire

Total

Cu Sn Mn Si Al P Pb

Others

98.0 1.0 0.5 0.5 0.01 0.15 0.02 0.50

Min. Max. Max. Max. Max. Max. Max. Max.

Typical Mechanical Properties of Weldmetal

Tensile strength Yield strength Elongation

210 MPa 60 MPa 29%

Packaging

Diam. (mm) 1.6 2.4 3.2

Pack 5kg 5kg 5kg

Length (mm) 1000 1000 1000

Diam. 5kg Pack TALARC Pty Ltd

10-16 Syme St

1.6mm CTCDEOX16 Brunswick, Vic 3056

2.4mm CTCDEOX24 Ph. +61 3 9388 0588 Fax: +61 3 9388 0710

3.2mm CTCDEOX32 W: www.talarc.com E: sales@talarc.com

You might also like

- C 70 SuperthermDocument2 pagesC 70 SuperthermMandeep SinghNo ratings yet

- Stainless SteelDocument1 pageStainless SteelSadashiva sahoo100% (1)

- Alloy 308Document4 pagesAlloy 308Branko FerenčakNo ratings yet

- AUTROD 316LSiDocument2 pagesAUTROD 316LSijoao guilhermeNo ratings yet

- PDS-OK AristoRod 38 Zn-Rev6Document2 pagesPDS-OK AristoRod 38 Zn-Rev6joao guilhermeNo ratings yet

- Classifications: Austenitic Stainless Welding Wire (Low C, 18%Cr-8%Ni-Mo)Document1 pageClassifications: Austenitic Stainless Welding Wire (Low C, 18%Cr-8%Ni-Mo)felipeNo ratings yet

- Consumables For E911 Crmo Steel: En/Din AstmDocument3 pagesConsumables For E911 Crmo Steel: En/Din Astmmohamed AdelNo ratings yet

- 89 Aristorod Rev4 ER120S GDocument2 pages89 Aristorod Rev4 ER120S Grusf123No ratings yet

- Esab, Ok 309L (29.12.16)Document1 pageEsab, Ok 309L (29.12.16)RodrigoNo ratings yet

- Tetra S 316L-G: Technical Data Sheet Cored Welding WireDocument1 pageTetra S 316L-G: Technical Data Sheet Cored Welding WirePeter TvardzíkNo ratings yet

- E16 8 2Document4 pagesE16 8 2Branko FerenčakNo ratings yet

- 6030P Daiko CuMn13AlDocument1 page6030P Daiko CuMn13AlAris WicaksonoNo ratings yet

- Alloy 6082 - Rev2012Document2 pagesAlloy 6082 - Rev2012Ysraels Santisteban DurandNo ratings yet

- Alloy 309Document3 pagesAlloy 309Branko FerenčakNo ratings yet

- 230 Broadway Huntington Station, NY 11746 P: 631.547.5470 - F: 631.547.5475 100 Commerce Way Aliquippa, PA 15001 P: 724.378.6351 - F: 724.378.2505Document1 page230 Broadway Huntington Station, NY 11746 P: 631.547.5470 - F: 631.547.5475 100 Commerce Way Aliquippa, PA 15001 P: 724.378.6351 - F: 724.378.2505mohamed AdelNo ratings yet

- Technical Date Sheet Welding Wire: E R 7 0 S - GDocument2 pagesTechnical Date Sheet Welding Wire: E R 7 0 S - GRahmat RiskiNo ratings yet

- SC-Copper: Copper Tubes For Plumbing and Heating SystemsDocument10 pagesSC-Copper: Copper Tubes For Plumbing and Heating SystemsDeepak kumarNo ratings yet

- Duplex Stainless SteelsDocument25 pagesDuplex Stainless Steelspym1506gmail.comNo ratings yet

- Afrox MIG/TIG 904L: Welding Consumables Stainless SteelDocument5 pagesAfrox MIG/TIG 904L: Welding Consumables Stainless SteelBranko FerenčakNo ratings yet

- 2005 Carbon SteelDocument65 pages2005 Carbon SteelmageshkumarNo ratings yet

- Consumables To Match Cast & Wrought Alloy 800: Astm Bs en & DinDocument3 pagesConsumables To Match Cast & Wrought Alloy 800: Astm Bs en & Dinankitniranjan1390No ratings yet

- Dual Shield 9000b3 PDFDocument1 pageDual Shield 9000b3 PDFqaNo ratings yet

- 4 Selectarc Mig 308lsi 309lsi Et 316lsi FT Web AnglaisDocument1 page4 Selectarc Mig 308lsi 309lsi Et 316lsi FT Web Anglaisamir moniriNo ratings yet

- Indian Standard Steel SectionsDocument9 pagesIndian Standard Steel SectionsAmitava SilNo ratings yet

- 70cuni TigDocument3 pages70cuni TigGiannhs SeitaridhsNo ratings yet

- Fio Fluxado Mx-100tDocument1 pageFio Fluxado Mx-100tFilipe CordeiroNo ratings yet

- Ok 347 AutrodDocument2 pagesOk 347 Autrodjoao guilhermeNo ratings yet

- CSF-81T en 2014Document1 pageCSF-81T en 2014NGUYEN VINHNo ratings yet

- CM-9CB TG-S9Cb US-9CbDocument3 pagesCM-9CB TG-S9Cb US-9Cbamit singhNo ratings yet

- Inconel 82 (Austral-Wright)Document1 pageInconel 82 (Austral-Wright)Claudia MmsNo ratings yet

- E9018 G Welding ElectrodeDocument1 pageE9018 G Welding ElectrodeSai PrasathNo ratings yet

- Tetra V 309L-G: Technical Data Sheet Cored Welding WireDocument1 pageTetra V 309L-G: Technical Data Sheet Cored Welding WireawNo ratings yet

- Wb56S M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb56S M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- Selectrode: 317L Flux Coated TigDocument3 pagesSelectrode: 317L Flux Coated TigUta GilangNo ratings yet

- Materilas-An Overview: 3.1 Austenitic Stainless Steel 316LDocument13 pagesMaterilas-An Overview: 3.1 Austenitic Stainless Steel 316LRS CreationsNo ratings yet

- Steel Grade Indian StandardsDocument5 pagesSteel Grade Indian StandardsPriyanathan ThayalanNo ratings yet

- Wb1500e Eni CiDocument1 pageWb1500e Eni CicwiksjNo ratings yet

- Microsoft Power Point - Deloro Stellite Advances in Wear Resistant Alloys and ProductsDocument56 pagesMicrosoft Power Point - Deloro Stellite Advances in Wear Resistant Alloys and ProductsMilanWaNo ratings yet

- OK 67.60 Esab 309LcDocument1 pageOK 67.60 Esab 309LcSadashiva sahooNo ratings yet

- CF10MC (1.4571)Document3 pagesCF10MC (1.4571)Gilcimar Cavalcante GilcimarNo ratings yet

- Cement Mill Test - Fairborn Cement Company Type-IA - Jan2022Document2 pagesCement Mill Test - Fairborn Cement Company Type-IA - Jan2022mohamed ElsayedNo ratings yet

- 1.4435 - C Stainless Steel DetailsDocument3 pages1.4435 - C Stainless Steel DetailsmeenakshiNo ratings yet

- DH 1232NSDocument1 pageDH 1232NSGopiNathNo ratings yet

- Ti AlloysDocument56 pagesTi AlloysX048Anshul JumoreNo ratings yet

- Welding ConsumablesDocument79 pagesWelding Consumablesazam RazzaqNo ratings yet

- CHS29 9Document1 pageCHS29 9sulis setiawanNo ratings yet

- En Aw 6082 Rev 2 Final PDFDocument3 pagesEn Aw 6082 Rev 2 Final PDFtechspawNo ratings yet

- FWDocument1 pageFWDeepak BhatiNo ratings yet

- Chemical CompositionDocument13 pagesChemical Compositionssharma3474No ratings yet

- TR Torsion Specimens Datasheet 0517 PDFDocument1 pageTR Torsion Specimens Datasheet 0517 PDFSebastian CorralesNo ratings yet

- 316 Chemical Composition Standard Inventory SpecificationsDocument3 pages316 Chemical Composition Standard Inventory Specifications18118135No ratings yet

- Jetblast™ Copper SlagDocument4 pagesJetblast™ Copper SlaglambtranNo ratings yet

- Metalurgia BásicaDocument30 pagesMetalurgia BásicaClever Ricardo ChinagliaNo ratings yet

- Fundamentals of Fabrication WeldingDocument22 pagesFundamentals of Fabrication WeldingKevinNo ratings yet

- Laser Settings For LMM6000 MaterialsDocument2 pagesLaser Settings For LMM6000 MaterialsMiguel Angel Martinez SanchezNo ratings yet

- Filler Wire For Gtaw PDFDocument27 pagesFiller Wire For Gtaw PDFrezaNo ratings yet

- M.M.A. Welding Electrode: Classifications & ApprovalsDocument1 pageM.M.A. Welding Electrode: Classifications & ApprovalscwiksjNo ratings yet

- Exercício Avaliativo IDocument13 pagesExercício Avaliativo IRogério JuniorNo ratings yet

- XavierDocument11 pagesXavierRogério JuniorNo ratings yet

- Mil e 22200 - 10CDocument40 pagesMil e 22200 - 10CRogério JuniorNo ratings yet

- Cranfield Report Mat. No.5Document38 pagesCranfield Report Mat. No.5Rogério JuniorNo ratings yet

- Mode I Fracture Toughness of Fiber-Reinforced Polymer Composites: A ReviewDocument28 pagesMode I Fracture Toughness of Fiber-Reinforced Polymer Composites: A ReviewRogério JuniorNo ratings yet

- CCascelli Masters ThesisDocument88 pagesCCascelli Masters ThesisRogério JuniorNo ratings yet

- Mode-I Interlaminar Fracture Toughness in Unidirectional Carbon-fibre/Epoxy CompositesDocument12 pagesMode-I Interlaminar Fracture Toughness in Unidirectional Carbon-fibre/Epoxy CompositesRogério JuniorNo ratings yet

- Polymers 11 00523Document11 pagesPolymers 11 00523Rogério JuniorNo ratings yet

- Digital Image Correlation Measurements As A Tool of Composites Deformation DescriptionDocument6 pagesDigital Image Correlation Measurements As A Tool of Composites Deformation DescriptionRogério JuniorNo ratings yet

- ASTM5528Document13 pagesASTM5528Rogério JuniorNo ratings yet